Beruflich Dokumente

Kultur Dokumente

ZZbellows Baloney

Hochgeladen von

punitg_2Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ZZbellows Baloney

Hochgeladen von

punitg_2Copyright:

Verfügbare Formate

Bellowsv1BT.

qxd

19/07/07

12:26 pm

Page 26

PLANT EQUIPMENT

Bellows

baloney

Flixborough did no favours for bellows manufacturers,

particularly Teddington. Brian Tinham talks to its technical

team about the real world

ontrary to popular misconception, metal

bellows expansion joints are as useful as

any other of the tools in the plant

engineers armoury provided good mechanical

engineering practice is followed. So says bellows

manufacturer Teddington Engineered Solutions, the

firm whose predecessors equipment was linked to

the Flixborough disaster 34 years ago.

Its defensiveness is entirely understandable. The

company makes the very valid point that it was

flawed plant modifications at Flixborough that led to

the catastrophic chain of events (Plant Engineer,

May/June 2007, page 8), not the bellows

themselves. Yet, ever since, bellows have been

tarred with the brush of suspicion. At the London

Flixborough Revisited conference last April,

HAZOP/HAZAN guru and celebrated author Trevor

Kletz declared: You should avoid bellows on

flammable and dangerous services. Use them only

on steam and low pressure systems.

Thats plain nonsense, says Peter Evans, chief

design engineer at Teddington. Youve got to

remember that, on Flixborough, prior to Reactor

Five being removed, the bellows were perfectly well

installed and operating within engineering

guidelines. The cause of the problem was the

dogleg connection, installed using the original

bellows, but inadequately supported on scaffolding

meaning the system became inherently unstable.

That situation was unacceptable then and is

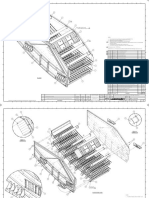

Above: bellows on an LNG

carrier. Right: on hot and

cold reheat pipework.

Below: on a blast furnace

26

unacceptable today for any bellows installation.

He refers to a designers guide to bellows,

recognised by engineers at the time and cited in

the court inquiry and, in fact, produced back in

the 1970s as Teddingtons own catalogue for plant

engineers. Bellows, in their nature, are a critical

element in a piping system they are designed to

allow a certain flexibility, depending on how theyre

restrained. That bellows installation was

fundamentally changed, with just an ONC engineer

on-site who paid no regard to the impact of what

he was doing on the bellows and pipework. It

became an accident waiting to happen.

Engineering common sense

This should be the lesson of Flixborough: plant

modifications of any kind and bellows are no

exception must be referred to competent

engineers for validation and acceptance. Yes, some

care is required in handling bellows theyre flexible

elements, so in lifting, stacking and so on, its

important not to damage or stress the

convolutions. But thats little more than engineering

common sense, and there are similar precautions

for everything from control valves and actuators to

instrumentation, bearings, gaskets and seals you

name it. And we dont just use them on steam or

low pressure service.

Also, theres an interesting counterpoint: right up

to the design life specified, bellows need no

maintenance. The only reasons to change them are

if they get damaged accidentally, or the service

changes. Evans explains: We design bellows for a

fatigue life, whether thats 1,000, 5,000 or 500,000

cycles. On process plant, for example, they know

July/August 2007

Plant Engineer

Bellowsv1BT.qxd

19/07/07

12:27 pm

Page 27

PLANT EQUIPMENT

updated 40-year-old American EJMA (Expansion

Joint Manufacturers Association) code, around

which the new standard is written, provides

comprehensive guidance.

That said, the list of bellows types, materials,

sizes etc, is considerable and often bespoke to the

application much like process transmitters and

automatic valves. Hence Engineered Solutions in

Teddingtons company name. Unrestrained bellows

can, for example, allow axial and lateral movement

and, depending on mechanical construction,

Bellows applications

July/August 2007

Plant Engineer

tolerate 40bar, as long as the

support structure of the pipework is man enough.

These tend to be used on pipes at a low level so

there are no problems with installing anchors,

explains Evans. But our catalogue gives the figures

for calculating the loads used to design these.

Beyond these, however, if the loads prove too

great, theres a world of restraint mechanisms

allowing single- or multi-plane movements. Evans

lists: double bellows with tie-bars that allow lateral

movement only; hinged types that allow angulations

in one plane; gimbal-based devices that take

movement in two planes; and combinations

allowing movement in any plane required.

If a customer is not happy designing a bellows

system, they can send the pipework isometric to us

and we will recommend the type of unit, or design

the whole system, says Graydon Similarly, if

anybody has an issue of where to put a bellows or

what to do with it if its in service, were here to

help. And he also suggests that, where possible,

the company will police good practice: If it

becomes apparent that a customers choice

doesnt make sense, we will gently intervene. PE

Points

theyre going to shut down, say, every six

months and thats when the major

movement is going to occur, along with

smaller transients every week or whatever. So

we select materials to suit, also taking

into account the fluid service,

corrosion resistance and so on, to

ensure that the bellows will outlast

the plant.

Says Glen Graydon, business

development manager: Whenever

we see a premature bellows failure,

its because of incorrect installation for example,

bellows not restrained as per design specification,

or some change causing the same thing. Last

summer, a major oil refinery in the UK shut down

while a pressure vessel was taken off-line. After

completing the work, they wanted to do a pressure

test. But, rather than putting the pipework back on

the bellows as per the design, they supported the

bellows with a jack and fixed a plate over the end.

It was an engineering change on a restrained

bellows. The first we knew was a cry for help, with

the plant wanting replacement bellows before they

could go back into production.

Fair point, and it comes down to nothing more

than knowing the tools of your trade or, in

mechanical engineering terms, understanding the

loads on your piping and the bellows contribution

to those, and then facilitating the movement

required. An international standard (EN 14917,

Metal Bellows Expansion Joints for Pressure

Applications) is due for publication this year,

following BS 04/30118252, 2004 (which was for

design, not application). But in the meantime, the

Teddington Engineered Solutions boasts bellows for a huge range of applications everything

from seagoing LNG carriers to blast furnaces, process plant, and oil and gas installations.

We were involved with the first ever LNG carriers back in 1968, for example, says Jason

Thomas, commercial manager. No mean feat, given the cryogenic service and rolling motion of

the sea, plus inevitable movement during loading and offloading. We designed those using our

own design codes, alongside oceanographic information showing the forces such a ships

superstructure could expect over its lifespan, he explains. There have been zero failures.

Apart from that, the company recently completed a jetty project, for which it was initially

asked only to supply costs for axial bellows. Two weeks later, the engineer came back with

calculations showing huge pressure loads so big that they would require pipe anchors set in

concrete 120 metres deep! We suggested restrained units, harnessing the natural change of

direction in the pipework to allow them to work in a lateral plane. Problem solved.

Thats impressive, but so are its hazardous service applications, such as bellows at the

bottom of blast furnaces. Again, Teddington claims success, only making the

point that, while it can design out most problems, it cant rule out postinstallation mechanical damage. Says Thomas: In some cases, we put

protective covers on our bellows, but accidents can happen and thats

mostly due to people, for example, driving over them with forklift trucks.

Technical

pointers

For maintenance, Teddington

Bellows recommends nothing

more than regular postinstallation inspection,

depending on the environment.

But even that is the exception,

rather than the rule

In nuclear reactors, bellows

dont see the light of day for

20 or 30 years and thats in

an extremely challenging

environment. Mechanically,

theres nothing to harm them

Bellows usage is little more

than engineering common

sense, and there are similar

precautions for everything

from control valves and

actuators to gaskets

27

Das könnte Ihnen auch gefallen

- Process DesignDokument4 SeitenProcess DesignHarymsl MslNoch keine Bewertungen

- An Engineers CasebookDokument87 SeitenAn Engineers CasebookParesh AdhwaryuNoch keine Bewertungen

- Katalog CijeviDokument73 SeitenKatalog CijeviTheLizardKingNoch keine Bewertungen

- Boiler Codes Require Updating ToLDokument9 SeitenBoiler Codes Require Updating ToLmahmoud_allam3Noch keine Bewertungen

- Select Expansion Joints ProperlyDokument4 SeitenSelect Expansion Joints ProperlySeungmin Paek100% (2)

- SFP Catalog 3 Fabric Exp JointsDokument32 SeitenSFP Catalog 3 Fabric Exp JointsJosé MoránNoch keine Bewertungen

- Pressure VesselDokument29 SeitenPressure VesselJosephNoch keine Bewertungen

- Design of Pressure Vessel Using Asme Code, Section Viii, Division 1Dokument7 SeitenDesign of Pressure Vessel Using Asme Code, Section Viii, Division 1bbmoksh100% (2)

- HeadsUP Stellite Delamination in HP, HRH Steam ValveDokument3 SeitenHeadsUP Stellite Delamination in HP, HRH Steam Valveabdulyunus_amirNoch keine Bewertungen

- Pressure Vessel Costly MistakeDokument11 SeitenPressure Vessel Costly MistakearjayNoch keine Bewertungen

- Todays Advanced Hose and Hydraulic SystemsDokument19 SeitenTodays Advanced Hose and Hydraulic SystemsJuan Eduardo PFNoch keine Bewertungen

- A Guide to Ship Repair Estimates in Man-hoursVon EverandA Guide to Ship Repair Estimates in Man-hoursBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Tensacciaia Rock AnchorsDokument28 SeitenTensacciaia Rock AnchorsjoebriffaNoch keine Bewertungen

- Good Practices RecoommendedDokument2 SeitenGood Practices RecoommendedyopatmetNoch keine Bewertungen

- Desigen Pro HAF LIFE2Dokument27 SeitenDesigen Pro HAF LIFE2Saleamilak tamiruNoch keine Bewertungen

- Principle No. 7 - Design With Adequate SafetyDokument8 SeitenPrinciple No. 7 - Design With Adequate SafetyMehdi KoneshlouNoch keine Bewertungen

- PIP VEFV1100M Vessel - S&T Heat Exchanger Standard Details (Metric Units)Dokument55 SeitenPIP VEFV1100M Vessel - S&T Heat Exchanger Standard Details (Metric Units)Muhamad Amar Hakimmie SuhaimiNoch keine Bewertungen

- Catalouge For Lenton CouplersDokument18 SeitenCatalouge For Lenton Couplerss.skumar1Noch keine Bewertungen

- Pressure Vessels: Avoid Costly Design MistakesDokument8 SeitenPressure Vessels: Avoid Costly Design Mistakesmarcel linaNoch keine Bewertungen

- TENSACCIAI - Rock and Soil AnchorsDokument0 SeitenTENSACCIAI - Rock and Soil Anchorsnovakno1Noch keine Bewertungen

- Introduction To Piping Engineering: Gerald H. May, P.EDokument46 SeitenIntroduction To Piping Engineering: Gerald H. May, P.EdcsamaraweeraNoch keine Bewertungen

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Von EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Bewertung: 5 von 5 Sternen5/5 (2)

- Vessels For High Pressure Dust CollectorsDokument4 SeitenVessels For High Pressure Dust CollectorsWade ColemanNoch keine Bewertungen

- Pressure VesselDokument26 SeitenPressure VesselMohd Azharudin Mohadi100% (1)

- Previews - 2033457 PIP VEFV1100MDokument5 SeitenPreviews - 2033457 PIP VEFV1100Mabdulloh_99100% (1)

- Vertical Unfired Pressure Vessel ComponentsDokument17 SeitenVertical Unfired Pressure Vessel ComponentsÑůti Yė ÃbůNoch keine Bewertungen

- GT Allow Fogging On 7faDokument2 SeitenGT Allow Fogging On 7faRakesh GSNoch keine Bewertungen

- Hydroformed Metal Bellows - Design HandbookDokument128 SeitenHydroformed Metal Bellows - Design Handbookchipulino100% (1)

- From Evolution To Revolution Electric Motors in Oil and Gas Exploration - Whitepaperpdf.renderDokument5 SeitenFrom Evolution To Revolution Electric Motors in Oil and Gas Exploration - Whitepaperpdf.renderveeraNoch keine Bewertungen

- (Done) Basic Questions Asked in Piping EngineerDokument4 Seiten(Done) Basic Questions Asked in Piping EngineerFerinoviardiNoch keine Bewertungen

- Expansion JointsDokument17 SeitenExpansion Jointsravi00098Noch keine Bewertungen

- Coiled Tubing: State of The Industry and Role For NETL: June, 2005Dokument32 SeitenCoiled Tubing: State of The Industry and Role For NETL: June, 2005Greg AndersonNoch keine Bewertungen

- 87 RajkumarDokument5 Seiten87 RajkumarmhdsolehNoch keine Bewertungen

- Bus DuctDokument60 SeitenBus Ductkumaratdbg100% (1)

- Pipe Line Emergency Repair SystemDokument21 SeitenPipe Line Emergency Repair SystememadazNoch keine Bewertungen

- Rapid and Durable Repairs of Blast FurnacesDokument9 SeitenRapid and Durable Repairs of Blast FurnacesFabiano MoraisNoch keine Bewertungen

- Field Fabrication and Installation of Piping SystemsDokument5 SeitenField Fabrication and Installation of Piping SystemstribleprinceNoch keine Bewertungen

- Use of Glass Reinforced Epoxy (GRE) Piping For Fire Water Applications - OffshoreDokument10 SeitenUse of Glass Reinforced Epoxy (GRE) Piping For Fire Water Applications - OffshoreMubeenNoch keine Bewertungen

- Typical Questions For Piping EngineerDokument6 SeitenTypical Questions For Piping EngineerVenkataratnam Gollapalli100% (1)

- Hose & Fittings Technical HandbookDokument60 SeitenHose & Fittings Technical HandbookLeobardo IslasNoch keine Bewertungen

- Wilson Walton KoreaDokument19 SeitenWilson Walton KoreakazishahNoch keine Bewertungen

- Diaphragm AFGlobal High-PressureDokument8 SeitenDiaphragm AFGlobal High-PressureAnonymous nw5AXJqjdNoch keine Bewertungen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Research Paper On Eot CraneDokument4 SeitenResearch Paper On Eot Craneadyjzcund100% (1)

- RioPipeline2017 2515 Rio Pipeline 2017 United MininDokument9 SeitenRioPipeline2017 2515 Rio Pipeline 2017 United MininJose Anisio SilvaNoch keine Bewertungen

- Advances in Gasket Designs Making Progress1Dokument3 SeitenAdvances in Gasket Designs Making Progress1HieuNoch keine Bewertungen

- Design and Installation of A Production Jack-Up With StorageDokument16 SeitenDesign and Installation of A Production Jack-Up With StorageMoe LattNoch keine Bewertungen

- 1 Method Statement For Barapullah Post Tensioning Rev-CDokument20 Seiten1 Method Statement For Barapullah Post Tensioning Rev-CJkkhyhNoch keine Bewertungen

- Pressure VesselsDokument31 SeitenPressure VesselsRho Natta MatahariNoch keine Bewertungen

- Tools and EquipmentDokument22 SeitenTools and EquipmentPhoukham PHILAVONGNoch keine Bewertungen

- Piping Engineering Interview Questions: Datasheet PDF Search Site. - Download Datasheets For FreeDokument18 SeitenPiping Engineering Interview Questions: Datasheet PDF Search Site. - Download Datasheets For FreeG mohan PrasaadNoch keine Bewertungen

- Repairs, Modifications, and Strengthening With Post-Tensioning, PTI Journal, July 2006Dokument17 SeitenRepairs, Modifications, and Strengthening With Post-Tensioning, PTI Journal, July 2006Viet Duc DangNoch keine Bewertungen

- Tie Back Liner Casing-1Dokument18 SeitenTie Back Liner Casing-1حسين الفيتوريNoch keine Bewertungen

- 300+ TOP PIPING Engineering Interview Questions and Answers PDFDokument22 Seiten300+ TOP PIPING Engineering Interview Questions and Answers PDFMd AtiullahNoch keine Bewertungen

- Metallurgy and Mechanics of Welding: Processes and Industrial ApplicationsVon EverandMetallurgy and Mechanics of Welding: Processes and Industrial ApplicationsRegis BlondeauNoch keine Bewertungen

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerVon Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNoch keine Bewertungen

- Machines, Tools and Methods of Automobile ManufactureVon EverandMachines, Tools and Methods of Automobile ManufactureBewertung: 4 von 5 Sternen4/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Nuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresVon EverandNuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresBewertung: 5 von 5 Sternen5/5 (1)

- Trading Account - ChargesDokument6 SeitenTrading Account - Chargespunitg_2Noch keine Bewertungen

- The Overview of Gold Etfs and Its Various Positive Features: Mohdsaleem Matloobullah KhanDokument11 SeitenThe Overview of Gold Etfs and Its Various Positive Features: Mohdsaleem Matloobullah Khanpunitg_2Noch keine Bewertungen

- New Org Chart - LNT PowerDokument1 SeiteNew Org Chart - LNT Powerpunitg_2Noch keine Bewertungen

- Project Director: Construction Manager EHS Manager Qa/Qc ManagerDokument1 SeiteProject Director: Construction Manager EHS Manager Qa/Qc Managerpunitg_2Noch keine Bewertungen

- Project Director Head (Project Controls) Project ManagerDokument1 SeiteProject Director Head (Project Controls) Project Managerpunitg_2Noch keine Bewertungen

- 11 TradeDokument3 Seiten11 Tradepunitg_2Noch keine Bewertungen

- About Kotak Gold ETF (KGETF) Scheme FactsDokument3 SeitenAbout Kotak Gold ETF (KGETF) Scheme Factspunitg_2Noch keine Bewertungen

- GEOJIT Equity Trading - Call and Trade Services - Free Online Trading ServicesDokument2 SeitenGEOJIT Equity Trading - Call and Trade Services - Free Online Trading Servicespunitg_2Noch keine Bewertungen

- Securities Transaction Tax11234Dokument2 SeitenSecurities Transaction Tax11234punitg_2Noch keine Bewertungen

- Trading Holidays For The Calendar Year 2014Dokument1 SeiteTrading Holidays For The Calendar Year 2014punitg_2Noch keine Bewertungen

- Larsen & Toubro Limited MSQ (Epcc 1) Up Gradation: LT/MSQ/P/DPT//007Dokument4 SeitenLarsen & Toubro Limited MSQ (Epcc 1) Up Gradation: LT/MSQ/P/DPT//007punitg_2Noch keine Bewertungen

- Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: Procedure For Joint NumberingDokument3 SeitenLarsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: Procedure For Joint Numberingpunitg_2Noch keine Bewertungen

- Procedure For Installation Static Equipment For MSQ Upgradation UnitDokument7 SeitenProcedure For Installation Static Equipment For MSQ Upgradation Unitpunitg_2Noch keine Bewertungen

- 1 Procedure For Radiography TestingDokument9 Seiten1 Procedure For Radiography Testingpunitg_2Noch keine Bewertungen

- NC 306 29JUL2010Dokument1 SeiteNC 306 29JUL2010punitg_2Noch keine Bewertungen

- Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011Dokument11 SeitenLarsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011punitg_2Noch keine Bewertungen

- Larsen & Toubro Limited MSQ (Epcc-1) Upgadation Project: ContentsDokument5 SeitenLarsen & Toubro Limited MSQ (Epcc-1) Upgadation Project: Contentspunitg_2Noch keine Bewertungen

- Contents:: Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) ProjectDokument3 SeitenContents:: Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Projectpunitg_2Noch keine Bewertungen

- 30 1 Static Equipment Horizontal ErectionDokument2 Seiten30 1 Static Equipment Horizontal Erectionpunitg_2Noch keine Bewertungen

- 01 Procedure For Structural SteelDokument9 Seiten01 Procedure For Structural Steelpunitg_2Noch keine Bewertungen

- Udhakar Chchasare: Total Experience:-THREE YEAR & ONE MONTH Experience in QA/QC & NDTDokument4 SeitenUdhakar Chchasare: Total Experience:-THREE YEAR & ONE MONTH Experience in QA/QC & NDTpunitg_2Noch keine Bewertungen

- 31 1 Static Equipment Vertical ErectionDokument2 Seiten31 1 Static Equipment Vertical Erectionpunitg_2Noch keine Bewertungen

- ABRO Company ProfileDokument7 SeitenABRO Company Profilepunitg_2Noch keine Bewertungen

- FRM-OHS-HOT - WORK - PERMIT - Permit & GuidelinesDokument2 SeitenFRM-OHS-HOT - WORK - PERMIT - Permit & Guidelinespunitg_2Noch keine Bewertungen

- PROC-OHS-INCIDENT-REPORTING - Procedure and Corrective ActionDokument6 SeitenPROC-OHS-INCIDENT-REPORTING - Procedure and Corrective Actionpunitg_2Noch keine Bewertungen

- Rock Cycle Crayon LabDokument4 SeitenRock Cycle Crayon Labapi-251355123Noch keine Bewertungen

- Mechanical Designer Resume TemplateDokument1 SeiteMechanical Designer Resume TemplateHubertNoch keine Bewertungen

- Seamless VS Welded TubesDokument1 SeiteSeamless VS Welded Tubeshirenkumar patelNoch keine Bewertungen

- LGFP 2: SKF Food Compatible Bearing GreaseDokument2 SeitenLGFP 2: SKF Food Compatible Bearing GreaseJurun_BidanshiNoch keine Bewertungen

- Code 1 WPS Rev 0 PDFDokument18 SeitenCode 1 WPS Rev 0 PDFEarl HarbertNoch keine Bewertungen

- 10-Hydrotesting of Soluforce Pipe SystemsDokument9 Seiten10-Hydrotesting of Soluforce Pipe SystemsEl hadi BouasriaNoch keine Bewertungen

- 1600 Wall Sys3 - ADokument24 Seiten1600 Wall Sys3 - ABlack DiscipleNoch keine Bewertungen

- Kitchen: Library Study MM School of ArchitectureDokument1 SeiteKitchen: Library Study MM School of ArchitectureAteeq RaoNoch keine Bewertungen

- Experiment 4 CombustionDokument8 SeitenExperiment 4 CombustionJof RomanNoch keine Bewertungen

- Concrete Material and MixtureDokument51 SeitenConcrete Material and MixtureAina Aqilah100% (1)

- Design and Control of CONCRETE MIX PDFDokument459 SeitenDesign and Control of CONCRETE MIX PDFCRISTIAN RAMIREZ75% (8)

- Suction Cups/grippers: Duraflex® BagDokument2 SeitenSuction Cups/grippers: Duraflex® BagBe HappyNoch keine Bewertungen

- Bible Saintgobain PamDokument742 SeitenBible Saintgobain PamfrankytgNoch keine Bewertungen

- EMT 272 Semiconductor Fundamentals Semiconductor Physics: PN JunctionDokument39 SeitenEMT 272 Semiconductor Fundamentals Semiconductor Physics: PN Junctionayuni2602Noch keine Bewertungen

- Bulletin 446 - 1/06 - Alumina Loading Problems - Western AustraliaDokument2 SeitenBulletin 446 - 1/06 - Alumina Loading Problems - Western Australialevent364Noch keine Bewertungen

- ACI 304R Guide For Meas., Mix., Transp., & Placing ConcDokument41 SeitenACI 304R Guide For Meas., Mix., Transp., & Placing ConcVasanth KumarNoch keine Bewertungen

- Polymer Processing Design Week 1Dokument53 SeitenPolymer Processing Design Week 1Abdul RahmanNoch keine Bewertungen

- 48 50p-4tDokument238 Seiten48 50p-4tMickey MayoNoch keine Bewertungen

- Ansys Tutorial 3Dokument4 SeitenAnsys Tutorial 3deathesNoch keine Bewertungen

- 1301A01422 Zaranda 3500Dokument2 Seiten1301A01422 Zaranda 3500Edgar FloresNoch keine Bewertungen

- Cargo Handling Manual - SOE 12k LEG (01-TECHNICAL - 1304275 - 1 - 01) PDFDokument283 SeitenCargo Handling Manual - SOE 12k LEG (01-TECHNICAL - 1304275 - 1 - 01) PDFМаксим Шабатын100% (2)

- SMM COMSOL Simulation MontiDokument6 SeitenSMM COMSOL Simulation Montitamarco85Noch keine Bewertungen

- Comfort & Harmony: Bouncer Asiento Transat Wiegewippe Balanço-bercinho кресло-качалкаDokument28 SeitenComfort & Harmony: Bouncer Asiento Transat Wiegewippe Balanço-bercinho кресло-качалкаJohn SmithNoch keine Bewertungen

- K-Tron Premier Rep Catalog Dec 2010 PDFDokument429 SeitenK-Tron Premier Rep Catalog Dec 2010 PDFGerardo González33% (3)

- Ueg 36Dokument2 SeitenUeg 36PRADO_COMETA50% (2)

- Raychem 132KV LinkBoxDokument4 SeitenRaychem 132KV LinkBoxjoydeep_d3232Noch keine Bewertungen

- Service Manual: CB 18S CB 27S CB 37SDokument85 SeitenService Manual: CB 18S CB 27S CB 37SMack DieselNoch keine Bewertungen

- BomDokument2 SeitenBomkdfdfybNoch keine Bewertungen

- Storage Tank DetailDokument22 SeitenStorage Tank DetailRamu NallathambiNoch keine Bewertungen

- Activated Carbon FilterDokument9 SeitenActivated Carbon Filtersanabilbaig100% (1)