Beruflich Dokumente

Kultur Dokumente

Qs 1 Audit Checklist

Hochgeladen von

Minh Vuong TranCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Qs 1 Audit Checklist

Hochgeladen von

Minh Vuong TranCopyright:

Verfügbare Formate

!

!

!"#$%&'()*+$,-.,/0(")$

!&%0()1$"1").2$*3.$4!"#5$

Company:

Location:

Date:

Auditor:

Rating Definitions and Scoring Terms:

Rating "1" (Major CAR) The required training, written program, practice, or procedure nonexistent or required training or written program

inadequate (i.e., required practice and procedure in place sporadically - less than 2/3 implemented).

Rating "2" (Minor CAR) The training or written program adequate or requiring minor revisions (i.e., practice or procedure is in place with

isolated instances of nonconformance - no more than 1/3 of the time. e.g., lack of practice or documentation due to personnel turnover, nonperformance by field personnel, or extenuating circumstances.)

Rating "3" (No CAR required) The company consistently adheres to specific training and written program requirement; required practice

and procedures consistently meet the letter of the standard.

PAGE 2 of 19, 9/09

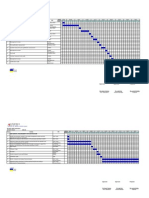

Audit Item

QS1 REFERENCE

Number

A. Quality Control Manual

1.

6.1

Quality System

Requirements

2.

6.1.1

Quality Control

Manual - Format

M.A.R.

RATING

1 2 3

Company has established and maintains a written

quality system appropriate to the type, range, and

volume as required per job specifications and

requirements.

Elements of the quality system are documented.

Documented policies, objectives, and commit to

good quality management and industry practices.

Policies, procedures, and objectives are documented

in a quality control manual.

There is written documentation that the quality

manual is communicated to all affected personnel.

There is evidence that written procedures are

followed by all affected personnel.

Company meets audit criteria and is certified to

SSPC QP-1, QP-3, QP-6 or QP-8.

The quality control manual shall follow the format outlined

in ANSI Q10013-Guidelines for Developing Quality

Manuals. At a minimum, the quality manual, written

procedures, and forms shall contain:

Title and Identification

Date of Issuance

Issuers name and title

Signature of approval

Revision updates

Numbered Documents, Forms, and Procedures

Controlled or uncontrolled documentation is identified

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1

1

1

1

1

1

1

2

2

2

2

2

2

2

3

3

3

3

3

3

3

COMMENTS

PAGE 3 of 19, 9/09

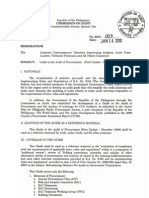

Audit Item

Number

3.

QS1 REFERENCE

6.2

Quality Control

Manual Systems

and Procedures

Submittal Item

Quality Manual

M.A.R.

RATING

The written quality manual clearly states the companys

policies and operational procedures as they pertain to

inspection activities:

At a minimum, the quality manual shall contain:

A quality policy statement, including objectives and

commitments, by executive management (QS16.2.1).

The organization and management structure of the

company (group, division, department, etc.), its place

in any parent organization and relevant

organizational charts (QS1-6.2.2).

The reporting relationship between management,

technical operations, support services and the quality

system (QS1-6.2.3).

Procedures for control (including distribution) and

maintenance of all quality control procedures and

corporate record keeping and retention policies

(QS1-6.2.4).

Job descriptions of key staff and reference to the job

descriptions of other staff (QS1-6.2.5).

Identification of the companys approved signatories

(QS1-6.2.6).

The Companys procedures for achieving traceability

of measurements against industry standards and

manufacturers recommendations (QS1-6.2.7).

The Companys general scope of inspections and

tests. (The precise scope of an inspection will be

determined by the terms of the individual contract or

work order.) (QS1-6.2.8).

Appropriate and clear reference to the inspection,

verification and test procedures to be used (QS16.2.9).

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

COMMENTS

PAGE 4 of 19, 9/09

Audit Item

Number

QS1 REFERENCE

M.A.R.

6.2 (continued)

Quality Control

Manual Systems

and Procedures

4.

6.3.1

Quality Plans

Procedures for performing inspections and tests

(QS1-6.2.10).

Reference to any inspection equipment and

reference measurement standards used (QS16.2.11).

Reference to procedures for inspection,

calibration, verification and maintenance of

equipment as required (QS1-6.2.12).

Procedures for handling non-conforming

materials or products (QS1-6.2.13).

B. Quality Plans

Company shall define and document how

requirements for quality are met.

Quality plan is consistent with company quality

system and shall be documented in a format as

required per company procedures or a jobspecific required format.

The contractor shall include as a minimum the

following activities as appropriate in meeting the

specified requirements for products, projects, or

contracts:

Preparation of quality plans.

Identification and acquisition of any controls,

processes, or equipment needed to achieve the

required quality.

Ensuring compatibility of the production process

and the applicable documentation.

Revisions are issued as needed to continue

improvement and meet new and existing

requirements.

RATING

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

COMMENTS

PAGE 5 of 19, 9/09

Audit Item

Number

5.

QS1 REFERENCE

6.3.2

Work plans

M.A.R.

Company has a separate written work plan,

including an inspection plan for each job

phase.

An approved plan is prepared for each task

that requires performance of productive

work prior to the start of work on that

specific project.

Plan is revised and updated to stay current

with all requirements.

The plan is a compilation of all processes

that make up the required work. Each

process shall include as a minimum:

A written description of the process.

Qualification requirements for personnel

performing the work.

Auditors Note: All QP1 craft personnel must

meet criteria for craft worker assessments

and have current and valid certifications as

required per job specifications (C-7, C-14,

C-12, C-13, etc).

Methods used to ensure personnel

accomplishing the procedure have direct

knowledge of the requirements prior to

beginning work.

Methods used to control procedure.

Acceptance and rejection criteria.

RATING

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

COMMENTS

PAGE 6 of 19, 9/09

Audit Item

Number

6.

QS1 REFERENCE

6.4

Procedures for

Project Document

Review

M.A.R.

7.

8.

9.

6.5.1

Document and Data

Control

6.5.2

Document and Data

Approval and

Issuance

6.5.3

Document and Data

Revisions

Company shall establish and maintain

documented procedures for project

documentation review (QS1-6.4.1).

At acceptance acceptance of a contract, the

project documents are reviewed (QS1-6.4.2) to

ensure that:

Requirements are adequately defined and

documented.

There is documentation that all ambiguities and

differences are resolved and approved.

The Company has the capability to meet all

contract and specification requirements.

There are procedures showing how

amendments and changes to project contracts

and specifications are documented and issued

to project personnel (QS1-6.4.3).

Records of contract and job specifications are

maintained (QS1-6.4.4).

The Company has implemented and maintains

documented procedures to control all

documents and data that relate to the

requirements of QS-1.

Individual documents are clearly legible and

have a unique numbering system for

identification where applicable.

Company has procedures for reviewing

documents and their approval of adequacy by

authorized personnel.

A master list or equivalent document control

procedure identifying the current revision status

of documents is established.

The document control procedures shall ensure

that:

!

Pertinent issues of appropriate documents are

available at all locations where operations

essential to the effectiveness of the quality

system are performed.

There are procedures for removing invalid and

or obsolete documents.

Retained obsolete documents are clearly

marked as such.

Changes to documents and data are reviewed and

approved by personnel that performed original review and

approval or by other authorized personnel.

RATING

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

COMMENTS

PAGE 7 of 19, 9/09

Audit Item

Number

10.

QS1 REFERENCE

6.6

Internal Review

Spot checks

M.A.R.

There is written evidence that inspection results/tests

are independently reviewed in the field on a spot

basis by a competent supervisor to ensure

conformance with specifications and other contract

requirements.

Tthere is a company policy for spot checks, and

documentation of specific project changes.

RATING

1 2 3

1 2 3

Auditor note: Where specifically documented, and

performed by a qualifying auditor, independent of the

inspection program, such field checks can be considered

part of the internal audit process. Look for sign-off

specific to this task and corresponding travel/expense/trip

records

Internal Review

Internal audits

Company has a plan that outlines the particulars of

internal audits (who, when, where, etc.). At a

minimum, the plan meets SSPC Guidelines for

internal auditing (see Appendix A of this checklist)

Qualified personnel conduct the Audits.

Audits are conducted, findings documented, and

results reported to management in accordance with

company procedure for internal audits.

Projects requiring internal auditing by clients are

audited.

An internal audit is performed upon receipt of a

formal client or prime contractor complaint regarding

the inspection process.

Unless otherwise instructed by contract, corrective

actions are documented and implemented within 5

working days after notifying executive management

of results.

Findings are tracked until corrected.

Records of corrective action follow up being

performed are maintained.

C. Organization and Management

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

COMMENTS

PAGE 8 of 19, 9/09

Audit Item

Number

11.

QS1 REFERENCE

5.1

5.2.1A

5.2.6A

12.

13.

14.

M.A.R.

5.2.6B

5.2.1B

5.2.7

RATING

Quality System Program

The QM System function must be identifiable as

a separate unit within the organization and

operate as such.

1 2 3

The organizational chart clearly shows lines of

authority.

1 2 3

Company practices, procedure manuals, and job

duties performed should confirm the separate

identity of the QS Function.

1 2 3

Company employs a QS Manager who has the

responsibility and authority to implement and

monitor compliance with all QM System

Procedures, as they apply to all industrial/marine

coating application operations where a QS1 or

equivalent QMS system is required.

1 2 3

QS Manager or QCS Supervisor present during Audit

Duties, Qualifications & Training

1 2 3

1 2 3

The QM System Manager needs to report directly to

Executive Management.

1 2 3

The QS Manager or the designated QCS Supervisor

must be an SSPC Certified PCS, or SSPC PCI Certified

Coatings Inspector, or NACE Level III Certified Coatings

Inspector; or hold a BS in Corrosion Science, Corrosion

Engineering, or Materials Science/Engineering, and have

a minimum of 10 years of relevant corrosion control or

protective coatings-related experience

1 2 3

Note: Review resumes and QM training certificates for

QS Manager and backup QS Managers

QS Manager Back-Up Plan

Written plan appointing a designated back up having the

required QM System Manager qualifications.

Back-up plan must be in writing and be approved by

Executive Management and requires the designated

replacements to report directly to Executive Management

when functioning as assistant or back up QM System

Manager

1 2 3

1 2 3

COMMENTS

PAGE 9 of 19, 9/09

Audit Item

Number

15.

QS1 REFERENCE

5.2.3

M.A.R.

RATING

Written processes, procedures, and controls are

established and distributed by the QS Manager to all

persons involved in QS programs.

1 2 3

Contractor has to demonstrate that the QS Manager is

actively involved in QS activities on an ongoing basis.

QS Manager Review of All QS Personnel

1 2 3

5.2.2

There is evidence that the QS Manager periodically

monitors QS personnel work (e.g., daily upon project

"start up," then weekly until QS Manager is satisfied with

QS personnel abilities.

1 2 3

5.2.4

Verification that all persons under the QS managers

supervision are supervised have responsibilities and

authorities documented.

1 2 3

16.

Note: "Work" is defined, in this instance, as project

documentation but could also include on-site observation

of QS personnel. The QS Manager or an Assistant QS

Manager, depending on company structure, might

perform this function. Inspection results are verified and

signed by a competent supervisor not directly performing

the inspections.

17.

5.2.3

QS Review by a Responsible Executive (RE)

The QC Manual and effectiveness of its implementation is

to be reviewed by the RE and that review documented

annually.

1 2 3

COMMENTS

PAGE 10 of 19, 9/09

Audit Item

Number

18.

QS1 REFERENCE

7.4

Physical

Qualifications of

Inspectors

M.A.R.

19.

8.1

Equipment and

equipment

reference materials

D. Personnel

Each inspector has the physical ability to access all

areas of the job requiring inspection (QS1-7.4.1)

Each inspector shall show proof of being examined

no less than every 10 years to ensure natural or

corrected near distance visual acuity. The

inspector shall read the J-1 letters of a standard

Jaeger Test Chart or equivalent, at a distance of not

less than 12 inches with one or both eyes, corrected

or uncorrected (QS1-7.4.2).

Each inspector is examined Each inspector shall

show proof of being examined no less than every 10

years for color perception using the Ishihara Test or

the Farnsworth D-15 Test (QS1-7.4.3).

Examinations are administered by a licensed medical

practitioner (or person certified by a licensed medical

practitioner to administer tests.) A licensed medical

practitioner to provide the necessary data to

determine the inspectors color perception may

evaluate the inspector. Such inspectors may only be

certified to perform inspection work within the

inspectors color perception capability (QS1-7.4.5).

The Company has a program to identify any other

physical qualifications required to perform the

assigned duties (QS1-7.4.6).

Inspectors requiring the physical examinations are

examined by a licensed medical practitioner or

equivalent at intervals not to exceed one year to

confirm continued qualification to perform assigned

duties (QS1-7.4.6).

E. Equipment and Equipment Reference Materials

Inspection personnel are furnished all items of

equipment, including references to perform

inspections tests.

20

8.2

Maintenance of

inspection

equipment

Review of inspection reports and equipment

calibration records confirm compliance.

Auditor note: Project records should document all

equipment issued to each project or each inspector.

Procedures and manufacturers instructions for

maintenance and calibration requirements for each

piece of equipment are provided to each inspector

(QS1-8.3.8).

All equipment is maintained in accordance with

manufacturers recommendations.

RATING

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

COMMENTS

PAGE 11 of 19, 9/09

Audit Item

Number

QS1 REFERENCE

M.A.R.

RATING

Records indicate that defective equipment is clearly

identified and removed from service (QS1-8.3.9).

Calibration records shall be maintained for each

instrument. The records shall include:

The name of the instrument (QS1-8.3.1).

Manufacturers name, type identification, and serial

number or other unique identification (QS1-8.3.2).

Date instrument was received & date placed in

service (QS1-8.3.3).

Current location of instrument (QS1-8.3.0)

Condition of the instrument when received (e.g.,

new, used reconditioned) (QS1-8.3.5).

Manufacturers operating and calibrating instructions

for the instrument (QS1-8.3.6).

Dates and results of the instruments calibration and

date of expiration (QS1-8.3.7).

Records of all current and valid calibration

certificates.

1 2 3

21.

22.

8.3

Calibration of

Inspection

Instruments

9.0.

Measurement

Traceability

23.

V.F.1

24.

9.2

Measurement

Traceability

(In service)

10.1A

Inspection

methods/practices

(general)

F. Measurement Traceability and Calibration

21.1-Procedures for ensuring inspection and testing

equipment calibration are issued to each inspector

(QS1-9.1).

21.2- there is evidence that measurements, where

applicable, are traceable to nationally recognized

standards (QS1-9.2).

Auditor note: When traceability to national standards is

not applicable, there is a procedure or instrument

manufacturers instructions to correlate results.

22.1- where relevant, reference standards and

measuring and testing equipment are subjected to inservice checks (calibration verification) between

calibrations.

22.2- Inspectors note field calibration verification or

accuracy checks on inspection reports.

22.3- Inspectors note equipment model and serial

number for measurements taken with each

instrument on inspection reports.

G. Inspection Methods and Practices

23.1- Inspectors are furnished up-to-date instruction

manuals, which include current standards,

instructions on calibration and use of equipment

references, at least annually.

23.2- Records demonstrating that individual

inspectors have received and understand procedures

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

COMMENTS

PAGE 12 of 19, 9/09

Audit Item

Number

QS1 REFERENCE

M.A.R.

25.

10.1B

Inspection

methods/practices

(general)

for use and calibration verification of equipment.

23.4- Inspectors are provided job site specifications,

product data sheets, MSDS, appropriate standards

and other applicable job site documents and

equipment (QS1-10.1.1).

23.5-There are post-job inspection files, which

document what was furnished to the inspector at the

job site.

23.6- there is evidence that inspectors are brought

up-to-date, at least annually, on new standards, new

tests, new instruments, and new practices.

Auditor note: Look for an annual (or routine) meeting or

class to discuss inspection changes. Review meeting

outline or class syllabus for applicability. Other

acceptable methods include disseminating changes

through traceable documents and self-study materials.

23.1- Inspectors are furnished up-to-date instruction

manuals, which include current standards,

instructions on calibration and use of equipment

references, at least annually.

23.2- Records demonstrating that individual

inspectors have received and understand procedures

for use and calibration verification of equipment.

23.4- Inspectors are provided job site specifications,

product data sheets, MSDS, appropriate standards

and other applicable job site documents and

equipment (QS1-10.1.1).

23.5-There are post-job inspection files, which

document what was furnished to the inspector at the

job site.

23.6- there is evidence that inspectors are brought

up-to-date, at least annually, on new standards, new

tests, new instruments, and new practices.

Auditor note: Look for an annual (or routine) meeting or

class to discuss inspection changes. Review meeting

outline or class syllabus for applicability. Other

acceptable methods include disseminating changes

through traceable documents and self-study materials.

RATING

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

COMMENTS

PAGE 13 of 19, 9/09

Audit Item

Number

26.

27.

28.

QS1 REFERENCE

M.A.R.

10.7

Computers and

other data recording

devices

Where computers or automated equipment are used for

the recording, processing, manipulation, reporting,

storage or retrieval of calibration or inspection data, the

inspection company ensures that:

Procedures are established and implemented for

protecting the integrity of data; such procedures shall

include, but not be limited to, integrity of data entry or

capture, data storage, data backup and replication,

data transmission and data processing, controlled

access to computer files.

Data backup and replication, data transmission and

data processing, controlled access to computer files.

Procedures shall be established to verify protection

of the datas integrity (QS1-10.7.1).

Procedures to verify computer and automated

equipment are secure and ensure proper functioning

(QS1-.7.2).

H. Traceability of Records and Reports

There are procedures for insuring quality of inspection

and support activities as follows:

Inspection procedures and recording systems (QS111.2.1). .

Procedures for receipt of specifications and revisions

(QS1-11.2.2).

Records of standards and specifications or coatings

inspection work records and their utilization (QS111.2.3).

System for filing, distribution, storing and retrieving of

inspection reports (QS1-11.2.4).

Procedures to ensure that each major significant

activity (e.g., surface preparation, coating

application, and curing of primer, intermediate and

topcoat application) was inspected and documented

(QS1-11.2.6).

Procedures to verify that specified steps were taken

in storing, handling, and applying coatings, in

compliance with OSHA, EPA, state, and local

regulations and applicable NFPA standards (QS111.2.7).

There is evidence that:

The inspection company maintains a record system

to suit its particular circumstance and comply with

any applicable regulations.

record all original observations, calculations and

derived data, calibration records and a copy of the

calibration certificate, or inspection report, for an

11.2

Traceability of

records and reports

11.3

Record System

RATING

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

COMMENTS

PAGE 14 of 19, 9/09

Audit Item

Number

QS1 REFERENCE

M.A.R.

appropriate period.

The records for each inspection and test contain

sufficient information to permit their repetition

I. Certificates and Reports

RATING

1 2 3

COMMENTS

PAGE 15 of 19, 9/09

Audit Item

Number

34.

QS1 REFERENCE

12.0

Certificates and

reports

M.A.R.

The results of each inspection, test, or series of

inspections or tests carried out by the inspection

company are recorded in a written report accurately

and objectively, in accordance with any instructions

in the inspection or test methods. The reports

include all the information necessary for the

interpretation of the inspection or test results and all

information required by the method used.

Each report includes at least:

1. A descriptive title.

2. Name and address of Inspection Company, and

location where the inspection was carried out.

3. Identification of the instrumentation (such as

serial number).

4. Name and address of client.

5. Name and address of coating Application

Company.

6. Description and clear identification of the

structure or equipment inspected.

7. Description of the test area and results of the

inspection or test.

8. Date of inspection.

9. Identification of the inspection or test method

used, or clear description of any non-standard

method used.

10. Reference to sampling procedure, if relevant.

11. Any deviations from, additions to or exclusions

from the inspection or test method, and any other

information relevant to a specific inspection or

test, such as environmental conditions.

12. Measurements, examinations and derived results,

supported by tables, graphs, sketches and

photographs as appropriate, and any failures

identified.

13. A signature and title, or an equivalent

identification of the persons accepting

responsibility for the content of the report and

date of issue.

14. Where relevant, a statement to the effect that the

results relate only to items inspected/tested.

15. A statement that the report shall not be

reproduced except in full, without the written

approval of the company.

16. Where the report contains results of inspections

or tests performed by sub-contractors, these

results shall be clearly identified.

RATING

1 2 3

1 2 3

COMMENTS

PAGE 16 of 19, 9/09

Audit Item

Number

35.

QS1 REFERENCE

M.A.R.

13.0

Subcontracting

36.

14.0

Outside Support,

Supplies and

Services

J. Subcontracting

Where and when company subcontracts any

part of its work to meet conformance to QS1 it

as a minimum is required to show that

subcontractors are competent and meet all the

criteria as described in QS1.

The company shall show proof of written

acceptance by the client of all subcontractors

used.

K. Outside Support and Supplies

Company shows evidence of using outside services

and supplies that are of adequate quality to sustain

the clients confidence on worked performed.

Company shall maintain records of all suppliers for

whom it obtains support services or supplies required

to perform work as required.

L. Complaints

RATING

1 2 3

1 2 3

1 2 3

1 2 3

COMMENTS

PAGE 17 of 19, 9/09

Audit Item

Number

37.

QS1 REFERENCE

15.1 and 15.2

M.A.R.

Company shall have a documented policy and

procedures for the resolution of complaints received

by clients.

34.2- a record shall be kept of all complaints and of

the actions taken by the company to resolve the

complaint.

RATING

1 2 3

1 2 3

COMMENTS

PAGE 18 of 19, 9/09

Appendix A

I. Guidance on Meeting QS1 Internal Audit Requirement & SSPC Position

Statement on Internal Auditing Requirements for QS1 Certified Coating and

Lining Firms:

This position statement applies to the your internal auditing of coating and lining work. The internal audit program consists of all internal audits, annual management

evaluations, corrective actions, and follow-up.

A. Introduction: Why Implement an Internal Auditing Program?

Unlike the audit of a companys financial statements, internal quality auditing is used as a tool for monitoring the state of your companys quality management system

(QMS). An effective internal audit process can benefit your company by improving operating efficiency (e.g., reducing waste and rework) and reducing business risks (e.g.

warranty service demands, latent defects, and litigation problems). When you take the time to identify areas of inefficiency, you are always looking at your coating QS

services with an eye toward improving your performance (i.e., reducing rework by getting it right the first time, every time).

The use of internal audits in conjunction with a QMS provides a framework for evaluating compliance. Internal audits also create an environment where continual

improvement is both expected and desired.

If your firm implements a QMS merely to comply with QS1, your company is missing the point of the QMS. Likewise, if you implement an internal auditing program just to

meet a QS1 audit item, you are again overlooking the benefits of continuous improvement.

The QMS provides the structure from which you can develop a baseline for management and operations / production personnel to improve processes in a controlled

fashion. The internal audit process plays an important role in:

Continually assessing your companys compliance with its QMS

Helping you evaluate the effectiveness of previous improvement efforts

Identifying future opportunities for improvement

Top management must be the first to recognize the value of the QMS and the internal audit program. There must be a total commitment from top management to

implement the QMS and to continually improve your companys operations. An effective internal audit program is critical for monitoring your companys QMS and

identifying where further efficiencies can be applied.

B. Who Makes a Good Internal Auditor?

ISO/ASQ QE19011-2002 Auditing identifies the following personal attributes for an auditor:

Ethical (fair, truthful, sincere, honest, and discreet)

Open-minded (willing to consider alternative ideas or points-of-view)

Diplomatic (tactful in dealing with people)

Observant (actively aware of physical surroundings and activities)

Perceptive (instinctively aware of and able to understand situations)

Versatile (adjusts readily to different situations)

Tenacious (persistent, focused on achieving objectives)

Decisive (reaches timely conclusions based on logical reasoning and analysis)

Self-reliant (acts and functions independently while interacting effectively with others)

Your internal auditors should have all these characteristics, plus a keen eye for problems associated with operating the business and the ability to synthesize knowledge

and observations into meaningful recommendations for improvement. Successful internal auditing also requires using certain techniques that are not necessarily

PAGE 19 of 19, 9/09

complicated, but not always self-explanatory. Like all areas of business and management, once youve identified an individual with the desired personal characteristics,

some training and experience will be required for the individual to perform satisfactorily.

C. Auditor Training and Qualifications

ISO/ASQ QE19011-2002 also provides numerous recommendations for auditor qualifications and experience. Additionally, the effective internal auditor must have general

knowledge of coating and linings and company operations, as well as technical knowledge of the protective coatings industry.

The American Society for Quality (ASQ) has an Auditor Certification Program that is appropriate for internal auditors. While ASQ certification is not required for QS1 internal

auditors, it may be worth considering for the individual(s) in your company heavily involved in internal auditing. The Body of Knowledge for the Certified Quality Auditor

Program can be found at www.asq.org, or specifically at http://www.asq.org/cert/types/cqa/bok_new.html. ASQ also offers a self-study-auditing course in both at home

and online versions. At a minimum, any individual assigned auditing functions should have completed ASQ e-Learning Courses Auditing (CQA) Fundamentals I and

Auditing (CQA) Fundamentals II, or ASQs Foundations in Quality Learning Series Certified Quality Auditor (self-study), or an equivalent. ASQ e-Learning Course

Quality 101 (web-based training) will provide a good foundation for anyone involved in developing,

Managing, auditing, or otherwise maintaining a QMS.

D. Compliance with QS1

SSPC expects QS1 firms to perform internal audits on a minimum of 50% of their coatings and linings projects. One way to demonstrate compliance with this quantitative

requirement is to keep a log of annual (FY calendar) projects with notations on the log showing that jobs were internally audited, the name of the internal auditor, and the

date(s) of the internal audit. The log should link specific project records to the appropriate internal audit records.

If you already have such a log or list and use it for other purposes, this is acceptable. To assist you in identifying projects for auditing, here is a list of situations that might

pose unusual risks and must be considered high-priority projects for internal auditing:

Using or having used a QS Inspector new to your company.

Using or having used a newly trained, inexperienced QS Inspector.

Doing work for a new client.

Doing a new category of work, regardless of whether you have an experienced QS Inspector on the project.

Receiving a complaint about quality from a client or the prime contractor, or the material or equipment supplier.

Receiving a formal request from a client to audit project documents and test procedures/results.

Executing a contract that requires internal auditing.

You should allow for internal audits to be both announced and unannounced at the discretion of your Technical Quality Manager (TQM) or Quality Control/Assurance

Manager (QCM) or the Responsible Executive (RE).

E. Audit Sample Size

Much value can be derived from internal audits when appropriate sampling techniques are used. You should have procedures in place to implement the internal audit

policy, including selecting projects, sampling, evaluating, and reporting. Internal audits should be fair and objective. Before beginning any audit, the internal auditor must

become familiar with the details of the coating specification, especially acceptance criteria, as well as details of the QS1 records, test procedures, and results. Results must

be reviewed for completeness, accuracy, and relevance.

When the audit is complete, the internal auditor must sign the report and distribute copies to the TQM and the RE. All audit reports (internal and external),

Das könnte Ihnen auch gefallen

- New York Agreement To SubleaseDokument3 SeitenNew York Agreement To SubleaseGreg BatemanNoch keine Bewertungen

- To Understand The Audit ActivitiesDokument1 SeiteTo Understand The Audit Activitiesulsan busanNoch keine Bewertungen

- SOP HTA Internal AuditDokument13 SeitenSOP HTA Internal Auditjulita08Noch keine Bewertungen

- Procedure On Handling Complaints AppealsDokument10 SeitenProcedure On Handling Complaints AppealsRajender Kumar BaruaNoch keine Bewertungen

- Sample Internal Audit Report 2Dokument9 SeitenSample Internal Audit Report 2Joel Espiritu Custodio86% (21)

- QSP 9 2 Internal Audit PreviewDokument3 SeitenQSP 9 2 Internal Audit PreviewAnandababuNoch keine Bewertungen

- Audit Non Conformance ReportDokument4 SeitenAudit Non Conformance Reportbudi_alamsyah100% (2)

- I-Sec-Checklist For Background VerificationDokument3 SeitenI-Sec-Checklist For Background VerificationbalasundarbeNoch keine Bewertungen

- Audit Plan 2018 lbc1Dokument23 SeitenAudit Plan 2018 lbc1r0wanNoch keine Bewertungen

- Supplier Performance Assessment FormDokument1 SeiteSupplier Performance Assessment FormkarupukamalNoch keine Bewertungen

- Welder Performance Qualification WPQDokument3 SeitenWelder Performance Qualification WPQramzi5ben5ahmed100% (1)

- Quality Internal AuditDokument4 SeitenQuality Internal AuditĐàm DuyênNoch keine Bewertungen

- Processing of Letters of AuthorityDokument5 SeitenProcessing of Letters of AuthorityAlexis MariNoch keine Bewertungen

- Purposes of Evaluation-Goals of The System/ When A Project Is SuccessfulDokument10 SeitenPurposes of Evaluation-Goals of The System/ When A Project Is SuccessfulAbdul Kader MandolNoch keine Bewertungen

- ISO 9001 Internal Audit ChecklistDokument6 SeitenISO 9001 Internal Audit Checklistjmwaweru71% (7)

- Bgas Paint Faults, BittinessDokument49 SeitenBgas Paint Faults, BittinessslxantoNoch keine Bewertungen

- Topic 1 - QA-QC OrientationDokument14 SeitenTopic 1 - QA-QC OrientationJohn P. BandoquilloNoch keine Bewertungen

- Checklist Aero AS9100 PDFDokument2 SeitenChecklist Aero AS9100 PDFprabhakaranmeNoch keine Bewertungen

- ProQC ExampleReport SA8000 AuditDokument25 SeitenProQC ExampleReport SA8000 AuditMuhammad Shoaib100% (1)

- 15.0 Non-Destructive Examination of Welds: Adiographic EstingDokument5 Seiten15.0 Non-Destructive Examination of Welds: Adiographic EstingRagesh K RaviNoch keine Bewertungen

- Iso 9001 Activity Plan '05Dokument3 SeitenIso 9001 Activity Plan '05jvenrqzNoch keine Bewertungen

- Prepare for ISO AuditDokument4 SeitenPrepare for ISO AuditrwillestoneNoch keine Bewertungen

- Lanco Vendor - Registration - FormDokument9 SeitenLanco Vendor - Registration - Formajaymkum@yahoo.comNoch keine Bewertungen

- Sample Audit PlanDokument6 SeitenSample Audit PlanHecel Olita100% (2)

- External Audit Corrective Action PlanDokument1 SeiteExternal Audit Corrective Action PlanAde Haris MustafaNoch keine Bewertungen

- Internal Quality Audit Rev 00Dokument26 SeitenInternal Quality Audit Rev 00Keith AmorNoch keine Bewertungen

- Audit Preparation ListDokument2 SeitenAudit Preparation ListRajanNoch keine Bewertungen

- Internal Audit Plan Template PDFDokument8 SeitenInternal Audit Plan Template PDFSita Aulia50% (2)

- PRESERVATION AND MATERIAL CONTROL AUDITDokument4 SeitenPRESERVATION AND MATERIAL CONTROL AUDITAngel Angeleye100% (3)

- Quality Assurance Quality ControlDokument23 SeitenQuality Assurance Quality ControlIrsyad RosyidiNoch keine Bewertungen

- Internal Audit Progress Report and Quarter 2 PlanDokument10 SeitenInternal Audit Progress Report and Quarter 2 PlanPitt Si EndutNoch keine Bewertungen

- How To Conduct Effective Internal Audit PlanningDokument22 SeitenHow To Conduct Effective Internal Audit PlanningLyne LerinNoch keine Bewertungen

- Internal Audit Checklist Optimized for ISO 9001 ComplianceDokument25 SeitenInternal Audit Checklist Optimized for ISO 9001 ComplianceadnanNoch keine Bewertungen

- Republic of The Philippines Metropolitan Naga Water District 40 J. Miranda Avenue Naga CityDokument2 SeitenRepublic of The Philippines Metropolitan Naga Water District 40 J. Miranda Avenue Naga CityTeejay Altair TormesNoch keine Bewertungen

- Internal Audit ISO 9001Dokument7 SeitenInternal Audit ISO 9001Hamada Ahmed100% (1)

- Fabricators QC Qa Plan Checklist Form 675 070 17Dokument3 SeitenFabricators QC Qa Plan Checklist Form 675 070 17novernandoNoch keine Bewertungen

- Guide On The Audit of Procurement - 1st Update, Dec 2009 (InDokument771 SeitenGuide On The Audit of Procurement - 1st Update, Dec 2009 (InCatherine Aguirre Ferenal67% (3)

- Internal Audit Planning and Scheduling Sample FormatDokument3 SeitenInternal Audit Planning and Scheduling Sample FormatAkasha KhanNoch keine Bewertungen

- Pre-Qualification Questionnaire: ConfidentialDokument4 SeitenPre-Qualification Questionnaire: ConfidentialMazhar MahadzirNoch keine Bewertungen

- ISO 9001 Audit of Rove Hotels LLC Identifies Risk and Opportunity Management Needs ImprovementDokument3 SeitenISO 9001 Audit of Rove Hotels LLC Identifies Risk and Opportunity Management Needs ImprovementOmar MuktharNoch keine Bewertungen

- CP16 PDFDokument21 SeitenCP16 PDFMarcus AntoniusNoch keine Bewertungen

- OP009 Impartiality Integrity Confidentiality Issue 4 13.06.18Dokument6 SeitenOP009 Impartiality Integrity Confidentiality Issue 4 13.06.18Mariam KhanNoch keine Bewertungen

- Audit Question SampleDokument27 SeitenAudit Question SampleimamudeenNoch keine Bewertungen

- How To Conduct Effective Stage-1 Audit-Training Presentation DocumentsDokument21 SeitenHow To Conduct Effective Stage-1 Audit-Training Presentation DocumentsYolanda Desi Chavira PutriNoch keine Bewertungen

- Bechtel Quality Audit ProcedureDokument17 SeitenBechtel Quality Audit ProcedureYusufNoch keine Bewertungen

- QA QC PresentationDokument109 SeitenQA QC Presentationklibi89% (9)

- Inspection ProcedureDokument10 SeitenInspection ProcedureMoustafa BayoumiNoch keine Bewertungen

- Container Consulting Services Quality Manual - ISO 9001Dokument7 SeitenContainer Consulting Services Quality Manual - ISO 9001Richard TroianoNoch keine Bewertungen

- AR1 Audit - Report (Stage 2) MajikDokument8 SeitenAR1 Audit - Report (Stage 2) MajikRachel TangNoch keine Bewertungen

- QC Planning For SuccessDokument7 SeitenQC Planning For SuccessAbdul hafizNoch keine Bewertungen

- 1 2015 Section 9 1Dokument20 Seiten1 2015 Section 9 1Tamekia HodgesNoch keine Bewertungen

- ISO 9001:2015 CS 6 Desktop Audit - 2017Dokument4 SeitenISO 9001:2015 CS 6 Desktop Audit - 2017YasirdzNoch keine Bewertungen

- 141 ISACA NACACS Auditing IT Projects Audit ProgramDokument85 Seiten141 ISACA NACACS Auditing IT Projects Audit ProgramkirwanicholasNoch keine Bewertungen

- 141 ISACA NACACS Auditing IT Projects Audit ProgramDokument86 Seiten141 ISACA NACACS Auditing IT Projects Audit Programkautaliya100% (6)

- Section 8 - Quality Assurance/Quality Control PlanDokument3 SeitenSection 8 - Quality Assurance/Quality Control PlanJoemon T JoyNoch keine Bewertungen

- Management System Certification: Telephone: 0300 330 5797 E-Mail: WebsiteDokument5 SeitenManagement System Certification: Telephone: 0300 330 5797 E-Mail: WebsiteSunil AroraNoch keine Bewertungen

- HSSE & SP Audit ProcedureDokument41 SeitenHSSE & SP Audit Proceduregangadharan000100% (3)

- IRIS Top 25 QuestionsDokument4 SeitenIRIS Top 25 QuestionsAndrew KerrNoch keine Bewertungen

- Reviewing PQP Guide To InspectorsDokument21 SeitenReviewing PQP Guide To InspectorsMohamed S. ElrapatNoch keine Bewertungen

- QS/QC QuestionsDokument16 SeitenQS/QC QuestionsJh Hedra100% (1)

- VNMDokument9 SeitenVNMMinh Vuong TranNoch keine Bewertungen

- Iso 9001 CRMDokument6 SeitenIso 9001 CRMleovenceNoch keine Bewertungen

- External Document Update 21.09.18Dokument10 SeitenExternal Document Update 21.09.18Minh Vuong TranNoch keine Bewertungen

- Documentation Requirements 14001 Tcm14 85638Dokument4 SeitenDocumentation Requirements 14001 Tcm14 85638Zayin ValerieNoch keine Bewertungen

- Bang So Sanh LinhDokument24 SeitenBang So Sanh LinhMinh Vuong TranNoch keine Bewertungen

- Spectromaxx: The New Art of Analyzing MetalDokument4 SeitenSpectromaxx: The New Art of Analyzing MetalMinh Vuong TranNoch keine Bewertungen

- Best Practices For Effectiveness ChecksDokument4 SeitenBest Practices For Effectiveness ChecksMariver LlorenteNoch keine Bewertungen

- ISO Audit Report SummaryDokument19 SeitenISO Audit Report SummaryMinh Vuong Tran100% (1)

- 6 - 3 - 2 Contingency Plan 1Dokument1 Seite6 - 3 - 2 Contingency Plan 1Minh Vuong TranNoch keine Bewertungen

- 00 - QA-F-08-VP - Validation of Special Process - BlankDokument1 Seite00 - QA-F-08-VP - Validation of Special Process - BlankMinh Vuong TranNoch keine Bewertungen

- Risk TableDokument1 SeiteRisk TableMinh Vuong TranNoch keine Bewertungen

- C M Và T V NG Eco 1 2 3 4 5 - Full HD - Đ.m.cư NGDokument8 SeitenC M Và T V NG Eco 1 2 3 4 5 - Full HD - Đ.m.cư NGMinh Vuong TranNoch keine Bewertungen

- Comparison of Professional Testing Services Pte Ltd's CTOD Procedure with API 5L 45th RequirementsDokument2 SeitenComparison of Professional Testing Services Pte Ltd's CTOD Procedure with API 5L 45th RequirementsMinh Vuong TranNoch keine Bewertungen

- Episode 2Dokument11 SeitenEpisode 2Minh Vuong TranNoch keine Bewertungen

- ScopeDokument5 SeitenScopeMinh Vuong TranNoch keine Bewertungen

- A370 1997Dokument46 SeitenA370 1997Narendrasinh JadejaNoch keine Bewertungen

- ESOS - AdvertisingDokument20 SeitenESOS - AdvertisingHarry JakeNoch keine Bewertungen

- Steels Repair IACS REC 47 Pdf193Dokument63 SeitenSteels Repair IACS REC 47 Pdf193Josep Maria Montoy CanadellNoch keine Bewertungen

- ESOS - AdvertisingDokument20 SeitenESOS - AdvertisingHarry JakeNoch keine Bewertungen

- Content: Standard Operating Procedure (SOP) Use and Maintenance of An IncubatorDokument7 SeitenContent: Standard Operating Procedure (SOP) Use and Maintenance of An IncubatorEndo LNoch keine Bewertungen

- Ppap Worksheet (GM 1411) : S Master Status: Lab StatusDokument6 SeitenPpap Worksheet (GM 1411) : S Master Status: Lab Statuscong daNoch keine Bewertungen

- Radiooperater S Općom Ovlasti: Ispitna Pitanja Za Zvanje Iz Predmeta: Pravila Radio SlužbeDokument12 SeitenRadiooperater S Općom Ovlasti: Ispitna Pitanja Za Zvanje Iz Predmeta: Pravila Radio SlužbeKristijan PolicNoch keine Bewertungen

- Modelling and Simulation PV Station VRTDokument4 SeitenModelling and Simulation PV Station VRTDaniel ManjarresNoch keine Bewertungen

- If A Pedestrian Is Hit and Lands On The Front of The Car, The Airbag InflatesDokument1 SeiteIf A Pedestrian Is Hit and Lands On The Front of The Car, The Airbag InflatesYu SunNoch keine Bewertungen

- Roushini Siddiqua: Contact No.Dokument4 SeitenRoushini Siddiqua: Contact No.Surabhi KhannaNoch keine Bewertungen

- Risen Energy - Reference Projects - CODokument20 SeitenRisen Energy - Reference Projects - COCesar Arturo SolerNoch keine Bewertungen

- Giddings & Lewis Sect10 MaintenanceDokument10 SeitenGiddings & Lewis Sect10 MaintenanceAngel AdautaNoch keine Bewertungen

- What Is Amplitude ModulationDokument15 SeitenWhat Is Amplitude ModulationRachhan Khorn100% (1)

- The Term Telecommunication Means Communication at A DistanceDokument2 SeitenThe Term Telecommunication Means Communication at A DistanceAnonymous MXgopYDENoch keine Bewertungen

- Autosar TR SwcmodelingguideDokument57 SeitenAutosar TR SwcmodelingguideRadu ButnaruNoch keine Bewertungen

- Selecting Software Testing ToolsDokument29 SeitenSelecting Software Testing ToolsJay SawantNoch keine Bewertungen

- Ahmad RaqibDokument3 SeitenAhmad RaqibMohamad IkhwanNoch keine Bewertungen

- Business Analyst Interview Questions Answers Part 1Dokument9 SeitenBusiness Analyst Interview Questions Answers Part 1ravisolan100% (2)

- Sun Tzu and Information Warfare PDFDokument178 SeitenSun Tzu and Information Warfare PDFtazman10102458100% (4)

- BioTeK Power Wave UserManualDokument176 SeitenBioTeK Power Wave UserManualAFWNoch keine Bewertungen

- MySQL Triggers GuideDokument21 SeitenMySQL Triggers Guidesatya prakash singhNoch keine Bewertungen

- Rayos X Odont Cranex - S - M PDFDokument206 SeitenRayos X Odont Cranex - S - M PDFDaniel Parada VanegasNoch keine Bewertungen

- 2021-12-Clamp Proximity Sensor TestingDokument4 Seiten2021-12-Clamp Proximity Sensor TestingSARET respaldoNoch keine Bewertungen

- Course Outline - Design Sketching (AutoRecovered)Dokument10 SeitenCourse Outline - Design Sketching (AutoRecovered)Krishnanunni Karayil UllasNoch keine Bewertungen

- Siebel 8.1 Integration With Avaya IC 7.2Dokument3 SeitenSiebel 8.1 Integration With Avaya IC 7.2Shipra JainNoch keine Bewertungen

- The Unified Kill ChainDokument19 SeitenThe Unified Kill ChainManuNoch keine Bewertungen

- Window 11 User GuideDokument83 SeitenWindow 11 User GuideKonstantinosGNoch keine Bewertungen

- PS Series: Robotic Total StationsDokument4 SeitenPS Series: Robotic Total StationsAlina Gabriela TodicaNoch keine Bewertungen

- Metastat Command Shows Soft Partition in Errored StateDokument3 SeitenMetastat Command Shows Soft Partition in Errored StatecresmakNoch keine Bewertungen

- Résumé For Arjun JayaramanDokument1 SeiteRésumé For Arjun JayaramanArjun JayaramanNoch keine Bewertungen

- dgtww201311 DL PDFDokument60 Seitendgtww201311 DL PDFvrider81Noch keine Bewertungen

- The Machine As Seen at The End of The Mechanical Age 1968Dokument222 SeitenThe Machine As Seen at The End of The Mechanical Age 1968Manuel Bogalheiro100% (2)

- What is Big Data? Four V's and Uses in BusinessDokument222 SeitenWhat is Big Data? Four V's and Uses in BusinessraviNoch keine Bewertungen

- The 5D BlueprintDokument18 SeitenThe 5D BlueprintAmerican Kabuki50% (4)

- Rulebook For Technovision'11: Electrical and Electronics EngineeringDokument5 SeitenRulebook For Technovision'11: Electrical and Electronics EngineeringKhushbu BuchchaNoch keine Bewertungen