Beruflich Dokumente

Kultur Dokumente

S4 Column Design

Hochgeladen von

Cristina-Alexandra CrăciunCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

S4 Column Design

Hochgeladen von

Cristina-Alexandra CrăciunCopyright:

Verfügbare Formate

I.C.E.

, IV, 2015-2016

Steel Industrial Building-Design Project

Stage 4 Column Design

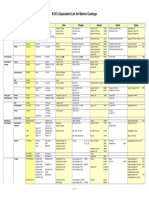

4.1. Actions and combinations for design

4.2. Critical lengths of the column

4.3. Sizing the cross section

4.4. Verifications in U.L.S. combinations

4.4. Classification of the cross section

1.

4.4. Verifications for strength under combined state of

2.

stresses

2.4. Verifications for stability

3.

M,V- min/max

max

N Ed

VEdcor

cor

M Ed

corespunzator

N Ed

VEdmax

cor

M Ed

cor

N Ed

VEdcor

max

M Ed

4.1. Design values

in combinations N,

4.2. Critical lengths of the column

Static scheme adopted:

- in the transversal frame plane the column is fixed in the foundation and hinged at

the top; buckling about y-y:

Lcr,y = 0.7hc

- in the longitudinal direction the column is doubly hinged at the extremities;

buckling about z-z:

Lcr,z = hc

Still, as these values do not correspond entirely with the real conditions of

restraining in the plane of the frame (transversally) and normal to the plane of the

frame, in the longitudinal direction of the structure, thre may be a paralel possibility

to evaluate the critical lengths.

Buckling about y-y

Use the relationships for a rigurous approach with the help of the Woods curves:

I.C.E., IV, 2015-2016

Steel Industrial Building-Design Project

I.C.E., IV, 2015-2016

Steel Industrial Building-Design Project

Buckling about z-z:

I.C.E., IV, 2015-2016

Steel Industrial Building-Design Project

The restraining conditions at L/2, L/3 due to the second order structure that

sustain the walling system (joists) are considered doubly pinned.

4.3. Sizing the cross section

Choose a hot rolled universal section for columns, like HEA,HEB,HEM

Estimate a trial section with a selfweight determined with:

gc,k = (0.15..0.20)[kN/m]hc [m]

where hc is the length of the column from the base plate up to the capital level

Geometric characteristics

h ....mm

Sectional

characteristics

A .....mm 2

b ...mm

I y .....mm 4

t w ...mm

I z ....mm 4

t f ...mm

I t ......mm 4

r ...mm

W pl , y .....mm3

AV , Z ......mm 2

Sizing the section for the column

1) MEd Mpl,y,Rd =Wpl,y fyd

Extract Wpl,y min

lim=120; y=Lcr,y/iy

2)

Extract iy min

4

I.C.E., IV, 2015-2016

Steel Industrial Building-Design Project

3) Go to tabels and choose section

4) Verify:

max

cor

M ycor, Ed

M ymax

N Ed

N Ed

, Ed

0.7

0.7

fy

fy

fy

fy

A

W pl , y

A

W pl , y

M0

M0

M0

M0

i

4.4. Verifications in U.L.S. combinations

4.4.1. Classification of the cross section

Class 1 SR EN 1993-1-1:2006, tab. 5.2

Web:

c d h 2t 2r ;

f

t tw

max

N Ed

1

1

2

c tw f y

I.C.E., IV, 2015-2016

Steel Industrial Building-Design Project

Flanges:

I.C.E., IV, 2015-2016

Steel Industrial Building-Design Project

4.4.2. Verifications for strength under combined state of stresses

Members in bending in the presence of axial an shear forces, combined M-N-V

stresses (SR EN 1993-1-1, pct. 6.2.9.1).

The effect of axial force upon the rezistent bending moment about the relevant axis

of the symmetric class 1 sections, like I and H will be checked if:

NEd 0.15Npl,Rd and NEd 0.5hwtwfy,d

So:

M Ed M N , Rd

where:

MEd = Mmax,Ed

MN,Rd = MN,y,Rd

M N , y ,Rd M pl , y ,Rd

1 n

1 0,5a

cor

N Ed

N pl , Rd

A 2 b

tf

A

, dar a 0,5

Resistance to shear (SR EN 1993 1-1-, pct. 6.2.6)

VEd

1

Vc, Rd

Vc, Rd V pl , Rd (in absenta rasucirii )

max

VEd VEd

si V pl ,Rd

Av, z ( f y / 3)

M0

Av , z

Av, z A 2bt f t f (2r tw )

- shear area in the z-z plane

for I and H sections:

The effect of shear upon the plastic resistant bending moment (SR EN 1993-1-1, pct. 6.2.8)

mai be neglected if:

Vmax, Ed

V pl , Rd

0,5 se neglijeaz

If:

Vmax, Ed

V pl , Rd

0,5 se calculeaza M y ,V , Rd

M y ,V , Rd

Aw2

Wy , pl

4t w

M0

cu Aw hw t w

2VEd

si

1

Vz , pl , Rd

And the verification is :

I.C.E., IV, 2015-2016

Steel Industrial Building-Design Project

M Ed M y ,V , Rd

4.4.3. Verifications of stability of the column under compression and

bending about y-y (SR EN 1993-1-1, pct. 6.3.3)

M y , Ed

N Ed

k yy

1

N b , y , Rd

M b , y , Rd

M y , Ed

N Ed

k zy

1

N b, z , Rd

M b, y , Rd

where:

N Ed , M y , Ed

- design values of the internal axial forces and moments in the

relevant combination of actions;

A f y

A f y

W y , pl f y

N b, y , Rd y

N b, z , Rd z

M b, y , Rd LT

M1

M1

M1

;

;

y , z

- reducing factors of byckling about y-y and z-z;

LT

- reducing factor for flexural torsional buckling (open sections);

k yy , k zy

- interaction factors (Annex B, SR EN 1993-1-1)

- buckling curves:

- imperfections factors:

8

I.C.E., IV, 2015-2016

Steel Industrial Building-Design Project

Buckling about y-y:

y

Lcr , y

iy

y

1

y

93.9

; 1

_

1 y ( y 0.2) y2

y 0.5

y2

_

y2

A f y

Nb, y , Rd y

M1

Buckling about z-z;

_

L

z cr , z

z z

iz

1

,

_

1 z (z 0.2) z2

z 0.5

z

z

_

2

z z2

A f y

Nb, z , Rd z

M1

Flexural torsional buckling:

I.C.E., IV, 2015-2016

LT

Steel Industrial Building-Design Project

LT

,

1

LT

Lcr , z / iz

2

1 Lcr , z / iz

C1 1

20 h / tf

0.25

Alegerea curbei de flambaj:

curba b, cu LT 0.34

curba c, cu LT 0.49

LT ,0 0.4

0.75

_

_

_

2

LT 0.5 1 LT (LT LT ,0 ) LT

LT

1

_

2

2

LT LT

LT

Wy , pl f y

M b, y , Rd LT

M1

Interaction factors determined according to the symplified method,

Anexa B, SR EN 1993-1-1:2006

10

I.C.E., IV, 2015-2016

Steel Industrial Building-Design Project

11

I.C.E., IV, 2015-2016

Steel Industrial Building-Design Project

4.5. Capital of the column

RGZ - truss reaction

(1) cap plate

tc=15.20 mm

(2) - stiffener

td t w

bd 0.5b tw

hd

The length of the stiffener (2) is determined considering the necessary length of the

fillet welds that connect it to the web of the column:

R

s GZ f vw,d

RGZ

Aw

lw lw,d 2aw

lw,d

4awfvw,d

Aw 4 aw lw,d

hd lw (modulat la10mm)

4.6. Column base plate

For the base plate

tp=20mm

B b 2tt 4 2d 0

L h 4 2d0

12

I.C.E., IV, 2015-2016

Steel Industrial Building-Design Project

For the gusset (if necessary)

tt 15mm

bt L

4.6.1 Anchor bolt (hold down bolt)

The column is gixed in the foundation with 4 anchor bolts. The diameter of the bolt

is determined from the condition to resist to traction ( tension stresses may be

developed under the base plate due to the effect of the bending moment).

Ft , Ed Ft ,Rd

cor

M max

y, Ed N Ed

Ft , Ed

ht f

2

0.9 As fub

Ft , Rd 2

M 2

d s 0.89d d

As

Ft ,Ed M 2

2 0.9 fub

d s2

A

s

4

ds

4 As

ds

0.89

4.6.2. Base plate subjected to compression

The design is based on the theoretical model presented in SR EN 1993-1-8: the

flexible base plate is replaced by an equivalent rigid plate, this one being obtained

from the print of the column cross section to which a stripe with the dimension c is

added on the perimeter of the column section, where:

13

I.C.E., IV, 2015-2016

c tp

Steel Industrial Building-Design Project

fy

3 f jd

M0

f jd

- resistance of the grout layer between the base plate and

the foundation.

The characteristic values of the resistance of both the grout and the concrete are

considered

Class of resistance of the concrete

C20/2 C25/30 C30/3 C35/4 C40/50

5

7

5

2

13

16,7

20

23,3

26,7

fcd N / mm

f jd N / mm 2

13

16,7

20

23,3

26,7

If the pressure under the equivalent surface of the base plate is considered as

evenly distirbuted the rezistance to compression is:

Fc,Rd f jd Aeff

And the verification to compression is:

max F

N Ed

c, Rd

4.6.4. Base plate under axial force and bending moment

CASE 1

excentricity zone

verification

Resistant moment in the

connection

14

I.C.E., IV, 2015-2016

M

L

e Ed

N Ed

6

Steel Industrial Building-Design Project

M max

y, Ed M j ,Rd

Both left and right are

active in compression

Fc , Rd

Rezistence of the conpressed area in the connection

The resistance is given by the lowest value between the resistance of the column

flange and the part of the web in compression and the resistance to compression of

the base plate (as the sum between the active parts in compression):

Fc, Rd min Fc, fc, Rd ; Fc, pl , Rd

M c, Rd M pl ,Rd

Fc, fc,Rd

ht f

h t f

Fc, pl ,Rd f jd Aeff

Aeff 2 beff

leff ; beff

2c t f ;

leff

2c b

Fc,l , Rd Fc,r ,Rd Fc, Rd

z h t f

zc,l zc,r

h tf

2 2

e=excentricity

FC,l,Rd

- resistance to compression of the left area of the connection;

FC,r,Rd

- resistance to compression of the right area of the connection.

15

I.C.E., IV, 2015-2016

Steel Industrial Building-Design Project

CASE 2

excentricity

M Ed

L

N Ed

6

zone

verification

Left side in tnesion and

right side in

compression (reversible

in symmetric situations)

M max

y, Ed M j,Rd

Resistant moment in the

connection

zC ,r

h tf

2 2

zT ,r

h

2d0

2

zT ,r h

tf

2

2d 0

Fc,r , Rd

Resistance of the zone in compression It will be determined as the lowest value from the resistances of the components of

the connection under compression forces

Fc, Rd min Fc, fc, Rd ; Fc, pl , Rd

M c, Rd M pl ,Rd

Fc, fc,Rd

ht f

h t f

Fc, pl ,Rd f jd Aeff

Aeff beff leff ; beff 2c t f ;

leff 2c b

Resistance of the zone in tension - FT,l,Rd

FT , Rd min( Ft , pl , Rd ; Ft ,wc, Rd )

Ft , pl , Rd

- resistance of the zone of the base plate obtained from a number of

equivalent T-stubs, which depend on the type of failure mechanisms developed:

Ft , pl ,Rd min( FT ,12, Rd ; FT ,3,Rd )

16

I.C.E., IV, 2015-2016

Steel Industrial Building-Design Project

Mode 1-2 complete plastic failure mechanism of the base plate:

2 leff ,1 M y, pl , Rd

FT ,12, Rd

m

Mode 3 failure mechanism of braking the anchor bolts in tension

FT ,3, Rd Ft ,Rd 2

0.9 As fub

M 2

17

Das könnte Ihnen auch gefallen

- Steel Structures enDokument4 SeitenSteel Structures enCristina-Alexandra CrăciunNoch keine Bewertungen

- Durability of RC Concrete StructuresDokument8 SeitenDurability of RC Concrete StructuresCristina-Alexandra CrăciunNoch keine Bewertungen

- Composites Are Materials Consisting of Two or More ChemicallyDokument14 SeitenComposites Are Materials Consisting of Two or More ChemicallyCristina-Alexandra CrăciunNoch keine Bewertungen

- Geotechnics ICEDokument3 SeitenGeotechnics ICEMacovei AlinNoch keine Bewertungen

- 1 Seismology For Civil EngineersDokument14 Seiten1 Seismology For Civil EngineersParaschiv VictorNoch keine Bewertungen

- Foundation Engineering ICEDokument3 SeitenFoundation Engineering ICECristina-Alexandra CrăciunNoch keine Bewertungen

- TEMA 1+2 Sap2000 (Truss + 3D Framework)Dokument30 SeitenTEMA 1+2 Sap2000 (Truss + 3D Framework)Cristina-Alexandra CrăciunNoch keine Bewertungen

- Annex2 Bill of Quantities Lot1Site2Dokument135 SeitenAnnex2 Bill of Quantities Lot1Site2Emilian MarginaNoch keine Bewertungen

- Compound Steel Beams Solved ExampleDokument7 SeitenCompound Steel Beams Solved ExampleCristina-Alexandra CrăciunNoch keine Bewertungen

- Number 1 Intrebari BetonDokument2 SeitenNumber 1 Intrebari BetonCristina-Alexandra CrăciunNoch keine Bewertungen

- 1 Introduction in GeologyDokument16 Seiten1 Introduction in GeologyCristina-Alexandra CrăciunNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Citizen Kane Script by Herman J. Mankiewicz and Orson Welles PDFDokument135 SeitenCitizen Kane Script by Herman J. Mankiewicz and Orson Welles PDFFlavio Roberto Mota100% (2)

- Snow White and the Seven DwarfsDokument2 SeitenSnow White and the Seven DwarfsYudhi NugrahaNoch keine Bewertungen

- Name Danish Reza: Sub Retail MGT - MBA 2 - Sem: Faculty Shalini SrivastavDokument13 SeitenName Danish Reza: Sub Retail MGT - MBA 2 - Sem: Faculty Shalini SrivastavdanishrezaNoch keine Bewertungen

- Importer contact details listDokument23 SeitenImporter contact details listNikhil ChaudharyNoch keine Bewertungen

- Coating Equivalent List KCCDokument3 SeitenCoating Equivalent List KCCchrismas_g100% (2)

- TBT 03 Plan To Help A Friend Flannel Graph Color enDokument8 SeitenTBT 03 Plan To Help A Friend Flannel Graph Color enMyWonderStudio100% (64)

- I III IV V Blocked and Broken Chord ProgressionDokument1 SeiteI III IV V Blocked and Broken Chord ProgressionAnonymous p937DJJQSr100% (1)

- ABRSM Piano Exam 2013Dokument19 SeitenABRSM Piano Exam 2013cem_mponce100% (1)

- Kids Ramadan TrackerDokument10 SeitenKids Ramadan TrackerZaheen Mubashir67% (3)

- PDPR - Basic WardrobeDokument49 SeitenPDPR - Basic WardrobeAnne DiazNoch keine Bewertungen

- Solid Edge ShortcutsDokument3 SeitenSolid Edge Shortcutsabekkernens100% (1)

- NURSE UNIFORMDokument9 SeitenNURSE UNIFORMawhie dg.masikkiNoch keine Bewertungen

- Form and Meaning - Studies in Literary Techniques in The Book of JonahDokument204 SeitenForm and Meaning - Studies in Literary Techniques in The Book of JonahXavier Casamada100% (3)

- Computer Graphics BasicsDokument67 SeitenComputer Graphics BasicsAnas KhanNoch keine Bewertungen

- CS381 - Introduction To Multimedia Quiz 1: FalseDokument7 SeitenCS381 - Introduction To Multimedia Quiz 1: FalseEncarnado AprilNoch keine Bewertungen

- The Spiritual Vessel (Kli)Dokument1 SeiteThe Spiritual Vessel (Kli)Carla MissionaNoch keine Bewertungen

- Elapsed Time Word Problems TV Show WorksheetDokument2 SeitenElapsed Time Word Problems TV Show WorksheetmarialisaNoch keine Bewertungen

- Clement of AlexandriaDokument6 SeitenClement of Alexandriaacts2and38100% (4)

- Note Name WorksheetsDokument15 SeitenNote Name WorksheetsCarey Tyler-Lelond100% (10)

- Percubaan PMR 09 Sabah Marking Scheme MTK Paper 2Dokument5 SeitenPercubaan PMR 09 Sabah Marking Scheme MTK Paper 2732456100% (3)

- Aston Martin Magazine Winter 2009Dokument63 SeitenAston Martin Magazine Winter 2009bsc99Noch keine Bewertungen

- DH-IPC-HDW2239T-AS-LED-S2: 2MP Lite Full-Color Fixed-Focal Eyeball Network CameraDokument3 SeitenDH-IPC-HDW2239T-AS-LED-S2: 2MP Lite Full-Color Fixed-Focal Eyeball Network CameraMEL ANGELESNoch keine Bewertungen

- Ten Scenes For Two FlutesDokument37 SeitenTen Scenes For Two FlutesSamuel Dickenson67% (3)

- Led Fundamentals: Luminous EfficacyDokument10 SeitenLed Fundamentals: Luminous EfficacyKalp KartikNoch keine Bewertungen

- Book case study and kindergarten net case explore play-based learningDokument12 SeitenBook case study and kindergarten net case explore play-based learningShabnamNoch keine Bewertungen

- I. Supply The Correct Tense or Form of The Verbs in ParenthesesDokument4 SeitenI. Supply The Correct Tense or Form of The Verbs in ParenthesesNhung PhạmNoch keine Bewertungen

- Succeed in Cambridge Pet 10 Practice tests-KEYS PDFDokument2 SeitenSucceed in Cambridge Pet 10 Practice tests-KEYS PDFTienNguyen50% (6)

- Philippine Literature The Contemporary PeriodDokument2 SeitenPhilippine Literature The Contemporary PeriodMikkoy18100% (3)

- 3.1 Basic Trigonometry: Question PaperDokument7 Seiten3.1 Basic Trigonometry: Question PaperReddy GirinathNoch keine Bewertungen

- Death and The Kings Horseman Play PaperDokument3 SeitenDeath and The Kings Horseman Play Paperapi-312901831Noch keine Bewertungen