Beruflich Dokumente

Kultur Dokumente

Optimization of Production Conditions of Nisin Bactreocin Produced From Lactococcus Lactis and Its Effect On Staphylococcus Aureus

Hochgeladen von

Bassam MalasOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Optimization of Production Conditions of Nisin Bactreocin Produced From Lactococcus Lactis and Its Effect On Staphylococcus Aureus

Hochgeladen von

Bassam MalasCopyright:

Verfügbare Formate

Optimization of production conditions of Nisin bactreocin

produced from lactococcus lactis and its effect on

Staphylococcus aureus

Yazji S*,Mohamad M*,Malas B**

*Dept. of Food Science, Faculty of Agriculture, University of. Damascus

**Postgraduate student (PhD), Dept. of Food Science, Faculty of Agriculture, University of.

Damascus.

Abstract:

Best isolate lactococcus lactis B18 been selected according to its

effect on Staphylococcus aureus and were (6) mm as inhibition

diameters by halls method after pH modification, and nisin gene has

been detected by PCR technique, best production medium has been

selected and was M17 broth besides to 3% lactose and 3% yeast

extract, then production conditions have been optimized and were for

Staphylococcus aureus (pH: 6.5, temperature: 37oC, Incubation

time: 96H, and inoculation size: 1,5Ml), the inhibition diameter

became 11 mm.

Keywords: lactococcus lactis, nisin, Staphylococcus aureus.

Corresponding author: Email: bassammallas@hotmail.com , bassammmallas@gmail.com

Tel: +963 0955162805, +9630837255153.

Introduction:

In recent years bacterial antibiotic resistance has been considered a

problem due to the extensive use of classical antibiotics in treatment

of human and animal diseases (Roy, 1997; Lipsitch et al, 2000;

Yoneyama and Katsumata, 2006). As a consequence, multiple

resistant strains appeared and spread causing difficulties and the

restricted use of antibiotics as growth promoters. So, the continued

development of new classes of antimicrobial agents has become of

increasing importance for medicine (Kumar and Schweiser, 2005;

Fisher et al, 2005). In order to control their abusive use in food and

feed products, one plausible alternative is the application of some

bacterial peptides as antimicrobial substances in place of antibiotics

of human application. Among them, bacteriocins produced by lactic

acid bacteria have attracted increasing attention, since they are

active in a nanomolar range and have no toxicity.

Bacteriocins are proteins or complexed proteins biologically active

with antimicrobial action against other bacteria, principally closely

related species. They are produced by bacteria and are normally not

termed antibiotics in order to avoid confusion and concern with

therapeutic antibiotics, which can potentially illicit allergic reactions in

humans and other medical problems (Deraz et al, 2005).

Bacteriocins differ from most therapeutic antibiotics in being

proteinaceous agents that are rapidly digested by proteases in the

human digestive tract. They are ribosomally synthesized peptides,

and this fact creates the possibility of improving their characteristics

to enhance their activitiy and spectra of action (Saavedra et al,2004).

Antibiotics are generally considered to be secondary metabolites that

are inhibitory substances in small concentration, excluding the

inhibition caused by metabolic by-products like ammonia, organic

acids, and hydrogen peroxide. It is likely that most if not all bacteria

are capable of producing a heterogeneous array of molecules in the

course of their growth in vitro (and presumably also in their natural

habitats) that may be inhibitory either to themselves or to other

bacteria (Jack et al, 1995). Bacteriocin production could be

considered as an advantage for food and feed producers since, in

sufficient amounts, these peptides can kill or inhibit pathogenic

bacteria that compete for the same ecological niche or nutrient pool.

This role is supported by the fact that many bacteriocins have a

narrow host range, and is likely to be most effective against related

bacteria with nutritive demands for the same scarce resources

(Deegan et al, 2006).

Nisin is the most widely exploited and applied bacteriocin. It is

active against Gram (+) positive bacteria including highly pathogenic

and food spoilage microorganisms including S. aureus, B. cereus,

and L. monocytogernes. In the United States, its use has been

approve since 1988 by FDA for use in cheese, heat treated- chill

stored soups and pasteurized cheese spreads which are stored in

chill temperature. Nisin belongs to the Class I lantibiotics, is

composed by thirty-four amino acids and has a pentacyclic structure

with one lanthionine residue (Ring A) and four methyllanthionine

residues (rings B, C, D, E) nisin Z, the natural variant of nisin is

different only in that the histidine molecule on place 27 is replaced by

asparagines (Oliveira et al 2005).Nisin can be effective at nanomolar

concentrations depending on the target strain. Nisin is ribosomally

synthesized as a precursor peptide that is later enzymatically

modified. This prepeptide is biologically inactive and contains a c-

terminal prepeptide domain, following a variety of posttranslational

modification reactions, is cleaved from the N-terminal leader

sequence to yield the mature antimicrobial compound. It is an auto

regulatory two component system which can be activated fully by

nisin in very low sub toxic amounts (ng/ml) (Mierau 2005).Nisin is

heat stable at 121C but for prolonged heating, becomes less heat

stable, especially between pH 5 to 7. Nisin is sensitive to chymotrypsin but resistant to trypsin, elastase, carboxyl peptidase,

pepsin, and erepsin. Nisin is utilised as a food additive, is

commercially produced and is assigned under the number E234

(Mierau 2005) (Mierau and Lei 2005). And cause the severity and

likely hood of illnesses caused by pathogens specially

Staphylococcus aureus .

So that this research aimed to Optimize Nisin production conditions

and study its effect on Staphylococcus aureus .

Materials and Methods:

1- Selecting the best isolate according to its effect

Staphylococcus aureus

Lc.lactis has been isolated by using M17 media (MERCKGermany), added to it glucose sugar 0,5 % (Andr. et al, 2011).

And after isolation Lc.lactis from food samples and biochemical

assays have been done in former research, best isolate has been

selected according to its inhibition effect on Staphylococcus

aureus 10788, from BioBall company Australia by using halls

method (Tagg. and McGiven. 1971).

2- Detect nisin

technique:

gene

by

polymerase

chain

reaction

2-1. Total DNA Isolation

After bacterial cell growth at M17 broth at 37oC, the culture

Centrifuged at 7000g for 10 min and resuspend the cells in 5 mL of

lysis buffer. Then Incubated in a 37oC water bath for 2 h, 500 l of

10% SDS and 100 l of 25 mg/mL proteinase K was added.

Incubated in a

55oC water bath for 2 h. 2 mL of 5 M sodium chloride and 6 mL of

chloroformisoamyl alcohol then added, Incubation at room

temperature for 30 min. 1 volume of 100% isopropanol was added,

and washed with ice-cold 70% ethanol. Air-dry the DNA and

resuspend it in 600 l of TE buffer. (John and, Alicia 2001).

For the polymerase chain reaction: 2 l Dna isolated, 2.5 l Reaction

Buffer 10X, 3 l MgCl2, 0.5 l dNTPs, 1 l DNA polymerase, 1 l

primers, total size has been completed to 25 l by distilled water.

And nisin gene detection primers nucleated sequence Nisin F:

CGGCTCTGATTAAATTCTGAAG,

Nisin

R:

GGATTAGCTAGTAGTAACTGTTC.

2-2. Thermal program for polymerase chain reaction

Preheating at 92oC for 10 M for on cycle then, Denaturation phase:

94C for 54 S, Annealing phase: 50oC for 45 S, Extension phase: 72

oC for 45 S, For 30 cycles, and final extension at 72 oC for 10 M.

2-3. Electrophoresis has been done at Agarose gel 1.5% within

EDTA-Tris (TE) solution, to Separate nucleic acid fragments.

Samples are loaded into wells of an agarose gel and subjected to an

electric field, 85 volt, 150 amber, then studied at gel documentary.

3- Statistical program used was mini tab to optimize

temperature, pH, incubation time, inoculation size. After

choosing the best medium for nisin production

3-1. Choosing of production medium: five media has been used to

choose best medium for nisin production, M17 broth, M17 broth

besides to 0.5 % glocuse, M17 broth besides to 3% lactose and 3%

yeast extract, MRS, and MRS besides to 1% tween 80.

After choosing best broth for nisin production from lactococcus lactis

(M17 broth besides to 3% lactose and 3% yeast extract) production

conditions have been optimized.

3-2. Optimization of production conditions:

-

Choosing pH degree: many pH degrees have been tested for

production of nisin from lactococcus lactis (4.5 5 - 5.5 6 6.5).

Choosing temperature: many temperature degrees have been

tested for production of nisin from lactococcus lactis (25 28

31 34 - 37) oC.

Choosing incubation time: many times have been tested for

production of nisin from lactococcus lactis (12 24 48 72 96)h.

Choosing inoculation size: many sizes have been tested for

production of nisin from lactococcus lactis (0.5 1 1.5 2

2.5)ml.

Results:

Lc.lactis isolation and Selecting the best isolate according to its

effect on 1111 typhimurium and Staphylococcus aureus

Best isolate B18 been selected according to its effect on

Staphylococcus aureus as inhibition diameters by halls method after

pH modification. And the inhibition diameters were by average for

Staphylococcus aureus 6 mm.

Figer (1):

Choosing production medium and Optimization of nisin production

conditions:

Optimum production medium for nisin production was M17 broth

besides to 3% lactose and 3% yeast extract,

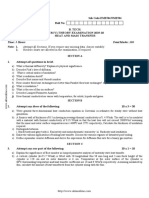

Tabe (1): Estimated Regression Coefficients for Staphylococcus

aureus :

Term

Coef

SE Coef

Constant

8.88523

0.7051

12.602

0.000

pH

0.57240

0.4070

1.406

0.178

Temperature

0.69745

0.4337

1.608

0.126

Time

-0.14398

0.4112

-0.350

0.731

Substrate

0.56852

0.4076

1.395

0.181

pH*pH

-0.37727

0.3358

-1.123

0.277

Temperature*Temperature

-0.76817

0.3339

-2.301

0.034

Time*Time

-0.79261

0.3767

-2.104

0.051

Substrate*Substrate

-0.90801

0.3200

-2.837

0.011

pH*Temperature

1.23106

0.8656

1.422

0.173

pH*Time

-0.47199

0.6346

-0.744

0.467

pH*Substrate

0.09389

0.5186

0.181

0.858

Temperature*Time

0.87932

0.8279

1.062

0.303

Temperature*Substrate

-0.36494

0.6823

-0.535

0.600

R-Sq = 76.9%

Response Optimizer plot:

Optimal

Hi

D

Cur

1.0000 Lo

pH

6.50

[6.50]

4.50

Temperat

37.0

[37.0]

25.0

Time

96.0

[96.0]

12.0

Substrat

2.50

[1.50]

0.50

ST

Maximum

y = 11.3537

d = 1.0000

Effect on Staphylococcus aureus

It has been noticed that the production of bacteriocin nisin and its

effect on Staphylococcus aureus . the inhibition diameter became 11

mm.

The optimum parameters were pH: 6.5, temperature: 37, Incubation

time: 96, and inoculation size: 1,5

The results disagree with scientist Mall results for the nisin

production medium and temperature (Mall et al 2010). And agree

with scientist Cheigh results for the nisin production medium but not

for production conditions (Cheigh 2002).

Discussion:

1- The main inhibition factor against Staphylococcus aureus was

by nisin bacteriocin after pH modification.

2- Optimization results on nisin production and its effect on

Staphylococcus aureus were: pH 5.5, temperature 31oC,

incubation time 54H, inoculation size 1.5 Ml.

REFERENCES:

-

Deegan, L. H. Cotter, P. D. Hill, C. and Ross, P. 2006.

Bacteriocins: Biological tools for biopreservation and shelf-life

extension. Int. Dairy J., 16, 1058-1071.

Deraz, S. F. Karlsson, E. N. Hedstrom, M. Andersson, M. M.

and Mattiasson, B. 2005. Purification and characterisation of

acidocin D20079, a bacteriocin produced by Lacto1111

acidophilus DSM 20079. J. Biotechnol., 117, 343-354.

Fisher, J. F. Meroueh, S. O. and Mobashery, S. 2005.

Bacterial resistance to beta-lactam antibiotics: compelling

opportunism, compelling opportunity. Chem. Rev., 105, 395424.

Jack, R. W. Tagg, J. R. and Ray, B. 1995. Bacteriocins of

Gram-positive bacteria. Microbiol. Rev., 59, 171-200.

Kumar, A. and Schweiser, H. P. 2005. Bacterial resistance to

antibiotics: active efflux and reduced uptake. Adv. Drug Deliv.

Rev., 57, 1486-1513.

Lipsitch, M.; Bergstrom, C. T. and Levin, B. R. 2000. The

epidemiology of antibiotic resistance in hospitals: paradoxes

and prescriptions. Proc. Natl. Acad. Sci. USA, 97, 1938-1943.

Roy, P. H. 1997. Dissemination of antibiotic resistance. Med.

Sci., 13, 927-933.

Saavedra, L. Minahk, C. Holgado, A. P. De R. and Sesma, F.

2004. Enhancement of the enterocin CRL35 activity by a

synthetic peptide derived from the NH2-terminal sequence.

Antimicrob. Agents

Chemother., 48, 2778-2781.

Yoneyama, H. and Katsumata, R. 2006. Antibiotic Resistance

in Bacteria and Its Future for Novel Antibiotic Development.

Biosci. Biotechnol. Biochem., 70, 1060-1075.

Oliveira, P. Nielsen, J. Forster, J. 2005. Modelling

Lactococcus lactis using a genome-scale flux model. BMC

Microbiology Journal. 5, 39-48.

Mierau, I. 2005. Optimization of the Lactococcus lactis nisincontrolled gene expression system NICE for industrial

applications. Microbial Cell Factories. 4, 16-28.

Mierau, I. Lei, J. P. 2005. Industrial scale production and

purification of an heterogenous protein in L.lactis using the

Nisin-controlled gene expression system NICE: The case of

lysostaphin. Microbial Cell Factories. 4, 1-9.

Mall, P. Mohanty, K. B. Patankar, B. D. Mody, R. and Tunga,

R. 2010. Physiochemical Parameters Optimization for

EnhancedNisin Production by Lactococcus lactis (MTCC 440)

BRAZILIAN ARCHIVES OF BIOLOGY AND TECHNOLOGY.

v.53 n.1: pp. 203-209.

John, F. T. Spencer and Alicia, L. Ragout de Spencer 2001.

Food Microbiology Protocols Humana Press Inc. Totowa, New

Jersey 07512.

AndreAbts, AntoninoMavaro,1 Jan Stindt,1 Patrick J.

Bakkes,1 SabineMetzger, Arnold J. M. Driessen,3 Sander H.

J. Smits,1 and Lutz Schmitt1. 2011. Easy and Rapid

Purification of Highly Active Nisin.

Cheigh, I. C. Choi, J. H. Park, H. Kim, S. B. Kook, M. C. Kim,

T. S. Hwang, J. K. and Pyun, Y. R. 2002. Influence of growth

conditions on the production of a nisin-like bacteriocin by

Lactococcus lactis subsp. Lactis A164 isolated from kimchi.

Journal of Biotechnology. 95, 225235

Tagg, J. R. and McGiven, A. R. 1971. Assay System for

Bacteriocins. Applied Microbiology. 21( 5 ) : 943.

Das könnte Ihnen auch gefallen

- Consumer Trends Sauces, Dressings and Condiments in FranceDokument17 SeitenConsumer Trends Sauces, Dressings and Condiments in FranceBassam MalasNoch keine Bewertungen

- Sauces, Spices, and Condiments: Definitions, Potential Benefits, Consumption Patterns, and Global MarketsDokument15 SeitenSauces, Spices, and Condiments: Definitions, Potential Benefits, Consumption Patterns, and Global MarketsBassam MalasNoch keine Bewertungen

- Standard For Fish SauceDokument5 SeitenStandard For Fish SauceBassam MalasNoch keine Bewertungen

- 20051f PuddingDokument10 Seiten20051f PuddingBassam MalasNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Data Sheet For T-8101.RevCDokument5 SeitenData Sheet For T-8101.RevCSuresh SjNoch keine Bewertungen

- Interdisciplinary Project 1Dokument11 SeitenInterdisciplinary Project 1api-424250570Noch keine Bewertungen

- Introduction To Entrepreneurship: Bruce R. Barringer R. Duane IrelandDokument29 SeitenIntroduction To Entrepreneurship: Bruce R. Barringer R. Duane IrelandAnonymous Yp8H9QwNoch keine Bewertungen

- HimediaDokument2 SeitenHimediaWiwit MarianaNoch keine Bewertungen

- 311762en WDokument36 Seiten311762en WOprisor CostinNoch keine Bewertungen

- Python Versus Matlab: Examples in Civil EngineeringDokument32 SeitenPython Versus Matlab: Examples in Civil EngineeringNiranjanAryan100% (1)

- Boomer L2 D - 9851 2586 01Dokument4 SeitenBoomer L2 D - 9851 2586 01Pablo Luis Pérez PostigoNoch keine Bewertungen

- Holy Spirit Mass SongsDokument57 SeitenHoly Spirit Mass SongsRo AnnNoch keine Bewertungen

- Note 15-Feb-2023Dokument4 SeitenNote 15-Feb-2023Oliver ScissorsNoch keine Bewertungen

- List of Marketing Metrics and KpisDokument5 SeitenList of Marketing Metrics and KpisThe KPI Examples ReviewNoch keine Bewertungen

- 67 9268Dokument34 Seiten67 9268Salvador ReyesNoch keine Bewertungen

- Evelyn Arizpe - Teresa Colomer - Carmen Martínez-Roldán - Visual Journeys Through Wordless Narratives - An International Inquiry With Immigrant Children and The Arrival-Bloomsbury Academic (2014)Dokument290 SeitenEvelyn Arizpe - Teresa Colomer - Carmen Martínez-Roldán - Visual Journeys Through Wordless Narratives - An International Inquiry With Immigrant Children and The Arrival-Bloomsbury Academic (2014)Lucia QuirogaNoch keine Bewertungen

- Continuous Improvement SYMPOSIUM SCRIPTDokument3 SeitenContinuous Improvement SYMPOSIUM SCRIPTChanda Marie AsedillaNoch keine Bewertungen

- Cosmology Questions and Answers - SanfoundryDokument9 SeitenCosmology Questions and Answers - SanfoundryGopinathan MNoch keine Bewertungen

- CE - 441 - Environmental Engineering II Lecture # 11 11-Nov-106, IEER, UET LahoreDokument8 SeitenCE - 441 - Environmental Engineering II Lecture # 11 11-Nov-106, IEER, UET LahoreWasif RiazNoch keine Bewertungen

- Declaration of Absence of Conflict of InterestDokument1 SeiteDeclaration of Absence of Conflict of InterestJvhelcoronacondat CondatNoch keine Bewertungen

- Joy BoosterDokument2 SeitenJoy BoosterAlexsandro TorezinNoch keine Bewertungen

- Ancient India: Book Recommendation: Indian Feudalism Urban Decay in India - RS SharmaDokument5 SeitenAncient India: Book Recommendation: Indian Feudalism Urban Decay in India - RS SharmaShraddha 7Noch keine Bewertungen

- Concept of ConstitutionDokument32 SeitenConcept of ConstitutionDorepe Icon0% (1)

- Extension of MDRRMO OfficeDokument12 SeitenExtension of MDRRMO OfficeJustin YuabNoch keine Bewertungen

- Stats 116 SUDokument128 SeitenStats 116 SUCNoch keine Bewertungen

- Installing Go Language in UbuntuDokument3 SeitenInstalling Go Language in UbuntupanahbiruNoch keine Bewertungen

- Library SectionsDokument4 SeitenLibrary SectionsGello Sotnuiq100% (4)

- Delay Codes1 3Dokument10 SeitenDelay Codes1 3AhmedNoch keine Bewertungen

- Btech Me 5 Sem Heat and Mass Transfer Eme504 2020Dokument2 SeitenBtech Me 5 Sem Heat and Mass Transfer Eme504 2020SuryaNoch keine Bewertungen

- Tasha Giles: WebsiteDokument1 SeiteTasha Giles: Websiteapi-395325861Noch keine Bewertungen

- Year 10 English Unit Plan AdvertisingDokument5 SeitenYear 10 English Unit Plan Advertisingapi-333849174Noch keine Bewertungen

- Vacuum Braking SystemDokument20 SeitenVacuum Braking SystemPrashant RaiNoch keine Bewertungen

- Forklift Driver Card and Certificate TemplateDokument25 SeitenForklift Driver Card and Certificate Templatempac99964% (14)

- Instrumentation Design BasicsDokument28 SeitenInstrumentation Design BasicsCharles ChettiarNoch keine Bewertungen