Beruflich Dokumente

Kultur Dokumente

Question Paper

Hochgeladen von

balaguru780 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

29 Ansichten3 SeitenAnnna University Question paper Design of jigs, Fixtures and press tools

Originaltitel

Question paper

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAnnna University Question paper Design of jigs, Fixtures and press tools

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

29 Ansichten3 SeitenQuestion Paper

Hochgeladen von

balaguru78Annna University Question paper Design of jigs, Fixtures and press tools

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

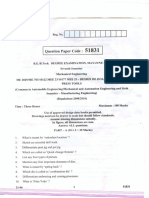

Reg. No. :

Question Paper Code : 21831

B.EJB.Tech. DEGREE EXAMINATION, NOVEMBER/DECEMBER 2015.

Seventh Semester

Mechanical Engineering

ME 2029/ME 703/10122 MEE 23/1017 MEE 23 — DESIGN OF JIGS, FIXTURES

AND PRESS TOOLS

(Common to Automobile Engineering/Mechanical and Automation Engineering and

Sixth Semester ~ Manufacturing Engineering)

(Regulations 2008/2010)

‘Time : Three hours Maximum : 100 marks

‘Use of approved design data books permitted.

Drawings need not be drawn to scale but should follow standards,

Assume missing dimensions suitably.

In figure, all dimensions are mm.

Answer ALL questions.

PART A — (10 x 2= 20 marks)

What is duplicate locating? *

List the materials that are often used in Jigs, Fixtures and Press tools.

Define the term: liner bushes.

ee pe

What forces does a drill bit exert on a workpiece?

5. Compare the compound and progressive dies.

6. What is a stripper? .

7. What you mean by spring back in sheet metal forming?

8. What is the role of an ejector in die set?

9. What do you understand by the terms : Single and Double action dies?

10. Highlight the role of computers in sheet metal forming analysis.

11.

12,

13.

14,

(a)

)

@)

)

(a)

)

(a)

&)

PART B — (6 x 16 = 80 marks)

With suitable examples, discuss the various methods of clamping. (16)

Or

Discuss the following with suitable sketches

@ Pneumatic clamps a

(i) Platejclamps Cy

Git) Quick action clamps ®

Discuss in detail

(@ Linear indexing

(i) Rotary indexing.

(ii) Important accessories of Jigs and Fixtures.

Or

Discuss the following in detail with suitable illustrations :

@ Plate type Jigs for drilling 6

(i) Facing fixture for milling ©

(ii) A welding fixture. )

@ Calculate the dimensions of the rectangular die block of heat

treated alloy tool steel. The die block is supported by two supports

at a distance of |= 120 mm. The workpiece material has a thickness

of t = 3 mm and ultimate tensile strength o,,= 380 MPa. The

workpiece dimensions are length = 120 mm and breadth = 100 mm.

)

"unch Holder; Guide plates. (8)

(ii) Write short notes on : Die-Bk

Or

(@ Based on what criteria, press tools are selected? ©

i) Explain the step-by-step procedure for the computation of press

capacities and tonnage requirements for cutting and drawing

operations. ao)

(@ _ Calculate the bending force for a 45° bend in aluminium sheet of

2mm thick and 1.3 m long, with a die opening which is 8 times the

metal thickness. The bend is to be made by air-bending methods.

(20)

(ii) What are the variables affecting metal low in drawing operation?

©

Or

Discuss the procedure to develop blanks for forming and drawing

operations. (6)

2 - 21831

16.

@

(b)

With suitable sketches, discuss the following

@

Gi)

Gi)

Gv)

@

Gi)

Bulging

Swaging

Embossing

Coining. ae)

. Or ,

Discuss the importance of various tooling in NC machines. ®

Design a fixture to hold the weld- samples of size 200 mm x 200 mm

with thickness of 10 mm. ®

3 21881

Das könnte Ihnen auch gefallen

- 2.ISCA RJMatS 2013 002Dokument5 Seiten2.ISCA RJMatS 2013 002balaguru78Noch keine Bewertungen

- ME 6019 Non Destrictive Testing and Materials SyllabusDokument2 SeitenME 6019 Non Destrictive Testing and Materials Syllabusbalaguru780% (2)

- Annals 2011 3 32Dokument6 SeitenAnnals 2011 3 32balaguru78Noch keine Bewertungen

- 2.ISCA RJMatS 2013 002 PDFDokument5 Seiten2.ISCA RJMatS 2013 002 PDFbalaguru78Noch keine Bewertungen

- Mech JRF ISRO 2017 v2Dokument4 SeitenMech JRF ISRO 2017 v2balaguru78Noch keine Bewertungen

- An Overview of Development of Fiber Reinforced Polymer Composite Coiled Spring For Automobile ApplicationsDokument14 SeitenAn Overview of Development of Fiber Reinforced Polymer Composite Coiled Spring For Automobile Applicationsbalaguru78Noch keine Bewertungen

- Vibration AbsorberDokument3 SeitenVibration Absorberbalaguru78Noch keine Bewertungen

- 2016 April R2008 Design of Jigs, Fixtures and Press ToolsDokument2 Seiten2016 April R2008 Design of Jigs, Fixtures and Press Toolsbalaguru78Noch keine Bewertungen

- Strength of Materials Part - A AnswersDokument3 SeitenStrength of Materials Part - A Answersbalaguru78Noch keine Bewertungen

- SyllabusDokument2 SeitenSyllabusbalaguru78Noch keine Bewertungen

- Nov Dec 2014 Anna Univ Question PaperDokument5 SeitenNov Dec 2014 Anna Univ Question Paperbalaguru78Noch keine Bewertungen

- Nov Dec 2014 Anna Univ Question PaperDokument5 SeitenNov Dec 2014 Anna Univ Question Paperbalaguru78Noch keine Bewertungen

- Call For Papers - ICSSCCET 2015Dokument7 SeitenCall For Papers - ICSSCCET 2015balaguru78Noch keine Bewertungen

- April May 2014 Design of Jigs and Fixtures Anwer KeyDokument17 SeitenApril May 2014 Design of Jigs and Fixtures Anwer Keybalaguru78Noch keine Bewertungen

- Numerical and Experimental Investigation On Aerodynamic Characteristics of SMA Actuated Smart Wing ModelDokument6 SeitenNumerical and Experimental Investigation On Aerodynamic Characteristics of SMA Actuated Smart Wing Modelbalaguru78Noch keine Bewertungen

- Anna University Chennai SyllabusDokument95 SeitenAnna University Chennai SyllabusRAAM MECHNoch keine Bewertungen

- ACD Lab Manual Spur Gear DesignDokument4 SeitenACD Lab Manual Spur Gear Designbalaguru780% (1)

- Annals 2011 3 32Dokument6 SeitenAnnals 2011 3 32balaguru78Noch keine Bewertungen

- Design of Transmission Systems-May June 2014Dokument3 SeitenDesign of Transmission Systems-May June 2014balaguru78Noch keine Bewertungen

- Injection MoldingDokument66 SeitenInjection Moldingbalaguru78100% (2)

- Page No.: 2.1. Electromagnet Coil 2 2.2. Permanent Magnet 3 2.3. IR Transmitter and Receiver 4Dokument1 SeitePage No.: 2.1. Electromagnet Coil 2 2.2. Permanent Magnet 3 2.3. IR Transmitter and Receiver 4balaguru78Noch keine Bewertungen

- Chapter - 8 Cost EstimationDokument1 SeiteChapter - 8 Cost Estimationbalaguru78Noch keine Bewertungen

- Synopsis: Magnet, Electromagnet, IR Transmitter and Receiver. The Transmitter andDokument1 SeiteSynopsis: Magnet, Electromagnet, IR Transmitter and Receiver. The Transmitter andbalaguru78Noch keine Bewertungen

- Chapter - 4 Working PrincipleDokument2 SeitenChapter - 4 Working Principlebalaguru78Noch keine Bewertungen

- Chapter - 7 List of MaterialsDokument2 SeitenChapter - 7 List of Materialsbalaguru78Noch keine Bewertungen

- Chapter - 7 List of MaterialsDokument2 SeitenChapter - 7 List of Materialsbalaguru78Noch keine Bewertungen

- List of FiguresDokument2 SeitenList of Figuresbalaguru78Noch keine Bewertungen

- Synopsis: Magnet, Electromagnet, IR Transmitter and Receiver. The Transmitter andDokument1 SeiteSynopsis: Magnet, Electromagnet, IR Transmitter and Receiver. The Transmitter andbalaguru78Noch keine Bewertungen

- Chapter - 3 Design of Equipment and Drawing: 3.1. Machine ComponentsDokument6 SeitenChapter - 3 Design of Equipment and Drawing: 3.1. Machine Componentsbalaguru78Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)