Beruflich Dokumente

Kultur Dokumente

Ecc-326 DS en 04.2011 V1.0

Hochgeladen von

Taimoor AhmedOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ecc-326 DS en 04.2011 V1.0

Hochgeladen von

Taimoor AhmedCopyright:

Verfügbare Formate

Analogue Speed Governors

ECC-326 Series

Features and Benefits

Full PID setting

(Speed, Gain & Stability

Adjustments)

Designed to Read from

Speed Signal/

Frequency from an

AC Generator

Manufactured by:

Governors America Corp.

Speed Control Unit

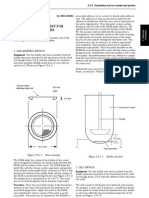

The ECC-326 speed control unit is an all electronic device designed to control engine

speed with precise response to transient engine loads changes. This closed loop speed

control, when connected to a proportional actuator and supplied with a speed signal/

frequency from the main AC generator, will control a wide variety of engines in an isochronous mode. The speed signal input must be in the frequency range of 40 to 80 Hz.

The ECC-326 is a hard potted module designed to operate with high reliability in harsh

environments. The adjustment procedure is considered to be simple.

Standard features include: protection against reversal of the battery supply, accidental

shorts in the actuator wiring, high voltage transient on the DC and AC lines, and the loss

of the speed signal or battery supply.

HUEGLI

TECH

SWITZERLAND

Analogue Speed Governors

ECC-326

Description

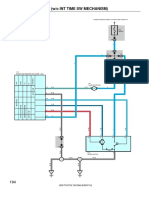

Wiring

The generators frequency, when used as an engine speed

signal, can be either 50 or 60 Hz nominally. The minimum

and maximum amplitude levels required to operate the

ECC-326 are 1V AC to 260V AC. The generators residual

voltage must reach 1 V AC so the loss of speed signal will

be defeated and allow the actuator to open the fuel valve

to start the engine. Other than the Min and Max AC input

values, the control is not very sensitive to the wave shape or

the voltage levels from the generator.

Basic electrical connections are shown in the Wiring

Diagram, Fig. 1. Battery and actuator connections should

be #16AWG (1.3mm2) or larger. Long cables require an

increased wire size to minimize voltage drops. The battery

positive (+) input, Terminal F, should be fused for 15A.

Connection to the generator: The two input Terminals, D and

E, should be connected to the generators AC windings.

These connections can be either line to line or line to

neutral. Terminal E should be connected to the neutral if this

connection is chosen. See the wiring diagram for various

connections to the generator.

When the speed signal is received by the controller, the

signal is conditioned to operate the GAC proprietary speed

sensor circuit. If the speed signal disappears for longer than

approximately 0.2 seconds, the actuator output will be shut

off (loss of speed signal protection). When cranking the

engine, the control unit will sense a very low frequency and

operate the actuator to start the engine.

Adjustments

WARNING

An overspeed shutdown device, independent of the governor system, should be provided to prevent loss of engine

control which may cause personal injury or equipment

damage.

The internal summing circuit receives the speed signal and

combines it with the speed setting reference adjustment

along with the remote speed trim setting. The output of the

summing circuit is the input to the dynamics control circuits

of which the gain and stability adjustments are a part. These

control functions provide isochronous and stable performance.

Before Starting the Engine

Check to insure that the GAIN, STABILITY and external

SPEED TRIM controls, are set to their mid positions.

Start the Engine

The ECC-326 control is factory set to operate at approximately 60 Hz generator frequency.

Crank the engine with DC power applied to the governor

system. The actuator will energize (within 1.5V DC of battery

voltage) and force the fuel control to its maximum fuel position until the engine starts. The governor system should then

control the engine at near rated speed.

If the engine is unstable after starting, turn the GAIN, and

STABILITY, CCW until the engine speed is stable.

During engine cranking, the actuator should be fully energized and should move to the maximum fuel position. The

actuator will remain in that state during engine cranking and

acceleration up to the operating speed. With the engine at

a steady load, the actuator will be energized with sufficient

current to maintain the governed speed set point.

The output circuit to the actuator provides a controlled

switching current loop to the proportional actuator at a

frequency of about 200 Hz. This switching frequency is well

beyond the natural frequency response of the actuator,

thus there is no visible motion of the actuator due to this

switching circuit. Switching of the output transistor reduces

internal power dissipation and provides for efficient power

control up to 10 Amps of continuous current at 25C. A

proportional actuator will respond to the average current to

position the engine fuel control lever.

Governor Speed Setting

The governed speed set point can be increased by the CW

rotation of the SPEED adjustment.

The Remote speed adjustment (optional) can be used as a

FREQ TRIM control. See Diagram 1.

Governor Performance

Once the engine is at operating speed and at no load, the

following governor performance adjustments should be

made.

The ECC-326 is compatible with all proportional GAC actuators except the ACB2000 which has too a high current

requirement (15A).

A.

Rotate the GAIN adjustment CW until instability

develops. Gradually move the adjustment CCW until stability

returns. Move the adjustment 1/8 of a turn further CCW to

insure stable performance.

HUEGLI

TECH

SWITZERLAND

Analogue Speed Governors

ECC-326

B.

Rotate the STABILITY adjustment CW until instability develops. Gradually move the adjustment CCW until

stability returns. Move the adjustment 1/8 of a turn further

CCW to insure stable performance.

the engine if a non linearity exists in the fuel control. A strip

chart recorder or storage oscilloscope with appropriate

electronics can be used to measure generator frequency to

further optimize the governors performance.

C.

Normally, adjustments made at no load result in

satisfactory performance across the entire load range.

GAIN readjustment might be required after load is applied to

If instability cannot be corrected, or further performance

improvements are required, refer to the Instability section

under SYSTEM TROUBLESHOOTING.

Diagram 1. System Wiring/Outline

HUEGLI

TECH

SWITZERLAND

Analogue Speed Governors

ECC-326

Specifications

Performance

Isochronous Operation........................................................0.250%

Speed Range (unless stated in units specifications)....................

...............................................................................................40 - 80 HZ

Speed Drift with Temperature....................................................1%

Speed Trim (see units specifications)................................+/- 2 Hz

Environmental

Ambient Temperature...........................-40 to 185F (-40 to +85C)

Relative Humidity..............................................................up to 100%

Reliability

Vibration........................................................................5G, 20-500 Hz

Shock............................................................................................20Gs

Testing............100% Functional Testing before and after potting

Physical

Dimensions..........................................See Wiring Diagram (Fig. 1)

Weight.........................................................................0.75 lb (0.34 kg)

Mounting.........................................................................Any Position

Input Power

DC Supply...........................................12V DC (8 - 15 VDC) Nominal

..............................(24V DC available as special order)

Polarity........................................Negative Ground (case isolated)

Power Consumption...........................<50 mA + Actuator Current

Maximum Actuator Current...............................................10 Amps

Generator Frequency Sensing...........................................................

..........................................................Load on generator, 40K OHMS

...........................................................Minimum sensing 1 VAC RMS

................................................................Maximum voltage 260 VAC

HUEGLI TECH AG (LTD)

Murgenthalstrasse 30

4900 Langenthal Switzerland

Phone: +41 62 916 50 30

Fax:

+41 62 916 50 35

e-mail: sales@huegli-tech.com

www.huegli-tech.com

HUEGLI TECH

SWITZERLAND

ECC-326_DS_EN_04.2011

HUEGLI

TECH

Features and specifications are subject to change without prior notice

Local Distributor / Partner:

Das könnte Ihnen auch gefallen

- Hitachi Lift UAG SN1Dokument20 SeitenHitachi Lift UAG SN1Taimoor Ahmed100% (1)

- Turn Signal and Hazard Warning Light: 2003 Toyota Tacoma (Ewd517U)Dokument2 SeitenTurn Signal and Hazard Warning Light: 2003 Toyota Tacoma (Ewd517U)Taimoor AhmedNoch keine Bewertungen

- Wiper and Washer (W/O Int Time SW Mechanism) : From Power Source System (See Page 54)Dokument2 SeitenWiper and Washer (W/O Int Time SW Mechanism) : From Power Source System (See Page 54)Taimoor AhmedNoch keine Bewertungen

- Toyota B EngineDokument26 SeitenToyota B EngineTaimoor Ahmed100% (2)

- BMW - US 5series - 2010 PDFDokument36 SeitenBMW - US 5series - 2010 PDFTaimoor AhmedNoch keine Bewertungen

- New Wiring Diagram Electric EMS2-tad1640ge PDFDokument2 SeitenNew Wiring Diagram Electric EMS2-tad1640ge PDFVanHoang96% (23)

- 2010 E Class PDFDokument14 Seiten2010 E Class PDFTaimoor AhmedNoch keine Bewertungen

- 5L-E Engine: DescriptionDokument2 Seiten5L-E Engine: DescriptionTaimoor AhmedNoch keine Bewertungen

- Renault K-Type EngineDokument24 SeitenRenault K-Type EngineTaimoor AhmedNoch keine Bewertungen

- Eco+ Augusta: Instruction HandbookDokument48 SeitenEco+ Augusta: Instruction HandbookTaimoor AhmedNoch keine Bewertungen

- Toyota 1KZ-TE EngineDokument2 SeitenToyota 1KZ-TE EngineJia Sajeel75% (12)

- Cliafkd Allo: Instruction Handbook Car DoorsDokument44 SeitenCliafkd Allo: Instruction Handbook Car DoorsTaimoor AhmedNoch keine Bewertungen

- Renault K-Type EngineDokument24 SeitenRenault K-Type EngineTaimoor AhmedNoch keine Bewertungen

- Perkins 20 KvaDokument1 SeitePerkins 20 KvaTaimoor AhmedNoch keine Bewertungen

- Diesel Generator: Dca25 Dca45 Dca125Dokument1 SeiteDiesel Generator: Dca25 Dca45 Dca125Taimoor AhmedNoch keine Bewertungen

- Optimizing Generator RPM For Standby Power Generation White PaperDokument4 SeitenOptimizing Generator RPM For Standby Power Generation White PaperTaimoor AhmedNoch keine Bewertungen

- Diesel EngineDokument1 SeiteDiesel EngineTaimoor Ahmed100% (1)

- DKG-154 Remote Start Unit: Installation and Operating InstructionsDokument2 SeitenDKG-154 Remote Start Unit: Installation and Operating InstructionsTaimoor AhmedNoch keine Bewertungen

- Technical DescriptionDokument24 SeitenTechnical DescriptionTaimoor AhmedNoch keine Bewertungen

- 51Dokument1 Seite51Taimoor AhmedNoch keine Bewertungen

- Base Industrial Engine EFI: 1.6-Litre 4-CylinderDokument2 SeitenBase Industrial Engine EFI: 1.6-Litre 4-CylinderTaimoor AhmedNoch keine Bewertungen

- 2uz HistoryDokument130 Seiten2uz HistoryTaimoor Ahmed100% (2)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ESolarMark - CO2 - 30 WattDokument2 SeitenESolarMark - CO2 - 30 WattJose Diaz100% (1)

- Mil DTL 17849FDokument23 SeitenMil DTL 17849FOm Parkash SharmaNoch keine Bewertungen

- Bulletin 446 - 1/06 - Alumina Loading Problems - Western AustraliaDokument2 SeitenBulletin 446 - 1/06 - Alumina Loading Problems - Western Australialevent364Noch keine Bewertungen

- Recrystallization NotesDokument9 SeitenRecrystallization NotesanrychoNoch keine Bewertungen

- IGCSE Chemistry DefinitionsDokument5 SeitenIGCSE Chemistry DefinitionsTanmay Karur100% (1)

- Project TitleDokument2 SeitenProject TitleDENNIS RAMIREZNoch keine Bewertungen

- Pyrolysis Presentation - PPTM (Autosaved) .PPTMDokument13 SeitenPyrolysis Presentation - PPTM (Autosaved) .PPTMSoul LyricsNoch keine Bewertungen

- 3 M Conductive TapeDokument12 Seiten3 M Conductive TapebabaranddNoch keine Bewertungen

- Ana Aerodur 3001 Hs Base Coat g30424 Pms214c Red enDokument14 SeitenAna Aerodur 3001 Hs Base Coat g30424 Pms214c Red enSreejith SNoch keine Bewertungen

- Wiki Rainflow-Counting AlgorithmDokument3 SeitenWiki Rainflow-Counting Algorithmeslamdoostsimco0% (1)

- Batch Dyeing Process, Batch Dyeing Process For Textiles, Process of Batch DyeingDokument3 SeitenBatch Dyeing Process, Batch Dyeing Process For Textiles, Process of Batch DyeingVipin Singh KandholNoch keine Bewertungen

- Aerospace Material Specification: Nickel Plating (Electrodeposited)Dokument12 SeitenAerospace Material Specification: Nickel Plating (Electrodeposited)BHUSHAN100% (2)

- 2.9.4. Dissolution Test For Transdermal PatchesDokument3 Seiten2.9.4. Dissolution Test For Transdermal PatchesSandeep KumarNoch keine Bewertungen

- Lecture 02 01 Process DevelopmentDokument20 SeitenLecture 02 01 Process DevelopmentDon ReloNoch keine Bewertungen

- Rate Book - 2011-NCP Building DPTDokument244 SeitenRate Book - 2011-NCP Building DPTthak_raj84Noch keine Bewertungen

- 1301A01422 Zaranda 3500Dokument2 Seiten1301A01422 Zaranda 3500Edgar FloresNoch keine Bewertungen

- Parts, Adhesives and SealantsDokument44 SeitenParts, Adhesives and SealantsClaris BaylenNoch keine Bewertungen

- Air ElectricityDokument74 SeitenAir ElectricityNurettinAlp100% (1)

- BS 4514 2001 PDFDokument18 SeitenBS 4514 2001 PDFanas shehabi100% (1)

- Greensand Casting PDFDokument10 SeitenGreensand Casting PDFNirmal KushwahaNoch keine Bewertungen

- RI 4 Defect CausesDokument50 SeitenRI 4 Defect CausesSathishkumar Srinivasan100% (1)

- Raichu R 2000Dokument7 SeitenRaichu R 2000Shawn StevensNoch keine Bewertungen

- 3D Printing of Reduced Graphene Oxide NanowiresDokument5 Seiten3D Printing of Reduced Graphene Oxide NanowiresDuniaNoch keine Bewertungen

- Storage Tank DetailDokument22 SeitenStorage Tank DetailRamu NallathambiNoch keine Bewertungen

- Ingersoll Rand Air Fi Ltration: E-Mail Sales@mbairsystems - Co.uk WWW - Mbairsystems.co - Uk WWW - Airwinch.co - UkDokument7 SeitenIngersoll Rand Air Fi Ltration: E-Mail Sales@mbairsystems - Co.uk WWW - Mbairsystems.co - Uk WWW - Airwinch.co - Ukrodonganjaya22Noch keine Bewertungen

- R600 enDokument10 SeitenR600 enGinoGuanNoch keine Bewertungen

- Mercedes DifferentialsDokument8 SeitenMercedes DifferentialsAntonio Sanchez SanchezNoch keine Bewertungen

- Electronics Y2 PDFDokument237 SeitenElectronics Y2 PDFNebuchadnezzar Buggy Andamon SaysonNoch keine Bewertungen

- OrthogonalDokument4 SeitenOrthogonalGuan Ni YeoNoch keine Bewertungen

- Plastiment VZ PDFDokument2 SeitenPlastiment VZ PDFDarwin SyahputraNoch keine Bewertungen