Beruflich Dokumente

Kultur Dokumente

TT VS TT Cards

Hochgeladen von

pradeep.selvarajan0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten3 SeitenTE VS TT

Originaltitel

TT VS TT cards

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenTE VS TT

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten3 SeitenTT VS TT Cards

Hochgeladen von

pradeep.selvarajanTE VS TT

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

By Gary Prentice

nen making temperature measure

‘ments, two ways have traditionally

been employed to get process read-

ings back to a monitoring and con.

trol system. One method is to use sensor

extension wires to carry the low-level sig

nals (olim or mV) generated by field

‘mounted RTD oF thermocouple sensors

Another is o install emperature transtit-

ters at or near the measurement point. The

{ransmitter amplifies and conditions the

sensor signal. It also transmits it over a

‘twisted wire pair back to the control room,

Direct wiring strategies have sgenerally

bbeen considered less expensive and some:

times easier. Because of cost considerations,

transmitters were often reserved for control

and applications where signal and loop

integrity were a must. Today's highly func

tional microprocessor-based field-mount

‘temperature transmitters are comparable in

price to direct wiring strategies. When the

additional advantages of using intelligent

transmitters are factored in, you ean save

considerable time and avoid maintenance

headaches. Ths fs especially true when the

measurement point is located a long dis

tance from the readout andl control system,

Cut Wiring Costs

The direct wiring of thermocouples to a

contro] system requires the use of thermo~

couple extension wires. Extension wire can

cost several times more than common,

shielded copper wire used for a temperature

transmitter’s 4-20 mA signal. The savings

in wire cost can go a long way toward pay:

ing for the temperature transmitter. The

Tonger the wire run, the greater the poten-

tial savings.

In retrofit situations, you may want to

switch to transmitters, but you may be

reluctant to do so because you mistakenly

Dolieve that new copper wires must be run

to accommodate the 4-20 mA. This is not

necessarily the ease. Temperature transmit-

ters can be installed atthe sensor, and the

in-place RTD or thermocouple extension

‘wires can be used to transmit the 4-20 mA.

back to the control system. The qualifier is

Because thermocouple wire has higher

resistance than copper wire, you should run

the resistance calculation on your extension

wire to make sure you do not over-burden

the temperature transmitter. If these caleu-

lations confirm that you can use the exis

ing field wiring, you will have no addition-

al installation time or material costs. And,

you still get all the advantages of using,

Temperature transmitters,

Why Use

Temperature

Transmitters

Instead

of Direct

Wiring?

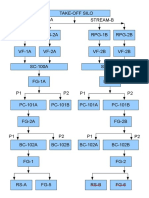

This point-by-point comparison

examines the advantages

and consequences

Spey

Daina romperenre J

trans comb con-

ted hndle ntl vey

tempercure senor ope

and tompereture rege

Protect Against Plant Noise

Common in nearly every industrial envi-

ronment, RFI (radio frequency interference)

and EMI (electromagnetic interference) can

negatively affect process signals. Before you

climinate RFI and EMI as the possible cul

prits of erratic signals, you should consider

some of their common sources: mobile and

stationary radios, TVs, hand-held walkie

talkies, radio-controlled overhead cranes,

radar, induction heating systems, static dis

change, high-speed power-switching ele

ments, high ac current conductors, large

solenoids and relays, transformers, AC and

DC motors, welders, and even fluorescent

lighting. Ifyou have one or more of these

in your plant, you may have an RFI/EMI

problem. The result is sometimes just a

minor inconvenience. Other times, it can be

as serious as a nuisance plant tip.

Ina direct wiring scheme, the low-level

signals generated by an RTD (ohm) or ther-

mocouple (mV) are particularly susceptible

to the signal-degrading effects of REI/EML

Compounding the problem, sensor exte

sion wires can behave much like an

RF/EM antenna by actually drawing plant

noise to the wires and affecting weak, low.

level signals.

Conversely, a properly designed tempera

ture transmitter effectively negates the

elfects of RFI in two ways. Ifthe RFI/EML is

fon the temperature sensor, the transmitter’s

REI filtering will prevent the noise from

propagating to the transmiter’s output. IF

the noise is being picked up on the 4-20

mA side of the transmitter, the 4-20 mA,

signal strength will be less distorted by the

REI than would a mV level signal. The

transmiter’s output has a higher signal-to-

noise ratio. When specifying your transmit:

ter, always check for RFV/EMI protection. If

there is no specification given, it’s usually

because the instrument is not designed! to

resist noise. I probably will not perform

‘very well in a noisy plant environment

Reduce Hardware Costs

With direct wiring, it is necessary to pro-

‘vide temperature input cards for the DCS

and PLC. These cards usually cost more per

point than does a 4-20 ma input card. If

‘you are using temperature transmitters, the

lower cost 4-20 mA input cards help to pay

for the transmitters, Additionally, you are

keeping in inventory one less boar type

and reducing another source of mainte-

nance confusion

Temperature transmitters usually can han-

dle more sensor types than can a tempera

ture input board for a DCS or PLC. That

tenables the user to select the sensor type

that is ideal for the application and not be

ay

January/February 2007

S13

limited by what sensors can be handled by

Aan input card in a direct wired scheme.

‘Sensors that are likely acceptable toa tem-

perature transmitter and not to a DCS/PLC

Input card are four-wiee RTDs, 1000-ohm

RTDs, and 10-ohm copper RTDs.

‘With an fnelligent temperature transmit-

ter, you can simply change out the sensor

and reconfigure the transmitter to accom-

rmodate the diferent sensor type. The loop's

‘ovsted pate wiring and existing 4-20 mA

input hoards don't even have 10 be touched

Because you never know what sensor you'll

fend up with, make sure you select a univer:

sal transmitter that configures to aecept al

‘common temperature sensor types and tem-

perature ranges

You gain more application flexibility if

‘you use a temperature transmitter with ade-

‘quate inputfoutput isolation. Temperature

sensors insulated with MgO will eventually

Ho to ground. Ifthe sensor is an RTD, you

must discard it and buy new. But IF hat

sensor is a TC and you have isolation ese

‘where in the measurement loop, the

‘grounded TC still provides a valid tempera

ture measurement. IF you place the loop

isolation in the transmitter, you gain the

Nexibility of being able 10 use non- sola

4-20 mA input cards, which are generally

the leat expensive input cards. Pall your

TCs are grounded, no error-causing ground

loops ean occur when you use isolated TTS,

Enhance Accuraey and Stability

Using temperature transmitters can sub:

stantially enhance measurement accuracy.

DDCS and PLC systems measure readings

over the entire (very wide) range of a sen

sor. IC is well known that measuring a nar

cl

nono ange produces

Far more accura

measurements. Transmitters can be calibrat-

ced to any range within a sensor's overall

capabilities. Their measurements are more

precise than is possible with most direct

‘wiring strategies. Some transmitters deliver

accuracy ratings of 20.13°C (20.23°F) when

paired with a common PtiO0 RTD sensor

over a 200-deqree spat,

IT-you need even better accuracy, you ean

‘vin a universal transmitter to precisely

match a particular sensor. Even though sen

sors ane designed! to have a high degree of

conformance to an established curve, cach

fane — even precision sensors ~ will vary

slightly from its stated specification. By using

the TT electronics to match the TT tothe se:

sor, you eliminate this final bit of error.

Ic called sensor-to-ransmitter trimming.

The transmitter is connected to the sensor

andl then immersed in calibration baths

maintained at stabilized temperatures. The

transmitter then “captures” two readings

From the sensor, representing the upper and

Tower range values , and stores them in non

volatile memory.

The transmitter uses

these values to com-

pensate for deviations

between the sensor's stated linearization

curve and its actual measurements. When

transmitters are paired with 21,000 ohm

RID, this technique results in he amazing

measurement accuracy of up 10 20.014°C

(20.025) over a 100-degee span

To further enbarice measurement accuracy,

some transmitters can be trimmed to

respond to two data points within the

selected zero and span measurement range

This advantage allows a complete range to

bbe monitored, while placing measurement

emphasis on a specific szment of the range

most crtal to the process.

Simplify Engineering

In place of numerous sensor lead-wire and

DCS/PLC input board combinations, engi-

neering designs and drawings will need 10

show only one wire type (twisted wire pait)

nd one input board type (4-20 mA). This

fone wire and one input board system

‘means maintenance is greatly simplified,

and the chances of loop *mis-wiring” are

Virtually eliminated.

Throughout the lifetime of a process,

enhancements are routinely made to

accommodate the manufacture of upgraded

fr even completely new products. Process

changes may require different measurement

ranges or greater temperature accuracy than

‘was previously required. Either of these

conditions may necessitate a change in the

type of sensors that are used

Lower Maintenance Expenses

“Temperature transmitters have come a

long way since the days of fixed-range,

inflexible instruments. Some transmiters

are not only universal in regards to input

type and range, but they also incorporate

powerful sensor diagnostics that save eon-

siderable time and money.

‘Temperature transmitters with Intelligent

diagnostic capabilities help you keep track

fof sensor operation and quickly find and

diagnose sensor failures. Capable of contin-

ually monitoring the sensor, if a wire breaks

for otherwise stops sending a signal during

‘operation, the transmitter sends the output

‘upscale oF downscale to warn of sensor

burnout and other unwanted conditions.

Furthermore, the transmitters can ell you

‘hich wire has broken via an error message

either on an integral digital display or using,

PC configuration software, Specific Fault

messages eliminate the work of removing

the sensor or checking all the lead wires to

diagnose a problem. During startups, in the

riddle of the night, or in the middle of

winter, this ean be & huge time-saving

advantage.

‘Avoid Lead Wire Imbalances

‘Where feasible, use four-wire RTDs and

specify a temperature transmitter that is able

tw accept a “true” four-wire RTD input. The

‘advantage is that four-svite RTD measuring

circuits effectively cancel out errors caused

by resistance imbalances in the current-car~

tying leads. Every oi of imbalance in the

RTD sensor's lead wires ean produce as

‘much as a 2.5°C error in the measurement

Serious imbalances usually occur gradually

‘overtime and are caused by corrosion of

the lead wire. Occasionally, improper instal~

lation techniques also cause resistance

imbalances from lead length differences,

wire gage mismatches, loose connections,

terminal block corrosion, and work hard

Ing from bending and other stresses.

Intelligent temperature transmitters are

capable of accepting “tue” four-wire RTD

inputs and provide a constant current

‘source to the outer leads of the RTD. The

voltage drop is measured across the inner

leads, which isa high impedance loop.

Because there Is essentially no current low

in the voltage loop, voltage is directly pro-

portional o RTD resistance. Lead resistance

Is ignored. You will get a very accurate

"Weak" Low-Level Signal

(ohm or mv)

‘Temperature

Sensor

(BT or

‘Sensor Lead and Control System

Extonsion Wire

Terminations

oF thermocouple.

Readout and

Temperature Transmitter camden

‘A temperature transmitter amplifies and conditions the primary sensor signal and then carries it

over a twisted pair wire tothe control room.

measurement providing the

resistance value of the RTD

= plus coresion, plus wire

resistance ~ ig less than

2,000 ohms (typically). A

Tour-wire RTD costs about

the same as a three-wire

anu ean be used with less

‘expensive, smaller gauge

‘wire without concem for

added resistance, Ml

RTO

Gary Prentice isa tempera

ture applications engincer

‘at Moore Industves-

International Ine, a Ieader

in signal interface instru

‘ments for industriat

process control, system

Integration, and factory

‘automation. More informa

Flow is availabe by calling

518-199-4747, sending an

‘email 0 grprent@ix.net-

‘com.com, or visiting

‘Transmitters with diagnosties

‘can indicate which wire has

broken via an error messege om

‘the integral digital display.

Das könnte Ihnen auch gefallen

- SAIC-J - 6022 - Rev 0Dokument13 SeitenSAIC-J - 6022 - Rev 0pradeep.selvarajanNoch keine Bewertungen

- Cable Size Calculations Based On Motor HPDokument4 SeitenCable Size Calculations Based On Motor HPpradeep.selvarajanNoch keine Bewertungen

- Mukesh Kumar's 8.5+ years experience in infrastructure advisoryDokument7 SeitenMukesh Kumar's 8.5+ years experience in infrastructure advisorypradeep.selvarajanNoch keine Bewertungen

- 19-20-330-340-PLC DWG-250MW-BIKANER-RAJ-As BuiltDokument41 Seiten19-20-330-340-PLC DWG-250MW-BIKANER-RAJ-As Builtpradeep.selvarajanNoch keine Bewertungen

- Energies 08 08716Dokument21 SeitenEnergies 08 08716pradeep.selvarajanNoch keine Bewertungen

- SOP For Turbine ChecklistDokument1 SeiteSOP For Turbine Checklistpradeep.selvarajanNoch keine Bewertungen

- 600mw Operation ManualDokument243 Seiten600mw Operation Manualer4varun83% (6)

- PES S 1 20 KZ Talking Point EJ V5 1Dokument6 SeitenPES S 1 20 KZ Talking Point EJ V5 1pradeep.selvarajanNoch keine Bewertungen

- ATT01 - 7347-400 Operation Manual Main Cooling Water RackDokument17 SeitenATT01 - 7347-400 Operation Manual Main Cooling Water Rackpradeep.selvarajanNoch keine Bewertungen

- Boilers HeatersDokument24 SeitenBoilers HeatersPato FuentesNoch keine Bewertungen

- SOP For Turbine ChecklistDokument11 SeitenSOP For Turbine Checklistpradeep.selvarajanNoch keine Bewertungen

- SOP For Boiler Light Up ChecklistDokument9 SeitenSOP For Boiler Light Up Checklistpradeep.selvarajan100% (1)

- Detergent Flushing of Pre Boiler SystemDokument23 SeitenDetergent Flushing of Pre Boiler Systempradeep.selvarajanNoch keine Bewertungen

- Udupi Power Corporation Ltd. Ims Department Manual Doc. No. 0 Operation Rev. No. 0 Upcl Sop-Cold Startup Date 05.05.10 Page No. 1Dokument25 SeitenUdupi Power Corporation Ltd. Ims Department Manual Doc. No. 0 Operation Rev. No. 0 Upcl Sop-Cold Startup Date 05.05.10 Page No. 1pradeep.selvarajanNoch keine Bewertungen

- Issued For Asbuilt: 1 X 660 MW Cirebon Coal Fired Power PlantDokument13 SeitenIssued For Asbuilt: 1 X 660 MW Cirebon Coal Fired Power Plantpradeep.selvarajanNoch keine Bewertungen

- Issued For Asbuilt: 1 X 660 MW Cirebon Coal Fired Power PlantDokument13 SeitenIssued For Asbuilt: 1 X 660 MW Cirebon Coal Fired Power Plantpradeep.selvarajanNoch keine Bewertungen

- Sample PID Symbols and LegendsDokument32 SeitenSample PID Symbols and Legendstwinbrothers97% (29)

- Area Classification IEC NECDokument18 SeitenArea Classification IEC NECin107247100% (1)

- Best Practice For Thermal Power PlantsDokument186 SeitenBest Practice For Thermal Power Plantsnao100% (27)

- Handbook of ValvesDokument98 SeitenHandbook of Valvespradeep.selvarajanNoch keine Bewertungen

- Block Diagram For Master & Slave ClockDokument1 SeiteBlock Diagram For Master & Slave Clockpradeep.selvarajanNoch keine Bewertungen

- Issued For Asbuilt: 1 X 660 MW Cirebon Coal Fired Power PlantDokument13 SeitenIssued For Asbuilt: 1 X 660 MW Cirebon Coal Fired Power Plantpradeep.selvarajanNoch keine Bewertungen

- 03 ID FD Logic SystemDokument40 Seiten03 ID FD Logic Systempradeep.selvarajan100% (1)

- Hot Extraction Vs InsituDokument5 SeitenHot Extraction Vs Insitupradeep.selvarajanNoch keine Bewertungen

- Area Classification IEC NECDokument18 SeitenArea Classification IEC NECin107247100% (1)

- Techinical Information Handbook Wire and Cable PDFDokument328 SeitenTechinical Information Handbook Wire and Cable PDFctsak83% (6)

- CW - Acw Scheme REV1 ModelDokument1 SeiteCW - Acw Scheme REV1 Modelpradeep.selvarajanNoch keine Bewertungen

- Control Valve CavitationDokument7 SeitenControl Valve Cavitationpradeep.selvarajanNoch keine Bewertungen

- Cavitation of ValvesDokument64 SeitenCavitation of ValvesMiguel Angel Razo100% (2)

- Cavitation of ValvesDokument64 SeitenCavitation of ValvesMiguel Angel Razo100% (2)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)