Beruflich Dokumente

Kultur Dokumente

Shade Sorting

Hochgeladen von

syed asim najam100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

4K Ansichten3 SeitenShade sorting is the process of assigning samples of the same nominal color into groups having no significant color variation. Shade numbering calculates a shade number for each sample based on how close its color is to the standard. Shade sorting feature assigns samples into shade groups and provides data on which samples belong to each shade group.

Originalbeschreibung:

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenShade sorting is the process of assigning samples of the same nominal color into groups having no significant color variation. Shade numbering calculates a shade number for each sample based on how close its color is to the standard. Shade sorting feature assigns samples into shade groups and provides data on which samples belong to each shade group.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

4K Ansichten3 SeitenShade Sorting

Hochgeladen von

syed asim najamShade sorting is the process of assigning samples of the same nominal color into groups having no significant color variation. Shade numbering calculates a shade number for each sample based on how close its color is to the standard. Shade sorting feature assigns samples into shade groups and provides data on which samples belong to each shade group.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

SHADE SORTING

Color is the most important aspect of any garment. It would not

be an exaggeration to say that to many consumers color is quality

and the decision whether or not to buy a garment rests on its

color.

Also, in fabric form the marketability of any fabric

depends on its color, which again depends on dyeing and its

preparatory processes. Therefore, good color and excellent

color/shade matching, for suits or coordinates, and even between

panels within a garment, are extremely important for

profitability.

The shade of a color may vary from lot to lot or from bolt(a roll

of fabric) to bolt. Such variation may be due to one or more of

the following factors:

1. Variation in maturity of cotton fibers.

2. Changes in merges of synthetic fibers.

3. Variation in sizing formula.

4. Inconsistent bleaching.

5. Varying absorbency of the fabric due to a variation in the

process variables in mercerization.

6. Variation in the pressure, temperature, and/or chemical

concentrations of dyes in the dyeing process.

These are just few factors that affect shade uniformity.

Sorting methods are appropriate for use when the normal

color variation within a process is greater than a visible amount of

difference and this difference is unacceptable to a customer.

The dyeing of textile is a good example. Variation in temperature,

humidity, dye strength, and the dye uptake characteristics of

cloth can result in color variation that is visible and unacceptable

between cloth pieces used in a cut and sew shirt product.

Shade numbering, sorting, and tapering are used in many

industries, but particularly the textile industry.

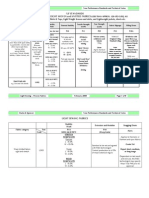

Shade Numbering:

The shade numbering feature performs calculations on the sample

data and assigns each sample a shade number based on how close

its color is to the standard.

The Shade Sorting:

The Shade sorting is the process of assigning samples of the

same nominal color into groups having no significant color

variation. Use of modern spectrophotometers and color

measurement technology make it possible to obtain precise color

differences between samples. shade sorting feature calculates a

shade number for each sample based on how close its color is to

the standard, but ALSO has the ability to sort all samples into

shade groups and provide data on which samples belong to each

shade number. A shade coding to each sample read based on how

close it is to the product standard.

One of popular shade sorting system is the Simon

method, known as the 555 system. In this system each color is

given a three digit numeric shade sort code. Using the CIE

L*C*h* color space as an example, the first digit shows lightness

of the color as compared to the standard color. If the color is

lighter than the standard this digit will be above 5, and below 5 if

it is darker. If the color is more saturate than the standard color

the second digit will be above 5 and below 5 if it is duller than

the standard. Similarly, the third digit in the shade sort code

indicates the hue variation from the standard.

SSS SHADE SORTING SYSTEM:

In a color matching is a very reliable system and it is based upon

modification of shade with reference to bare color. The SSS

code sis assigned for standard sample and its value started from

111-999. This code is assigned for a sample

The shade tapering:

The shade tapering feature is also known as color sequencing. The

software performs calculations that arrange the samples from

lightest to darkest or dullest to brightest and report them in this

order so that each sample is as close as possible in shade to the

samples next to it.

Das könnte Ihnen auch gefallen

- 555 Shade SortingDokument3 Seiten555 Shade SortingSainathan AiyarNoch keine Bewertungen

- Textile Testing: Presented By: Nisha Sangle Ankita Desai Poonam Patil Gayathri RangnathanDokument23 SeitenTextile Testing: Presented By: Nisha Sangle Ankita Desai Poonam Patil Gayathri RangnathanChaaya AaldarNoch keine Bewertungen

- Quality Aspects of Garment - A ReviewDokument4 SeitenQuality Aspects of Garment - A ReviewSazid RahmanNoch keine Bewertungen

- Apparel Quality Management: Assignment Ii Total Quality Management Practices in Opex Group, BangladeshDokument11 SeitenApparel Quality Management: Assignment Ii Total Quality Management Practices in Opex Group, BangladeshShivani JayanthNoch keine Bewertungen

- Fabric Inspection ProcedureDokument6 SeitenFabric Inspection ProcedureMayan DynastyNoch keine Bewertungen

- Print DurabilityDokument3 SeitenPrint DurabilityDoulat Ram100% (2)

- Carr and Latham's Technology of Clothing ManufactureVon EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerBewertung: 4 von 5 Sternen4/5 (1)

- Factors Affect Color Fastness of Dyed TextilesDokument3 SeitenFactors Affect Color Fastness of Dyed TextilesRezaul Karim Tutul100% (2)

- Materials GPQ PDFDokument20 SeitenMaterials GPQ PDFAmirul IslamNoch keine Bewertungen

- Sample Room DepartmentDokument5 SeitenSample Room DepartmentRajib DasNoch keine Bewertungen

- Point System For Evaluating Quality in TextilesDokument115 SeitenPoint System For Evaluating Quality in TextilesBenjamin OchoaNoch keine Bewertungen

- Essential Fabric Quality Reports For Bulk Cutting Approval of Fabrics-12Oct20Dokument5 SeitenEssential Fabric Quality Reports For Bulk Cutting Approval of Fabrics-12Oct20M. Harunur RashidNoch keine Bewertungen

- ALDI ManualDokument44 SeitenALDI Manualleo100% (1)

- Wale and Course Count of Weft Knitted Fabrics: Standard Test Method ForDokument6 SeitenWale and Course Count of Weft Knitted Fabrics: Standard Test Method ForjiandapaNoch keine Bewertungen

- Standards and SpecificationDokument35 SeitenStandards and SpecificationBhaswati PandaNoch keine Bewertungen

- Care LabelDokument21 SeitenCare Labelmonisha100% (1)

- Fabric - Physical Test MatrixDokument1 SeiteFabric - Physical Test MatrixNazmul hasanNoch keine Bewertungen

- Controlling and Check Points in Spinning ProcessDokument10 SeitenControlling and Check Points in Spinning ProcessBithy Paul100% (1)

- Fabric Quality InspectionDokument37 SeitenFabric Quality InspectionFaysal AhammadNoch keine Bewertungen

- Processed Fabric InspectionDokument5 SeitenProcessed Fabric InspectionTamrat TesfayeNoch keine Bewertungen

- Dry Cleaning Fastness TestDokument5 SeitenDry Cleaning Fastness TestAkriti Dixit0% (1)

- Textile Testing and Quality ControlDokument25 SeitenTextile Testing and Quality ControlGreen University Textile100% (2)

- Apparel Quality Standard & Implementation PDFDokument125 SeitenApparel Quality Standard & Implementation PDFRommel Corpuz100% (1)

- Global URBN Fabric and Apparel Testing Manual 2.25.2019Dokument81 SeitenGlobal URBN Fabric and Apparel Testing Manual 2.25.2019THYAGUNoch keine Bewertungen

- Technical Training For GPQ and Floor Quality Auditor: Presented By, Md. AL Arafat HossainDokument40 SeitenTechnical Training For GPQ and Floor Quality Auditor: Presented By, Md. AL Arafat Hossainrummanbsc8923Noch keine Bewertungen

- Anti Treatment Knits PrintDokument22 SeitenAnti Treatment Knits Printn.tNoch keine Bewertungen

- Assignment On An Overview of Quality and Quality Control in Textile IndustryDokument9 SeitenAssignment On An Overview of Quality and Quality Control in Textile IndustryZAyedNoch keine Bewertungen

- Dyeing FaultsDokument100 SeitenDyeing FaultsNaim UddinNoch keine Bewertungen

- SpiralityDokument9 SeitenSpiralitySenthil KumarNoch keine Bewertungen

- Colour FastnessDokument37 SeitenColour FastnessSivakumar K100% (1)

- STDS'M&SDokument8 SeitenSTDS'M&SSazid Rahman100% (1)

- WASH & GARMENT DYE SOP Denim & CasualDokument17 SeitenWASH & GARMENT DYE SOP Denim & CasualTwaha M&S100% (1)

- Textile DocumentDokument28 SeitenTextile DocumentKhandaker Sakib FarhadNoch keine Bewertungen

- Spreading and Marker Making ModesDokument13 SeitenSpreading and Marker Making ModesCHARUVI RANJANNoch keine Bewertungen

- On Textile TestingDokument17 SeitenOn Textile TestingGourav Arora100% (2)

- Testing Procedures For Fabrics and TrimsDokument48 SeitenTesting Procedures For Fabrics and Trimsshivanift100% (1)

- SGSTesting SoftlinesandHardlinesDokument0 SeitenSGSTesting SoftlinesandHardlinesthanhuong122Noch keine Bewertungen

- Sanya Kapoor - Pre - Production Process AssignmentDokument7 SeitenSanya Kapoor - Pre - Production Process AssignmentsanyaNoch keine Bewertungen

- Training ReportDokument69 SeitenTraining ReportKeshav Dhawan33% (3)

- Fabric Testing & ApprovalDokument51 SeitenFabric Testing & ApprovalOjasvi Agarwal100% (1)

- Utm JSML FinalDokument48 SeitenUtm JSML FinalVaisistha BalNoch keine Bewertungen

- Manufacturing Process: Fabric Inspection - Four Point SystemDokument7 SeitenManufacturing Process: Fabric Inspection - Four Point SystemhimaniNoch keine Bewertungen

- Apparel Quality Management: Assignment On: Quality Control/Management System in RMG SectorDokument10 SeitenApparel Quality Management: Assignment On: Quality Control/Management System in RMG SectorAbid hasanNoch keine Bewertungen

- Research & Development in TextileDokument40 SeitenResearch & Development in Textileapi-19978170100% (2)

- 01 Denim Fabric and Garments PDFDokument12 Seiten01 Denim Fabric and Garments PDFabul hossain100% (3)

- Sample Section:It Is The First Section Of: Garment Manufacturing ProcessDokument6 SeitenSample Section:It Is The First Section Of: Garment Manufacturing ProcesssantumysoreNoch keine Bewertungen

- Fabric Testing - ThicknessDokument5 SeitenFabric Testing - ThicknessTarang Mathur100% (1)

- National Institute of Fashion Technology Patna: Time and Action CalenderDokument17 SeitenNational Institute of Fashion Technology Patna: Time and Action CalenderKARISHMA RAJ100% (1)

- Plant Layout - IDokument16 SeitenPlant Layout - ITanya rajNoch keine Bewertungen

- Fabric and Testing Manual EU Own Buy Apparel: Version 1, February 16Dokument25 SeitenFabric and Testing Manual EU Own Buy Apparel: Version 1, February 16Tahir NizamNoch keine Bewertungen

- QMS - F.02 Fabric Inspection Training ModuleDokument22 SeitenQMS - F.02 Fabric Inspection Training ModuleDebashishDolonNoch keine Bewertungen

- Determining Fabric Quality: Prepared By: Riza Leigh I. FiguesDokument55 SeitenDetermining Fabric Quality: Prepared By: Riza Leigh I. FiguesRizaLeighFiguesNoch keine Bewertungen

- KQATEX1 Apparel Textile Requirements 150310Dokument17 SeitenKQATEX1 Apparel Textile Requirements 150310Ammar Maqsood100% (1)

- Fabric Defects: - Causes - Types - 4 Point System For MeasuringDokument8 SeitenFabric Defects: - Causes - Types - 4 Point System For MeasuringTarang MathurNoch keine Bewertungen

- Marker EfficiencyDokument2 SeitenMarker EfficiencyGaurav ShakyaNoch keine Bewertungen

- 4pt, 10pt SystemDokument12 Seiten4pt, 10pt SystemShaaban Noaman100% (1)

- D3107 07 (Reapproved 2011)Dokument6 SeitenD3107 07 (Reapproved 2011)Muhammad HugoNoch keine Bewertungen

- 555 VS Group TaperDokument3 Seiten555 VS Group TaperNazmul HassanNoch keine Bewertungen

- Color & Gloss MeasurementDokument4 SeitenColor & Gloss MeasurementDaniela MateiNoch keine Bewertungen

- SamplingDokument2 SeitenSamplingsyed asim najamNoch keine Bewertungen

- MercerizationDokument3 SeitenMercerizationsyed asim najamNoch keine Bewertungen

- Lec01 AFDokument30 SeitenLec01 AFsyed asim najamNoch keine Bewertungen

- Shearing of Wool.Dokument9 SeitenShearing of Wool.syed asim najamNoch keine Bewertungen

- SingeingDokument3 SeitenSingeingsyed asim najamNoch keine Bewertungen

- Production and Operations Management As Nucleus in The OrganizationsDokument4 SeitenProduction and Operations Management As Nucleus in The Organizationssyed asim najamNoch keine Bewertungen

- Colour MatchingDokument3 SeitenColour Matchingsyed asim najam100% (1)

- ScouringDokument2 SeitenScouringsyed asim najamNoch keine Bewertungen

- Q.A and Q.CDokument6 SeitenQ.A and Q.Csyed asim najamNoch keine Bewertungen

- BleachingDokument3 SeitenBleachingsyed asim najamNoch keine Bewertungen

- DesizingDokument4 SeitenDesizingsyed asim najam100% (2)

- Short Introduction of Textile ProcessesDokument4 SeitenShort Introduction of Textile Processessyed asim najamNoch keine Bewertungen

- Colour Order SystemDokument1 SeiteColour Order Systemsyed asim najamNoch keine Bewertungen

- Reactive DyeDokument8 SeitenReactive Dyesyed asim najam100% (1)

- Textile Testing and Quality ControlDokument6 SeitenTextile Testing and Quality Controlsyed asim najam100% (4)

- Disperse DyesDokument8 SeitenDisperse Dyessyed asim najamNoch keine Bewertungen

- Cone Test:: Waterproof/breathable FabricsDokument4 SeitenCone Test:: Waterproof/breathable Fabricssyed asim najam100% (1)

- Dyes and PigmentDokument24 SeitenDyes and Pigmentsyed asim najamNoch keine Bewertungen

- Identifiaction of FibersDokument3 SeitenIdentifiaction of Fiberssyed asim najamNoch keine Bewertungen

- Jet Dyeing MachineDokument16 SeitenJet Dyeing Machinesyed asim najamNoch keine Bewertungen

- Digital Printing: Submitted To: Sir Hanif MemonDokument30 SeitenDigital Printing: Submitted To: Sir Hanif Memonsyed asim najamNoch keine Bewertungen

- Water Repellent FinsihingDokument12 SeitenWater Repellent Finsihingsyed asim najam100% (4)

- Garment InspectionDokument10 SeitenGarment Inspectionsyed asim najam100% (7)

- Denim Washing (Thesis)Dokument77 SeitenDenim Washing (Thesis)syed asim najam94% (31)

- 1.0 Executive Summary: TH THDokument26 Seiten1.0 Executive Summary: TH THBabamu Kalmoni JaatoNoch keine Bewertungen

- Resource AllocationDokument33 SeitenResource AllocationMazhar AbbasNoch keine Bewertungen

- Taxation Deduction QuestionnaireDokument5 SeitenTaxation Deduction QuestionnaireJanaela100% (1)

- Teamcenter 8.3 Release Bulletin: Publication Number PLM00001 G (01-037134-083)Dokument273 SeitenTeamcenter 8.3 Release Bulletin: Publication Number PLM00001 G (01-037134-083)Tungdinh NguyenNoch keine Bewertungen

- Human Resource Policies in Colombia First Draft JonasDokument7 SeitenHuman Resource Policies in Colombia First Draft JonasKabir RaiNoch keine Bewertungen

- MS Preweek QuizzerDokument23 SeitenMS Preweek QuizzerJun Guerzon PaneloNoch keine Bewertungen

- DMCI ConstructionDokument3 SeitenDMCI ConstructionMara Ysabelle VillenaNoch keine Bewertungen

- OEE Calculation USDokument2 SeitenOEE Calculation USFeroz GullNoch keine Bewertungen

- Price Bid ScreenDokument2 SeitenPrice Bid ScreenchtrpNoch keine Bewertungen

- Corporate Social Responsibility Practices in Garments Sector of Bangladesh, A Study of Multinational Garments, CSR View in Dhaka EPZDokument11 SeitenCorporate Social Responsibility Practices in Garments Sector of Bangladesh, A Study of Multinational Garments, CSR View in Dhaka EPZAlexander DeckerNoch keine Bewertungen

- Value Stream MappingDokument40 SeitenValue Stream Mappingjinyue7302Noch keine Bewertungen

- Knowledge Area Process Name InputsDokument19 SeitenKnowledge Area Process Name Inputsk_Dashy8465Noch keine Bewertungen

- European Cybersecurity Implementation Overview Res Eng 0814Dokument26 SeitenEuropean Cybersecurity Implementation Overview Res Eng 0814Gabriel ScaunasNoch keine Bewertungen

- Work Book by David Annand PDFDokument250 SeitenWork Book by David Annand PDFTalal BajwaNoch keine Bewertungen

- Survey of Wonder CementDokument51 SeitenSurvey of Wonder Cementmonikakhandal100% (2)

- HRM in IDBI BankDokument75 SeitenHRM in IDBI BankAkshayBorgharkar80% (5)

- 07jul2016Dokument3 Seiten07jul2016enjay_578Noch keine Bewertungen

- Designing A Performance Measurement System - A Case Study in The Telecom BusinessDokument12 SeitenDesigning A Performance Measurement System - A Case Study in The Telecom BusinessOlusegun OkinNoch keine Bewertungen

- CF-Chap 02-Analysis of Financial StatementDokument58 SeitenCF-Chap 02-Analysis of Financial StatementM7Noch keine Bewertungen

- OFFICE MANAGEMENT-noteDokument53 SeitenOFFICE MANAGEMENT-notereem mazeeNoch keine Bewertungen

- Small: Manufacturing EnterprisesDokument378 SeitenSmall: Manufacturing EnterprisesEdictedNoch keine Bewertungen

- Timesheet: January, February, MarchDokument4 SeitenTimesheet: January, February, MarchkhuonggiaNoch keine Bewertungen

- Extract of Annual Return 2019 20Dokument47 SeitenExtract of Annual Return 2019 20ajaykumarbmsitNoch keine Bewertungen

- Motor CertificateDokument1 SeiteMotor CertificateNeil VickeryNoch keine Bewertungen

- Magic Quadrant For Content-Aware Data Loss PreventionDokument16 SeitenMagic Quadrant For Content-Aware Data Loss PreventionpfvNoch keine Bewertungen

- Homework Chapter 2: BE 3-4 Larned Corporation Recorded The Following Transactions For The Past MonthDokument3 SeitenHomework Chapter 2: BE 3-4 Larned Corporation Recorded The Following Transactions For The Past MonthLee Xing100% (1)

- Cadenas Drives USA PDFDokument238 SeitenCadenas Drives USA PDFCamilo Araya ArayaNoch keine Bewertungen

- Majesco To Present at The Aegis Capital Corp. 2016 Growth Conference On September 22, 2016 (Company Update)Dokument2 SeitenMajesco To Present at The Aegis Capital Corp. 2016 Growth Conference On September 22, 2016 (Company Update)Shyam SunderNoch keine Bewertungen

- Market Analysis - Fairness IndustryDokument18 SeitenMarket Analysis - Fairness IndustryVishal VinitNoch keine Bewertungen

- 020 2003 MercantDokument22 Seiten020 2003 MercantRamVasiNoch keine Bewertungen