Beruflich Dokumente

Kultur Dokumente

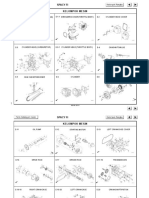

Szr660 Service Manual

Hochgeladen von

vancapOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Szr660 Service Manual

Hochgeladen von

vancapCopyright:

Verfügbare Formate

I

4SU·ME1

SZR 660 ('95) SERVICE MANUAL

@ 1996 BELGARDA S .. p .. A.

R&D TeCHNICAL DIVISION 1·t edition February 1996 All rights reserved.

Any reprinting or unauthorised use without the wrihen permission of 8elgarda S .. p .. A~ is expressly prohibited ..

Although some of the dramngs and pholographs used in this manual are taken from otner manuals and do not refer direcUy to the model in question. the procedures described and the details illustrated are nonetheless relevant and suitable to the user's purposes.

?

•

DEFECTIVE BRAKESI TRBL OIL LEAKS OR MALFUNCTIONING OF FRONT FORK SHTG

L....- __ ____., __ ____.

DEFECTIVE BRAKES

POOR BRAKING PROBABLE CAUSES

L Front and rear disk brake ~~---.....--. Brake pads worn

• Brake disk worn

• Water in the brake fluid

• Brake fluid leak

• Brake truid tank defective

• Bleed cap not sealed to calipers

• Fastening bolt loose

• Brake hose cracked

• Brake disk dirty or greasy

• Brake pads dirty or greasy

• Incorrect brake fluid lever

OIL LEAKS OR MALFUNCTIONlNG OF FRONT FORK

PROBABLE CAUSES ~~------~~~~~~~~. Inner tube defor~ed, da~aged or rusty

• Outer tube damaged or cracked

• Oil seal lip damaged

• Ojl seal assembled incorrectJy

• Oil level incorrect (excessive)

• Shock-absorber rod stop bolt loose

• a .. ring on cap broken

• Drain bolt loose

• Drain bolt gasket damaged

OIL LEAKS

MALFUNCTIONING I

9-7

PROBABLE CAUSES

• Inner tube deformed, damaged or rusty

• Outer tube deformed or damaged

• Fork spring damaged

• Piston worn or damaged

• Shock-absorber rod deformed or damaged

• Incorrect oi I viscosity

• Incorrect oil level

• Cartridge defective (overhaul)

?

•

TRBL UNSTABLE STEERING SHTG

UNSTABLE STEERlNG

PROBABLE CAUSES

Handle bar -~----~-~_-. Assembled crooked or incorrectly

Steering ~~~-----------r--. Handle bar crown assembteo incorrectly

• Lower bracket crooked

• Lower steering column lnstatled incorrectly (ring nut s not tighten ed correctly)

• Bearing or bearing tracks damaged

Front fork --~-~~~~~~[-. Oil Jevel not the same in both tubes

• Spring broken

• Front fork crooked

Tyres --~~~~~~~~~-.[-. lyre pressure incorrect for type of load

• Tyre pressure incorrect

• Tyres worn non-uniformly

Wheels --------~~~,------. Wheels balanced incorrectly • Wheel deformed .8earingloose

• Wheel axle deformed or loose

• Wheels excessively off-centre

Frame -~~-~~~~--____'Lr---: ~:~;%~~ damaged

• Ball track installed incorrectly

Rear swing arm ~~~~~~~----'L'------. Bushes or bearings consumed • Deformed or damaged

Rear shock absorber -----~[. Spring yielded

• Spring preload incorrect

• Oil leak

Transmission chain -~~-----. Chain set incorrectly

Cowling -~----~~~-----'-L-. Damaged or broken

• Assembled incorrectly

9-8

(y

GEN INFO

CARB

Cl)

SPEC P f'

INSP ADJ

~)

ENG

(1) (!)

COOL

CHAS A ELEC §

(9)

?

•

TRBL SHTG

@

@

(14)

(13) .

. - ~

(11) C~ (~)

1 1 1

- - -

m (§) B

(~ @ @

(~

1

-

a

SYMBOL LEGEND

(Refer to illustrations)

Symbols (1) to (9) are used to indicate chapter number and content

(1 ) General information

(2) Technical specifications

(3) Periodic inspection and adjustment (4) Engine overhaul

(5) Cooling system

(6) Carburetor

(7) Chassis

(8) Electrical s

(9) Troubleshooting

Symbols (10) to (16) serve to specify the following elements:

(10) Fiuid

(11) Lubricant (12) Special tool

(13) Screw tightening

(14) Wear and tear limit~ clearance (15) Engine speed

(16) Resistance (0) ~ Voltage (V), E;ectric Current {A}

Symbols (17) to (23) in the exploded diagram indicate type of lu bricant and locati on of nrbrlcanon point

(17) Apply engine oil (18) Apply gea roil

(19) Apply molybdenum disulfide oH (20) AppJy wheel bearing grease

(21) Apply lightweight Jithium .. soap grease (22) Apply molybdenum disulfide grease (23) Apply rocking liquid (LOCTJTE®)

[ A-3 I

CONTENTS

GENERAL INFORMATION

G INFO

Pf

-

SPEC

TECHNICAL SPECIFICATIONS

2

PERIODIC INSPECTION AND ADJUSTMENT

ENGINE OVERHAUL

ENG

COOLING SYSTEM

CARBURETOR

CHASSIS

ELECTRICALS

?

•

TROUBLESHOOTING

9

TRBL SHTG

GEN ~ [A-5 I

INFO

CHAPTER 1° GENERAL INFORMATION

IDENTI FICATION OF MOTORCYCLE "r r • ~ ~ • ~ " " " • + • + ~ • " •• + + + •• + + " " ~ ~ " • " ~ ~ -" A+6

IDE NT I Fi CAT lO N N U M B E A ~ - - - ~ " " " " - - - - - ~ " " " " " _ _ " " " " r _ " " r ~ ~ • r ~ " • • • + + + A - 6

ENG t N ESE R lA L N U M BE R ~ - - - - - _ " " " " _ r ~ _ " " " " " r _ " " " r ~ " " " r ~ " • • + • • • + + + ~ A-6

I M PO RT A NT INFO R M A TIO N ~ ~ ~ ~ ~ . . . . + ~ ~ • • + + + ~ ~ • • • + • • " " ~ ~ " " " ~ ~ " " ~ _ " " " " ~ r " A-6

PREPARATlON FOR DISASSEMBLY AND REASSEMBLY .. + + • " ~ ~ " " ~ ~ ~ " " " "" A~6

SPAR E PARTS ~ ~ ~ ~ ~ ~ ~ . + •• ~ • ~ ~ ~ • ~ • ~ " " " " " __ " " " r __ " " " __ " " r _ ~ " r _ ~ " " " • " " A-7

GASKETS. OJL SEALS AND O-RINGS" " " " " " ~ _ ~ " " " " _ ~ " " r ~ " " • _ ••• r + •• + A-7

LOCK WASHERS. PLATES AND COTTER PINS + ~ ••• " ~ + ~ " " ~ _ " " ~ ~ ~ " " ~ _ ~ " ~ _ A-7

BEARl NGS AND OIL SEALS _ . " " " __ ~ " " " r __ " " " " " • ~ ~ " • r + ••• + + •• + + •••••• + A-7

CI RC LIPS ~ ~ ~ ~ ~ + ~ ~ " " ~ • ~ " " " _ •• " " " ~ " " " " " " r _ ~ " • " • ~ ••• ~ ••• + + • " •• " A-7

S PEe I A L TOO LS ~ ~ . . + + • • + • • • ~ • + ~ ~ ~ ~ • • ~ _ ~ ~ " " " _ _ _ " " ~ _ " " " " r _ " " r ~ " • • + " • " • • • A - 7

GEN ~ INFO (9--eJ

GEN ~ IDENTIFICATION OF MOTORCYCLE INFO ~~

.___-_ ...... _-____.

rOENTIFICATION OF MOTORCYCLE

IDENTIFICATION NUMBER

The identification number is stamped on the right of the steering head pipe.

Progressive serial number:

SZR 660

4SU-040101 (0) version ZD04SU10000000101 (I-GR-P) version Z004SU1 00000201 01

[F-8-N-S-OK·NL .. (A .. CH)] version ZD04SU10000060101 (E) version

1 ~ M otorcycfe identif cation numbe r

/": .. .; ...

...... " : ......

ENGINE SERIAL NUMBER

The engine seriaf number is stamped on the right of the engine~

Progressive engine serial number:

SZR 660 45U-000101

1 ~ Engine serial number

NOTE:

• The first three digits in these numbers identify the model; the other digits form the progressive production number of the unit

• Diagrams and specifications may be altered without prior warning.

1-1

I A-6 I

GEN ~ IMPORTANT INFORMATION INFO ~

.._---.L __ ---J

IMPORTANT INFORMATION

PREPARATION FOR DISASSEMBLY AND REASSEMBLY

1. Remove aU dirt. mud. dust and foreign objects prior to disassembly.

2.. Use proper material and tools. Refer to sec .. tion ~SPEC1AL TOOLSt•

3~ When disassembling the cycle, keep together mated parts: gears, cylinders. pistons and other parts 'mated' in the course of normal wear and tear .. Such parts must be either re .. used together or completely replaced.

4. During disassembly, clean all parts and place them in trays in order of disassembfy. This makes reassembly quicker and helps assure that all parts are assembled properly.

5~ Keep away from fire and sources of heat

1 .. 2

GEN ~ INFO <.9-eJ

IMPORTANT INFORMATION

OR

SPARE PARTS

1. We recommend original Yamaha parts for all replacements, Use the oil and grease recom .. mended by Yamaha for all assembly and adjustment operations.

Products of other makes with the same function and appearance might be inferior in quality.

GASKETS, OIL SEALS AND O-RINGS

1. All gaskets, oil seals and O-rings should be reptacec during engine overhauls. An gasket surfaces" oil seal lips and O-rings must be cleaned prior to assembly.

2. Properly oil all mating parts and bearings during reassembly. AppJy grease to oil seal lips.

LOCK WASHERS, PLATES AND COTTER PINS

1. All lock washers, plates (1) and cotter pins must be replaced once removed. Lock tabs must be bent along the bolt or nut surfaces after the bolt or nut has been properly tightened.

BEARINGS AND OIL SEALS

1 ~ Fit bearings and oil seals with the rnanutacturer's mark or number facing outwards (ie, the stamped letters must bevisible). When installing oil seals, apply a light eoa ting of lightweight lithium-based grease to the seal lips. Oil the bearings liberally when installing.

(1 ) Oil seals

CAUTION:

Do not use compressed air to dry the bearings. This damages their outer surface.

(1) Bearing

I A-7

I

IMPORTANT INFORMAT[ONI GEN ~ SPECIAL TOOLS INFO ~

----"'------1

CIRCLIPS

1. AU circlips should be inspected carefully prior to reassembly. Always replace piston ring clips after one use.

Replace twisted circlips. When installing a circlip (1), make sure that the sharp-edged corner (2) is positioned opposite the thrust (3) it receives. See the i Ilust ration he re .

(4) Shaft

SPECIAL TOOLS

Special tools are required to perform proper disas-

'(

sembly and reassembly operations and for proper

tuning up .. The use of such tools avoids damage due to the use of unsuitable toots and/or makeshift techniques.

The shape and part number used for the special tool differ by country, so two types are provided .. Refer to the list provided to avoid errors when placlnc an order.

For USA. CON

PIN. YM-ODDDD~ YS-DDDDD, ACC-ODODD

Except for USA, CDN

PIN. 90890-00000

YU-ODDDO YK-ODDDD

Tool number

Tool name

III u strati 0 n

YM~08035

VALVE ADJUSTMENT TOOL

90890--01 311

VALVE ADJUSTMENT TOOL

INDUCTIVE ENGINE SPEED INDICATOR

1-4

GEN ~ SPECIAL TOOLS INFO C9-eJ

'--- ____._ __ -----I-

Tool number

Tool name

Illustration

90890-03113

INDUCTIVE ENGINE SPEED INDICATOR

YM-33277-A

INDUCTIVE STROBOSCOPIC LAMP

90890& 03141

YU-33223

90 890~03081

INDUCTIVE STROBOSCOPIC LAMP

PRESSURE GAUGE

PRESSURE GAUGE

YU-33223~3

ADAPTER FOR PRESSURE GAUGE

90890-04082

ADAPTER FOR PRESSURE GAUGE

YM-01312~A

FUEL LEVEL GAUGE

90890-01312

FUEL LEVEL GAUGE

YU~01304

P1STON PIN CLIP PULLER

1-5

I A-a I

GEN ~ SPECIAL TOOLS INFO ~

""___-";;;;;;"""""'--...,_..._.I

Tool number

90890-01304

YS-01880

Tool name

Illustration

90890-01701

YU-33270

90890-01362

PISTON PIN CLIP PULLER

.......

.... ~

YM·04063-A

ROTOR HOLDER

90890~04063

YM-91 042

90890-04086

ROTOR HOLDER

ROTOR SCREW PULLER

ROTOR SCREW PULLER

ADAPTER FOR ROTOR SCREW PULLER

ADAPTER FOR ROTOR SCREW PULLER

ALL~PURPOSE CLUTCH HOLDER

AlL~PURPOSE CLUTCH HOLDER

CRANKCASE SEPARATING TOOL

1 .. 6

GEN ~ SPECIAL TOOLS INFO C9~

Tool number

Tool name

90890-01135

CRANKCASE SEPARATING TOOL

II lustration

YU-01 083~A

90890-01 083

90890~01 084

SllOlNG HAMMER UNIT

SLIDING HAMMER BOLT

SLlDtNG HAMMER WEIGHT

YM-04019

VALVE SPRING COMPRESSION CLAMP

90890-04019

YM-91043

VALVE SPAtNG COMPRESSION CLAMP

VALVE HOUSING CUTTER

lu-

L~

~... . .

i •

• I.. • I. • _ _ _ ..::

YMa04064

90890~04064

VM-04066

6 mm (0.24 in) VALVE GUIDE PULLER

6 mm (O~24 in) VALVE GUIDE PULLER

6 mm (O~24 in) VALVE GUIDE REAMER

1-7

I A-9 I

GEN ~ SPECIAL TOOLS INFO (9~

Tool number

90890-04066

Tool name

Jllustra1ion

90890-04065

YU-900S0

6 mm (0.24 in) VALVE GUIDE REAMER

90890~O 1274

90890-01275

YMa90069

90890~04059

YM-91044

90890-04081

6 mm (0.24 in) VALVE GUIDE lNSTALlER

6 mm (0.24 in) VALVE GUIDE INSTALLER

DRIVING SHAFT INSTALLATION UNIT

DRIVING SHAFT INSTALLATION HOSE

DRIVING SHAFT iNSTALLATION BOLT

#10 (M14) ADAPTER (FOR DRIV1NG

SHAFT INSTALLATION)

#10 (M14) ADAPTER (FOR DRIVING

SHAFT INSTALLATION)

CRANK SPACER

CRANK SPACER

GEN ~ SPECIAL TOOLS IN FO (9~

Tool number

90890~O 1 288

Tool name

Illustration

ACC~ 11 001 ~01

SPACER (FOR CRANK)

90890-85505

90890~O 1 325

YU~33984

90890~O' 352

SEALANT (QUICK GASKET)® Yamaha Bond No. 121S®

YU-01268

SEALANT (QUICK GASKET)® Yamaha Bond No. 1215®

90890~O 1268

RADIATOR CAP TESTER

RAOIA TOR CAP TESTER

ADAPTER

(FOR AADIA TOR GAP TESTER}

ADAPTER

(FOR RAorA TOR CAP TESTER)

FRONT FORK SERVICE KIT ASSV

---

~

RING NUT WRENCH

RING NUT WRENCH

1-9

,A-101

GEN =--.

SPECIAL TOOLS INFO ~

Tool number

Tool name

IUustration

90890-01385

90890-031 44

YU-03112

90890~03112

RING NUT WRENCH

D1NAM1C SPARK TESTER

IGNITION CHECKER

POCKET TESTER

POCKET TESTER

1-10

SPEcpf IA-121

CHAPTER 2° TECHNICAL SPECIFICATIONS

GENERAL SPECIFICATIONS, , , .. , , , , ~ ~ . , , , . ~ ~ , , , , ~ . , , , ... , , , .. , , , .. , , , , A-13

MAINTENANCE SPECIFICATIONS , , , , .. , , , , .. , , , , .. , , , , , ~ , , , , . , , , , , , , , , , A+ 14

ENGINE .,. ~ . ' , , ~ . , , , ~ . , , , . ~ . , , , , . ~ , , , , ~ , , , , . ~ , , , , , .. , , , ~ , , , , , .. , A-14

ELECTR Ie SYSTEM .. + + • , •• + + • ' , • ~ ~ •• ' , + + • ' , • + ~ •• , • + ~ •• ' • ~ •• ' • ~ • , • A-16

CHASS lS + + + + + + + + + + + + + + + + .. 8-2

TIG HTEN I N G TORO U ES ~ ~ , , . ~ , , , ~ ~ , , , , . ~ ~ ~ . , , . ~ , , , . ~ , , , , , . , , , , ~ , , , , . ~ , , 8 .. 3

GENERAL TORQUE SPECJFrCATIONS . , , , .. , , , , ~ , , , , , ~ . ' , , . ~ . , , .. , , , . 8-6

DEFINIT[ON OF MEASUREMENT UNITS . + • , , , + + ' , •• + + ••• ' ~ + • ' • ' + ••• ~ ~ + • • • 8-6

LUBRICATION POINTS AND TYPE OF LUBRICANT, , . ~ , , , , , ~ , , , . ~ , , , , ~ ~ , , , , 8 ... 7

ENG IN E .,", .. " ... ,', ... ,'" ~ .. , , . ~ . , , . ~ .. , , ... , , , , . , , , , ~ ~ , , , , . 6-7

CHASSI S ' . + + • r •• + + •• + + + + ••• + + + ~ + , ~ + + , • , ~ ~ 8-7

L U B RIC A T ION LA YOU T , . + + • • + + + • • • + + + r ' • + + .. .. • • • + + r • • + + + , • • ~ + • • • + ~ r , • + .. B - 8

COO LIN G LA YOU T , , . , , , , . , , , ~ , , , , . . ~ . , , , . . . , , , , ~ . , , , . . . ' , . ~ , , , , ~ . , , , . B-1 0

CABLE ROUT r N G , , , , . ~ , , , . , , , , . , , , , , , . , , , , . . , , , , . , , , , . . , , , , , , , , , . , , , , 8 .. 11

SPEC JUf

------------------------

GENERAL SPECIFICATIONS SPEC P f TECHN1CAL SPEcrFICATIONS - GENERAL SPECIFICATIONS

Model code number

Initial engine stamp number Initial frame stamp number

4SU1

4SU-000101

4SU·040101 (0) version

ZD04SU1000000Q101 (I-GR~P} version Z004SU1 00000201 01 (F-B-N-S-DK-NL-(A-CH}]

version Z004SU10000060101 (E) version

Dimensions:

Overall length Overall width Overall height Seat height Wheel base

Minimum ground clearance

2.040 mm 740mm

'.140 mm 770mm 1.410mm 145 mm

Basic weight

159 kg

Minimum turning radius

3.150 mm (lett): 3.200 mm (right)

Engine:

Engine type Model

Cylinder layout Displacement Bore x stroke Compression ratio Starting system

4-Sltoke, SQHe. liquid cooled, 5-va~ve 4SU1

Single cylinder, inclined forward 659 cc

100x84 mm

9.2:1

Electric starter

Lubrication:

Type

Recommended engine oil

Dry sump with separate oil tank SHELL SUPER 4TX 20W/50

Capacity (engine oil):

Periodic oil change

With oil finer replacement Total amount

2~6 liters 2+7 liters 3.0 titers

Coolinq system:

Type

Water/coo'ing liquid ratio Circuit liquid total quantity Expansion tank capacity From ~LO~ to uFULL'"

Liquid with forced clrcutanon and electric fan 500/0 .. 500/0

1 ~4 liters

0.55 liters

0.210 liters

Air finer:

Type

Fuel (type):

Tank capacity:

Total

Reserve amount

Dry tilter element

Premium Grade Fuel. If Premium Grade gasoJine is not available. then unleaded gasoline with octane grade (R.O.N.) of 91 or higher can be used

'4 liters 2.5 liters

Carburetor:

Type/Manufacturer

Y26PV-3jfTEIKEI

Spark plug:

Type/Manufacturer Electrode gap

DPRBEA-9 or DPR9EA~9/NGK O.8 .... 0~9 mm

Clutch:

Type

Wet I m ulti-disc

2·1

I A-13]

GENERAL SPECIFICATIONS SPEC P f

Transmission:

Type

Primary reduction system Primary reduct ion ratio Secondary reduction system Secondary reduction ratio Operation

Gear ratio:

Frame:

Frame type Caster a ngJeff rail

Tires:

Type Size:

Front

Rear

15t 2nd 3rd 4th 5th

Constant mesh 5-speed Straight-tooth gears 71/34 (2.088)

Chain drive

39/15 (2.600)

Left foot operation 30/13 (2.308) 27/17 (1.588) 24/20 (1.200) 21/22 (0.954)

, 9/24 (0.792)

Oettabox aluminium frame 24°/102 mm

TubeJess

, lOna ZA17 TX15 (MICHELIN)- 110no ZR17 TL (DUNLOP) 150/60 ZR17 TX25 (MICHELIN) .. '50/60 ZR17 TL (DUNLOP)

Tire inflation pressure (cold tires) ba(-kglcm2 (psi) Rider only

With passenger

Front Rear

2 (28) 2.2 (32)

2.2 (32) 2.5 (37)

Brakes:

Front brake type Operation

Rear brake type Operation

Front suspension:

Rear suspension:

Wheel traver:

Front Rear

E r eet ric svste m :

Ignition system Battery typeNoftage Fuses

Generator

Headlight type

Bulb specifications:

Headlights (halogen) Tail/Brake light

Turn lights

Front parking light Numberplate light

Wa rning ramps: ~N" (neutral) - "Hiqh beam" "Low fuel~ - "Turn lights~

2 .. 2

Sing1e 320 mm disk brake Right hand operation Single 210 mm disk brake Right foot operation

Adjustable upside-down telescopic fork, dia. 41 rnrn, Upstde Down

Aluminium swinging fork with adjustable shock absorber

120mm 121.5 mm

T.C.I r (Digita')

CTX9 BS YACHT MF/12V BAh 20A (Main) • 7.SA (Electric fan) A.C~ 12V

Provided with quartz lamp (ha1ogen)

12V·2x55W '2V-21/5W 12V-10W 12V .. 5W 12V-5W l2V-4x1 ~2W

SPEC ffiO

MAINTENANCE SPECrFICA TfONS r ,

------~----------------------~----------------

MAINTENANCE SPECIFICATIONS

ENGINE

Part

Standard

Limit

Cylinder head:

0.03 mm

"The lines show where you have to site the measuring slide rule

Cylinder:

Bore

Measurement point (a) I

100.005 - 100r07 mm 50 mm

Chain advance (left)

35.54 mm 29.91 mm

36.35 mm 29.96 mm

O.03mm

Rocker/rocker shaft

Rocker outer diameter Rocker shaft inner diameter Rocker-shaft backlash

®

Cam shaft outer diameter 22.967 .... 22.980 mm

Backlash between cam shaft and cap 0+020 .... 0+054 mm Cam size:

Cam shaft:

Advance method

A

75 AN 2015 126 links

Automatic

12.000 - 12.018 mm 11.976 ... 11.991 mm 0.009 ~ 0.042 mm

B

___.-:_/ - - .-

Cam shaft eccentricity limit Timing chain:

Timing chain type Link number

Timing chain adjustment method

2-3

MAINTENANCE SPECIFICATIONS SPEC P f

Part

Standard

Limit

Valves. valve seats, valve guide:

Valve clearance (cold):

Suction Exhaust

0.1 0 .- 0.15 mm 0.15 - 0.20 mm

Valve sizes:

Suction:

-AU head diameter

~BN face width

"CI~ seat width

"0" edge thickness

Exhaust

NAN head diameter

N811 face wid1h

~Cn seat width

-Oil edge thickness

29+9 - 30~ 1 mm 2.25 mm

0+9 _, 1.1 mm Or8S -- 1715 mm

31~9 ..... 32.1 mm 2+26 mm

049 - 1.1 mm O~85 ~ 1.15 mm

)\ (

I ..... C·, .\

/ "-

f

"-

} "D ,j

J

-- --

• ,~ AI~ --. 1 •

Head Face Seat Edge

diameter width width thickness -

Rod outer diameter:

Suction

Exhaust

Guide inner diameter:

Suction

Exhaust

8ack'ash between rod and guide:

Suction

Exhaust

Rod eccentricity limit AJ

-~~ ~ . --~

V1 --{J-

5.975 - 5~990 mm 5.960 - 5.975 mm

6.000 mm ~ 6.012 mm 6.000 - 6.012 mm

0.010 mm -- 0.037 mm O~025 -- 0.052 mm

0 .. 9 ..... 1.1 mm

5 .. 95 mm 5 .. 93 mm

6+05 mm 6.55 mm

0.08 mm 0 .. 1 mm 0.01 mm

Valve seat standard width:

Suction and Exhaust

Suction: wAIr 35r69 -- 35.79 mm

jlB~ 30.06 - 30~ 16 mm

lie" 5.74 mm

Exhaust: 11AI~ 36.50 - 36.60 mm "B" 30~ 11 - 30.21 mm ~CII 6 .. 55 mm

MAINTENANCE SPECIFICATIONS SPEC fJ f

Part

Standard

Limit

Valve springs:

Free length:

Suction Exhaust Position size

(with closed valve):

Suction Exhaust

Winding sense (top view):

Suction and exhaust Slope limit:

-"r-

..,_......{~~

(" -:.J

~ __.J

2 :J r.:: -;:...J

--...-;; =--

r-_ .-J

:r~ ::;,

r ~

__ :lII.

~

27.50 mm 31.00 mm

Clockwise

-

2.5°/1.4 mm 2.5°/1.6 mm

"' '\ \. \. '\ , '\ \. -. ,\.,' ,\. '\ '\. -, " Suction

Exhaust

Compression force (with closed valve):

Suction Exhaust

Piston:

·~DII piston size ~~H~I measurement

point

(

J

0.15 mm

1 O~2 - 11 ~8 kg 12+3 -- 14+ 1 kg

99~945 ,._ 99T985 mm 2.5 mm

1+0 mm

Suction side 0.050 ~ 0.070 mm

Trapezoidal Conic

B = 1~2 mm T::: 3+8 mm

B = 1.2 mm T ~ 4+0 mm

8 = 2~5 mm T = 3.4 mm

L~ \.l.I

1 ~ - ~ ~y- ------+--, H

, ~ 0 ~

Piston allowance

Piston pin off-centring Piston-cylinder backlash

Rings:

Type:

Upper ring Lower ring

Sizes (6 x T):

Upper ring

I JIB

~T~

Lower ring

! ~JB

I. .. i

T

~)J8

~> t-.T-I

Scraper ring

2-5

rA-151

MAINTENANCE SPECIFICATIONS SPEC fJ f

Part

Standard

Limit

End clearance (with mounted ring):

Upper ring

Lower ring Scraper ring

Side backlash (with installed ring):

Upper ring

Lower ring Scraper ring

0.30 -- O~45 mm O~30 .... O~45 mm 0.20 - 0+70 mm

O~04 -.. 0.08 mm 0.03 ~ 0.07 mm O~015 -.. O~042 mm

-

....

-

Main shaft:

t4 A ~ shaft width ~C~ oft-centrinq limit

MD~ backlash M F~ small end

backlash

74.95 - 75400 mm

(f -

l--.....,

0.35 .... 0.65 mm

0.8 ..... 1~O mm

Cylinder gear

Balancing weight:

Advance method

Clutch:

Friction plate:

Thickness Quantity

F ricti on p I ate:

Thickness Quantity

Clutch plate:

Thickness Quantity

Di stortion limit

Clutch spring:

Free length Quantily

Clutch release method

2.74 - 2.86 mm 6 parts

2.94 -- 3.06 mm 2 parts

1.2 mm 7 parts

42~8 mm 5 parts

Rack and pinion external traction

2.6 mm

2.8mm

0.2 mm

Gear box:

Principal axis off .. centring limit

lnterrnediate shaft off-centring limit

0.08 mm

O~08 mm

Selector:

Type

Drum with cam and guide bar

MAINTENANCE SPECIFICATIONS SPEC P f

Part Standard Limit

Lubrication system:

Oil filter:

Type Paper

Oil pump:

Type Trochoidal

Extremity clearance 0.12 mm ~

Lateral clearance 0.03 - 0+08 mm -

Derivation valve adjustment pressure 80 - 120 kPa (0.8 -- 1 +2 kg/cm2) ~

Cooling system:

Radiator Width 431 mm -

Height 133mm -

Thickness 32 mm -

Valve adjustment pressure 95 - 125 kPa (0.95 -" 1.25 kg/cm2) ~

Expansion tank capacity 0.55 litri -

From ~LOWu to uFULLIl 0.21 0 titri -

Liquid pump:

Type Single suction centrifugal pump

Reduction ratio 33/34 (0.971) ~

Thermostat:

Opening temperature 80 ~ 84°C (176 - 183(JF) ~

Carburetor:

Identification initials 4SU-OO -

Main jet (M.J.)

Primary carbu retor #140 -

Secondary carburetor #165 -

Main air jet (M.A.J+)

Primary carburetor 01.0 -

Secondary carburetor 01+0 -

Jet needle (J.N~)

Primary carbu retor 5096-3/5 -

Secondary carburetor 5X7C-4i5 -

Nozzle jet (N~J.)

Primary carbu retor V·OO -

Secondary carburetor 02.7 -

Piiot air jet (P +A.J~) 00.6 -

Pilot jet (P .J.) #50 -

Pilot output (P+O+) 0.8 -

Bypass (B~P.) 01.0 -

Pilot screw (P ~S+) ca. 3 turns open -

Valve seat {V.S.} 02.5 -

Starter jet (G.S.) #76 -

Fuet teve! (F, L.) 6.0 .... 8.0 mm under float chamber -

Fica t he rght match rng surface

(F.H+) 25.0~27.0 mm -

Engine idle speed 1 ~300 + 50 rpm -

Suction pressure at englne idle speed 26.6~34.6 kPa (200 .... 260 mmHg) - 2-7

I A-161

MAINTENANCE SPECIFICATIONS SPEC fO f

ELECTRIC SYSTEM

12° at 1 t300 rpm 38° at 6t500 rpm EI ectrlc type

Limit

Standard

Part

Voltage:

12V

Ign ition system:

Minimum spark advance (B.T+D4C.) Maximum spark advance (B+T+D+C.) Spark advance device

50 -

-

.

o

..

o

lcc

40

"386/6,500 rpm

-

Q) o c: ro >

~ co

.:::L.

~

ctS 0..

C/)

20 -

10 . 14~/2)555+200 rpm

~ r-t -I

i ~o/350 rpm

r

• • --r T t l I.

0 1 2 3 4 5 6 7 8 9 10 Engine speed (x 1 ~OOO rpm)

Spark unit:

Model/Manufacturer TNDF19/NIPPONDENSO

Pick-up coil resistance 184 ... 276 !l at 20°C (68°F) -

(colour) (BlueNeUow - GreeOlWhite)

19 n ition coil:

Model/Manufactu rer J0268/NIPPONDENSO

Primary coil resistance 3.4-4~6 Q at 20cC (68°F) -

Secondary coil resistance 10.4-15.6 kQ at 20aC (68CF) -

Spark plug cap:

Type Resin

Spark plug cap resistance 10 k11 at 20°C (68F) -

Charge system:

Type CA magnet generator SPEC rOo I B-1 1

MAINTENANCE SPECIFICATIONS r ,

Part

Standard

Limit

AC Alternator:

ModeVManufactu re r Recharge output

Armature resistance (windinq) (coiour)

26

24

22

.......

:;:I 20

a.

-- 18

::!I

0

tV 16

~ 14

n:s

J::.. 12

of.)

w 10

a:

8

6

4

2

0 TLMZ55JN IPPONDENSO 14V~ 24~5A at 51000 rpm O.20-0L30 {l at 20°C (68°F) (White - White)

Voltage regufator/Rectifie r:

Model/Manufacturer SH650AlSHINDENGEN

Voltage regulator:

Type Short clrcuit semiconductor

Not charged adjusted voltage 14L2-15.2V -

Rectifier:

Capacity 25A

Resistance voltage 240V

Battery:

Electrolyte density 1.320 -

""I'. _ - _.

Electric s tarter system:

Type Constant mesh gear

Starter motor:

ModellManufacturer SM~13/MITSU8A

Capacity 0+8 kW

Brush length 12.5 mm Smm

Commutator diameter 28mm 27mm

Mica cut (depth) O.7mm ~

Ignition relay:

Model/Manufactu re r MSSD-191/HITACHr

Nominal amperage 100A

Horn:

Type Flat

Model/Manufacturer 220/CEV-PAGANI

Max. intensity 2L5A ---1,,-

~ ~ - '-j - - -- -_. -- ~ '-----1'- - ---

·__'__;_f-''_ ---1'- -- -- '__' - -~

. ' ..........

- +----II-----+- - t- ..

- - 1- - - ,. ............... ---+-----ilo--

~ - - I-- ~- - -~ _ _ _ j--, _ ~

_. . - - - - .. ~ I---- - . - - - - r---'

1- -; - -----+- ............... ,___+--+-~t____ Ir- - ~ -----i-+__+_ - ~

01 234 5678

Engine speed {x t JlOO rpm)

MAINTENANCE SPECIFICATIONS SPEC JUf

Part Standard Limit

~

Turn light relay:

Type Warm-wire type

Model/Manufacturer 301877102lCEV-PAGANJ

Automatic stop device None

Flashing frequency 60-120 cycles/min -

Power 10Wx2+2W

Electric fan:

ModeUMan ufactu rer VA27-A37/C .. 46A 12V/SPAL

Thermostatic switch:

Model/Manufacturer VF10SNN. THERMOSTAT

Operating temperature 102-10aoC (215L6-226.4°C): ON -

98°C (20B.4°F): OFF -

Thermo unit:

ModeVManufacturer KIAL 41/NIPPONDENSO

Coil resistance 226 11 at 50°C (122°F) -

26~4 n at 115°C -

Electric circuit switch device:

Type Fuse

rndividua~ amperage 20A (main)

7~5A (electric tan) 2 .. 10

Pf I

MAINTENANCE SPECIFICATIONS SPEC

CHASSIS

Part

Standard

Limit

Steering:

Bearing type

Taper roller bearing

-~~------

------ -_._-------1-------- .---~. ~~~~. __ . __ ~_... ~ _

Front suspension:

Fork travel

Fork spring: free length Spdng constant (K) Optional sprin 9

Oil amount

Oil level

Oil type:

Inner tube external diameter

120mm 402mm

7.95 N/mm (0.795 kgJmm) None

300 cu.cm 130mm

from upper edge

of inner tube (fuUy compressed, without spring)

BEL RAY Me 10 SAE5 41 mm

Rear suspension:

Shock absorber travel Free spring length Spring-loaded tength:

Standard Minimum Maximum

Spring constant (K) Travel

Optional spring Gas pressure

48mm 175 mm

166 mm 161 mm 170 mm

125 N/mm (12.5 kg/mm) Zero-65 mm

None

12 kg/sq.cm (170 psi)

Rear arm:

Clearance limit

Side clearance

O.4~O.7 mm

at the rear arm axle

1,,0 mm at the rear arm end (move rear arm from side to sde)

F rant wheeJ:

Type

Rim size Wheel material

Wheel eccentricity limit:

Vertical Laterat

Light alloy 3.00x1711 Alurnlnlurn

0.5 mm 0.5 mm

8-2 I

MAINTENANCE SPECIFICATIONS SPEC JDf

Part

Standard

Limit

Rear wheel:

Type

Rim size Wheel material

Wheel eccentricity lirnll Vertical

Lateral

Light atloy 4.00x17M

Aluminium

--

0.5 mm 0.5 mm

Drive chain:

Type/Manufacturer Number of rinks Chain slack

135 ORS·A REGINA CHAIN 110

25-40 mm

Front disk brake:

Type

External disk diameter Disk thickness

Pad thickness

Interna1 master cylinder diameter Internal caliper cylinder diameter

Quantity Brake fluid type

Single 320mm 4mm

5.0 mm 13mm 30/34 mm 2 parts 00T#4

3.5 mm 0.8 mm

Rear disk brake:

Type

External disk diameter Disk thickness

Pad thickness

Internal master cylinder diameter Internal caliper cylinder diameter Brake fluid type

Single 210mm Smm 4.0mm 11 mm 32mm DOT #4

4mm 0.8 mm

Brake pedal lever:

Brake lever free play (travel)

Brake pedal position

2 .... 5mm

at the lever end 50mm

below the footrest plane

Clutch [ever and throttle qrip:

Clutch lever free play

Th rettle cable free play

10 .... 15 mm

at the lever end 3.0-5.0 mm

at the grip flange

2-12

ffiO I 8-3 I

MAINTENANCE SPECIFICATIONS SPEC r «

TIGHTENING TORQUES

Thread QJy Tightening torque Note

Part to be tightened

size Nm mkg

Head

Flange bolt M9 4 38 3.8

Flange bolt M9 2 38 3.8

Socket head bolt M6 1 10 1.0

Stud bolt (exhaust pipe) M6 4 7 0.7

Screw plug M18 ~ 55 5+5 -IG

Spark plug M12 1 18 1 T8

Cylinder head cover

Socket head bolt M6 16 10 1.0

Cylinder head cover

Socket head bolt M6 1 10 1.0

Cylinder head lateral cover M32 2 12 1.2

Socket head bolt M6 4 10 1 .0

Gear unit assembling

Socket head bolt M6 1 10 1 ~O

Engine speed indicator stop cap

Flat head screw M6 1 7 0+7

Cylinder

Flange bolt M10 2 42 4.2

Flange bolt Ml0 2 42 4.2

Socket head bolt M6 2 10 1.0

1 support

Socket head bolt M6 1 10 1_0

Balancer shaft gear

Hexagonal nut M16 1 60 6.0 Usea

Rotor (AC magnet) lock

Hexagonal nut M14 1 150 15.0 washer

Lock nut {valve clearance adjustment}

Hexagonar nut M6 4 14 1.4

2 retainer guide

Hexagonal bolt M6 2 8 0+8

Tl mlnq sprocket

Flange bolt M7 2 20 2TO

Timing chain tensioner

Hexagonal head bolt M6 2 10 1 +0

Rocker shaft stop

Socket head bolt M6 2 10 1.0

Cooling liquid pump

Socket head bolt M6 3 10 1.0

1 tube

Socket head bolt M6 1 10 1.0

2 tube

Flange bolt M6 1 10 1 ~O

Thermostat assembly

Flange bolt M6 2 10 1.0 2-13

MAINTENANCE SPECIFICATIONS SPEC 9' ,

Thread Qrty Tightening torqu e Note

Pa rt to be \;ghtene d size

Nm mkg

Finer (coolant)

Cylindrica 1 socked head bolt M6 1 10 i.o

Oir pump

Socket head bolt M6 2 10 1.0

Oil delivery/return hose

Truncated cone head screw M6 2 7 0.7

Draining plug (oil sump) M14 1 30 3.0

Oil fi Ite r cove r

Socket head bolt M6 3 10 1 ~O

Drainage screw M5 1 5 0.5

Radiator

Flange bolt M6 4 10 1 ~O

Oil pump assembly

Flange bolt M6 3 10 1.0

2 cover

Truncated cone head screw M6 1 7 O~7

Oil suction net filter

Truncated cone head screw M6 2 7 0.7

Drainage hole

Plug screw M14 1 30 3~O

Filter cover

Socket head bolt M6 1 10 1.0

Socket head bolt M6 2 10 1.0

Filter cove r drainage

Screw MS 1 5 O~5

1 ojl tube

Socket head bolt M6 4 10 1.0

Orin ed jo i nf M12 1 35 3.5

2 oil tube

Socket head bolt M6 2 10 1.0

Drilled joint M12 1 35 3+5

Connecting oil hose

Bolt M10 2 20 2.0

Socket head bolt M6 1 10 1.0

Carbu retor joint

Socket head bolt M6 4 10 1.0

Left carburetor joint

Clamp M4 1 2 0.2

Right carburetor joint

Clamp M5 1 5 0.5

Ca rbu re to r join t (I e ft, air tnt e r) 0.2

Clamp M4 1 2

Carburetor joint (right. air filter) 0.5

Clamp MS 1 5 MAINTENANCE SPECIFICATIONS SPEC )D f I: B-~ I

Thread QJy Tightenrng torque Note

Part to be tightened •

size Nm mkg

Air cleaner case

SeJf- ta pping screw M9 7 5 0.5

Air cleaner cover

Crosshead screw M5 3 5 O~5

Exhaust pipe

Nut M6 4 10 1~O

1·2 exhaust pipes

Socket head bolt M6 1 10 1.0

Silent-Block to f rarne

Flange nut MB 1 23 2~3

Silent-Block to bracket

Flange nut M8 1 23 2.3

1 exhaust pipe to bracket

Flange screw M8 1 23 2.3

Muffler and exhaust pijpe

Socket head bolt M6 1 10 1.0

Muffler assembling

Flange bolt M10 1 40 4+0

1 - 2 oil sump

Socket head bolt M6 9 10 1 +0

Socket head bolt M6 4 10 1.0

Socket head bolt M6 1 10 1.0

Holdfast (cable)

Truncated cone head screw M6 1 7 0.7

1 crankcase cover

Socket head bolt M6 6 10 1.0

Socket head bolt M6 1 10 , .0

Socket head bolt M6 1 10 1.0

Socket head bolt M6 1 10 1 ~O

Plug screw M8 1 10 1.0

2 crankcase cover

Socket head bolt M6 2 10 , .0

3 crankcase caver

Socket head bolt M6 5 10 1.0

Socket head bolt M6 3 10 , .0

Socket head bolt M6 2 10 1.0

Bearing cover plate -c

Flat head screw M6 3 7 0.7

Locking plate

Socket head bolt M6 2 10 1.0

Clutch spring

Screw with washer M6 5 8 0.8

Clutch hub

Nut M20 1 90 9.0 Usea

lock

Primary transmission gear washer

Nut M20 1 120 '2~O Use a

lock

Thrust lever assembly (stop) washer

Bo't M6 1 6.5 O~65

Thrust lever assembly

Screw M8 1 12 1 ~2 2-15

MAINTENANCE SPECIFICATIONS SPEC JOf

Part to be tightened Thread Q.ty Tightening torque Note

size Nm mkg

Guide sprocket Use a

Nut M18 1 110 11.0 lock

Oir seal cover washer

Socket head bolt M6 2 10 1.0

Stop lever

Screw with washer M6 1 10 1.0

Gearbox arm

Bolt M6 1 10 1,0

Stator coil

Truncated cone head screw M6 3 7 0.7 -G

Neutral switch M10 1 20 2~O

1 lateral cylinder head cove r M32 2 12 1.2

Spring tensione r

Hole M16 1 20 2~O

Starter

Frange bolt M6 2 10 1 ~O

1 cover

Socket head bolt M6 1 10 1.0

Socket head bolt MS 3 10 r.o

Starter un idi rectionaf elu tch -I~

Socket head bolt M8 3 30 3~O Stop

Pick .. up coil -It?]

Truncated cone head screw M5 2 5 0.5

fgnition coil

Socket head bolt M5 2 5 0,5

Voltage regulator

Hexagonal head bolt M6 2 5 0+5

Ign;tion unit

Hexagonal head screw M6 2 5 0.5

Thermo switch

Truncated cone head screw M16 1 28 2.8

Thermo unit

Truncated cone head screw PT1/8 1 15 1 ~5 2-16

fif I

MAINTENANCE SPECIFICATIONS SPEC

Thread Tightening

Part to be tightened Q.ty tor ue Note

size Nm mkg

Engine assembnng:

Front engine bracket and frame M10x1.2S 1 65 6~5 Axle

Front engine bracket and engine Ml0 x 1.25 2 65 6+5 Flange bolt and

locknut

Upper cylinder head bracket and frame M10 x 1.25 2 65 6.5 Socket head bolt

and locknut

Upper engine bracket and cylinder head M10 x 1 ~25 1 65 6.5 Socket head bolt

and locknut

Rear/upper engine and frame M10 x 1,25 1 65 6.5 Socket head bolt

and locknut

Rear/~ower engine and frame Ml0 x 1.25 1 65 6,5 Bolt

Lower/rear engine axle tightening M6 x 1.0 1 10 1.0 Socket

head screw

Driver footrest and frame M8 x 1 ~25 4 23 2.3 Special screw -----___.__,.~~~-___...__------"---

Tightening sequence:

Crankcase (L)

Crankcase (R)

@

2-17

8-51

MAINTENANCE SPECIFICATIONS SPEC JC> f

Thread Tightening

Part to be tightened Q.ty torque Note

.

size Nm mkg

Passenger footrest and frame M8 x 1.25 4 25 2.5 Hexagonal head screw

with flange

Foot rest to bracket M10 x 1.5 2 50 5.0 Socket thin head

screw

Side stand:

Side stand bracket to frame M10x1.25 2 55 5+5 Screw

Stand pivot M10x1~25 1 40 4.0 Pivot

Stand nut M10 x 1.25 1 35 3.5 Special nut

Rear small frame:

Upper rear small frame to main frame Ml0 x 1.25 2 40 4~O Hexagonal head screw

fastening with f1ange

lower rear small frame to main frame M8 x 1.25 2 23 2.3 Hexagonal head screw

fastening with flange

Front small frame:

Rear small frame to steering head fastening MB x 1 +25 2 25 2.5 Hexagonal head screw

with trange

Roar small frame to main frame M8 x 1 ~25 1 23 2.3 HexagonaJ head screw

fastening with flange

Sid e panel/fender/rea r cowli ng/fu el ta nk:

Roar wheel fender to rear arm M6 x 1 3 10 1+0 Hexagonal head screw

Front wheel fender to front fork M6 x 1 4 10 1 ~O Socket thin head screw

Front wheel fender to front fork M6 x 1 2 10 1.0 Socket thin head screw

and locknut

Battery case to rear small frame M6 x 1 5 10 1~O Hexagonaf head screw

Rear cowling to rear small frame M6 x 1 2 10 1.0 Socket thin head screw

Fuel tank to frame M6 x 1 1 10 1.0 large socket thin head

screw

Fuel tank to rear small frame M6 x 1 1 10 1.0 Socket thin head screw

Fuel pump to bracket M5 x 0.75 2 5 0.5 Flange nut

Bracket to fuel tank M6 x 1 2 7 0.7 Cyrindricaf head screw

Front smaH frame and headlight M6 x 1 4 7 0.7 Locknut

Front small frame and instrumentation M5 x 0.75 3 5 0.5 Flange nut

Front small frame and mirrors M6 x 1 4 10 1.0 Flange cap nut

S~de panel to frame bracket M6 x 1 2 10 1.0 Hexagonal head screw

Bracket to frame M6 x 1 2 10 1.0 Socket thin head screw

Air connection to front small frame M6 x 1 2 10 1 ~O Socket head screw

Side panel, air connection to bracket M5 x 0+75 3 5 0.5 Socket thin head screw

Front fork/handle bar:

Handle crown and fork M8 x 1.25 2 23 2~3 Socket head screw

Handle crown and handle bar fastening M6 x 1 2 10 1 ~O Socket head screw 2 .. 18

cDO I 8-6 I

MAINTENANCE SPECIFICATIONS SPEC r,

Thread Tightening

Part to be tightened Q.ty torque Note

.

size Nm mkg

Under bracket and fork MB x 1.25 4 23 2~3 Socket head screw

Handle bar fastening to fork M8 x ; .25 4 23 2.3 Socket head screw

Handle crown nut M22 x '.0 1 110 11 ~O Nut

Counterweight to handle bar fasten ing M8 x 1.25 2 25 2.5 Socket head screw

Upper steering ring nut

and steering column M25 x 1.0 2 3 0.3 Ring nut

Rear/front braki ng circu it:

Front brake master cylinder and M6 x 1 +0 2 10 , .0 Socket head screw

fastening bracket to handle bar

Brake fluid tank (front bracket) M6 x 1 +0 2 10 1.0 Socket head screw

Front brake master cylinder and brake hose M10 x 1.0 1 15 1.5 Joint

Front brake caliper and brake hose M10 x 1.0 1 15 1.5 Joint

F rant and rear brake fluid

bleeder screw M10 x 1.0 1 6 0.6 Air bleeder

Front brake caliper to front fork M10 x 1.5 2 50 5~O Hexagonal head screw

with flange

Front wheel axle M16 x 1.5 1 70 7.0 Ax!e

Front wheel axle fastening bolt M8 x 1.25 1 1S 1.5 Socket head screw

FronVrear brake disk and hub M8 x 1 ~25 6+3 23 2.3 Socket thin head screw

Footrest and rear brake master cylinder M6 x t.O 2 13 1.3 Hexagonal head screw

Bracket and rear brake fluid tank M6 x 1 +0 1 4 0.4 Socket head screw

Rear brake caJiper and bracket M8 x 1 ~25 2 23 2.3 Socket thin head screw

Rear brake caliper and brake hose M10 x 1 ~O 1 15 1.5 Joint

Rear brake master cylinder and brake hose M10 x 1.0 1 15 1 ~5 Joint

Driven sprocket and hub clutch M8 x 1.25 6 23 2~3 Hexagonal head screw

Rear wheel axle nut M14 x 1.5 1 80 8.0 Axle + locknut

Shock absorber/rear arm:

Rear arm/rear arm axle

and main frame M18x1.5 1 110 '1 Axle + locknut

Rear arm and connecting rods M10 x 1.25 1 40 4rO Bolt + locknut

Relay arm and connecting rods M10 x 1.25 1 40 4.0 BoU + locknut

Relay arm and frame M10 x 1.25 1 40 4.0 8011 + locknut

Relay arm and shock absorber M10x 1.25 1 40 4.0 BoU + locknut

Shock absorber and frame M10 x 1 ~25 1 40 4.0 BoU + locknut

Chain guard seal and rear arm M6 x 1.0 1 5 0.5 Hexagonal head screw

Chain case and rear arm M6 x 1.0 2 9 0.9 Hexagonal head screw 2-19

GENERAL SPECIFICATIONS ABOUT TIGHTENING ffi 0

TORQUES/DEFINITION OF UNITS OF MEASUREMENT SPEC f,

GENERAL SPECIFICATIONS ABOUT TIGHTENING TORQUES

A B Genera1 specification

about tightening torques

(Nut) (Bolt)

Nm mkg

10mm 6mm 6 0.6

12mm Smm 15 145

14 mm 10mm 30 3.0

17mm 12mm 55 5.5

19 mm 14mm 85 845

22mm 16mm 130 13.0 This table indicates the tightening torques for stand ... ard attachments with ISO-pitch thread. Torque specifications for special components or units are indicated in the related sections of this manual. In order to avoid any damage! tighten those units with many fastenings by following a progressive cross sequence, until the final tightening torque is obtained. Unless otherwise specified. the tightening torques given are meant for clean and dry threads. AU components must be at ambient temperature.

A: Distance between flat parts B: External thread diameter

DEFINITION OF UNITS OF MEASUREMENT

Unit Meaning Definition Measure

mm millimetre 10-3 metres Length

em centimetre 10-2 metres Length

kg kilogram 10J grams Weight

N Newton 1 kg x mlse& Force

Nm Newton-metre Nxm Torque

mkg metre per kilo mxkg Torque

Pa Paskal N/m2 Pressure

N/mm Newton per mm N1mm Sprin 9 constant

L LItre Volume or capacity

Cubic centimetres -

ern"

rpm Ravo lut ions per mi nute - Engine speed 2 .. 20

SPEC ffiO I 8-7 i

LUBRICATION POINTS AND LUBRICANT TYPE r ,

-------------------------------------------------------------

LUBRICATION POINTS AND LUBRICANT TYPE

ENGINE

Lubrication points (part name) Lubricant type

Oil sear edges {completely) ~

Bearing retainer ~Ie

Rod pins 118

Rod (b~g end) -CiS

Pistons and piston rings ~Ie

Hub (balancer drive sprocket) -lIS

_. -- ·I·---.-.-....r-.

Piston pins >Ie

Valve stem and gU1de ~I@

011 seal (varve stem end) -cl(~

Rocker shaft and rocker arm 119

Cam and bearinq (camshaft) -c18

Rotor and rotor housing (oil pump) ~18

Disengagement control rod ~

Primary driven gear and primary shaft -o

Sliding gea r {transmission) ~I@

-

Free gear (transmisslon) -;10

Shift forks and fork guide ba r 19

-- ~ ,-

Gearshift cam and bearing (gearshift cam) 18

_.

Gearshift shaft -o

Rod housing coupled surfaces Bonding agent (rapid seal adhestve)®

Yamaha bond No. 1215®

Coupled surfaces (cvtinder head and cylinder head cover) Bonding agent (rapid seal adheslve)®

Yamaha bond No. 121S® 2-21

LUBRICATION POINTS AND LUBRICANT TYPE SPEC JD f

CHASSIS

Lubrication points (part name) Lubricant type

Gear unit (tachometer) ~

011 seal edges (completely) ~

Wheel axle (front and rear wheels) ~

Rear wheel hub and clutch ~

Bearing brasses (rear arm) and relay arm ~

P ivot rod (rear arm) ~

--

8earin 9 brasses (rear s hock absorber) ___;;iO=i

Bearing brasses (shock arm and link) -g~~

Bearing (shock arm and Jink) -:;~~

Pivot points (brake pedal and gearshift selector) ;a§j:~

Bearings (steeering cotumn) ~~~

Throttle grip end :;~~

Pivot points (brake lever and clutch lever) n]Ji~

Clutch cable end ;~~t

Pivot points (side stand) :;~i

Beartn 9 brasses (chain te nsioner) ~t

Grease nipple (rear arm) :;;iJ&~

Grease nipple (shock arm) -=ij{)b~

Grease nipple (shock link) ~I 2-22

LUBRICATION LAYOUT SPEC l' f I 8-8 I

------------------~---------------------------

[A] INTAKE

[BJ RETRJEVAL

LUBRICATION LAYOUT SPEC 1'f [AJ INTAKE

[8] RETRIEVAL

(1) Camshaft

(2) Oi I delivery hose (3) on filter

(4) Oir pump

(5) Main driving shaft (6) Drive shaft

(7) OiJ hose

(8) Oif delivery hose

LUBRICATION LAYOUT (1) Oir tank

(2) Oil pump

(3} Oil pump strainer (enqine)

I8J .... ' __ __.I rnJ [: :1

@[ __ 1 [ill [ f

2-24

2-23

18] f :: J

rru [. : ..... : 18}[ 1

I

rnJ r I LUBRICATION LAYOUT SPEC 1>1' I 8-9 I

--------------------------------------------------

[Aj INTAKE

[8] RETRIEVAL

(1) Camshaft

(2) Oil delivery hose (3) Oil fiJter

(4) Connecting rod pin (5) Main driving shaft

(6) Secondary drive shaft (7) Drain plug

2-25

(1 ) Oil delivery hose (2) Oil filter

(3) Oir pump

(4) Transmission

(5) Oil pump strainer

LUBRICATION LAYOUT SPEC 1> f [AI INTAKE

[BJ RETRIEVAL

2-26

C~O~O~L~IN~G~L~A~Y~O~U~T-------~C~O~O!:!LI~NG~LA~Y~O~U~T I SPEC )U 01 I 8-1 0 I

(1) Thermostat I I •

(2) Radiator

(3) E'ectric fan

(4) Pump

(5) Inlet hose (6) Outlet hose

2

6

3

5

4

2-27

18-11 I

CABLES ROUTING SPEC jU f

CABLES ROUTING SPEC JOf

CABLES ROUTING Rectifier 11. Connector 17~ Throttle cables 1. Recovery tank 84 Starter motor cable 154 Cables holder 21 . Odometer cable

6. Clamp 12~ (+) cable breather pipe 94 BaHery (+) cable! 16 .. Side stand switch sleeve

1. Clutch cable 7. Rear taiUight 13 .. Fuer impulse pipe ~rnJ Cfr. page 2 .. 32 2. Clamp Starter relay 17. Breather pipes 22. Odometer cable

2~ Fuse holder connector 144Clamp 3. Clutch cable 1 04 Starter relay 18.Cables holder 23. Recovery tank supply

3~ (-) cable 8. Flasher relay 1 5+ Recovery tank 44 Coil 11. Flasher relay 194 Oil delivery hose hose

4. Rear brake hose 9. C~OJ. unit breather pipe 5. Cramp 124 Taillight connector 204 Engine oil breather

5. Regulator/ 1 O. Starter relay is.con 6. Throttle cable s 13. Rear brake hose pipe (to engine 0;1

7. Oil remeval hose 14. Battery tank) 17 ~---

~------ 1

16

15

14 ~~r

13

2

12

3

11 ---.~--

~--.........._--

4

10

5

9

6

8

2

3 4

5

6

7

8

9 10

11 12

1

23

22 21 20 19 1 B 17 16 15 14 13

18-121

CABLES ROUTING SPEC 1>1

1 . Number plate and 7~ Low fuel siqnat 14.Clamp 21. Rear stop swltcn 1 .. Carburetor suction 8. Fuel impulse 14. Clamp 21. Front brake hose and

connector cable 1 5. Front brake cal iper 22~ Rear brake supply connection hose • 15. Odometer cable

di rection Indicator pipe throttle cables

cables 8~ Air cleaner case 16. Front brake hose hose 2. Clutch cable 9. Fuel tank water 16. Aecovery tank holder

2. Rear brake hose 9 ~ Cable holder 17. Horn 3. Clamp discharge pipe supply pipe

3. Rear brake fluid 1 O, Cable holder 18. Cooling radiator fan 4. Fuel tap suction 10.Cabtes holder 17.Front brake fluid

reserve tank 11. Clutch cable connector connection hose 11 . Starter motor cable supply hose

4. Reg u lator/R ecti f ie r 12~ Throttle cables 19. Breather pipes 5. Low fuel signal 12. Recovery tank 18. Front stop switcn

5. Clamp 13. Recovery tank 20. Rear brake master connector cable breather pipe cable

6. (-) cable supply hose cylinder 6. Earth cable 13. Instrumentation 19. Front brake hose

7. Battery bleeder lighting connector 20 .. Front lamps

pipe cable assembly cable __ ---- - 1 1 4

5

10

6

9 7

8

CABLES ROUTING SPEC P f

1

2

6

11 12 13 14

7

8

9 10

3

4

5

22 21 20 19

18 17 16 15

2-31

17 ~-----.

~~-13 ---- 14

1a~:.....,...-- 19~-- 20~--

21---

----- 15 ...____~~ 12

16

2-32

INSP ADJ

CHAPTER 3°

PERIODIC INSPECTION AND ADJUSTMENT

PERIODIC MAINTENANCE/LUBRICATION INTERVALS. " " " ~ ~ ~ " " " " ~ " " " " " _ " " " "" 8 .. 15

SEATt FUEL TANK AND REAR COWLING - ~ " " " " - - " " " " ~ ~ + •••• + + ~ ••• " + + " " " •• _ 8-16 A EMOV AL AN D J N ST ALLA TIO N ~ ~ " " " " ~ ~ + • " • ~ + + •••• ~ ~ ~ " " " " __ " " " " _ " " " " "" 8-16

cow LrNG """"."""" - ~ " " " ~ " " " " - " " " " " " ~ ~ . " " . ~ + + • " • ~ + + " " " " r ~ " " " " " r " " " " ~ ~ ~ ~ C-1

R EM OVA L AN D I NST ALLA lION " ~ ~ ~ ..... + + + • " • + ~ ~ " " " " " ~ " " " " " _ • " " " ~ ~ " " "" C-1

ENG I N E . + ~ • " " ~ + + ••• + + •••• + + " " " " r r ~ " " " " " - " " " ~ ~ ~ " " " • + + ••••• + + " " " " ~ ~ " " " "" C .. 2

V AL V E CL EARANCE ADJ USTM ENT "_""""" ~ ~ " " " ~ + + •••••• + ~ • " " • ~ " " r " __ ~" C.r2

DR rVE CHA I N ADJUSTMENT " " - ~ ~ " " " " ~ ~ ~ " " " + ~ ~ •••• + ~ ~ " " " ~ ~ " " " " _ ~ " " " " ~ _ C-3

10 L ESP E ED A OJ U S TM EN T + • • • + + + • • " • ~ ~ " " " " " _ ~ " " " " _ _ " " " " ~ ~ ~ " " • + + • • • •• C-3

THROTTLE CABLE FREE PLAY ADJUSTMENT ~ ~ " " ~ . ~ + ~ •••• + ~ " " " " r ~ " " " " ~ _ C·4

SPARK PLUG INSPECTION + •••••• + • " " " " ~ " " " " " ~ " " " " " • ~ ~ ~ " " • + + ••• + + • " •• C-4

I G N IliON TI MIN G CH ECK " " __ ~ " " " " " ~ + " • " • + + •••• + + ~ " " " r __ ~ " " " " ~ " " " " ~ ~ ~" C-5

CO M PRE S S ION r N S PEe Tr 0 N + • • " " • + ~ • " " " r _ " " " " ~ _ _ " " " " ~ ~ ~ " " • • + + " • • + + +. C - 6

ENG I N E 0 I L LEVEL CHECK " " ~ ~ . " " " " + + + • " • ~ + • " " " r __ " " " " ~ _ ~ " " " • ~ " " " " ~ ~ ~ C-7

ENG I N E 0 I L A E P LA C EM E NT. . ~ + ~ • " " " ~ ~ " " " ~ _ " " " " " " + + • • • • ~ • • " • + + • " • • ~ + ~ C· 8

ENGINE OIL PRESSURE CHECK _ " " " " " ~ ~ " " " " ~ . " " " .. ~ + • " " " • ~ " " " " " ~ " " " "" C~10

C L UTe H A OJ US TM E NT " ~ + ~ • • • • + ~ " • " " ~ ~ " " " " ~ _ " " " " " " ~ " " " " ~ ~ • " • • + • • " ". C -1 0

At R Fr L TE R CLEANING ... ~ ~ " " " " " " " " " " " _ ~ " " " ~ ~ ~ ~ " .. + + + •••• + + • " " ~ • " " "" C-11

SUCTION HOSE AND MAN1FOLD INSPECTION ~ ~ " " " r r ~ " " " " " ~ " " " " " ~ " " " " ~ ~ C-11 FU EL LIN E 1 N S PECT10N .. + + " • " " • " ~ " " " " __ " " " " ~ ~ ~ " " " • + + •••• + + • " " " ~ " " "" C-12 CRANKCASE VENTlLATION HOSE JNSPECTJON + ••• + r ~ ~ " " " r ~ " " " " " _ " " " " ~ _ C .. 12

EXHAUST SYSTEM I NSP ECTI ON . ~ + • " " " r " " " " ~ _ " " " " " " ~ ~ " " " • ~ •• _ • + + • " ". C-12

C H EC KI N G TH E COOLANT LE VEL r"""" ~ _ ~ " " " ~ ~ ~ " " " • • + + • • " • + • • " • ~ " " " "" C-12

CHANG 1 N G TH E COOLANT r ~ " " " " ~ ~ " " " ~ + + 4 •••• + ~ ~ • " ••• ~ " " " r _ " " " " _ " " "" C-13

COOLING SYSTEM INSPECTJON . " .. " " " " " ~ " " " ~ __ " " " " . ~ + + " •• ~ + •••• ~ ~ • ". C-14

CHASSIS " + + •• " r ~ " " " " _ " " " ~ ~ ~ ~ " •• + + ••• " ~ ~ " " " r __ " " " " ~ _ ~ " " " " + ~ " " • + + •••• + + C-1S

FRONT BRAKE A OJ US T MEN T ~ " " " " " ~ ~ " " " ~ ~ " . . " ~ + + + • " " • ~ " " " " r " " " " _ ~ " "" C-1S

REA R BRAKE ADJUSTM E NT " ~ ~ " " " ~ + + • " •• ~ " " " " " r _ ~ " " " " r " " " " " ~ " " • + + •• " C-1 5

B RAKE FLU I D LEV E L C HE C K. + ~ " " " " r ~ " " " " _ ~ " " " " " ~ ~ • " " • + + • " • ~ • " • • ~ ~ " "" C -16

BRAKE PA D WEA R I NSP ECTI ON ~ " " " . + •• " " ~ ~ ~ " " " " " " _ " " " " ~ " " " " ~ " " " ~ ~ ~ "" C-16

B A A K E HOSING INSPECTION . . + • • • • + + • " " _ _ ~ " " " " " ~ ~ " " " " ~ ~ " " • ~ ~ • • • + + •• C-1 6 B A A K Eel R C U J T BLEEDING ~ " " " " ~ " " " " ~ ~ " " ~ ~ ~ ~ . . . . . . ~ ~ " " " ~ " " " " r " " " " ~ _ "" D .. 1

DRIVE CHAiN TIGHTNESS INSPECTION AND ADJUSTMENT" " " " + • " • + + 0-1

DR I V E CHAt N LUBR leA TJON " " " " " ~ ~ " " " + + ••• + + + + • " " " " ~ " " " " • " " " " ~ " " " " ~ ~ ~ 0-2

FRONT FORK INSPECTrON ANO ADJUSTMENT ~ " " " " " " " " " " ~ _ " " " . ~ ~ . " ~ + + •• 0-2 SHOCK ABSORBER INSPECTION AND ADJUSTMENT" " ~ " " " " ~ " " " _ ~ . " ... + •• 0-3

INSP ADJ

S TEE R I N G J N S PEe TI 0 N ~ . . . ~ " " r r r - ~ " " " " " " " " " " " " " ~ ~ + • • _ " " _ " ~ + 4 " _ _ • 4 • •• D ... 4

TV REI N S PEe TI 0 N " " . + ~ • " • + ~ ~ " " " - ~ ~ ~ " " " " " ~ ~ - - ~ " " " ~ ~ 4 • + 4 • ~ • ~ _ " ~ ~ ~ ~ ~ "" D-5

W H EEL INS PEe TI 0 N ~ - ~ " " ~ ~ " " " ~ ~ - ~ " " " " " . . . . . . ~ . . . . . ~ . . ~ " _ " _ _ . . . ~ ~ " "" D-6 CAB L E 1 N S PEe T ION AND L U B R I CAT tON ~ + ~ ~ + + ~ ~ ~ ~ • ~ • + + • • • ~ • • • _ _ " ~ • • • • • ~ 0-6

LEV E A AN 0 P ED ALL U B R' CAT ION + ~ • • • " + ~ ~ ~ _ • " r • " • " " r • ~ " r _ " _ " ~ ~ • • ~ • • •• D-6

SID E STAN D L U B RIC A TI 0 N " _ _ ~ " " " _ _ " " " ~ _ _ _ _ _ " " " " ~ " " " . . ~ ~ ~ . . ~ 4 • 4 • • • ~ "" 0 .. 6

A E A A SWI N G A A M L U B A J C A TI 0 N " " ~ - ~ " " " " - - ~ - ~ ~ " ~ ~ ~ ~ 4 • • • ~ 4 • ~ 4 • 4 • • " • _ "" 0- 6

E LEe TR I C A LS. . . . ~ " " " r - - " " " ~ - - " " " - - - ~ " - - - " " " " ~ " ~ - ~ ~ " • • • • ~ ~ 4 • ~ ~ • + • • 4 • _ "r 0 ... 6

HEADLfGHT: LAMP REPLACEMENT AND SETTING ~ ~ . " ~ + ••••• ~ 4 •• ~ •• ~ r _ " _ ~ D"6

FUSE INSPECTION AND REPLACEMENT" " " r " " " " ~ ~ ~ _ ~ • ~ " • ~ ~ • ~ + 4 • ~ • • •• 0 .. 7

B A TIE A YIN S PEe TI 0 N """ ~ ~ " " " " - ~ " " " ~ ~ + ~ • 4 4 4 ~ + + • • • • • • • • • • • • ~ • • " r " " _ ~ 0-8

INSP PERIODIC MAINTENANCE/LUBRICATION INTERVALS ADJ

'--- __ __..L,_-----~

PERIODIC INSPECTION AND ADJUSTMENT

INTRODUCTION

This chapter lists the procedures necessary to perlorm the recommended inspections and adjustments. Observance of these preventive maintenance procedures will ensure proper functioning and longer life for

the vehicle.

The need for general overhauls will also be considerably reduced.

The information which follows applies to motorbikes already in use and new ones ready for sale. All maintenance personnel should be familiar with the instructions contained in this chapter.

PERIODIC MAINTENANCE/LUBRICATION INTERVALS

EVERY

AFTER

PART NOTES RUNNING 6~OOO km 121000 km

11000 km (4!000 mi) (StOOD mil

(600 mil or 6 months or 12 months

Valves' Check valve clearance. 0 0 0

Adjust if necessary.

Spark plug Check conditions. 0 0 0

Clean or replace if necessary,

Air filter Clean. Heplace if necessary+ 0 0

Carbu rstor" Check idle speed 0 0 0

and starter.

Adjust ~f necessary.

~.

Fuel Une* Check fuel pipes condition. 0 0

Replace if necessary.

Engine oil Replace (heat engine prior to 0 0 0

dumping oil),

Eng! ne oil tilter' Replace filter element. 0 0 0

Cooling system Check coolant leakage. 0 0

Repair if necessary.

Replace coolant every

24~OOO kms (16,000 rni)

or 24 months

Brakes: Check functioning/fluid/leakage. 0 0

See NOTE.

Correct if necessary.

C1utch Check functioning. 0 0

Adjust if necessary.

--- ._ --- --------

Rear arm Check that the rear arm unit is not 0 0 0

axle' loose.

Co rrect if n ecess ary ~

Grease moderately r 1r~ 11 3-1

[ 8-151

INSP PERIODIC MAINTENANCE/LUBRICATION INTERVALS ADJ

L....-~~:...........1. __ --J

EVERY

AFTER

PART NOTES RUNNJNG 61000 km 12~OOO km

1,000 km (4.000 mil (StOOD mi)

(600 mi) or 6 months or 12 months

Rear suspension Check functioning. 0 a

connection pins'" Grease

moderately. ** *

Wheels* Check balancingldamage/run-out. 0 0

Repair if necessary.

Wheel bearings* Check bearing clearance/damage. 0 0

Replace if necessary.

Steering bearinqs" Check bearing clearance. 0 0

Correct jf necessary ..

Lubricate moderately every

24JODO km (16~OOO mi) or 24 months

Front fork* Check functioning/oil leakage. 0 0

Repair if necessary.

Rear shock Check functioning/oil leakage. 0 0

absorber: Repair if necessary.

Drive chain Check chain slack/alignment+

Adjust if necessary, Every 500 km (300 mil

Clean and lubricate the chain.

Fittings/ Check all frame fittings and fasteners .. 0 0 0

fasteners' Tighten if necessary.

Side stand' Check functioning. 0 0 0

Repair if necessary.

Side stand Check functlonlnq. 0 0 0

switch' Clean or replace if necessary, **

Maintenance work on these elements should be performed by a Yamaha dealer. Medium-consistency bearing greaseL

Lithium soap-based grease.

NOTE:

Brake fluid replacement:

1. After disassembling the master and caliper cynncers. replace the brake fluid .. Check the Jever of the fJuid regularly and top up if necessary.

2. Replace the gaskets inside the master and caliper cylinders every 2 years.

3. Replace the brake hoses every four years or when they are cracked or damaged.

3·2

INSP SEAT, FUEL TANK AND REAR COWLING ADJ

L...---_"";;;;;.._...L __ ......"

SEAT, FUEL TANK AND REAR COWLING

2

3 9

14

3-3

18-16]

INSP SEATJ FUEL TANK AND REAR COWLING ADJ

'--_';;'____';;;;~-.....,_..___'

JOB INSTRUCTION CHART

Order Job name/Part name QJy Remarks

Removal of seat, fuel tank Remove the parts in the order.

and rear cowling The seat removed, fuel tank and rear cowl-

ing may be removed IndJvJdually ..

1 Key 1 NOTE:

2 Seat 1 Turn the key anticJockwise to remove the seat

and clockwise to reinstaH it

3 Screw 1

4 Screw 1

5 Fuel pipe 1 NOTE:

Before removing the fuel pipet close the tap by

turning the ring nut screw tightly clockwise.

6 Suction pressure intake pipe 1

7 Low fuel warning light 1

connector

a Tap water discharge pipe 1

9 Fuel tank 1

10 Screw 2

1 1 Pressure fasteners 2 NOTE:

Press down the rear cowUng extrernltles.

12 Pressure fasteners 2 NOTE:

Widen the rear cowting body sides carefully.

13 Taillight connector 1

14 Rear cowlinq 1

Reverse the removal procedure for in"

stallation .. 34

INSP COWLING ADJ

L.......,;"".....;.;....;;.........;;;....--"- __ __.

COWLING

1

2

7

.to.......... I

J

t

I

13

.

. j\ /

...... · ... 7--.-

....... 1 r

" ...

C'/ , • ...,

... .

" .... 0 f

/ 0 oj

8

5

6

/ i /~,

o / 1

J .

o I

1 1

-----

10

3

16 r/

15

12

3-5

[ C-1 I

INSP COWLING ADJ

......__-..........iiii ....... __ ---'

JOB 1NSTRUCTION CHART

Order Job name/Part name Q.ty Remarks

Removal of cowling Remove the parts in the order shown.

The right and left semifairings may be

removed separately.

1 Nut 2

2 Rear view mirror (R) 1

3 Screw 1

4 Screw 1

5 Screw 2

6 Side panel (R) 1

7 Nut 2

8 Rear view mirror (L) 1

9 Screw 1

10 Screw 1

11 Screw 2

12 Side panel (L) 1

13 Window front 1

14 Screw 1

15 Screw 2

16 Air flap 1

Reverse the removal procedure for lnstal-

lation .. INSP VALVE CLEARANCE ADJUSTMENT ADJ

'--- ""-- __ __~

ENGINE

8

"--..:=- -c ,

10

VALVE CLEARANCE ADJUSTMENT

NOTE:

• Valve clearance must be adjusted when the engine is at ambient temperature.

• Adjust valve clea ranee with the piston under compression at top dead centre.

CAUTION~

When removing the spark prug and tappet cover, be careful not to drop foreign objects inside the

•

engine.

A WARNING

Hold the motorcycle firmly in place to prevent it fall i n 9 over during the operation.

1. Remove:

• Seat

• Fuel tank

• Cowfing

• See the section '~SEAT! FUEL TANK AND REAR COWLINGII and IICOWLING".

2~ Remove:

• Screws (1) (2) (fastening the radiator)

• Screw (3)

3. Remove:

• Radiator (4 ) (disconnect the electric connector)

4. Loosen:

• Carburetor manifold clamps (5)

5. Remove:

• Air cleaner case assembly (6)

• Air pa nel (7)

6. Disconnect:

• Spark plug cap

7. Remove;

• Spark plug

• Tappet cover (8) (suction)

• Tappet covers (9) (exhaust)

8. Remove:

• Cap (10)

• Cap (11)

3-7

I C-~ I

INSP VALVE CLEARANCE ADJUSTMENT ADJ

'------.....__-_ .......

9. Turn:

• Driving shaft anticlockwise (using a wrench)

10+ Align:

• Reference mark "T" on the flywheel (1) with the fixed reference mark on the crank .. case (2)

NOTE:

Check that the piston is under compression at top dead centre.

(3) Ignition timing reference mark

11 ~ Check:

• Valve clearance using the special gauge (1 )

Out of specification ~ Adjust.

. .....

.....

.. . :., ..

Valve clearance (cold):

Suction: 0.10-0.15 mm Exhaust: 0.15-0.20 mm

12~ Adjust:

• Valve clearance

Adjustment:

• Loosen the lock nut (1).

• Fit a thickness gauge (2) between the rocker arm and the valve stem.

• Turn the adjuster (3) clockwise or anticlockwise using the special tool (4) to obtain the required clearance.

Special tool:

PIN .. YM .. OB035 PIN. 90890-01311

• Holding the adjuster firmry in place, lock tighten lock nut

Lock nut:

14 Nm (1 ~4 mkg)

3-8

INSP VALVE CLEARANCE ADJUSTMENT ADJ

• Measure valve clearance+

• rf the clearance is incorrect repeat the previous steps to achieve the required value.

13. Reassemble:

Reverse the removal procedure.

• Caps

• Ta ppet cove r (s uction)

• Tappet covers (exhaust)

• Spark p!ug

Tappet cover (exhaust): 12 Nm (1.2 mkg)

Bolt (tappet cove r-s ucti 0 n): 10 Nm (1.0 mkg)

Spark plug:

18 Nm (1.8 mkg)

14. Connect:

• Spark plug cap

15. Reassemble~

• Air paner

• Air cleaner case assembly

• Radiator

• Thermostat assembly

• Fuel tank

• Seat

• Cowling

• See the section i~SEAT. FUEL TANK AND

REAR COWLING" and '~COWLING".

Bolt (a ire leaner case): 5 Nm (0-5 mkg)

Carburetor manifold cramp (L): 2 Nm (0.2 mkg)

Carburetor manifold clamp (R): 5 Nm (0.5 mkg)

Bo It (rad iato r):

10 Nm (1.0 mkg)

Bolt (thermostat assembly): 10 Nm (1.0 mkg)

Screws (fuel tank):

10 Nm (1.0 mkg)

Screws (cowling):

10 Nm (1.0 mkg)

3-9

[ C~~ I

DRIVE CHAIN ADJUSTMENTI INSP IDLE SPEED ADJUSTMENT ADJ

..__----"_........._____.

DRIVE CHAIN ADJUSTMENT

The drive chain does not need to be adjusted.

JDLE SPEED ADJUSTMENT

1 . Start the engine and let it heat.

2. Connect

• The inductive engine speed indicator to the spark plug cable.

Inductive engine speed indicator:

PIN. YU-oa036-A PIN. 90890-03113

3. Check:

• The engine idle speed

• Out of specification 4 Adjust.

Engine idle speed: 1,250-1 t350 rpm

4. Adjust:

• Engine idle speed

1

Adjustment:

• Turn the air adjusting screw (1) until it is slighUy locked.

• Unscrew the air adjusting screw by 3 turns aprox.

Air adjusting screw:

Unscrew by 3 turns aprox.

• Turn the throttle stop knob (2) either way to obtain the engtne idle speed required.

Increases idle speed

Screwing

Unscrewing Decreases idle speed

..

_ ..... i~

5. Disconnect:

• Inductive engine speed indicator

6+ Adjust:

• Throttle cable free play

See the section ~ITHAOTTLE CABLE FREE PLAY ADJUSTMENTtI,

Throttle cable free pray: 3-5mm

3-10

INSP THROTTLE CABLE FREE PLAY ADJUSTMENT ADJ

L....- __ ----L __ ___'

THROITlE CABLE FREE PLAY ADJUSTMENT

NOTE:

Before ad justing the th rattle ca bl e free play, adjust the engine idle speed.

1. Check:

• Throttle cable free play (A)

• Out of specification ~ Adjust,

Throttle cable free pray: 3~5mm

2. Remove:

• Seat

• Fuel tank

• Air cleaner case

• Air panel

• See the section ·~SEAT, FUEL TANK AND REAR COWLINGlI and i'VALVE CLEARANCE ADJUSTMENT".

3, Adjust:

• Throttle cable free play

"

Ii

. ·i·· ...

:' ~ .... Zi-~ •• ,~, .'. • ~

, ...;.--::~'. . .

. ~ ---.,. ,..-: ..

. .-~.. . "... . p" .. ..tJ/!I1if'. ,

.. - . ~.

Adjustment:

• Loosen the 1 throttle cable (2) lock nuts (1).

• Turn the adjuster (3) clockwise or anticlockwtse to obtai n the req ui red free pl a y .

• If after Joosening the adjuster by 5 mm, the free play is sti II not correct, tiqhten the adj uster ( 4) on the 2 th rattle cable (5) once more.

• Tighten the lock nuts,

(1}1 (6) Lock nuts

3-11

I C-4 I

THROTTLE CABLE FREE PLAY ADJUSTMENTI INSP SPARK PLUG INSPECTION ADJ

.___......,_____;;;;,---"--__.

4. Reassemble:

• Air panef

• Air cleaner case

• Fuel tank

• Seat

Bolt (air cleaner case): 5 Nm (0 .. 5 mkg)

Carburetor manifold clamp (L): 2 Nm (0 .. 2 mkg)

Carburetor manifoJd clamp (R): 5 Nm (0.5 mkg)

Screws (fuel tank):

10 Nm (1 .. 0 mkg)

SPARK PLUG INSPECTION

1 ~ Remove:

• Seat

• Fuel tank

• Air cleaner case

• Air panel

• See the section I~SEAT! FUEL TANK AND REAR COWLINGn and IrVALVE CLEAR ..

ANCE ADJUSTMENT'

2. Disconnect:

• Spark plug cap

3. Remove:

• Spark plug

CAUTION:

When removing the spark plug, be careful not to drop foreign objects or dirt inside the engine.

4~ Inspect:

• Type of spark plug incorrect ~ Replace.

Standard spark plug:

DPR8EA·9 (NGK), DPR9EA-9 (NGK)

5. Inspect:

• Electrodes (1 ) Wear/Damage -+ Heplace.

• tnsulator (2)

Abnormal insulator colour -+ Replace the spark plug.

Normal insulator (2) colour is light tan.

3-12

INSP SPARK PLUG INSPECTION ADJ

'--- ......._ __ ....6

6. Clean:

• The spark plug with a suitable tool and a steel brush

7. Measure:

• Spark plug electrode gap {a) Use a wire or thickness gauge Out of specification ~ Regap.

Electrode gap:

O.a.-O.9 mm

8. Tight:

• Spark pluq

Spark plug:

18 Nm (1.8 mkg)

NOTES~ ~ _

• Before installing the spark plug, clean the surface and thread.

• Tighten the spark plug by hand before torquing to speci tication.

9. Connect:

• Spark plug cap

10. Install:

• Air panel

• Air cleaner case

• Fuel tank

• Seat

Bo It (air cleaner case): 5 Nm (0.5 mkg)

Carburetor manifoJd clamp (L): 2 Nm (0.2 mkg)

Carburetor manifold clamp (R): 5 Nm (0.5 mkg)

Screws (tuet tank):

10 Nm (1.0 mkg)

[ C-S I

\(.. .. ___.. , _.-~ -.-- .

c:--:'""- l ,. _;'~l:' :,·~:·~~~·.:Y .. /1;~-. ~ \.

p ') .... -- f· )' 1

n----=:· - .'. A;-'· »; ,.' , 111 l

~\ _j (' .. r .-:.=-=.~ ... ~,_~~ /.... '\ r /; .. _ - .v : , . .~ ..... ,

·\I~ i'~f.Qf~~::#;~'~~kJr:0\.l~ .. .:

\ I i 1; ...... ~. . , ' I tJo .., ,

~ \ _A . ..o;.::-;'''~. (\ _. ·0· . :..~:;__='\ /' .. . , L

\ \ - ...... :.-...; ~ .. , ,. . .. :. --...( .... \ -t: / '. \

1 ' .... \1'.1 ~ /::. "' ~ . J . .' ' ~

-~ .. ( ·.~\l~··:::rl'···. t·, !" ' e .:V~.oIJ.' '! \

',~ .~. '. '~·I I ... I. • .: : "... - '-...

~ ~ L~· 1'\ II!. '\ 1 • , • • •• _... • -,

............ ' _ I I. 1 1 •

1 T·.· . .. I ~ ~. ... .•. • . •.. c -. 1

\ -:,. -_ .. "¥.--:? I·. -, -/.'. . . u ~.-.

\ S·:·."':I <:: _··ti·l) '<:'. . ... :._:::::-.> .: 1- .I- • • 1 _. : •• - J ./

~ ~ ... I..·_' ......___ .' . - ,I

\ :;~ .. ~~/ '~>< ... ·~j~·~~:2-~q~c~'l

~ - ~.\ -, .. .\_.----1 r- _. -'i(_ - "I.~- ~4' '\' ~

.. .-.... ••.. '. ~.. .... :-1 f-'-::: .. "~I· ~.'

....... ;~ , ) ~ .. ' • .1' I" (~_ ... J 1

. ~... __ ) ( (I ~

::;-.... _ .. ~.-.' ,/_.' J. __ .. ~ ... ~,

~::.- -.{ <, ·1 ""liT ~

---- - .. ~:"""7" ~ •••• :. ;.-

- .

....... : : .. :: ::: ...

... .... :-. -r: :: •••

.......... :.; ...

l

................ :.

)

. . .... !

"-~

.. ~

... : .~

INSP IGNITION TIMING CHECK ADJ

.....__ __ ----a. __ -----I

IGNITION TIMING CHECK

NOTE:

Before checking the ignition timing adjustthethrott!e cable free play and the engine idle speed.

..... P'.............................. mzz IF FE

1. Start the engine and let it heat

2. Connect

• Inductive rev. counter

• Stroboscopic lamp to spark plug cable

Inductive engine speed indicator:

PIN .. YU-08036-A PIN. 90890 ... 03113

Stroboscopic lamp:

PIN. YM .. 332n .. A PIN .. 90890-03141

3. Remove:

• Cap (1)

CAUTION:

In certain conditions, the oil might spray out when the cap is removed .. Be careful therefore when removing the cap.

4_ Check:

• Advance ignition

Check:

• Heat engine and let it run to the number of revs required.

• Check that the firm reference (1) is in the field of reference mobile (2) on the llywheel.

Incorrect iqnition tirninq "'+ Check the ignition coil unit.

NOTE:

Ignition timing cannot be adjusted .

5. Install:

• Cap 6~ Remove:

• StrobOSCoP4C lamp

• Inductive engine speed indicator

3-14

JNSP COMPRESSION INSPECTION A OJ

'----~----....,.... ............... --.---

COMPRESSrON INSPECTION

NOTE:

Insufficient compression causes a loss of performance.

A WARNING

Set the motorcycle firmly in place to prevent it falling during the operation.

1. Rernove:

• Seat

• Fuel tank

• Air cleaner case

• Air panel

• See the section HSEAT1 FUEL TANK AND REAR COWLING" and ~'VALVE CLEARANCE ADJUSTMENT.

2+ Check:

• Valve clearance

Out of specifica t ton -+ Adj ust.

See the section IIVALVE CLEARANCE ADJUSTMENT'1.

3. install:

• Auxil ia ry fuel tan k

4. Start the eng ine and Ie t it h ea t • Stop the engine

5. Disconnect:

• Spark plug cap

6. Remove:

• Spark plug

CAUTION;

When removing the spark plug, be careful to prevent foreign bodies from dropping inside

the engine.

7. Apply:

• Pressure gauge (1)

• Adapter (2)

Pressure gauge:

PIN. YU ... 33223 PIN. 90890-03081

Adapter:

PIN. YU .. 33223-3 PIN .. 90890 .. 04082

3-15

I e-6]

lNSP COMPRESSION ADJUSTMENT ADJ

""'__--_""'_ __ ......J

8~ Check:

• Pressure under compression

Check:

• Check that the battery is fully charged and rev the engine with the starter. Hold down the accelerator until the reading on the pressure gauge is stable.

.a WARNING

Wh ile operating the starter, disconnect the spark plug cap to avoid sparks.

• Compare the pressure reading with those in the table.

Pressure under compression (at sealevel):

Standard:

1 t 100 kPa (11 kg/cm~, 156 psi)

Minimum:

900 kPa (9 kg/cm2, 128 psi)

Maximum:

1 t200 kPa (12 kg/cm2~ 171 psi)

• If the pressure reading is lower than minimum:

1 ) Add a few drops of oil to the cyl i nder th rough the hole in the spark plug.

2) Measure the compression agarn.

3) Compare the new reading wtth the first then proceed according to the indrcations in 1he table.

Pressure under compression (after adding oil to the cylinder)

Pressure same as before.

Piston worn or damaged.

Reading

Diagnosis

Pressure higher than before.

Cylinder head or piston rings, valves, gaskets may be taulty,

.... ----~~--+---~~~~-~----1

Inspect cylinder head, valve surfaces, piston

rim to check for carbon deposits.

Pressure above maximum value.

9~ Remove:

• Auxiliary fuel tank

• Pressure gauge (with adapter)

10. lnstall:

• Spark plug

See the section 44SPARK PLUG JNSPEC ..

TIONYJ•

11. Connect:

• Spark plug cap

12. Reassemble:

• Air panel

• Air cleaner case

• Fuel tank

• Seat

Bolt (a ir clea ner case): 5 Nm (0.5 mkg)

Carburetor manifold clamp (L): 2 Nm (O.2 mkg)

Carburetor manifold clamp (R): 5 Nm (O.S mkg)

Screws (fuel tank):

10 Nm (1.0 mkg)

3-16

I

INSP ENGINE OIL LEVEL CHECK ADJ

......_--_........_ __ ___.

ENGINE OIL LEVEL CHECK

CAUT10N:

Do not put additives into the engine oil. The latter also lubricates the clutch and additives might cause it to slide.

A WARNING

Never remove the oil tank cap when the engine is hot. The boiling oir might spill over, causing burns. Waft for the oil to cool to at least 60° or thereabouts.

This model is frtted with a dry crankcase lubrication system. A feed pump delivers oil to the eng!ne; after fulty lubricatinq the latter! the oil is returned to the tank by a scavenge pump. The oil level must

therefore be checked in the oil tank.

1. Set the motorcycle level and hold it upright.

2. Unscrew the oil tank cap (1) and clean the cap stem.

3. Insert the cap sucker rod into the ta n k. Do not unscrew; simply place on the fil~er.

4. Pull out the rod and check the oil leve1. The latter must be between the minimum (3) and maximum (2) levels.

NOTE:

To check the oil lever, place the cap with the rod on the ffl fer without screwi ng it,

For an exact check, hold the cycle upright.

If the oil level is below minimum -oJ. Add of up to minimum level,

Recommended engine oil:

SHELL SUPER 4TX 20W/50

5. Reassemble the oil tank cap-

3-17

I : C:-7 I

INSP ENGINE OIL LEVEL CHECK ADJ

......_ ""--_ ......

6. Start the engine and heal until the temperature reaches 60°C or thereabouts.

CAUTION:

Never start the engine when the 011 tank is empty ..

7. Run the engine at ~dle speed for about 10 seconds, holding the motorcycle firmly upright. Turn off the engine and add oil up to the

maximum level.