Beruflich Dokumente

Kultur Dokumente

M. E Thesis - Tin Whisker Growth

Hochgeladen von

Ashu Sharma0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

144 Ansichten80 SeitenTin whiskers grow sometimes in a matter of days and ot.her times only after years to lengths up to 9 IDmo (3 / 8in.) and 0.05 - 5.8.um (2-240 microinches) in diaIlletero the mechanism of spontaneous grm.th is beleived to be a strain releif phenomenon and is affected by the temperature, atmospheric conditions, plating thicknesses and substrate, plating composition and operating bath conditions.

Originalbeschreibung:

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenTin whiskers grow sometimes in a matter of days and ot.her times only after years to lengths up to 9 IDmo (3 / 8in.) and 0.05 - 5.8.um (2-240 microinches) in diaIlletero the mechanism of spontaneous grm.th is beleived to be a strain releif phenomenon and is affected by the temperature, atmospheric conditions, plating thicknesses and substrate, plating composition and operating bath conditions.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

144 Ansichten80 SeitenM. E Thesis - Tin Whisker Growth

Hochgeladen von

Ashu SharmaTin whiskers grow sometimes in a matter of days and ot.her times only after years to lengths up to 9 IDmo (3 / 8in.) and 0.05 - 5.8.um (2-240 microinches) in diaIlletero the mechanism of spontaneous grm.th is beleived to be a strain releif phenomenon and is affected by the temperature, atmospheric conditions, plating thicknesses and substrate, plating composition and operating bath conditions.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 80

PIN WHISKER GROWTH IN

THE COMMUNICATION INDUSTRY

N.A.d. Sabbagh

A DISSERTATION

in the

FACULTY OF ENGINEERING

Presented in Partial Fulfillment of the

requirements for the Degree of

Master of Engineering at

Sir George Williams University

Montreal, Canada

April, 1973

® Wad. Sabbagh 1973

ApsTAcT

‘TIN WHISKER GROWTH IN

THE COMMUNICATION INDUSTRY

N.A.J, Sabbagh

The growth of filiform crystals (whiskers) on tin coated

surfaces can cause short-circuit feilures in electrical

systems particularly in miniaturized equipment. Tin

whiskers grow sometimes in a matter of days and other

times only after years to lengths up to 9 mm. (3/Sin.)

and 0,05 - 5.8 am (2-240 microinches) in diameter. The

mechanism of spontaneous growth is beleived to be a strain

releif phenomenon and is affected by the temperature, etmos~

pheric conditions, plating thicknesses and substrate,

plating composition and operating bath conditions.

‘The condeposition of 20-40 percent lead in the tin deposit

reduces to a minimum the hazards associated with tin

whisker growth and ensures @ reliable corrosion protection

and a good solder joint. Annealing in an inert atmosphere

at a temperature of 191°C (375°F) ~ 218°C (425°F) for 4 br

after plating retards whisker formation.

TABLE _OF CONTENTS

LIST OF TABLES

LIST OF FIGURES

ACKNOWLEDGEMENTS

ABSTRACT

I INTRODUCTION

II TIN PLATE

IIT PROPERTIES OF TIN WIIISKERS

IV MECHANISM OF GROWTH

V_ FACTORS INFLUENCING WHISKER GROWTH

5.1 Temperature

5.2 Atmosphere, Irradiation and Stress

5.3 Thickness of Tin Deposits

5.4 Substrate of Tin Deposits

5.5 Tin Plating Bath Compositions

5.6 Tin Plating Operating Conditions

5.7 Alloying Tin Deposits

5.8 Annealing

VI EXPERIMENT ON COMBINED FACTORS

6.1 Experimental Techniques

6.2 Experimental Results

6.3 Summary of Results

ii

iv

vi

n

Ww

aL

al

22

24

26

aT

28

30

41

41

43

48

VII CONTROLLING TIN WHISKERS

VIII RESTORING DEFECTIVE EQUIPMENT

8.1 The Electric Shock Treatuent

8.2 The Pressure-Vacuum Technique

8.3 Chemical Etching

CONCLUSIONS

LIST OF REFERENCES

49

51

51

51

54

55

56

i

iid

LIST OF TABLES

Table 6.1 Effect of plating operating conditions

and annealing on whisker growth from a

potassium stannate bath. 44

Table 6.2 Effect of undercoatings on whisker

growth from a potassium stannate batis. 45

Table 6.3 Effect of undercoatings and annealing

on whisker growth from a bright sulfate

bath. 46

Pig.

Fig.

Fig.

Fig.

Pig.

an owe

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig.10

Pig.

Pigel2

Fig.13

Pig.J4

Fig.15

Pig.16

LIST OF FIGURES

Relay contact spring.

Tin whiskers on relay contact spring.

Whisker growth at elevated temperatures .

Aluminum nitride-oxide whiskers.

Cobweb sapphire wool.

Average whisker thickness: 0.035 mm

(1.4 microinches).

Sapphire whiskers at grain boundaries of

east aluminum - copper alloy.

Whisker thickness: 10-30 am (400-1200

microinches).

Tin whiskers.

Diameter: 5 am (200 microinches).

Tin whiskers groying straight.

Diameter: a) 0.05am @ microinches)

b) 5.8 wm (240 microinches)

Change in directing during tin whisker

growth.

Tin whiskers growing in spirals.

Stages in growth of tin whiskers.

Tin whiskers after annealing.

Length: 2.25 mm (3/32 in.) after 4 years.

Tin whiskers after annealing.

Length: 2.25 mm (3/32 in.) after 4 years.

Bright tin deposit.

Blisters on bright tin deposit after

annealing at 191°C (375°F) for 4 hr in

nitrogen.

Brittle bright tin deposit bent after

annealing at 191°C (375°F) for 4 br in

nitrogen.

ae ww

18

“

15

19

34

35

iv

Fig.17

Fig.18

Fig.19

Fig.20

Pig.21

Pig.22

Fig.23

Fig.24

LIST _OF FIGURES(CONT'D)

Cross-section of tin plated onto a

copper undercoating on brass.

Concentration of copper, zine and tin

of tin plated onto a copper undercoating

on brass.

Cross-section of tin plated onto a copper

undercgating on brass after annealing

at 191°C (375°F) for 4 hr in nitrogen.

Concentrations of copper, zinc and tin

of tin plated onto a copper undgrcoating

on brass after annealing at 191°C (375°F)

for 4 hr in nitrogen,

Square U-shaped channels under stresses.

Whiskers on tin coatings as plated on

brass from a potassium stannate bath.

Pressure - vacuum equipment used to

remove whiskers,

Tin whiskers collected by the pressure—

vacuum technique.

37

38

40

42

at

52

53

vi

ACKNOWLEDGEMENTS,

‘The author wishes to express his deep gratitude to his

thesis supervisor, H.J. McQueen, for his guidance and

advice. Specific thanks are due to the staff in the

Northern Electric Engineering Laboratories.

vii

Apsmacr

The growth of filiform crystals (whiskers) on tin coated sur-

faces can cause short-circuit failures in electrical systens

particularly in miniaturized equipment. Tin whiskers grow

sometimes in a matter of days and other times only after years

to lengths up to 9 mm, (3/8in.) and 0,05 - 5.8 mm (2-240 micro=

inches) in diameter. The mechanism of spontaneous growth is

beleived to be a strain releif phenomenon and is affected by

the temperature, atmospheric conditions, plating thicknesses

and substrate, plating composition and operating bath condi-

tions.

The co-deposition of 20-40 percent lead in the tin deposit

Yeduces to a minimum the hazards associated with tin whisker

growth and ensures a reliable corrosion protection and a

good solder joint. Annealing in an inert atmosphere at a

temperature of 191°C (375°F) - 218°C (425°F) for 4 hr after

Plating retards whisker formation,

CHAPTER

wmnopuerron

Electrical components in the communication industry are pro-

tected by metallic finishes to increase their corrosion resis—

tance and solderability. The spontaneous growth of filiforn

metallic crystals (or whiskers) from a variety of metals (tin,

silver, copper, zinc cadmium and aluminum) and their alloys

have been reported under various conditions. These

electrically conductive filaments have been found to bridge

gaps between components and thus can cause unexplained short~

circuits in the equipment.

Whisker growth was observed on electroplated tin, zinc and

cadmium in both high and low relative humidity within periods

of days to years after plating. Figs. 1 and 2 show a relay

contact spring electroplated witli tin that grew whiskers and

vas responsible for e grounded circuit. Also some eleotro-

deposited alloys such as tin-zinc, tin-cadmiiim, tin-nickel

and tin-lead have developed whiskers. Whisker growth of

copper and silver occurred only in the presence of sulfur or

sulfur bearing materials.

At room temperature, hot-dipped, sprayed and evaporated

metals developed whiskers on metallic and non-netallic

Fig. 1 - Relay contact spring:

Magnification 1,25X.

Fig. 2 - Tin whiskers on relay contact spring.

Magnification 13x.

»

ae

Fig. 1 - Relay contact spring-

Magnification 1,25X.

Pig. 2 - Tin whiskers on relay contact spring.

Magnification 13X.

-—haflt—

Fig. 1 = Relay contact spring+

Magnification 1, 25x.

Fig. 2 - Tin whiskers on relay contact spring.

Magnification 13x.

substrates. ‘in whiskers have grown on tin films evaporated

onto paper and freshly cleaned mica but the growth process

is usually longer and the whiskers smaller. Whiskers have

also grown on bulk materials such as tin, cadmium and zinc.

Solder alloys containing 30 percent lead, tin-lead-silver

alloy containing 34 percent lead and 6 percent silver, and

tin-aluminum alloys developed whiskers, No whiskers have

been reported on lead.

At elevated temperatures, brass (65 copper - 35 zinc),

colunbium, copper, gold, iron, lead, magnesium, molybdenui,

nickel, palladium, platinum, silver, tantalum, titatium,

tamgston and zine developed whiskers “’”, Im Fig. 8 the

growth occurred at a temperature of 400°C (752°F) during a

period of 60-140 hr of heating except for lead where whiskers

appeared at 200° (392°r)®,

Whiskers have not been observed on high purity metal, such

as zone refined tin, or on single tin crystals of nominal

purity, but whiskers were observed at grain boundaries of

polycrystalline materials and on the surface of the individual

grains. Crystals in whisker fornis have been grown from non-

metallic materials such as silicon dioxide, silicon carbide,

aluminum oxide, sapphire and graphite (Figs. 4-6).

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- History of The Turks v-1Dokument210 SeitenHistory of The Turks v-1aykutovski100% (11)

- The Process of Steel HistoryDokument22 SeitenThe Process of Steel HistorydaveNoch keine Bewertungen

- 10.1 Iron-Carbide Phase Diagram - STEELS: 3SP3 - Gordana A. CingaraDokument69 Seiten10.1 Iron-Carbide Phase Diagram - STEELS: 3SP3 - Gordana A. CingaraRyan TorresNoch keine Bewertungen

- Cooling Rate Effects On The As-Cast Titanium Nitride Precipitation Size Distribution in A Low-Carbon SteelDokument8 SeitenCooling Rate Effects On The As-Cast Titanium Nitride Precipitation Size Distribution in A Low-Carbon SteelYasser TawfikNoch keine Bewertungen

- Introduction To Chrome PlatingDokument7 SeitenIntroduction To Chrome PlatingWerner SchrammelNoch keine Bewertungen

- ImportantDokument2 SeitenImportantsafgkhjkNoch keine Bewertungen

- Engineering Materials and Metallurgy: 2017 Solved Question (Apr/May) and (Nov/Dec)Dokument62 SeitenEngineering Materials and Metallurgy: 2017 Solved Question (Apr/May) and (Nov/Dec)abdur rahmanNoch keine Bewertungen

- Iti-Fitter-Multiple-Choice-Questions-Heat-Treatment-Chapter-For-Iti-Job, - Iti-Fitter-Job, - Iti-Fitter-Govt-Job PDFDokument7 SeitenIti-Fitter-Multiple-Choice-Questions-Heat-Treatment-Chapter-For-Iti-Job, - Iti-Fitter-Job, - Iti-Fitter-Govt-Job PDFJerome100% (1)

- Non Ferrous AlloysDokument18 SeitenNon Ferrous Alloysamele25100% (1)

- Physical Chemistry of Metallurgical Processes by M ShamsuddinDokument6 SeitenPhysical Chemistry of Metallurgical Processes by M ShamsuddinTacachiri Chocamani Jaime100% (3)

- Iron PresentationDokument11 SeitenIron PresentationMuaaz QureshiNoch keine Bewertungen

- Londex Strip v6 0Dokument6 SeitenLondex Strip v6 0exinno888Noch keine Bewertungen

- Chapter 27 - Surface FinishDokument8 SeitenChapter 27 - Surface FinishJaanaNoch keine Bewertungen

- Iron and SteelDokument22 SeitenIron and SteelAmarendra Hassan100% (3)

- Diploma Work Shop TechnologyDokument10 SeitenDiploma Work Shop TechnologyadarshNoch keine Bewertungen

- 41Cr4 ExplanationDokument9 Seiten41Cr4 Explanationkumar QANoch keine Bewertungen

- Day-1 LECTURE 2-Welding TechnologyDokument64 SeitenDay-1 LECTURE 2-Welding TechnologySamNoch keine Bewertungen

- Relacion ASTM CorrosionDokument4 SeitenRelacion ASTM Corrosionbgdaniel07100% (1)

- Ch11 AllProblem KeyDokument55 SeitenCh11 AllProblem KeyHarnani Sharuddin100% (3)

- Heat TreatmentDokument9 SeitenHeat TreatmentsvsddsdsNoch keine Bewertungen

- 3321902Dokument8 Seiten3321902Er Mishal GandhiNoch keine Bewertungen

- Preparation of MgO Added Iron Ore Pellets and EffeDokument13 SeitenPreparation of MgO Added Iron Ore Pellets and EffePSS PrasadNoch keine Bewertungen

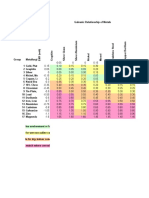

- Galvanic Relationship of MetalsDokument2 SeitenGalvanic Relationship of MetalsRay FaiersNoch keine Bewertungen

- TEQIP Mapping ReportDokument81 SeitenTEQIP Mapping ReportYASH GUPTANoch keine Bewertungen

- Handbook of Extractive Metallurgy: Edited by Fathi HabashiDokument6 SeitenHandbook of Extractive Metallurgy: Edited by Fathi Habashi1394203031Noch keine Bewertungen

- Mechismo 2022Dokument44 SeitenMechismo 2022NAGARAJUNoch keine Bewertungen

- ME3392 QB 03 - by LearnEngineering - inDokument20 SeitenME3392 QB 03 - by LearnEngineering - insanjay udhayaNoch keine Bewertungen

- Bearing Materials - Engineering Materials & Metallurgy Questions and Answers - SanfoundryDokument3 SeitenBearing Materials - Engineering Materials & Metallurgy Questions and Answers - SanfoundrySample UseNoch keine Bewertungen

- Is 2629Dokument23 SeitenIs 2629Abhishek KaliaNoch keine Bewertungen