Beruflich Dokumente

Kultur Dokumente

How To Calculate Filler Metal Consumption

Hochgeladen von

ASHIL PRABHAKAROriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

How To Calculate Filler Metal Consumption

Hochgeladen von

ASHIL PRABHAKARCopyright:

Verfügbare Formate

HOW TO CALCULATE FILLER METAL CONSUMPTION

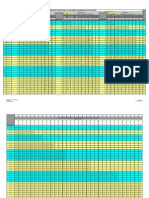

The following tables will help you estimate electrode quantity and cost for a variety of joints. The bases for

the tabulations are explained below. Should you encounter a variation in conditions or joint preparation

that is not shown in the tables, substitute appropriate figures in the W =D formula and calculate it.

Electrode requirements have been calculated as follows: 1-L

W =D

1-L

W=Weight of electrodes required

D=Weight of steel deposited

L=Total electrode losses

To arrive at the weight of steel deposited, it is necessary to calculate first the volume of deposited metal

(area of the groove multiplied by the length). Then this volumetric value is converted to weight by the

factor 0.283 pounds per cubic inch for steel. Where weld reinforcement is involved, it is added to the

requirements for net, unreinforced welds. These figures are based on the efficiency of the process used.

On square and "V" groove joints, the figures are based on stick electrode efficiency. For tubular wire

results, divide steel deposit weight by .80 and for solid wire divide by .90.

Size of fillet Steel deposited Pounds of electrodes required

L per linear foot per linear foot of weld* (approx.)

S

E (in inches) of weld (lbs.) Stick* Tubular Solid

E

1/8 0.027 .049 .034 .03

3/16 0.063 .114 .079 .07

F

I 1/4 0.106 .193 .133 .118

G 5/16 0.166 .302 .208 .184

U 3/8 0.239 .434 .298 .265

R 1/2 0.425 .773 .531 .472

E 5/8 0.663 1.205 .829 .737

3/4 0.955 1.736 1.194 1.061

1 1 1.698 3.087 2.123 1.890

*Includes scrap end and spatter loss

S Steel deposited per linear foot of Pounds of electrodes required per

Joint dimensions (in inches)

E weld linear foot of weld* (approx.)

E MTL. THICK BEAD Without rein- With rein- Without With

ROOT OPEN G

T WIDTH B forcement(lbs.) forcement(lbs.) reinforcement reinforcement**

F 3/16 3/8 0 ------ 0.088 ------ 0.16

0.020 0.109 0.04 0.20

I 1/16

0.027 0.129 0.05 0.23

1/4 7/16

G 1/16 0.039 0.143 0.07 0.26

U 5/16 1/2 3/32 0.033 0.153 0.06 0.27

R 1/16 0.050 0.170 0.09 0.30

3/32

0

1/8 1/4 1/32 ------ 0.119 ------ 0.21

1/32 0.013 0.132 0.03 0.24

E 0.020 0.199 0.04 0.36

3/16 3/8 1/16 0.040 0.218 0.07 0.39

2 1/16 0.053 0.261 0.10 0.47

1/4 7/16

3/32 0.080 0.288 0.14 0.53

Steel deposited per linear foot of Pounds of electrodes required per

Joint Dimensions (in inches)

weld linear foot of weld* (approx.)

S BREAD ROOT

E MTL. THICK WIDTH OPEN Without rein- With rein- Without rein- With rein-

E forcement(lbs.) forcements**(lbs.) forcement forcement**

T

B G

F 0.15 0.25

I 1/4 0.207 1/16 0.085 0.143 0.31 0.46

G 5/16 0.311 3/32 0.173 0.258 0.50 0.70

U 3/8 0.414 1/8 0.282 0.394

0.87 1.15

R 1/2 0.558 1/8 0.489 0.641

5/8 0.702 1/8 0.753 0.942 1.35 1.68

E 3/4 0.847 1/8 1.088 1.320 1.94 2.35

1 1.138 1/8 1.930 2.240 3.45 4.00

3

*Includes scrap end and spatter loss. **R=Height of reinforcement.

Figure 1 Figure 2

Figure 3

Das könnte Ihnen auch gefallen

- Calculation of Electrode ConsumptionDokument4 SeitenCalculation of Electrode ConsumptionhgolestaniNoch keine Bewertungen

- WPS-021, 09.07.07, Page-1Dokument2 SeitenWPS-021, 09.07.07, Page-1nidhinchandranvsNoch keine Bewertungen

- Electrodes CalculatorDokument2 SeitenElectrodes CalculatorAsebaho Badr100% (1)

- A. For Welding Sa 210 Gra1 To Sa 210 GR A1Dokument1 SeiteA. For Welding Sa 210 Gra1 To Sa 210 GR A1911targa100% (1)

- Piping Fab - Daily Report 150127R1Dokument232 SeitenPiping Fab - Daily Report 150127R1Irma MeutiaNoch keine Bewertungen

- Weld Consumable Calculator ComDokument7 SeitenWeld Consumable Calculator Comchetan85Noch keine Bewertungen

- A Guide To Estimating The Consumption of Welding Consumables-NADokument1 SeiteA Guide To Estimating The Consumption of Welding Consumables-NAManuel Antonio Santos VargasNoch keine Bewertungen

- Nozzle Weld DepositDokument4 SeitenNozzle Weld DepositmikeylesNoch keine Bewertungen

- Electrode CalculationDokument2 SeitenElectrode CalculationTejas PatelNoch keine Bewertungen

- Calculating Electrode Consumption For Pipe Per WeldDokument37 SeitenCalculating Electrode Consumption For Pipe Per WeldShankar Jha69% (13)

- Mild Steel Welding ElectrodeDokument12 SeitenMild Steel Welding ElectrodeVĩnh NguyễnNoch keine Bewertungen

- Fabrication Time EstimationDokument2 SeitenFabrication Time EstimationGlen Peter MirandaNoch keine Bewertungen

- Consumables NormsDokument24 SeitenConsumables NormsHema Nandh100% (1)

- Welding and Fabrication NoteDokument54 SeitenWelding and Fabrication NoteluminiousNoch keine Bewertungen

- Electrode Consumption On Pipe WeldingDokument2 SeitenElectrode Consumption On Pipe Weldinganjangandak2932100% (1)

- Thumb RuleDokument27 SeitenThumb Ruleavinashudupa67% (6)

- Electrode CalculationDokument2 SeitenElectrode Calculationkoyahassan100% (10)

- Electrode SelectionDokument85 SeitenElectrode SelectionVaibhavNoch keine Bewertungen

- Weld Consumable CalculatorDokument7 SeitenWeld Consumable Calculatorjappozander86% (7)

- Welder Qualification: Procedure Qualification Thickness & Dia LimitsDokument4 SeitenWelder Qualification: Procedure Qualification Thickness & Dia LimitsHoque AnamulNoch keine Bewertungen

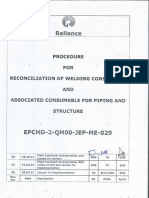

- Reconcilation of Welding Consumable and Associated Consumable For Piping and StructureDokument44 SeitenReconcilation of Welding Consumable and Associated Consumable For Piping and StructureRakesh Ranjan50% (2)

- Daily Welding Record LPDokument27 SeitenDaily Welding Record LProbby moneNoch keine Bewertungen

- Ss Pipe WeldingDokument3 SeitenSs Pipe WeldingshridharbshenoyNoch keine Bewertungen

- Electrode CalculationDokument2 SeitenElectrode CalculationKenshin HimuraNoch keine Bewertungen

- SS Pipe Fab & Erect CostsDokument5 SeitenSS Pipe Fab & Erect Costswally55bear67% (3)

- Cs Pipe Fab Amp Erect CostsDokument6 SeitenCs Pipe Fab Amp Erect CostsBudi SantonyNoch keine Bewertungen

- 1.1 Welder Test 86,350,000: PackageDokument2 Seiten1.1 Welder Test 86,350,000: PackageAhmad Dzulfiqar RahmanNoch keine Bewertungen

- How To Write A Welding Procedure Specification (WPS)Dokument5 SeitenHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- Welding Prcesses Estimation RecordDokument5 SeitenWelding Prcesses Estimation RecorddineshshankarNoch keine Bewertungen

- AWSPipeWeld - American Welding SocietyDokument2 SeitenAWSPipeWeld - American Welding Societybarukomkss100% (1)

- WPS - Api 5L X52 - Codigo Api1104Dokument1 SeiteWPS - Api 5L X52 - Codigo Api1104Cristhian Camilo Quiroga WalterosNoch keine Bewertungen

- RT Acceptance Criteria 10062019Dokument1 SeiteRT Acceptance Criteria 10062019Balkishan Dyavanapelly100% (2)

- Metal Chemical CompositionDokument1 SeiteMetal Chemical CompositionprathmeshNoch keine Bewertungen

- Electrode CalculationDokument2 SeitenElectrode Calculationtejasp8388100% (1)

- Procedure For WQTDokument13 SeitenProcedure For WQTdevikar8umNoch keine Bewertungen

- Estimate of Welding Rod Consumption - Piping StudyDokument3 SeitenEstimate of Welding Rod Consumption - Piping Studysaroat moongwattanaNoch keine Bewertungen

- N0200003 - NEW-F201-0 - Inspection & Test PlanDokument3 SeitenN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNoch keine Bewertungen

- 16 Electrode QualificationDokument11 Seiten16 Electrode QualificationAkhilesh Kumar67% (3)

- Weight Factor Plan: Project Work Package Contractor Revision DateDokument4 SeitenWeight Factor Plan: Project Work Package Contractor Revision DatescottigiancarloNoch keine Bewertungen

- Replace No.3 API Oil Separator Project: Daily Fitup ReportDokument20 SeitenReplace No.3 API Oil Separator Project: Daily Fitup Reportsajay2010Noch keine Bewertungen

- Piping Release Report (Spool For Paint)Dokument2 SeitenPiping Release Report (Spool For Paint)Siddiqui Abdul Khaliq100% (1)

- Proposal For Structural Steel WorksDokument1 SeiteProposal For Structural Steel Worksshabban4uNoch keine Bewertungen

- Böhler Welding CalcDokument2 SeitenBöhler Welding CalcMOHAN0% (1)

- Tool Fab - WorkshopDokument347 SeitenTool Fab - Workshophrdsby100% (1)

- Welding Progress MonitoringDokument13 SeitenWelding Progress MonitoringMashudi Fikri100% (1)

- Material GradesDokument1 SeiteMaterial GradesshisNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDokument15 SeitenSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalNoch keine Bewertungen

- Welder Qualification Follow ASME IX - Part 2 - Essential Variable For Welder Qualification!Dokument12 SeitenWelder Qualification Follow ASME IX - Part 2 - Essential Variable For Welder Qualification!Mahmoud Alwasif100% (2)

- Piping Daily Fit Up Quality Control and Inspection Report FormDokument4 SeitenPiping Daily Fit Up Quality Control and Inspection Report FormnguyenquanghiepNoch keine Bewertungen

- كيفية حساب كمية سلك اللحام المطلوبةDokument6 Seitenكيفية حساب كمية سلك اللحام المطلوبةMohamed AtefNoch keine Bewertungen

- Fit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemDokument1 SeiteFit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemAnonymous 0rt9KWmNNoch keine Bewertungen

- Control of Welding ConsumablesDokument6 SeitenControl of Welding ConsumablesRakesh RanjanNoch keine Bewertungen

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Dokument5 SeitenA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableNoch keine Bewertungen

- كيفية حساب كمية سلك اللحام المطلوبةDokument6 Seitenكيفية حساب كمية سلك اللحام المطلوبةBoodyBedaiwe50% (2)

- Template Painting ComputationDokument2 SeitenTemplate Painting Computationdadz mingiNoch keine Bewertungen

- Pre-Calculating Wire-Feed Speed, Travel Speed, and Voltage: Deposition Rate CalculationDokument5 SeitenPre-Calculating Wire-Feed Speed, Travel Speed, and Voltage: Deposition Rate CalculationnavasNoch keine Bewertungen

- FormulasDokument4 SeitenFormulascristiamhiguita6Noch keine Bewertungen

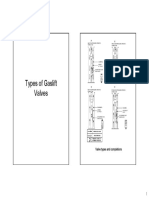

- 405.7 - Types of Gaslift ValvesDokument7 Seiten405.7 - Types of Gaslift ValvesHassan GDOURANoch keine Bewertungen

- Diamond Standard Series PDFDokument2 SeitenDiamond Standard Series PDFShag ShaggyNoch keine Bewertungen

- Alc-10030c Alcotec Alloy Selection BrochureDokument2 SeitenAlc-10030c Alcotec Alloy Selection BrochurefogdartNoch keine Bewertungen

- Tools ListDokument11 SeitenTools ListASHIL PRABHAKARNoch keine Bewertungen

- Ductile Iron Pipe Iso en Standards 5c348f95 PDFDokument24 SeitenDuctile Iron Pipe Iso en Standards 5c348f95 PDFASHIL PRABHAKARNoch keine Bewertungen

- Price Comparison Statement: BOQ Description Unit Qty ItemDokument9 SeitenPrice Comparison Statement: BOQ Description Unit Qty ItemASHIL PRABHAKARNoch keine Bewertungen

- The Implementation of A Steam Transformer PDFDokument9 SeitenThe Implementation of A Steam Transformer PDFASHIL PRABHAKARNoch keine Bewertungen

- PRO - 0699-302 - FP - 02-2020 - en - WEB 19 PDFDokument1 SeitePRO - 0699-302 - FP - 02-2020 - en - WEB 19 PDFASHIL PRABHAKARNoch keine Bewertungen

- Doha West Power Station: Rap Washing Schedule For Boiler # 7 (2018-2019)Dokument4 SeitenDoha West Power Station: Rap Washing Schedule For Boiler # 7 (2018-2019)ASHIL PRABHAKARNoch keine Bewertungen

- Ubc 2018 September Almuaisub Mohammed PDFDokument135 SeitenUbc 2018 September Almuaisub Mohammed PDFASHIL PRABHAKARNoch keine Bewertungen

- Sachidanandan Kavithakal PDFDokument332 SeitenSachidanandan Kavithakal PDFAjay J RaoNoch keine Bewertungen

- Flue Gas System Air Pre Heater: May 24, 2012 PMI Revision 00 1Dokument56 SeitenFlue Gas System Air Pre Heater: May 24, 2012 PMI Revision 00 1ASHIL PRABHAKARNoch keine Bewertungen

- Sample MECH Question Paper: KSEDokument6 SeitenSample MECH Question Paper: KSEASHIL PRABHAKAR100% (1)

- Suggested Sample Specification For Ductile Iron Pipe & Fittings For Water and Other LiquidsDokument3 SeitenSuggested Sample Specification For Ductile Iron Pipe & Fittings For Water and Other LiquidsASHIL PRABHAKARNoch keine Bewertungen

- NDT Request Form Sample DraftDokument1 SeiteNDT Request Form Sample DraftASHIL PRABHAKAR0% (1)

- Sample Experiance LetterDokument1 SeiteSample Experiance LetterASHIL PRABHAKARNoch keine Bewertungen

- Resume of A Project CoordinatorDokument3 SeitenResume of A Project CoordinatorASHIL PRABHAKARNoch keine Bewertungen

- B3 Shutdown Joint TrackingDokument10 SeitenB3 Shutdown Joint TrackingASHIL PRABHAKARNoch keine Bewertungen

- Salary Calculation SheetDokument2 SeitenSalary Calculation SheetASHIL PRABHAKARNoch keine Bewertungen

- Procedure To Get Police Clearance Certificate (PCC) From Home Country - Life in Saudi ArabiaDokument9 SeitenProcedure To Get Police Clearance Certificate (PCC) From Home Country - Life in Saudi ArabiaASHIL PRABHAKAR100% (1)

- Official IELTS Practice Materials Order FormDokument1 SeiteOfficial IELTS Practice Materials Order FormASHIL PRABHAKARNoch keine Bewertungen

- Drilling Fluids 2Dokument12 SeitenDrilling Fluids 2محمد باسم محمد حسينNoch keine Bewertungen

- Bhanu Parshad Kandel ReportDokument32 SeitenBhanu Parshad Kandel ReportSaugat ThapaNoch keine Bewertungen

- Edfa-Wdm Optical Network Design and Development Using Optisystem SimulatorDokument10 SeitenEdfa-Wdm Optical Network Design and Development Using Optisystem SimulatorJenyNoch keine Bewertungen

- Production Drawing & Pracctice Lab ManualDokument23 SeitenProduction Drawing & Pracctice Lab ManualVenkateswar Reddy Mallepally88% (8)

- Interaction With MatterDokument13 SeitenInteraction With MatterMark Gonzales100% (1)

- 69 - TD-125 Sandblasting of Tempered GlassDokument2 Seiten69 - TD-125 Sandblasting of Tempered Glasszahee007Noch keine Bewertungen

- Density of Air EquationDokument5 SeitenDensity of Air EquationaswarNoch keine Bewertungen

- IV B. TECH (Chemical Engineering) I SemesterDokument14 SeitenIV B. TECH (Chemical Engineering) I SemesterPiyush AmbulgekarNoch keine Bewertungen

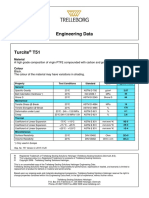

- Turcite T51 Engineering DataDokument1 SeiteTurcite T51 Engineering DataAntonio Rivera VillavicencioNoch keine Bewertungen

- What Is Camera Calibration - MATLAB & SimulinkDokument5 SeitenWhat Is Camera Calibration - MATLAB & SimulinkFreddy Doni Hutson PaneNoch keine Bewertungen

- Submersible Hydroo PDFDokument16 SeitenSubmersible Hydroo PDFtuanNoch keine Bewertungen

- Astm C39 C39M-16Dokument7 SeitenAstm C39 C39M-16Yao Leslie Armande MélissaNoch keine Bewertungen

- MCQ On MosDokument10 SeitenMCQ On MosAkshayThakur0% (1)

- Strength of Materials Laboratory ManualDokument33 SeitenStrength of Materials Laboratory ManualRock Man100% (1)

- Design CalculationDokument11 SeitenDesign CalculationShaikh Muhammad AteeqNoch keine Bewertungen

- SPE 110234 Overview of Beam Pump OperationsDokument11 SeitenSPE 110234 Overview of Beam Pump Operationsmanuel cabarcasNoch keine Bewertungen

- Short Curriculum Vitae Dr. Sushanta Kumar Panigrahi Educational ProfileDokument3 SeitenShort Curriculum Vitae Dr. Sushanta Kumar Panigrahi Educational ProfileDeepak SharmaNoch keine Bewertungen

- Problem 2.1: Solutions To Chapter 2 Exercise ProblemsDokument58 SeitenProblem 2.1: Solutions To Chapter 2 Exercise ProblemsGhazi AlArfaj50% (4)

- Simulation-Based Study of III-V (InSb) HEMT Device High Speed Low Power ApplicationsDokument3 SeitenSimulation-Based Study of III-V (InSb) HEMT Device High Speed Low Power Applicationsgodwinraj123Noch keine Bewertungen

- Figure 1. A Satellite (M) in The Equatorial Plane of The Earth (M) Experiences Only The Gravitational Force (Arrow) of The EarthDokument2 SeitenFigure 1. A Satellite (M) in The Equatorial Plane of The Earth (M) Experiences Only The Gravitational Force (Arrow) of The EarthAndika Surya BrataNoch keine Bewertungen

- Thermodynamics 1 - LN-Topic 2 (Pure Substances)Dokument8 SeitenThermodynamics 1 - LN-Topic 2 (Pure Substances)Mondaya, Jake Armond D.Noch keine Bewertungen

- NBGDokument7 SeitenNBGMuhammad B HartonoNoch keine Bewertungen

- Bostik Rheology Training Nov2nd, 2011 in AsiaDokument13 SeitenBostik Rheology Training Nov2nd, 2011 in Asiapopmart21Noch keine Bewertungen

- A New Approach To Investigate Scratch Morphology and Appearance of An Automotive Coating Containing nano-SiO2 and Polysiloxane AdditivesDokument12 SeitenA New Approach To Investigate Scratch Morphology and Appearance of An Automotive Coating Containing nano-SiO2 and Polysiloxane Additivesteaspoon2001Noch keine Bewertungen

- Optical Detectors Power Meter KingfisherDokument2 SeitenOptical Detectors Power Meter KingfisherMiguel San Román RosellNoch keine Bewertungen

- Ferroli Manual - Instalare - RLA IP - 200Dokument68 SeitenFerroli Manual - Instalare - RLA IP - 200gereseNoch keine Bewertungen

- High Field MRIDokument66 SeitenHigh Field MRIMilena RakinNoch keine Bewertungen

- Forces Acting in A DamDokument12 SeitenForces Acting in A Damfiraol temesgenNoch keine Bewertungen

- Question (Descriptive) Bank Unit - 1 and Unit-4Dokument19 SeitenQuestion (Descriptive) Bank Unit - 1 and Unit-4Ziyaul AijazNoch keine Bewertungen

- General Ser Vice Ball Valves: GB SeriesDokument13 SeitenGeneral Ser Vice Ball Valves: GB SeriesRyan DuhonNoch keine Bewertungen