Beruflich Dokumente

Kultur Dokumente

TLZ THLZ

Hochgeladen von

wiemez100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

4K Ansichten69 SeitenComefri Radial Fans have been designed specially for ventilation and air conditioning units. They offer the following advantages to the unit manufacturer: compact design for space saving installations low operational noise levels and vibration free running wide volume range and high pressure development designed for flexible applications and temperature range of -30degC to + 80degC fans.

Originalbeschreibung:

Originaltitel

TLZ_THLZ

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenComefri Radial Fans have been designed specially for ventilation and air conditioning units. They offer the following advantages to the unit manufacturer: compact design for space saving installations low operational noise levels and vibration free running wide volume range and high pressure development designed for flexible applications and temperature range of -30degC to + 80degC fans.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

4K Ansichten69 SeitenTLZ THLZ

Hochgeladen von

wiemezComefri Radial Fans have been designed specially for ventilation and air conditioning units. They offer the following advantages to the unit manufacturer: compact design for space saving installations low operational noise levels and vibration free running wide volume range and high pressure development designed for flexible applications and temperature range of -30degC to + 80degC fans.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 69

Radial Fans

comefri Radial Fans

Page

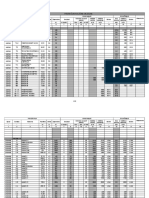

General information of the series TLZ, T-HLZ and HLZ 20

1. Fan Construction 2

2. Fan Accessories 7

3. Motor Selection "

4, Technical Information 12:15

4.1 General 12

4.2. Information on Sound Power Levels 12

4.3 Explanation of Performance Curves 3

4.3.1. Example of selection for TLZ 4

4.3.2. Example of selection for 1-HLZ and HLZ 15

5. Performance Curves 17-52

6. Dimensions and Weights

6.1 Dimensions TLZ 160 +710, TLZ 200 R + 710R 54

6.2 Dimensions TLZ710T + 1000T 55

6.3 Dimensions T-HLZ 180 + 710, T-HLZ200R + 710R 56

6.4 Dimensions T-HLZ710T = 1000T 57

6.5 Dimensions HLZ 400R = 500R 58

6.6 Dimensions HLZ 560T = 1000T 59

6.7 Dimensions T-HLZ 1120 + 1250 60

6.8 Dimensions HLZ 1120 + 1250 61

6.9 _ Dimensions of Fan Side Plates 62

6.10 Weights of Fans 63

7. _ Fan Discharge Positions and Accessories o

8 Example for Ordering 65.66

comefri Radial Fans

have been designed specially for ventilation and air conditioning units. They of-

fer the following advantages to the unit manufacturer:

* compact design for space saving installations

h efficiency operation for economic running costs

low operational noise levals and vibration free running

wide volume range and high pressure development

designed for flexible anplicatinns and temperature range of -A0°C: to + ANPC

fans TLZ T-HLZ and HIZ all dimensionally interchangeable

standardised components sized in accordance with R20 DIN 323

superb quality

short delivery from stock warehouses

prices to meet your budget

COMEFRI double inlet fans are available In the following range with dimensio-

rally identical casings

Pict Pic2

Type TL High capacity and efficiency

High capacity and eiciency Fan with backward curved implier

Fan with forward curved impeller

Forward and backward curved fans are engineered to identical dimensions for

interchangeabilty.

Fan inlet diameters are the same, as impeller diameter.

Although the fans have the same external dimensions size to size, their perfor-

mance curves vary significantly due to the different impeller design.

1. Fan Construction

1.1 Casings

All fan casings to size 1000 are manufactured from high quality galvanized

steel

oe he _rad

plates to scroll by

{Pittsburgh seam

Series TLZ size 160 up to 400 and T-HLZ 180 to 400

The casings are manufactured with Pittsburgh seams as described above.

This system gives great strength as well as ensuring leak proof jains. Predeilad

holes are located in the side plates to take either feet or frames as accessories.

These are supplied extra.

Pea

Fan casing of Fan types

‘ThZand THLZ size 460 0 710

Series TLZ and T-HLZ size 450 to 710

All casings are manufactured with Pittsburgh seams as described above and

on the inside of the side plates nuts are applied enabling easy fixina of feet

or frames by standard metric bolts, supplied as extra.

i>

ries & i; ‘i

Peng fan tp and Tn ’

Fema on neater bh. i

‘The series T bearing arrangement is shown

necessitating the frame to be suplied at an in-

tegral pertof the unit

Series TLZ and T-HLZ size 710 to 1000 and series HLZ 400 to 1000

Fans are supplied with integral bearing frames and cast iron plummer block

bearings housings; in the HLZ range this eystom start at size 560. Up to this si-

ze fans are supplied with removable frame as standard.

Pict

Fan casings of fan type T-HLZ and HIZ size

1120 t0 1400.

Series T-HLZ and HLZ 1120 to 1250

‘The fans are supplied with casings manufactured with heavy duty mild steel of

welded construction. Casings are split on the horizontal and are sunplied with

‘edge-on stiffeners. The heavy base frame is and integral part of the fan casing

providing a firm bed for the driving motor. Fans are paint finished with primer

and synthetic enamel final coat.

1.2 Fan Inlets

‘To ensure high efficiency, fans are supplied with aerodynamically shaped

fan inlets. These venturis form part of the side casing on the TLZ fans.

On fans serves T-HLZ and HLZ, the inlet cones are separate pieces, bolted to

the sideplate.

1.3 impelters

COMEFRI high efficiency impellers are specially designed to give high volu-

me and pressures whilst maintaining smooth vibration free running. Even at

hiah peripheral speeds the fans are stable. Fan impellers are statically and

dynamically balanced, in accordance with VDI 2060 and ISO 1940/1, grade G

6.3. Impeller diameters are in series R20 to DIN 323.

Pic?

High efficiency impeller with forward curved

innpeter type TLZ,

COMEFRI Fan series TLZ

‘These fans are supplied with forward curved impellers manufactured in galva-

nized shoot tool. The impollere are designed for maximum efficiency to latest

technology. Impeller blades are mounted on to a common backplate and loc-

ked onto 2 holding shroud. A substantial aluminium hub is rigidly ennnected

to the backplate and precision machined to receive the fan shaft.

Pict

High efficiency impeller with backward curved

blades type T-HLZ and HL2.

‘COMEFRI Fan series T-HLZ and HLZ

‘These fans are supplied with high efficionoy non overloading impellers

having backward curved blades. The blade shape results from research at

our test laboratory and is specially designed to give high volume and pres-

sure characteristics at high efficiency. Impellers sizes 180 to 450 are manu-

factured in glass reinforced polyamid whoroae fane above thie eize are made

from high quality mild steel. These impellers are of welded construction and

painted,

1.4 Shafts

Shafts are manufactured from high quality steel. keywayed at both ends and

at the impeller location point.

1.5 Bearings

Il fane aro cuppliod ac standard with pro groaced oosled for life ball boa

rings. These are always inspected prior to assembly to ensure quiet running

Bearings have an L10 life of 20,000 HRS at peak performance. Limiting

values for speed and power are indicated on the characteristic curves and

should not be oxoveded. Pullye chould be mounted close to the fan bea

ring. The various bearing types are described as follows.

Pico

Bearings of Radial Fan

to 710,

series TLZ size 160 up

Series TIZ size 160 to 710

Sealed-for-life bearings are located in formed support arms made from gal-

vanised steel. The bearing race is mounted in a unique rubber anti-vibration

housing which provides for sound insulation and smooth running (Pic 9).

Pic 10

: |

Bearings of Racial Fans soies T-HLZ size 180 a

fo 710 and HL cise A0OR to GOOR. ee

Series T-HLZ size 180 to 710 and HLZ 400 R to 500 R.

Bearings are similar to TLZ and are located with clamp collars.

Pie 1

Bearings for series HLZ.

Series HLZ size 560T to 1000T

Cast iron plummer blocks house self aligning ball journals. Bearings are pre-

‘teased for life but lubrication points are supplied in the housings.

Bic 12

Beating of Fan series TLZ and T-HLZ 710T to

10007.

Series TLZ and T-HLZ710T to 10007

Plummer blocks containing self aligning ball journals are used in this range.

‘The bearing being mounted onto the substantial fan frame.

Pic 13

Beating of Fan series T-HLZ and HLZ sizes

1120 t0 1400.

Series T-HLZ and HLZ sizes 1120 to 1250

‘These fans are supplied with pedestal bearings of heavy duty containing roller

bearings locked to the shaft with tapered sleeve.

2. Accessories

Alfano can be cupplicd with the following accessorice:

Pie 4

Fada Fan Type THLZ 500 wih feet,

2.1 Feet...F

Manufactured from galvanized sheet steel. The predrilled fan feet are supplied

separately with necessary fixing screws. Feet are available from fan size 160-

710.

Pic 15

Radial Fan Type TLZ 500 with outlet lange

and frame,

2.2 Outlet Flanges ...A

On TLZ fans to size 710 the outlet flanges can be supplied separately or fitted

to. custamer requirement. They are manufactured from galvanized steel and

drilled as the dimension sheets.

2.3 Fan Mounting Frames...

From size 200 to 710, separate fan frames are avallable as an alternative

method of mounting.

Pic 16

Radial Fan Type T-HLZ 225 complete with

‘outlet flange inspection door and condenss

2.4 Inspection door

Can be fitted to the fan casing and consist in a galvanized steel plate fixed

by quick release screws. Gaskots prevent leakage. For inspectian daar pasi-

tions see section 7 and 8.

25 Drain Plugs

Can be fitted at lowest point of the fan casing to Uraitt condensation. Plugs

are 3/8" gas thread and can be located in positions described in section 7

and 8.

Accessory ordering should always indicate the position required as detailed

7.2.

26 Anti-spark features

‘When colocting and inetalling fane for hazardous applications the relevant stan.

dards must be considered as sparking can occur from the following conditions:

— Contact sparking

— Heat build-up

— Build-up of electro-static

Consideration should also be given to the following:

Zone 0:

fans are not suitable for this application

Zone 1:

(Sub group G1-G3). Selection of fans in this category should take into conside-

ration the following:

— the max fan speed should be reduced by 20%

— the max shaft power should be reduced by 30%

— fans should only be selected for applications where the shaft is in the hori

zontal

— guards should have a mesh size of no more than 12 mm.

— design life of bearings at duty point should be 40000 hours minimum

— driving ropes of the anti-static type should only be used

Zone2:

standard fans described inthis catalogue are suitable.

To avoid sparking the following combinations or materials can be used:

— steel with copper or brass

— stainless steel with stainless steel

10

27 Inlet vane control

Pic 7

Inet vone contol.

Volume regulation can be achieved by using the COMEFAI inlet vane control, see

fig. 17 and 18. This energy saving device can be supplied as an integral part of T-

HLZ and HLZ fans from size 315. A special selection chart is available which is

for ueo with etandard porformance charts.

The vane controller comprises a set of adjustable radial vanes mounted inside

the inlet venturi. The vanes when set to the required angle regulate the volume

whilst directing the air into the impeller blade. The result is a considerable sa-

ving in motor power. All moving components are located inside the fan with

linkage to the outside to facilitate the adjustment of the control by either electric

cor pneumatic actuator.

Pic 18

Inlet vane central itd to fan T-HI7 BOR,

3. Motor Selection

The following safety margins should be added to the power requirements at

‘the fan shaft as shown by the performance curves.

Rating mz THz

up to 10 kW 20% 16%

over 10 kW 12% 12%

This safety margin compensate for transmission losses of the V-belt drive and

for possible minor inaccuracies in the calculation of tha system resistance.

When selecting the suitable motor special attention should be paid to the fact

that if the acceleration time of the fan is longer than the maximum accalera-

tion time of the motor the trip time of the motor starter overload must be in-

creased ar a larger motor or starter for heavy diity starting must he used.

‘The acceleration time can be calculated from:

a) in case of direct starting:

t= 12-108 dF

Paw

—

ule) — eceoaton tne

Sthgnel —mesemementot inet, J = mn BDF

nmin ~ nominal peat hefon

Py [KW] — motor rating

b) in case of A /A starting, the acceleration time compared with direct starting

155.5 times longer

"

4. Technical Explanations

12

4.1 General

The formulae, signs and Sl-units used in this catalogue correspond to the stan-

dards DIN 1301, DIN 1345, DIN 45635 and to the Eurovent-Recommendations.

O/T and 1/1.

‘Standard operating conditions for the fan performance curves:

e,

-2 kg/mm? (at 1013 mbar and 293 K (= 20°C)

4.2 Sound Levels

The measurement of noise levels are taken according to DIN 4635. For this

purpose a harmonic analyzer type 2107 and Herz-Octave Band Filter type 1615

of Messrs. BrOel + Kjaer are used. These precision measuring instruments

comply with DIN 45633. The sound power level L,., referred to W, = 10%

wart, required for calculation and design of sound absorbing units is marked in

the performance curves.

Key to Formula Symbols:

Ly — Total Sound Power Level (dB)

Ly? = Sound Power Level ata specific Octave Dand Mid-Frequency {dB}

L, — Sound Pressure Level (non-weighted) (ab)

‘Sound Pressure Level at a specific Octave Band Mid-Frequency [48]

‘Sound Prosoure Level (weighted) [aB(AN1

fn Octave Band Mid-Fraqueney THe]

AL — Difference between the total Sound Power Level L,, and the non -

weighted Sound Pressure Level L, [dB]

AL, — Difference between the total Sound Power Level L,, and the measu-

red value at the corresponding Octave Rand Mid-Frequency [aR]

AL, — Difference between the total Sound Power Level L. and to. the

weighted Sound Pressure Level Lux [dB]

‘The Sound Data of the fans is determined as follows:

1. The total Sound Power Level can be ascertained from the Performance Cur-

ves.

2. The Sound Power Level L,,* at the different Octave Band Mid-Frequencies

is determined from following equatior

Lt = by AL,

The values for ALy are given in Table 1

Table 1:

Octave Band

Mid-Frequency 1,, Hz

AL, [481 for TLZ 6} 7] 0] 12] 13] 15 | 19 | 23

AL,, [dB]

for T-HLZ and HLZ

3. The non weighted Sound Pressure Level L, of for all fan sizes at various

measuring distances is obtained from the following equation:

b= be AL

‘The values for AL are given in Table 2.

Table 2:

Distance from

the fan im 2m 3m 4m 5m

AL (a8) 6 12 15 18 20

4. The Sound Pressure Level L,* atthe diffarent Octave Band Mid-Fraquenciee

is obtained from the following equation:

bt = by AL,

The values for AL, — AL, are given in Table 1.

5. The weighted Sound Pressure Level L,,dB(A) is determined by the follo-

wing equation:

ba = Le — Ala

‘The values for AL, are aiven in Table 3.

Table 3:

Size gles alas alelsiaiaialelsiagisia

3 Tam [a0 rofso}a]rafaa} raf 2}ra) 12] 12]3fxaf1a| val ral ra) val

8 2m_|16|16|161 17/17 17] 17]18| 18] 18| 18] 19| 1919] 19|20|20|20|20

3 3 m_|19{19}12)20|20}20}20}2a}21]2a[20)22|22}2a|22\23\23\23]23

2 41m [22}29}0/2a\2a|29|2a\24|24]2]24[26]26|26|26|26)26)26)26

Z 5 m_|eal2alz4l25}25\25|25|26|26|26|26|27127127|27\28|28]2828

Please note that exact data regarding sound volume and frequency can only

be determined after assembly and operation at the place of installation as the

acoustic properties of the room, inherent frequencies as well as other oscilla-

tions and the effect of adiacent structures may considerably affect the sound

level.

4.3 Performance Curves of the COMEFRI Fans

‘The fan data, which have been determined by tests in our laboratory, according

to the latest recommendations and with high-precision measuring instruments,

are contained in the following performance curves. They show the total pressu-

re against from volume flow.

The curves indicate speed, circumferential velocity, power consumption at the

shaft and total sound power level LW.

Please note that the values indicated at the absciss, the dynamic pressure and

the outlet velocity relate to the total cross section of the fan outlet.

13

4.3.1 Selection Example of double inlet Fans with high

efficiency impeller with forward curved Diades, type TLZ

Reauired:

Volume flow V = 15000 m'/h

Total preeeure Ap, — 1000 Pa

Air density @ = 1,2kg/m?

Air temperaiure ¢ = 293 (20°C)

ems

256% 651685700

To determine: LE J

Fan size

peed

Power consumption

‘motor ouiput

Efficiency

Suuitu pressure rover

in dBIA) ata distance of 3m.

Golactad fram the Curva:

Radial Fan TLZ 500

Bs ma,

= 95 dB

= 95 — 21 = 74dR(AD

Motor rating

Sound power level

Sound pressure level

Circumferential speed a 25.9 m/sec.

Bunnie secure meh s

Static pressure Dy = 996 Fa (Totel - dynamic pressure)

Pitan alae = Wailea

Volume flow Vo = 15000 mvh

Efficiency > 06s

Absorbed power P= 6.1kW

°

ib

UE

4

4.3.2 Selecdun Example of duuble inlet Fans wi

hight

efficiency impeller with backw. curved blades, type T-HLZ

Required:

Volume tlow V = 15000 mish

Total pressure Ap, = 1000 Pa

Air density @ = 1,2 kg/m?

ie tampevatvies ¢ — 900 (2900)

To determina:

Fan size

Shand

Power consumption

Motor output,

Efficiency

Saund rraceute lavel

in dBIA) at a distance of 3 m.

Selected from the Curve:

Radial Fan T-HLZ 500

Fan speed

Circumferential speed

Dynamic pressure

Static pressure

Outlet velocity

Volume flow

Efficiency

Absorbed power

Motor rating

Souna power tevet

Sound pressure level

Radial Fan T-HLZ 500

comefri backward curved double inlet HLZ 500

i : hi

= 1800 min*

= 47.2 misec.

64 Pa

886 Pa (Total - dynamic pressure)

= 10,3 m/sec,

15000 m°/

= 0.80

DZ kW

= Py + 15%

= Bas

95 = 21 = 74dBIA)

15

5. Performance curves for Comefri Radial Fans

Series TLZ / T-HLZ / HLZ

Type

160

180

8

25

BBa

Begaees

710

88

1000

1120

1250

16

Paye

7

18-19

20-21

2-23

24 25

26-27

28-29

30:31

32.33

36-37

38-39

40-41

42-43

44-45

46-47

48-49

51

Radial Fan

forward curved double inlet

TL2Z 160

4250 min

35 kW

1800 Pa

Max. shaft ower

Mac. total pressure

umber of blades

Mais moment of ineria nt

3 ead 8heA

am?

a7

Volume

V tothh

Pes frm Wt

Outlet velocity

C2 Imnjsi

Press,

7

Radial Fan

forward curved double inlet

Max, shatt power

Number of biades

Mase mament of inertia.

Peniphral sed

7e%, 5) env 80% 900

ove

4500

2000

1800

+ 1600

[i500

[Ee

1000

Volume

V ith

PET 1a

Ps immu) | Press.

Our velocity

62 Injsi

8

Radial Fan

T-HLZ 180

z

tn aaa > |

en aie Bis

a e]2 3

case

*

vom |?

7

sc00

2

veer fH

fam 555

5

a

500

23

2000

3600

ats

3600

2400

3280

BB Pats

peas Las

. Via

ge T

Bs : z aie ae

BE a Be inmas) Press

: : Gute vetoy

epinis

20

Radial Fan

forward curved double inlet

Mex. shaft power

Number of bates

Tp nee

kW

Po

kgm?

SL 47h

900

V othr

eT om,

a tomwst | Press

Ouilet velocity

Inf

Radial Fan

bochward curved double i T-HLZ 200

2 ‘Man. spewd roe 6200 rnin? &

a | iar. shart poner roe Ww Beles

ge Max. total pressure 4p; = 2100 Pe 23 ze

a ¢ 7 martes foros 2 ° é a]? §

a3 Mass morrent of inert} ()2@2')= 0,010 _kg £3

[hh 0a Pe OT

\ 1%

(| }7 | -r0000

i Eso 95

|

; ob | Beam | ene

\ 8

be E ra00

Fes |.

000

. sso |"

F som | 535

|

jf 400 Fars

3800

\ \E 5600 fans

tf 3400

aa )

{ avi 200 33

2 * | fm

2sie | 25.5

t ars | 20

Ho \ if as [ats

— Toot 41+

500 1000 1500 2000-3000 seco

Be

es TEE BT an

ef b ' ea Aa BE uu asa) Be inst | Poss

: Wee * eed utiet velocity

3 In

a1

Radial Fan

forward curved double inlet

Max. coved

Wax, shaft powor

Wax, total pressure

‘Number of blades

Mass moment of inertia

Pome? 609 min

& 50 kW

2200 Pa

a2

J ueBs= 0028 kam?

Poriplaral sped

57% 62% 55% 4294)

Gute veroany

€p in/s

Radial Fan T-HLZ 295

: we roar 6200 mnt | | E

ig Max, total pressure Aces 2900 Po & <, =

ae , Number of Medes - 8 fe s

a9 Mass moment of inertia J ()252 aor kgm?

Pry. 4

an

L aawo | sus

E esse

ns

son

sso |

cm [59

“”

2

Laas

: [233

Red

| Outer vancy

ela

Radial Fan

forward curved double inlet

Bi enw

AL ims

i

}

Puipher! sped

ane

373

332

20.6

20.4

225

2

187

16,6

13.2

18

94

Jan toot

osu

24

noe pees ee

‘Max. shatt power Rent 5 RW i

Mex. total pressure Opps 2100 Pe t*

‘Nuroer of aves 2 38 aE

‘east mnamvenn os mertia sur@iz ugen ay? | EE

a A]

E 2000

[TF soe

oe

L sco0

| |

|| Lp

x

SLL Fsa00

‘eo

1000

om

10000 15000) veer

oo V inh

‘ 2 0. 20 300 500 ‘ooo [Pa Pe

2

2 | es inns)

| Outerveiocty

| a.

Press.

Radial Fan

backward curved double inlet

T-HLZ

250

3

Max. speed e099 min! ~ 5

) a. shaft power ao KW Pele x

‘Max, total pressure %00 Pa Pals

‘numberof biades eT é fe

amass moment of nersa J 11392) 2 902 Koni

R= 6I% 72% 76% 80% 75% 61%

= e [le p~ape pe p= pete

ToT | vad | oo | ves | 0 | vam | as | we |e [7s ae | oe] os | ee

oor | tase-| toor | wor | sre) veer | as | so | we | 75 | ase | or | ri | an | oro

oor | too | tio | rior | ess | tsea | oo | oo | w | 10 | sor | ov | aos | om | om

roo] set | amr | oor re [eee [20 | wo] ve | vo | seo | ras amt | sors | 700

tm2z[7[*>ets[+[+[~[“[*][y]ej»] a

oot | ta | wo | ot | sas |e [| aim | tao | tom | a | am | ro | nav |

woot | 125 | oor | as0 | ee | te | tart | taza | toro | toon | are | ase | ooo | 2xt00

Suet To change

87

Radial Fans Drawing

6.5

HLZ 400 R+500 R

Dimencione and technical details

%

355 [5x90

0 | 6x90

450 | 6x90

‘subject to change)

Radial Fans Drawing

HLZ 400 T+ 1000 T

- 6.6

imensions and technical details

A Hz...

mz laAT= >= [= >e>e,=Tapay>e ps pepe Le

wor | est | tor | sar | mos | ro | os | os | io | rs | p45 | 300 | sot | ae | a

sor | rea | soo | soo | aw | em | as | «| 12| 78 | 20 | soe | at | ano | oe

{ soot | aor | esa | ces | ses | oss | 25 “0 2 7s | 26 | ava | aes | sea | 301

seor | om [mis | mas) aie [re] as | so | 15 | 75 | as | ato | om | on | ae

oT | tooo | sor | ear | ato | raz | as | oo | is | rs | aro | art | seo | car | a0

[oor | tase | toor | toor | sre | 44s | as | co | | 75 | ase | ser | re | ort | soe

[ooo | set | zor [001 | r10 | s7ve [a0 [co [ve | v0 | seo | res | ome | sors | ron |

m [7 [TeTepTe ye ~~ >a % [us] an

oor [TRE | a0] Tae To a Tas ar | asa

[aor | ons | ae | om | as esi | ov v2 | 109 | 450 | 6x90

soot | 2 | ase | m1 | 3 rao_| var_| ze | 450 | 6x00

sot | is | soo | a8 | Boe sie ae eo | 205 | 500 | 7x90

rr zo0_| a7 | eo | 9x00

toot | tar | eo | ae | ee ve anit | tire za | sm | 0 | 11500 |

wor | tar | eo | ao | me | eu | tow ase [eat | eto | x t00

[oor | tae | esr [aso | ee | te [tare | suse za_| ass | woo | 2x t00

‘cxbjecte chonge

59

Radial Fans

‘T-HLZ 1120+ 1250

Dimensions and technical details

et gn condos

mzpTalaAlATal=|]e[/e,;e)elete]efe[ata

wr20 | 2050] aver | a76s | v42i | v4es | S46 | a100 | zoas | 22a | oe | ove | torr | wo | 60 | 18

Tzpaplelels= >a l[s][h[s][e]*]' [sl

[aso | 20 | as | 2040 | za70 | 770 | +170 | ose | ae | 43 | 589 | sas | sao | sooo | t40 | 215

mT pepe le fTelt pels ~~] ]* | an | ib

trad | 755] ved] 4 | 2s | Sos) as | te | ast | 600 | Tost | ware | tet | Px t2d | 11x 125

20 | eas | eve | ras | 160 | 535 | 1055 | 18 | a7ts | wore | raes | 7973 | 653 | 6x 160 | 9x 160

‘subject to change:

HLZ 1120 +1250

Radial Fans

Dimensions and technical details

Drawing

6.8

Seams?

w[ayvayalal=ye,a ;e]slale]e;e,eys

a0 ono | 1705 | Tos | 1421 | v46s | 9000 [71085] 2100 | 2100 | aie | ax2 | oer | ao | 75 | a1

waso_| sors | 2000 | aors | 1500 | 1659 | 3650 | za51 | 2005 | 2060 | 007 | wer | avo | so | 75 | 15

wle[el]slala]s]e][s[e]s]*]?]1[ufe

“ize | 25] ga | 000 | Bras | Vos_| Toso | e60_| Tosa | eso S25 | BOS | Tad | BTS | Tero | 0

7250 | 30 | 92s | aos | 2070 | 7ro_| v0 | 954 | v155 | 945 | 590 | 94s | seo | sooo | 2000) 10

mz [ete Te[eye[e[e~™[«[wfw]=]~ fafa,

Tao] tos | 7a [ors | Vas | es | os | ao | ao | wae] wo] ware | 270 | voor |x ast ws

12s0_| 205 | os [om | vas | v00 | 595 | wos | 20 | v7 | 1015 | v270 | 179 | 1059 ox 60] 10

cubjost to change

61

Radial Fans

TLZ 160 to 710 and T-HLZ 180 to 710

Side plate

Upto ew st ong

soon 88 er08 ON Te

Fans

B/8/k

a

Ba

3/8 8/8

BB) /B Ia):

318) 8/8/88] 1 |

B)g/g/8 8/8

Bg sla 88

3

SS 888 SiR ale

i Radial Fans Table

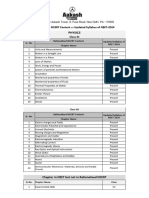

comefr TLZ, T-HLZ and HLZ 6.10

Weights

Fan and accessories weights in Kg)

2

° q 5 5

a fele] Py] ela |e} aeyé

wos os coe

m |v 72 my

as | m0 ves 2 | ow | a |=

| ms 263 «| 20 | 70 | a=

@ | m0 ar | w | 2 | 7 | v0

@ | «ao 2 |» | a7 | os | 17

wo 56.0 6.3 88 B 37 35 1.90

560 76.0 90.0 155, 24 75 158 200

om | oo me iw |» | 7 | we | 2»

™ 125.0 190 145.0 208 245, s 11.0 2.60

5 ze 2 | | « 200

~” me m [= | « aw

00 = wo | wo | 10

7 we | we

aaa to cone

63

7. Fan Discharge and Accessory Positions

‘The following positions are in accordance with Eurovent 1/1.

(

TA

72

73

Th

4 | |

t |

4

|

— be wef f— 4 ae

|

~~

te we

eto nie20

Pic 19 and 20 show right hand (RD) and left hand (LG) fans. Fan rotati

always decided whon looking from the drive side, .o. that coupled with the

‘motor. Fan discharges are therefore always described by either RD ... or

LG... followed by tho roquired outlet position (i.0. 80°).

Positions of accessories are described similarly, viewed from the drive side.

(600 7.4 and pie 19/20).

‘When inlet vane controls are specified it is essential to state the position of

the actuating arm, see 7.4.

Example of fan discharge and accessory position:

Fan diecharge LG 00°

Inspection door 135°

Drain 180°

IVC control 270°

Pie 21

8, Instructions for Ordering and Specifying

Pie 22 Pie 25

Radial Fan T1Z 400 F Fadal Fan TZ 500 RA

8.1 Allstandard fans are detailed on drawings 6.1, 62 and 63.

To order or specify fans thay must he dascrihed as follows:

Fan range either TLZ, THIZ or HIZ

Fan size which represents the diameter of impellers in mm (Le. TL7 450 or

THLZ 630).

82 Accessories are represented by the following symbols:

F =Feet

A = Outlet flange

R = Fan frame

Dr = Inlet vane contro!

| = Inspection door

= Condensation drain

Ex = Anti-Spark Feature

Fan accessories should be specified when ordering fans.

Example 1 (see Pic 22):

Fan TLZ 400 with feet TZ 400 F

Example 2 (see Pic 23):

Fan TLZ 500 with outlet flange and fan frame TLZ 500 RA.

65

&3 Fan sizes TLZ710 and THLZ 710 can be supllied as standard with or

without frames. see (6.1 and 6.3)

Pic 24 ‘se

Ordering Example.

8.4 Ordering Example

To order @ T-HLZ 355 with discharge position LG 90° plus feet, outlet flange,

Inspection door, drain and inlet vane control.

Order as follows:

T-HLZ 855 A - LG 90° | 225° Dr 0° K 180°

F355

‘The fans described in this catalogue are suitable for many and varied applica-

tions; but should you require special versions a complete technical team exists

to assist and advise.

Due to improvements which are introduced from time to time the company re~

serves the right to alter the products specified in this catalogue.

@comerri

Notes

Eat comet acer

10, Rue dee Fores Lumtre

Franco

Tol 4394-79 7003 90

Fax 1334-78 9063 75,

real Bain

Tel +4-1908:55 9¢ 68

Fax 64190858 79 86

‘wea: comefe com

Tol +1-27O-aRt 1448

ww. comet com

Das könnte Ihnen auch gefallen

- J.1. Jakka - VentilatoriDokument16 SeitenJ.1. Jakka - VentilatoriMilan ForgiariniNoch keine Bewertungen

- PSA Valves CriticalDesignFeatures MARKEDDokument41 SeitenPSA Valves CriticalDesignFeatures MARKEDdj22500Noch keine Bewertungen

- F ChartDokument7 SeitenF Charthemal4379Noch keine Bewertungen

- JULABO F25 HL Manual V6Dokument101 SeitenJULABO F25 HL Manual V6Douglas Bezerra BenizNoch keine Bewertungen

- Effect of Heat TreatmentDokument5 SeitenEffect of Heat TreatmentsupNoch keine Bewertungen

- Honeywell Rondostat Hr20 SpesificationDokument2 SeitenHoneywell Rondostat Hr20 Spesificationfrox123Noch keine Bewertungen

- Bohler PDFDokument12 SeitenBohler PDFLeandro AlmeidaNoch keine Bewertungen

- Iso TS 16829-2017Dokument36 SeitenIso TS 16829-2017RONALD ALFONSO PACHECO TORRESNoch keine Bewertungen

- 04 02 PDFDokument36 Seiten04 02 PDFIgor Ivanovski100% (1)

- Mcquay CAC Model AHU Catalog - VisionDokument92 SeitenMcquay CAC Model AHU Catalog - VisionStephen Lim0% (1)

- Technical Manual KX4Dokument352 SeitenTechnical Manual KX4George Henry100% (1)

- VENTAS - Heat - Recovery - Units CompressedDokument12 SeitenVENTAS - Heat - Recovery - Units CompressedDhio DhanzelNoch keine Bewertungen

- EN 12953-8-2001 - enDokument10 SeitenEN 12953-8-2001 - enעקיבא אסNoch keine Bewertungen

- Weishaupt Products and ServiceDokument44 SeitenWeishaupt Products and ServiceKitti WutthicharoensakNoch keine Bewertungen

- Austentite Steel Thermal StabilizationDokument17 SeitenAustentite Steel Thermal StabilizationArangamar KumaranNoch keine Bewertungen

- АрилјеМетал CatalogDokument10 SeitenАрилјеМетал CatalogAnonymous DjWqKpZ1Noch keine Bewertungen

- PATR 2510 Dictionary of Explosives Ammunition and WeaponsDokument367 SeitenPATR 2510 Dictionary of Explosives Ammunition and Weaponstotenkopf0424Noch keine Bewertungen

- Valvula de MariposaDokument12 SeitenValvula de MariposaErick HdezNoch keine Bewertungen

- Control Box - Boiler Parts - Boilerparts - Co.keDokument26 SeitenControl Box - Boiler Parts - Boilerparts - Co.keboilerpartsNoch keine Bewertungen

- Rotex Cylinder Catalogue Dia 400 To 1100Dokument6 SeitenRotex Cylinder Catalogue Dia 400 To 1100Arun Kumar KNoch keine Bewertungen

- SANHA Technical ManualDokument32 SeitenSANHA Technical Manualvineeth8624Noch keine Bewertungen

- Iecex Certificate of ConformityDokument4 SeitenIecex Certificate of ConformityFrancesco_CNoch keine Bewertungen

- TA Balancing Valve-STAFDokument12 SeitenTA Balancing Valve-STAFAnonymous FZs3yBHh7Noch keine Bewertungen

- Airtech - Pc51-Z - OrderingDokument4 SeitenAirtech - Pc51-Z - OrderingSnaider SilveraNoch keine Bewertungen

- Alfa Laval M6: Gasketed Plate-And-Frame Heat Exchanger For A Wide Range of ApplicationsDokument2 SeitenAlfa Laval M6: Gasketed Plate-And-Frame Heat Exchanger For A Wide Range of ApplicationsAnonymous Cpe6vcNoch keine Bewertungen

- 3.8. TCBL - nv01 - Proracun Kolicina Vazduha DI REV 1Dokument10 Seiten3.8. TCBL - nv01 - Proracun Kolicina Vazduha DI REV 1SrdjanNoch keine Bewertungen

- Boiler Feed Pump: Our Technology. Your SuccessDokument2 SeitenBoiler Feed Pump: Our Technology. Your SuccessJesus SamaelNoch keine Bewertungen

- Vit CFD Modeling Final ReportDokument16 SeitenVit CFD Modeling Final Reportrajeshps07Noch keine Bewertungen

- C 0024 - TLZ THLZ - 04 08Dokument46 SeitenC 0024 - TLZ THLZ - 04 08Oscar Alvitez DominguezNoch keine Bewertungen

- Comefri - TLZ-THLZ Fan Catalogue 04-08Dokument46 SeitenComefri - TLZ-THLZ Fan Catalogue 04-08João Guilherme Raimundo GarciaNoch keine Bewertungen

- Watlow AccessoriesDokument30 SeitenWatlow AccessoriesEliasNoch keine Bewertungen

- Ariel JGK and JGT CompressorsDokument5 SeitenAriel JGK and JGT CompressorsPablo GutierrezNoch keine Bewertungen

- Crosby-Pentair Omni 800, 900 DatasheetDokument24 SeitenCrosby-Pentair Omni 800, 900 DatasheetMijin28Noch keine Bewertungen

- Radial Fan Blower-RZR SeriesDokument98 SeitenRadial Fan Blower-RZR SeriesAbsar MamunNoch keine Bewertungen

- Vilter CatalogDokument28 SeitenVilter CatalogDang Anh Tuan0% (1)

- Nelson SilencersDokument4 SeitenNelson SilencerspowermanagerNoch keine Bewertungen

- Zinko CatalogDokument23 SeitenZinko CatalogJas SumNoch keine Bewertungen

- Phased Out Products: Gear Pumps and Motors General ProductsDokument18 SeitenPhased Out Products: Gear Pumps and Motors General ProductsAndrei VladNoch keine Bewertungen

- CatalogueDokument429 SeitenCatalogueHarkamal SinghNoch keine Bewertungen

- High Pressure Blowers 1Dokument11 SeitenHigh Pressure Blowers 1Miroslav Aleksic100% (1)

- Válvulas Bola SegmentadaDokument12 SeitenVálvulas Bola SegmentadarehynaldoNoch keine Bewertungen

- LC SCDokument28 SeitenLC SChardik033Noch keine Bewertungen

- Presented By: Sarikh Khan Roll No. 1001140040 B.Tech VII SemDokument13 SeitenPresented By: Sarikh Khan Roll No. 1001140040 B.Tech VII Semlokesh_045Noch keine Bewertungen

- Tran Tech BrochureDokument4 SeitenTran Tech BrochureOmar Reinoso TigreNoch keine Bewertungen

- Axial Flow Fans General Information: Elta Impeller RangeDokument8 SeitenAxial Flow Fans General Information: Elta Impeller Rangehardik033Noch keine Bewertungen

- FARRIS PSV MODEL 2700 New Cat PDFDokument20 SeitenFARRIS PSV MODEL 2700 New Cat PDFPeter James Castelo0% (1)

- CT S&P-Avr13-THGT-SélectionDokument78 SeitenCT S&P-Avr13-THGT-Sélectionkasztakatika100% (1)

- High Performance Butterfly ValvesDokument8 SeitenHigh Performance Butterfly ValvesTejas JasaniNoch keine Bewertungen

- HC Centrifugal Fans - Technical Catalogue 2010 ENG PDFDokument116 SeitenHC Centrifugal Fans - Technical Catalogue 2010 ENG PDFhalder_kalyan9216100% (3)

- Best Swivel Joints CatalogDokument8 SeitenBest Swivel Joints CatalogWalter PierNoch keine Bewertungen

- DEPA DiaphragmDokument4 SeitenDEPA DiaphragmmorizoneNoch keine Bewertungen

- Worthington D1022 Pump DataSheet P-701Dokument10 SeitenWorthington D1022 Pump DataSheet P-701Andrey Pulido Barrera100% (1)

- Trick Flow Head StatsDokument15 SeitenTrick Flow Head StatsdancaleyNoch keine Bewertungen

- L&T Ball ValveDokument12 SeitenL&T Ball ValvecdsenthilNoch keine Bewertungen

- Catálogo FarrisDokument20 SeitenCatálogo FarrissueNoch keine Bewertungen

- Rotex Pneumatic Cylinder CatalogueDokument4 SeitenRotex Pneumatic Cylinder Cataloguekumar ambujNoch keine Bewertungen

- Beam Master Gleeson ReelDokument2 SeitenBeam Master Gleeson ReelhecsaorNoch keine Bewertungen

- Brosur Pompa KSB Type CLTDokument20 SeitenBrosur Pompa KSB Type CLThenryhh111Noch keine Bewertungen

- Yugos SpicerDokument20 SeitenYugos SpicerCesar SegovianoNoch keine Bewertungen

- Steam BlowingDokument21 SeitenSteam BlowingAbhishek JainNoch keine Bewertungen

- CDW3 User manual-ENDokument56 SeitenCDW3 User manual-ENJason SonidoNoch keine Bewertungen

- 6 Major Reasons For Failure of Pile Foundation!Dokument1 Seite6 Major Reasons For Failure of Pile Foundation!Martin GriffinNoch keine Bewertungen

- MSD CDokument1 SeiteMSD CbarrozomariakatrinaNoch keine Bewertungen

- Argon Purging Systems (APS), Applicable To Purging Induction Melting Furnaces and Induction PowerDokument12 SeitenArgon Purging Systems (APS), Applicable To Purging Induction Melting Furnaces and Induction Powernirav patelNoch keine Bewertungen

- Anexo 3 Seleccion Equipos Volumen Variable de RefrigeranteDokument41 SeitenAnexo 3 Seleccion Equipos Volumen Variable de RefrigerantepabloabelgilsotoNoch keine Bewertungen

- Anti Fouling Paints ComparedDokument6 SeitenAnti Fouling Paints ComparedDean Foote100% (1)

- Plate Heat Exchanger Gaskets WEBSITEDokument2 SeitenPlate Heat Exchanger Gaskets WEBSITESHAKEEL ISMAIL LAMBAYNoch keine Bewertungen

- Beta Hcs o En1 906 Inf SmallDokument3 SeitenBeta Hcs o En1 906 Inf Smallalexxxabe0% (1)

- DW 30L278Dokument4 SeitenDW 30L278DeniRahayuYuniartoNoch keine Bewertungen

- Mod. Ct/Ev Mod. Ctc/Ev: Cooling Tower ApparatusDokument4 SeitenMod. Ct/Ev Mod. Ctc/Ev: Cooling Tower Apparatusessam essNoch keine Bewertungen

- Alucobest Aluminum Composite Panel For Architectural & BuildingDokument12 SeitenAlucobest Aluminum Composite Panel For Architectural & BuildingAli ZhangNoch keine Bewertungen

- Rheology of ConcreteDokument21 SeitenRheology of ConcreteSanchit GuptaNoch keine Bewertungen

- NopanDokument3 SeitenNopanM.Dwi CahyaNoch keine Bewertungen

- Earth Loop Impedance Tests PDFDokument20 SeitenEarth Loop Impedance Tests PDFnishanthaindikaNoch keine Bewertungen

- Hilti White Paper - FinalDokument7 SeitenHilti White Paper - Finalnoodlehead675Noch keine Bewertungen

- Brida Astm A105 VishualsteelDokument7 SeitenBrida Astm A105 VishualsteelRicNoch keine Bewertungen

- 5f72776f3e12c83107dc0f2e 56 ANSI Flange Access FittingDokument8 Seiten5f72776f3e12c83107dc0f2e 56 ANSI Flange Access Fittingiyandaseun8846Noch keine Bewertungen

- Sejmste1 19Dokument1 SeiteSejmste1 19hal9000_mark1Noch keine Bewertungen

- Materials PriceDokument1 SeiteMaterials PriceYuchen WuNoch keine Bewertungen

- Solar CarportDokument20 SeitenSolar Carportmohammed nafethNoch keine Bewertungen

- Coriolis Flow MeterDokument4 SeitenCoriolis Flow MeterIsares PodkohNoch keine Bewertungen

- Determination of Aggregate Crushing ValueDokument10 SeitenDetermination of Aggregate Crushing ValueArivalagan Revichandran100% (1)

- NCERT Rationalised Content Vs Updated Syllabus of NEET-2024 - PhysicsDokument1 SeiteNCERT Rationalised Content Vs Updated Syllabus of NEET-2024 - Physicsmohduwais695Noch keine Bewertungen

- Alfa Laval M-Line-10 IntroductionDokument2 SeitenAlfa Laval M-Line-10 Introductionkevin shiNoch keine Bewertungen

- 1-Internal Heat GainDokument15 Seiten1-Internal Heat GainWunNa100% (1)

- Standard SpecDokument21 SeitenStandard Specwhosane10% (1)

- Showroom Interior QuotationDokument1 SeiteShowroom Interior QuotationAngith Menon (Avi)0% (1)

- The Influence of Negative Skin Friction On Piles and Pile GroupsDokument7 SeitenThe Influence of Negative Skin Friction On Piles and Pile GroupsViet Anh PhamNoch keine Bewertungen

- Centrifugal Pump, Shipboard Use: Standard Specification ForDokument15 SeitenCentrifugal Pump, Shipboard Use: Standard Specification ForDarwin DarmawanNoch keine Bewertungen