Beruflich Dokumente

Kultur Dokumente

BOQ For Misc. Items

Hochgeladen von

piyush12660 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

1K Ansichten2 SeitenThe rate shall include 1) Provding and laying seperation layer of 0. Mm thick POLYETHYLENE SHEET to be laid on the RCC slab / sub grade before casting the floor. TRIMIX APPLICATIONVaccum dewatering operation including setting of channel shuttering on b line and level, vibrating concrete with double beam screed vibrator, levelling with trimix surface vibr, floating and further compaction with trimix skin flo floating disc, machine troweling using

Originalbeschreibung:

Originaltitel

BOQ for misc. items

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

XLSX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe rate shall include 1) Provding and laying seperation layer of 0. Mm thick POLYETHYLENE SHEET to be laid on the RCC slab / sub grade before casting the floor. TRIMIX APPLICATIONVaccum dewatering operation including setting of channel shuttering on b line and level, vibrating concrete with double beam screed vibrator, levelling with trimix surface vibr, floating and further compaction with trimix skin flo floating disc, machine troweling using

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

1K Ansichten2 SeitenBOQ For Misc. Items

Hochgeladen von

piyush1266The rate shall include 1) Provding and laying seperation layer of 0. Mm thick POLYETHYLENE SHEET to be laid on the RCC slab / sub grade before casting the floor. TRIMIX APPLICATIONVaccum dewatering operation including setting of channel shuttering on b line and level, vibrating concrete with double beam screed vibrator, levelling with trimix surface vibr, floating and further compaction with trimix skin flo floating disc, machine troweling using

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

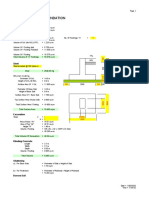

SPECIFICATION FOR BOQ

Trimix Flooring

Providing and laying Trimix Concrete for Flooring

Providing and laying Vaccum Dewatered Flooring - VDF / TRIMIX using pumpable grade RMC of spe

as per detailed technical specifications, including making bunds, 6 mm dia MS reinforcement @ 30

or as given in the drawing, necessary formwork, finishing the same to BROOM FINISH and to the sa

the Project Manager / Architect etc. all complete including necessary curing.

The rate shall include

1) Provding and laying seperation layer of 0.6 mm thick POLYETHYLENE SHEET to be placed with 1

over lapping and laid on the RCC slab / sub grade before casting the floor.

2) TRIMIX APPLICATION- Vaccum dewatering operation including setting of channel shuttering on b

line & level, vibrating concrete with double beam screed vibrator, levelling with trimix surface vibr

Vaccum Dewatering with Trimix vaccum pump, floating and further compaction with trimix skin flo

floating disc, machine troweling using approved machinery before application of broom finish.

3) Broadcasting over dewatered slab non metallic floor hardener Ironite No. 4 (non metallic dry sha

manufactured by IRONITE CO. OF INDIA LTD. or equivalent approved make as per the manufacture

instructions by mechanical spreader and by approved applicators.

4) Cutting the cured concrete for contraction / expansion joints of sizes 8 to 10 mm wide and 6 to 8

with mechanised screw and filling the same with bituminous filling as directed by the Architect or t

complete.

5) Gradient at the top, size of panel & location of the groove shall be as specified by the architect.

6) Each Panel shall be of size (3500 x 3500 mm) or as directed by the Artchitect.

Reinforcement Steel shall be measured and paid seperately under relevant items.

Das könnte Ihnen auch gefallen

- 14-Bill of Quantities Great BritainDokument2 Seiten14-Bill of Quantities Great Britainguliya123100% (2)

- Importance of CEP in Civil EngineeringDokument4 SeitenImportance of CEP in Civil EngineeringSalman ShujaNoch keine Bewertungen

- Chapter 9 Design of Composite ConstructionsDokument18 SeitenChapter 9 Design of Composite Constructionsapi-2661168786% (7)

- Quantity Surveying GUDokument24 SeitenQuantity Surveying GUTigst Tigst YzachewNoch keine Bewertungen

- IV B. Tech Lecture Notes on Estimation and CostingDokument110 SeitenIV B. Tech Lecture Notes on Estimation and CostingRakshith Gowda100% (1)

- Construction of A Culverts DesignDokument19 SeitenConstruction of A Culverts DesignNani CherryNoch keine Bewertungen

- Ce702 Estimation PDFDokument71 SeitenCe702 Estimation PDFDanish BhatNoch keine Bewertungen

- Department of Civil Engineering M.Tech Seminar Report 2021Dokument22 SeitenDepartment of Civil Engineering M.Tech Seminar Report 2021Classic PrintersNoch keine Bewertungen

- Materials & loading details for hospital buildingDokument2 SeitenMaterials & loading details for hospital buildingashishNoch keine Bewertungen

- To Give A Reasonably Accurate Idea of The CostDokument6 SeitenTo Give A Reasonably Accurate Idea of The Costmichael_angelo_pangilinan9286Noch keine Bewertungen

- 3 Story Office 1.30.09Dokument3 Seiten3 Story Office 1.30.09Shyam KumarNoch keine Bewertungen

- Dire Dawa University: Institute of Technology Construction Technology and Management ChairDokument30 SeitenDire Dawa University: Institute of Technology Construction Technology and Management ChairSemNoch keine Bewertungen

- Weighcom Company ProfileDokument11 SeitenWeighcom Company ProfileWeighcom Electrical in Kampala 0750614536Noch keine Bewertungen

- Design of RC BeamsDokument42 SeitenDesign of RC BeamsHarold Jackson MtyanaNoch keine Bewertungen

- Uganda Technical College Lira Estimating and Tendering Lecture NotesDokument77 SeitenUganda Technical College Lira Estimating and Tendering Lecture NotesIZIMBANoch keine Bewertungen

- Lab 2 FullreportDokument12 SeitenLab 2 FullreportMuhammad Zikry Bin RosliNoch keine Bewertungen

- Introduction ArshadDokument20 SeitenIntroduction ArshadShahrukh ansariNoch keine Bewertungen

- Total Project Cost:: Professional Cost and Construction CostDokument21 SeitenTotal Project Cost:: Professional Cost and Construction CostMIKE ARTHUR DAVIDNoch keine Bewertungen

- 5 - SpecificationsDokument69 Seiten5 - SpecificationsMark Angelo VarillaNoch keine Bewertungen

- Preliminary Works To Do Before Starting ConstructionDokument1 SeitePreliminary Works To Do Before Starting ConstructionAbok AduogoNoch keine Bewertungen

- Construction Project Management 101 (Handouts)Dokument107 SeitenConstruction Project Management 101 (Handouts)Genevieve Gayoso100% (1)

- 3 EstimatingDokument8 Seiten3 EstimatingHemantSharmaNoch keine Bewertungen

- Ancoring RebarsDokument44 SeitenAncoring Rebarsrvsingh17gmailcomNoch keine Bewertungen

- IS Codes For Building Construction PracticeDokument5 SeitenIS Codes For Building Construction Practicepraj24083302Noch keine Bewertungen

- Estimation and Costing (A70138) : Lecture NotesDokument73 SeitenEstimation and Costing (A70138) : Lecture Noteshakim imtiyazNoch keine Bewertungen

- 1 - Introduction To Construction Environment and Site WorksDokument2 Seiten1 - Introduction To Construction Environment and Site WorksAudrey EdnalaguimNoch keine Bewertungen

- Iare E&c Lecture Notes PDFDokument110 SeitenIare E&c Lecture Notes PDFRichik MondalNoch keine Bewertungen

- Types of Building Contract: 1. Lump Sum ContractsDokument48 SeitenTypes of Building Contract: 1. Lump Sum ContractstowiwaNoch keine Bewertungen

- Sigma Marine Coatings Manual - Part87Dokument2 SeitenSigma Marine Coatings Manual - Part87Tommy2020Noch keine Bewertungen

- Electrical Estimator's Manual - Electrical KnowhowDokument3 SeitenElectrical Estimator's Manual - Electrical KnowhowdedeerlandNoch keine Bewertungen

- Topic 1 - Duties & Responsibilities of Quantity SurveyorDokument39 SeitenTopic 1 - Duties & Responsibilities of Quantity SurveyorAneesa NajatNoch keine Bewertungen

- From WorkDokument42 SeitenFrom WorkPrashant SunagarNoch keine Bewertungen

- Quantity Surveying and Estimation GuideDokument11 SeitenQuantity Surveying and Estimation Guideparul vyasNoch keine Bewertungen

- Just What Does A Quantity Surveyor Do?Dokument4 SeitenJust What Does A Quantity Surveyor Do?jihaadfadilNoch keine Bewertungen

- Role of The Quantity Surveyor Construction EssayDokument5 SeitenRole of The Quantity Surveyor Construction EssayMahesh JayawardanaNoch keine Bewertungen

- CONSTRUCTION BOQ FOR WASTE MANAGEMENT BUILDINGDokument12 SeitenCONSTRUCTION BOQ FOR WASTE MANAGEMENT BUILDINGdonnec1Noch keine Bewertungen

- Course in Measurements QSDokument56 SeitenCourse in Measurements QSTT Engineering ManagementNoch keine Bewertungen

- Technical Specifications and Measurements for Building Construction WorksDokument67 SeitenTechnical Specifications and Measurements for Building Construction Workssamrawit aysheshimNoch keine Bewertungen

- Intro To SpecificationDokument6 SeitenIntro To SpecificationNur SofeaNoch keine Bewertungen

- Methods of Approximate Construction Cost Estimation PreparationDokument5 SeitenMethods of Approximate Construction Cost Estimation PreparationcivilNoch keine Bewertungen

- Quantity Surveying 2. What Is Quantity Surveying?: 5. Works To Be EstimatedDokument27 SeitenQuantity Surveying 2. What Is Quantity Surveying?: 5. Works To Be Estimatedshumet tadeleNoch keine Bewertungen

- Roles in Construction: Ron GatepainDokument18 SeitenRoles in Construction: Ron GatepainXenia Jane Bravo RigosNoch keine Bewertungen

- Objectives of On The Job Training ProgramDokument17 SeitenObjectives of On The Job Training ProgramArjun Kumar YadavNoch keine Bewertungen

- Lecture 1 Theory QS Measurement BQ SMMDokument40 SeitenLecture 1 Theory QS Measurement BQ SMMAtef RagabNoch keine Bewertungen

- Seminar 8th SemDokument31 SeitenSeminar 8th Sempratik peguNoch keine Bewertungen

- Construction Practice 1 For TechnicianDokument24 SeitenConstruction Practice 1 For TechnicianMichael_Mensah_2238Noch keine Bewertungen

- Timber WindowsDokument52 SeitenTimber WindowsNuwan Wasantha RupasingheNoch keine Bewertungen

- Letter To WASA Chairman Requesting Waiver For Plumbing LicenseDokument7 SeitenLetter To WASA Chairman Requesting Waiver For Plumbing LicenseJeffrey JamesNoch keine Bewertungen

- BOQ-of FoundationDokument8 SeitenBOQ-of FoundationJohn Carlo AbalaNoch keine Bewertungen

- Tender Process Explained in 15 StepsDokument16 SeitenTender Process Explained in 15 StepsHannan FarooqiNoch keine Bewertungen

- An Investigation On Design Procedure and Operations of Polymer Fibre Reinforced Concrete Pavements by S. Panda & N.H.S.rayDokument12 SeitenAn Investigation On Design Procedure and Operations of Polymer Fibre Reinforced Concrete Pavements by S. Panda & N.H.S.rayijr_journalNoch keine Bewertungen

- Ltem Description Qty Unit Rate Amount at Dwomo Primary SchoolDokument9 SeitenLtem Description Qty Unit Rate Amount at Dwomo Primary SchoolNuumo Kweipeh AnnanNoch keine Bewertungen

- Types of Construction ContractsDokument2 SeitenTypes of Construction Contractsclive_2201Noch keine Bewertungen

- ESTIMATING & CONTRACT MEASUREMENT PRINCIPLESDokument228 SeitenESTIMATING & CONTRACT MEASUREMENT PRINCIPLESNg Zhe ShengNoch keine Bewertungen

- My Part Assignment 1Dokument36 SeitenMy Part Assignment 1Adibako Richard D.Noch keine Bewertungen

- Design and Analysis of Water TanksDokument58 SeitenDesign and Analysis of Water TanksNdoro BeiNoch keine Bewertungen

- Construction Contract Types and Bill of Quantities GuideDokument9 SeitenConstruction Contract Types and Bill of Quantities GuideSumit SharmaNoch keine Bewertungen

- New Carparking BOQ - Gate2Dokument3 SeitenNew Carparking BOQ - Gate2Siva SankarNoch keine Bewertungen

- Ecolab Liquid Laundry Program - S53035Dokument4 SeitenEcolab Liquid Laundry Program - S53035Nikesh ShahNoch keine Bewertungen

- Sixth Semester Ug Examination April 2024 - Che6b09Dokument2 SeitenSixth Semester Ug Examination April 2024 - Che6b09jamsheer muhammedNoch keine Bewertungen

- CHE 321 - CH5 - Fatty AlcoholDokument27 SeitenCHE 321 - CH5 - Fatty AlcoholnorazifahNoch keine Bewertungen

- Final PPT Group 16Dokument34 SeitenFinal PPT Group 16IffatNoch keine Bewertungen

- Exp 8 CHM420Dokument15 SeitenExp 8 CHM420Nur Faizatul Atiqah100% (1)

- Aroma Chemistry Smell of BooksDokument1 SeiteAroma Chemistry Smell of BooksEstefanía Gómez RodríguezNoch keine Bewertungen

- SGL ScaleBuster 970 TDS v2Dokument3 SeitenSGL ScaleBuster 970 TDS v2Luis HenriqueNoch keine Bewertungen

- HW 01 SolutionDokument12 SeitenHW 01 SolutionJuan Sebastian Suarez Ospina63% (8)

- CH-201 MTE ProjectDokument16 SeitenCH-201 MTE Project45 Aadhya Roy100% (1)

- MATERIAL TECHNOLOGY - II - All ChaptersDokument51 SeitenMATERIAL TECHNOLOGY - II - All ChaptersMohammed Aseer100% (1)

- 248458-Article Text-902631-1-10-20210329Dokument10 Seiten248458-Article Text-902631-1-10-20210329Krittika SomruedeeNoch keine Bewertungen

- Class 11: Chemistry Project FileDokument18 SeitenClass 11: Chemistry Project FileShubham KumarNoch keine Bewertungen

- Tinuvin P - BASFDokument2 SeitenTinuvin P - BASFsriNoch keine Bewertungen

- Csec Chemistry - A5Dokument17 SeitenCsec Chemistry - A5Mencarty DocentNoch keine Bewertungen

- 03 - Molecular and Mixture DesignDokument109 Seiten03 - Molecular and Mixture DesignZaki WasitNoch keine Bewertungen

- Industrial Training Report on Panoli Intermediates Pvt LtdDokument58 SeitenIndustrial Training Report on Panoli Intermediates Pvt LtdSmit Gandhi50% (2)

- Spectrophotometric Determination of ASA ContentDokument3 SeitenSpectrophotometric Determination of ASA ContentJohn McLainNoch keine Bewertungen

- Nabl 400Dokument579 SeitenNabl 400Team Labs LaboratoryNoch keine Bewertungen

- Physical Chemistry 2nd Edition Ball Solutions ManualDokument10 SeitenPhysical Chemistry 2nd Edition Ball Solutions ManualMarkJonesqsmzj100% (15)

- Aakash Pathak AssignmentDokument3 SeitenAakash Pathak AssignmentAakash PathakNoch keine Bewertungen

- UNIT6.Autonomic PharmacologyDokument66 SeitenUNIT6.Autonomic PharmacologyKaye OmoNoch keine Bewertungen

- Advanced Level Problems: Q. No. 1 To 3 (3 Questions)Dokument78 SeitenAdvanced Level Problems: Q. No. 1 To 3 (3 Questions)Saravanan BNoch keine Bewertungen

- IFFCO Phulpur Training ReportDokument34 SeitenIFFCO Phulpur Training ReportROSHAN KUMAR GUPTANoch keine Bewertungen

- DSDA Sulphuric Acid PlantDokument4 SeitenDSDA Sulphuric Acid PlantAbijithNoch keine Bewertungen

- 2010-F3-CHEM Final Exam Paper ReviewDokument39 Seiten2010-F3-CHEM Final Exam Paper Review2E (04) Ho Hong Tat AdamNoch keine Bewertungen

- Inspection and Test Plan 4 - Trackworks: ConstructionDokument74 SeitenInspection and Test Plan 4 - Trackworks: ConstructionTAMILNoch keine Bewertungen

- General ClO2 Generation of ClO2 PDFDokument37 SeitenGeneral ClO2 Generation of ClO2 PDF1105195794Noch keine Bewertungen

- FLOURIMETRYDokument88 SeitenFLOURIMETRYchannanjappamcNoch keine Bewertungen

- Determining The Molar Concentration of Vinegar by TitrationDokument18 SeitenDetermining The Molar Concentration of Vinegar by TitrationYasinaNoch keine Bewertungen

- 2014 Dse Paper 1abDokument31 Seiten2014 Dse Paper 1abCantoneseNoch keine Bewertungen