Beruflich Dokumente

Kultur Dokumente

Speed and Feed - Carbide End Mills and Drills

Hochgeladen von

Vaibhav ShuklaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Speed and Feed - Carbide End Mills and Drills

Hochgeladen von

Vaibhav ShuklaCopyright:

Verfügbare Formate

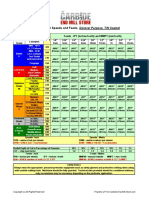

CARBIDE END MILLS

Speed and Feed Data - Applications in Various Materials

TECHNICAL DATA

Chip Load per Tooth

Material SFM 1/8" 1/4" 1/2" 1"

Aluminum Alloys 600-1200 .0010 .0020 .0040 .0080

Brass 200-350 .0010 .0020 .0030 .0050

Bronze 200-350 .0010 .0020 .0030 .0050

Carbon Steel 100-600 .0010 .0015 .0030 .0060

Cast Iron 80-350 .0010 .0015 .0030 .0060

Cast Steel 200-350 .0005 .0010 .0020 .0040

Cobalt Base Alloys 20-80 .0005 .0008 .0010 .0020

Copper 350-900 .0010 .0020 .0030 .0060

Die Steel 50-300 .0005 .0010 .0020 .0040

Graphite 600-1000 .0020 .0050 .0080 .0100

Inconel/Monel 30-50 .0005 .0010 .0015 .0030

Magnesium 900-1300 .0010 .0020 .0040 .0080

Malleable Iron 200-500 .0005 .0010 .0030 .0070

Nickel Base Alloys 50-100 .0002 .0008 .0010 .0020

Plastic 600-1200 .0010 .0030 .0060 .0100

Stainless Steel - Free Machining 100-300 .0005 .0010 .0020 .0030

Stainless Steel - Other 50-250 .0005 .0010 .0020 .0030

Steel - Annealed 100-350 .0010 .0020 .0030 .0050

Steel - Rc 18-24 100-500 .0004 .0008 .0015 .0045

Steel - Rc 25-37 25-120 .0003 .0005 .0010 .0030

Titanium 100-200 .0005 .0008 .0015 .0030

CARBIDE DRILLS

Speed and Feed Data - Applications in Various Materials

Feed Rate (IPR)

Material SFM 1/16" 1/8" 1/4" 1/2"

Aluminum Alloys 150-400 .0010 .0050 .0030 .0050

Brass & Bronze 100-300 .0005 .0010 .0020 .0040

Low Carbon Steel 85-150 .0005 .0010 .0020 .0040

Cast Iron 100-300 .0010 .0020 .0030 .0050

Hardened Steel RC-50 30-90 .0005 .0010 .0020 .0030

Copper 150-400 .0010 .0030 .0050 .0060

Die Steel 50-250 .0005 .0005 .0020 .0040

Inconel/Monel 30-90 .0005 .0005 .0010 .0015

Magnesium 200-650 .0015 .0030 .0050 .0080

Malleable Iron 80-250 .0010 .0020 .0030 .0050

Nickel Base Alloys 30-90 .0005 .0006 .0010 .0015

Plastic 250-600 .0015 .0030 .0040 .0060

Stainless Steel - Soft 50-150 .0005 .0005 .0020 .0040

Stainless Steel - Hard 30-90 .0005 .0005 .0010 .0015

Titanium - Soft 60-200 .0005 .0020 .0040 .0050

Titanium - Hard 45-200 .0005 .0008 .0020 .0040

Note: All speed and feed data are suggested starting points. They may be increased or de-

creased depending on machine condition, hole depth, finish required, coolant, etc. If drill depth

exceeds 3 diameters, reduce speed and feed for carbide drills.

114

Das könnte Ihnen auch gefallen

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Captured and Converted French Vehicles in German ServiceWWIIDokument14 SeitenCaptured and Converted French Vehicles in German ServiceWWIIaxiswarlordhcv100% (2)

- Speed and Feed-Variable Helix and RoughersDokument1 SeiteSpeed and Feed-Variable Helix and RoughersabyzenNoch keine Bewertungen

- Milling Speeds and FeedsDokument1 SeiteMilling Speeds and FeedsMahesh Deivasiga Mani DNoch keine Bewertungen

- Speed and Feed - RoughersDokument1 SeiteSpeed and Feed - Roughers03sri03Noch keine Bewertungen

- NTK General TechnicalDokument32 SeitenNTK General TechnicalsathishelakkiyaNoch keine Bewertungen

- Ingersoll CAT-009 HoleM TechDokument30 SeitenIngersoll CAT-009 HoleM TechLLNoch keine Bewertungen

- Standard ThreadmillsDokument1 SeiteStandard ThreadmillsshawntsungNoch keine Bewertungen

- Materilal AlloysDokument2 SeitenMaterilal AlloysNiranjan KumarNoch keine Bewertungen

- Speed and Feed - Countersink DataDokument1 SeiteSpeed and Feed - Countersink DataenricoNoch keine Bewertungen

- Copper Bonded Ground RodDokument7 SeitenCopper Bonded Ground RodAmiableimpexNoch keine Bewertungen

- ARTY - Aubert Et Duval - Produits - Longs - GB PDFDokument6 SeitenARTY - Aubert Et Duval - Produits - Longs - GB PDFScott_B4UNoch keine Bewertungen

- SAF Welding Cutting GuideDokument165 SeitenSAF Welding Cutting GuideSelvem0% (1)

- Carbide End Mill Speeds and Feeds, General Purpose, UncoatedDokument1 SeiteCarbide End Mill Speeds and Feeds, General Purpose, UncoatedMihir SevakNoch keine Bewertungen

- Asmd Cross IndexDokument24 SeitenAsmd Cross IndexDeepak GovindanNoch keine Bewertungen

- Aladin SDokument4 SeitenAladin SJeffrey BeanNoch keine Bewertungen

- Speeds and Feeds 1053 1054Dokument1 SeiteSpeeds and Feeds 1053 1054P CHNoch keine Bewertungen

- Copper Clad Earth ElectrodDokument7 SeitenCopper Clad Earth Electrodkvramanan_1Noch keine Bewertungen

- Mcode and Mname: Material - Cross - IndexDokument24 SeitenMcode and Mname: Material - Cross - IndexSama UmateNoch keine Bewertungen

- Copper Bonded Grounding Rod ManufacturerDokument7 SeitenCopper Bonded Grounding Rod ManufacturerUjjwal ShahNoch keine Bewertungen

- EarthingDokument19 SeitenEarthingraoNoch keine Bewertungen

- Metco 470AW 10-632Dokument8 SeitenMetco 470AW 10-632JSH100Noch keine Bewertungen

- Speeds & Feeds DrillsDokument9 SeitenSpeeds & Feeds DrillsHolleyMooreNoch keine Bewertungen

- Profile MFGT 1Dokument52 SeitenProfile MFGT 1RangaNoch keine Bewertungen

- Trimet Wire Catalog 2016Dokument67 SeitenTrimet Wire Catalog 2016Akaruii BowoNoch keine Bewertungen

- Counterboring Speeds and FeedsDokument1 SeiteCounterboring Speeds and FeedsMahesh Deivasiga Mani DNoch keine Bewertungen

- Carbide End Mill Feeds and Speeds General Purpose TiNDokument1 SeiteCarbide End Mill Feeds and Speeds General Purpose TiNjoshNoch keine Bewertungen

- HSS Carbide Reamers Speeds Feeds p497 498Dokument2 SeitenHSS Carbide Reamers Speeds Feeds p497 498Ravi DahiwalaNoch keine Bewertungen

- BS 970Dokument5 SeitenBS 970aezeadNoch keine Bewertungen

- En 8Dokument10 SeitenEn 8KarthikRajuNoch keine Bewertungen

- Handbook of Oceanographic Engineering MaterialsDokument97 SeitenHandbook of Oceanographic Engineering MaterialssleonNoch keine Bewertungen

- Dura Bar Machining GuideDokument4 SeitenDura Bar Machining GuidericassterNoch keine Bewertungen

- Reference Tables: General Guide For Cutting Speeds and Feeds For DrillsDokument1 SeiteReference Tables: General Guide For Cutting Speeds and Feeds For DrillsleonboneNoch keine Bewertungen

- Copper Bonded Earthing Rod ManufacturerDokument7 SeitenCopper Bonded Earthing Rod ManufacturerUjjwal ShahNoch keine Bewertungen

- Corus Aerospace Spec BookletDokument14 SeitenCorus Aerospace Spec BookletColinG7750% (1)

- 24UTP Railway GBDokument8 Seiten24UTP Railway GBwpsssamsungNoch keine Bewertungen

- Pipes Tubes of Nippon Steel Sumitomo MetalDokument16 SeitenPipes Tubes of Nippon Steel Sumitomo Metalsiva_nagesh_2Noch keine Bewertungen

- A07-297 OD Expanded Small PartsDokument12 SeitenA07-297 OD Expanded Small PartsKyle DriscollNoch keine Bewertungen

- Peeled Round Steel BarsDokument9 SeitenPeeled Round Steel BarsaxgasaNoch keine Bewertungen

- Alloy Weld 4643Dokument2 SeitenAlloy Weld 4643bastosgabiNoch keine Bewertungen

- Userguide For SSDokument26 SeitenUserguide For SSehsan4uNoch keine Bewertungen

- All Types of MaterialsDokument8 SeitenAll Types of MaterialsAniket KabadeNoch keine Bewertungen

- Millermatic 350P: The Power of BlueDokument4 SeitenMillermatic 350P: The Power of BlueVic HernandezNoch keine Bewertungen

- AFNOR 42 CD 4 SteelDokument2 SeitenAFNOR 42 CD 4 SteelMagoroku D. YudhoNoch keine Bewertungen

- C45 - Specification1Dokument7 SeitenC45 - Specification1gowtham_venkat_4Noch keine Bewertungen

- Flat Steel BarDokument2 SeitenFlat Steel BarsteelplateguangNoch keine Bewertungen

- Sds Eng PDFDokument8 SeitenSds Eng PDFdaviko313Noch keine Bewertungen

- 3 - Cutter Speeds and FeedsDokument23 Seiten3 - Cutter Speeds and FeedsAirlangga GoonersNoch keine Bewertungen

- Valve Material EquivalentsDokument3 SeitenValve Material EquivalentsAndre Villegas Romero100% (1)

- Copper Bonded Earthing Rod ManufacturerDokument7 SeitenCopper Bonded Earthing Rod ManufacturerUjjwal ShahNoch keine Bewertungen

- Swagelok Gaugeable Tube Fittings Alloy 400Dokument8 SeitenSwagelok Gaugeable Tube Fittings Alloy 400totcsabNoch keine Bewertungen

- Copper Bonded Earth Rod ManufacturerDokument7 SeitenCopper Bonded Earth Rod ManufacturerUjjwal ShahNoch keine Bewertungen

- Bars, Rods & RebarsDokument9 SeitenBars, Rods & RebarskxalxoNoch keine Bewertungen

- Cutting Data - Greenwood Tools LTDDokument3 SeitenCutting Data - Greenwood Tools LTDJayakrishnaNoch keine Bewertungen

- Radial Drilling MachinesDokument4 SeitenRadial Drilling MachinesMichael Adu-boahenNoch keine Bewertungen

- Copper Bonded Grounding Rod ManufacturerDokument7 SeitenCopper Bonded Grounding Rod ManufacturerUjjwal ShahNoch keine Bewertungen

- Asmd Cross IndexDokument24 SeitenAsmd Cross IndexPrabishNoch keine Bewertungen

- Pipe Welding Inserts: Robvon TypesDokument1 SeitePipe Welding Inserts: Robvon TypesDavid Luna MolinaNoch keine Bewertungen

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonVon EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNoch keine Bewertungen

- American Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingVon EverandAmerican Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingNoch keine Bewertungen

- Procedures - Copper WeldingDokument6 SeitenProcedures - Copper WeldingenricoNoch keine Bewertungen

- How Do I Set Up My TIG Welder?: Owner's ManualDokument2 SeitenHow Do I Set Up My TIG Welder?: Owner's ManualenricoNoch keine Bewertungen

- Garmin Map Converter InstructionsDokument3 SeitenGarmin Map Converter InstructionsenricoNoch keine Bewertungen

- Metric Thread - Coarse Pitch - MDokument3 SeitenMetric Thread - Coarse Pitch - MenricoNoch keine Bewertungen

- Drill & Tap SizesDokument2 SeitenDrill & Tap SizesenricoNoch keine Bewertungen

- Procedures - Copper WeldingDokument6 SeitenProcedures - Copper WeldingenricoNoch keine Bewertungen

- Electrolytic Rust RemovalDokument15 SeitenElectrolytic Rust RemovalenricoNoch keine Bewertungen

- Garmin Maps TutorialDokument6 SeitenGarmin Maps TutorialenricoNoch keine Bewertungen

- Amm 0.303 British HeadstampsDokument14 SeitenAmm 0.303 British Headstampsenrico100% (2)

- ODN 784 Handbook On Trench Mortar Fuzes 1918Dokument16 SeitenODN 784 Handbook On Trench Mortar Fuzes 1918enricoNoch keine Bewertungen

- Amm 3.7cm BK LDV 4000 10 COL 1944Dokument21 SeitenAmm 3.7cm BK LDV 4000 10 COL 1944enricoNoch keine Bewertungen

- Ammunition TablesDokument7 SeitenAmmunition Tablesenrico100% (1)

- Amm 0.303 BritishDokument9 SeitenAmm 0.303 Britishenrico0% (1)

- Amm 25mm Apfsds Mecar m935Dokument1 SeiteAmm 25mm Apfsds Mecar m935enricoNoch keine Bewertungen

- Italian Artillery Tables of Characteristics Artillery in The DesertDokument2 SeitenItalian Artillery Tables of Characteristics Artillery in The DesertEnrico959Noch keine Bewertungen

- Amm 105mm x617 TK L7 CN105F1 MecarDokument4 SeitenAmm 105mm x617 TK L7 CN105F1 MecarenricoNoch keine Bewertungen

- Tank Ammunition: 105mm Tk. HE M1010Dokument1 SeiteTank Ammunition: 105mm Tk. HE M1010enricoNoch keine Bewertungen

- Amm 105mm x617 TK M1057Dokument1 SeiteAmm 105mm x617 TK M1057enricoNoch keine Bewertungen

- BIOS 365 Paint of German AircraftsDokument29 SeitenBIOS 365 Paint of German AircraftsenricoNoch keine Bewertungen

- Amm 90mm x580 Mk8 Mecar M690Dokument1 SeiteAmm 90mm x580 Mk8 Mecar M690enricoNoch keine Bewertungen

- Amm 105mm x617 TK M1060Dokument1 SeiteAmm 105mm x617 TK M1060enricoNoch keine Bewertungen

- French Guns Technical Data 1940Dokument4 SeitenFrench Guns Technical Data 1940enrico100% (1)

- Amm 105mm x617 TK M1056Dokument1 SeiteAmm 105mm x617 TK M1056enricoNoch keine Bewertungen

- FM 4-30.16 - EOD - Multi-Service Tactics, Techniques and Procedures For Explosive Ordnance Disposal in A Joint Environment (2005)Dokument96 SeitenFM 4-30.16 - EOD - Multi-Service Tactics, Techniques and Procedures For Explosive Ordnance Disposal in A Joint Environment (2005)defendercc130100% (2)

- Amm 4.5inch British HowitzerDokument6 SeitenAmm 4.5inch British HowitzerenricoNoch keine Bewertungen

- Amm 3.7cm x264 BK Stuka PDFDokument8 SeitenAmm 3.7cm x264 BK Stuka PDFenricoNoch keine Bewertungen

- MIL-STD-1168B (Ammunition Lot Numbering and Amm. Data Card) PDFDokument50 SeitenMIL-STD-1168B (Ammunition Lot Numbering and Amm. Data Card) PDFzorlon1Noch keine Bewertungen

- Amm 3cm Mk108 Komet CannonDokument9 SeitenAmm 3cm Mk108 Komet CannonenricoNoch keine Bewertungen

- Amm 12.7mm x81 JapaneseDokument8 SeitenAmm 12.7mm x81 JapaneseenricoNoch keine Bewertungen