Beruflich Dokumente

Kultur Dokumente

Lean Production: D.Vasanth Kumar, 09Mf71 PSG College of Technology, Coimbatore

Hochgeladen von

Vasanth Kumar0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

23 Ansichten10 SeitenLean production is a business philosophy developed by Toyota that aims to eliminate waste in production processes. The seven forms of waste are overproduction, waiting, transportation, inefficient processes, excess inventory, wasted motions, and defects. Lean production originated from Henry Ford's Model A assembly line and was further refined by Toyota engineer Taiichi Ohno, who emphasized just-in-time production, continuous flow, and waste elimination to produce high quality vehicles with low costs.

Originalbeschreibung:

Originaltitel

6 sigma

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenLean production is a business philosophy developed by Toyota that aims to eliminate waste in production processes. The seven forms of waste are overproduction, waiting, transportation, inefficient processes, excess inventory, wasted motions, and defects. Lean production originated from Henry Ford's Model A assembly line and was further refined by Toyota engineer Taiichi Ohno, who emphasized just-in-time production, continuous flow, and waste elimination to produce high quality vehicles with low costs.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

23 Ansichten10 SeitenLean Production: D.Vasanth Kumar, 09Mf71 PSG College of Technology, Coimbatore

Hochgeladen von

Vasanth KumarLean production is a business philosophy developed by Toyota that aims to eliminate waste in production processes. The seven forms of waste are overproduction, waiting, transportation, inefficient processes, excess inventory, wasted motions, and defects. Lean production originated from Henry Ford's Model A assembly line and was further refined by Toyota engineer Taiichi Ohno, who emphasized just-in-time production, continuous flow, and waste elimination to produce high quality vehicles with low costs.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 10

LEAN PRODUCTION

D.VASANTH KUMAR, 09MF71

PSG COLLEGE OF TECHNOLOGY, COIMBATORE

What is lean production?

Lean Manufacturing

Business philosophy that was originally developed at the

Toyota motor company

Objective

To eliminate all forms of waste in the production process

SEVEN FORMS OF WASTE

Overproduction

Waiting for machines or operators

Transportation waste

Process waste resulting from inefficient, poorly designed

processes

Excessive inventory

Wasted motions

Waste of rework through producing defects

LEAN HISTORY

1903 ,Henry Ford - Model A, need for closer tolerances of

thousands of disparate parts, a must for success in mass

production

Interchangeability – mass production

Specialization Of Labor – Productivity increased

dramatically from shorter learning cycles and subsequent

perfection of the specialized task

Simple design

1914- Highland Park Model T plant, Conveyor

Almost a 100% increase in productivity was achieved

with this one change.

Maintaining close tolerances of thousands of disparate

parts from many different suppliers led Ford to bring all

suppliers in house for complete vertical integration

1949

Taiichi Ohno- Engineer of Toyota Motor Company visited

Ford’s River Rouge plant at Detroit

Mass production

Expensive press and die machines

Heavy capital investment

Die changes at the river rouge plant required at least 1 day

Ohno realized this system would not work for Toyota

production was only a few thousand vehicles per year,

compared to millions produced in Detroit

Extensive experimentation

Decrease the time and labor required to change dies

Toyota began scheduling changes every 2 to 3 h

Short production runs became the norm for Toyota,

resulting in fewer inventories of finished goods on hand.

And because the production cycle to produce one

completed vehicle was shortened

Quality issues

Earlier detection of defective parts translated to less

rework, which drove down production costs while

increasing the quality of the final product

Toyota has refined their Lean Production methods to

become one of the highest quality producers of value-

priced vehicles

Das könnte Ihnen auch gefallen

- The Case Study of ToyotaDokument12 SeitenThe Case Study of ToyotaVimala Selvaraj Vimala100% (1)

- A CASE STUDY ToyotaDokument10 SeitenA CASE STUDY ToyotaMd Alamgir Mollah0% (1)

- The Ford Production SystemDokument6 SeitenThe Ford Production SystemSulfikar Ahammed0% (1)

- The Machine That Changed The WorldDokument12 SeitenThe Machine That Changed The WorldAmar ChauguleNoch keine Bewertungen

- Efficient Music Production: How To Make Better Music, FasterVon EverandEfficient Music Production: How To Make Better Music, FasterNoch keine Bewertungen

- Toyota Success RecipeDokument7 SeitenToyota Success Recipeapi-3740973Noch keine Bewertungen

- Hino DPRDokument2 SeitenHino DPRhamm6780% (1)

- A Case Study of Toyota Marketing EssayDokument8 SeitenA Case Study of Toyota Marketing EssayHND Assignment HelpNoch keine Bewertungen

- Typical Factory Layout Vs The Toyota ApproachDokument18 SeitenTypical Factory Layout Vs The Toyota ApproachValerie Cardoz67% (3)

- Abhishek Bennette Nandakumar Joel RoshnaDokument29 SeitenAbhishek Bennette Nandakumar Joel RoshnaBennette AbrahamNoch keine Bewertungen

- Lean Enterprises and Lean Information SystemsDokument4 SeitenLean Enterprises and Lean Information SystemsLeo JafarNoch keine Bewertungen

- Total Cost MinimizationDokument6 SeitenTotal Cost MinimizationChetan Kini100% (1)

- The Machine That Changed The World: How Lean Production Revolutionized The Global Car WarsDokument16 SeitenThe Machine That Changed The World: How Lean Production Revolutionized The Global Car WarsManju DorennavarNoch keine Bewertungen

- Resumen HenryDokument2 SeitenResumen Henryomar vasquezNoch keine Bewertungen

- Operations Management Final ReportDokument20 SeitenOperations Management Final ReportRachit SrivastavaNoch keine Bewertungen

- Operations Management Final ReportDokument20 SeitenOperations Management Final ReportRachit SrivastavaNoch keine Bewertungen

- Henry FordDokument8 SeitenHenry FordGeraldine SuarezNoch keine Bewertungen

- Vision: To Become The World's Leading Consumer Company For Automotive Products and ServicesDokument34 SeitenVision: To Become The World's Leading Consumer Company For Automotive Products and ServicesSumeet NarangNoch keine Bewertungen

- Om Ford Assignment - Group 7Dokument3 SeitenOm Ford Assignment - Group 7Sasi SarvamNoch keine Bewertungen

- Quality 12thDokument9 SeitenQuality 12thMohammed QatariNoch keine Bewertungen

- Changes in Toyota Motors' Operations ManagementDokument14 SeitenChanges in Toyota Motors' Operations ManagementNafis SadikNoch keine Bewertungen

- The Model T Ford: Case StudiesDokument3 SeitenThe Model T Ford: Case Studiesedris9788Noch keine Bewertungen

- Standing On The Shoulders of GiantsDokument19 SeitenStanding On The Shoulders of Giantschakib salekNoch keine Bewertungen

- Job, Batch and Mass ProductionDokument37 SeitenJob, Batch and Mass ProductionNeha Ashani100% (24)

- A Case Study ON Toyota Production SystemDokument20 SeitenA Case Study ON Toyota Production SystemMohd NoorNoch keine Bewertungen

- Executive SummaryDokument20 SeitenExecutive SummarySachin UmbarajeNoch keine Bewertungen

- 6 Single Minute Exchange of DieDokument3 Seiten6 Single Minute Exchange of DiePriya GoyalNoch keine Bewertungen

- Strategies For LeadershipDokument7 SeitenStrategies For LeadershipAzhar Hussain0% (1)

- Henry FordDokument10 SeitenHenry FordmajovelazquezmNoch keine Bewertungen

- Case Study of Ford Co. PomDokument3 SeitenCase Study of Ford Co. PomZahid HassanNoch keine Bewertungen

- Case Lean SystemDokument10 SeitenCase Lean Systemvirjean pricilliaNoch keine Bewertungen

- Lean, Lean Tools Lean Implementation: Module 11 - October 7, 2015Dokument49 SeitenLean, Lean Tools Lean Implementation: Module 11 - October 7, 2015Trixibelle Lyah AllaineNoch keine Bewertungen

- Department of Business Administration Course - Level Course Code Topic Assigned Name of Tutor Name of Student Roll NoDokument9 SeitenDepartment of Business Administration Course - Level Course Code Topic Assigned Name of Tutor Name of Student Roll NoAnam Abdul QayyumNoch keine Bewertungen

- Toyota Case StudyDokument37 SeitenToyota Case StudyAbhishek Unnikrishnan80% (5)

- ProductionDokument5 SeitenProductionSachin UmbarajeNoch keine Bewertungen

- Asynchronous Activity 1Dokument3 SeitenAsynchronous Activity 1carriefan201Noch keine Bewertungen

- A Live Project On Just in TimeDokument15 SeitenA Live Project On Just in TimeSabhaya ChiragNoch keine Bewertungen

- BMW PPT FinalDokument27 SeitenBMW PPT FinalSambit RoyNoch keine Bewertungen

- Lean Product DevelopmentDokument6 SeitenLean Product Developmentandy_agnels2387Noch keine Bewertungen

- TQM in ToyotaDokument7 SeitenTQM in ToyotaJaspreet SinghNoch keine Bewertungen

- BMW - Group 4Dokument32 SeitenBMW - Group 4Manav KhuranaNoch keine Bewertungen

- TPS PosterDokument1 SeiteTPS PosterVignesh HegdeNoch keine Bewertungen

- 4.03B Ford Case StudyDokument3 Seiten4.03B Ford Case Studyjackson WNoch keine Bewertungen

- The Toyota Waypdf PDF FreeDokument16 SeitenThe Toyota Waypdf PDF FreeUma KANoch keine Bewertungen

- 2.GSI 2022 - The Automobile Industry - ADokument24 Seiten2.GSI 2022 - The Automobile Industry - Aw4kprtrn9vNoch keine Bewertungen

- Lean Production-1Dokument17 SeitenLean Production-1Sola Pramod KumarNoch keine Bewertungen

- CH 01Dokument12 SeitenCH 01FaisalsasaNoch keine Bewertungen

- Toyotafinalpresentation1 190127071123 PDFDokument78 SeitenToyotafinalpresentation1 190127071123 PDFShabaz ShaikhNoch keine Bewertungen

- Toyota Motor Corporation's Vehicle Production System Is A Way of "Making Things" That IsDokument4 SeitenToyota Motor Corporation's Vehicle Production System Is A Way of "Making Things" That IsPrathamesh PrabhuNoch keine Bewertungen

- Production ToyotaDokument18 SeitenProduction ToyotaRaj Kishor SinghNoch keine Bewertungen

- Cover Story - Toyota Kirloskar Auto Parts Transmissions For IMV Programme - Automotive Products FinderDokument2 SeitenCover Story - Toyota Kirloskar Auto Parts Transmissions For IMV Programme - Automotive Products FinderGolak MahantaNoch keine Bewertungen

- The Automobile Industry - : Environmental IssuesDokument33 SeitenThe Automobile Industry - : Environmental IssuesArnika KarekarNoch keine Bewertungen

- Revival of Manufacturing GiantsDokument4 SeitenRevival of Manufacturing GiantsTheetharappan AswinNoch keine Bewertungen

- Just in Time in FordDokument8 SeitenJust in Time in FordRaman BharathNoch keine Bewertungen

- TQM in ToyotaDokument6 SeitenTQM in ToyotabhatiaharryjassiNoch keine Bewertungen

- MASE lABDokument3 SeitenMASE lABAli Aslam100% (1)

- Daktronics Lean ManagementDokument6 SeitenDaktronics Lean ManagementKrutarthVashiNoch keine Bewertungen

- Just in Time Manufacturing SEMINARDokument15 SeitenJust in Time Manufacturing SEMINARpavithra222Noch keine Bewertungen

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsVon EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsBewertung: 4.5 von 5 Sternen4.5/5 (2)

- EG Lines MCQDokument3 SeitenEG Lines MCQVasanth KumarNoch keine Bewertungen

- The Application of TRIZ To Technology Forecasting A Case Study: Brassiere Strap TechnologyDokument16 SeitenThe Application of TRIZ To Technology Forecasting A Case Study: Brassiere Strap TechnologyVasanth KumarNoch keine Bewertungen

- Applied TRIZ in Improving Productivity in Textile IndustryDokument4 SeitenApplied TRIZ in Improving Productivity in Textile IndustryVasanth KumarNoch keine Bewertungen

- Eg MCQDokument5 SeitenEg MCQVasanth KumarNoch keine Bewertungen

- How Could The TRIZ Tool Help Continuous Improvement Efforts of The Companies?Dokument9 SeitenHow Could The TRIZ Tool Help Continuous Improvement Efforts of The Companies?Vasanth KumarNoch keine Bewertungen

- GVP College of Engineering (A) 2015Dokument3 SeitenGVP College of Engineering (A) 2015Vasanth KumarNoch keine Bewertungen

- Unit I Principles of Solar RadiationDokument70 SeitenUnit I Principles of Solar RadiationVasanth Kumar100% (1)

- Research, Innovations and ExtensionDokument2 SeitenResearch, Innovations and ExtensionVasanth KumarNoch keine Bewertungen

- No Part of This Publication May Be Reproduced or Distributed in Any Form or by Any Means, or Stored in A Database or Retrieval System, Without The Prior Written Permission of The PublisherDokument28 SeitenNo Part of This Publication May Be Reproduced or Distributed in Any Form or by Any Means, or Stored in A Database or Retrieval System, Without The Prior Written Permission of The PublisherVasanth KumarNoch keine Bewertungen

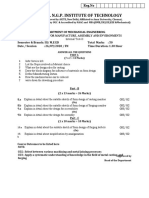

- Dr. N.G.P. Institute of TechnologyDokument1 SeiteDr. N.G.P. Institute of TechnologyVasanth KumarNoch keine Bewertungen

- Dr. N.G.P. Institute of TechnologyDokument1 SeiteDr. N.G.P. Institute of TechnologyVasanth KumarNoch keine Bewertungen

- Dr. N.G.P. Institute of TechnologyDokument1 SeiteDr. N.G.P. Institute of TechnologyVasanth KumarNoch keine Bewertungen

- CC7201-Design For Manufacture, Assembly and Environments Question BankDokument7 SeitenCC7201-Design For Manufacture, Assembly and Environments Question BankVasanth KumarNoch keine Bewertungen

- CC5291 Design For Manufacture Assembly and Environments MCQDokument8 SeitenCC5291 Design For Manufacture Assembly and Environments MCQVasanth KumarNoch keine Bewertungen

- Coursera PYWJ3AEB3Y3D PDFDokument1 SeiteCoursera PYWJ3AEB3Y3D PDFVasanth KumarNoch keine Bewertungen

- Enabler To Successful Implementation of Lean Supply Chain in A Book PublisherDokument8 SeitenEnabler To Successful Implementation of Lean Supply Chain in A Book PublisherVasanth KumarNoch keine Bewertungen

- Reheat and Regenerative Rankine Cycle: Presented by M.Suriyaprakash AP/MechDokument12 SeitenReheat and Regenerative Rankine Cycle: Presented by M.Suriyaprakash AP/MechVasanth KumarNoch keine Bewertungen

- Unit 3 BIGDokument3 SeitenUnit 3 BIGVasanth KumarNoch keine Bewertungen

- Unit I Two Marks: Jansons Institute of TechnologyDokument4 SeitenUnit I Two Marks: Jansons Institute of TechnologyVasanth KumarNoch keine Bewertungen

- Ce6306 - Strength of Materials: Unit V: Thin Cylinders, Spheres and Thick Cylinders 9Dokument4 SeitenCe6306 - Strength of Materials: Unit V: Thin Cylinders, Spheres and Thick Cylinders 9Vasanth KumarNoch keine Bewertungen

- Metrology and MeasurementDokument79 SeitenMetrology and MeasurementVasanth Kumar100% (1)

- Assessment and Reduction of Cost of Quality at Elgi Sauer Compressors LimitedDokument49 SeitenAssessment and Reduction of Cost of Quality at Elgi Sauer Compressors LimitedVasanth KumarNoch keine Bewertungen

- Strength of Materials Unit 3 Question Bank: Jansons Institute of TechnologyDokument3 SeitenStrength of Materials Unit 3 Question Bank: Jansons Institute of TechnologyVasanth KumarNoch keine Bewertungen

- D M S M U II: Ansons Nstitute OF EchnologyDokument6 SeitenD M S M U II: Ansons Nstitute OF EchnologyVasanth KumarNoch keine Bewertungen

- Unit 2 Linear and Angular MeasurementDokument90 SeitenUnit 2 Linear and Angular MeasurementVasanth Kumar33% (3)