Beruflich Dokumente

Kultur Dokumente

Inplant Training Report

Hochgeladen von

PurushottamCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Inplant Training Report

Hochgeladen von

PurushottamCopyright:

Verfügbare Formate

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd.

Kolhapur

AN

Inplant Training

AT

Kolhapur Zilla Sahakari Dudh Utpadak

Sangh L.T.D. Kolhapur.

Submitted By

Mr. Kore Purushottam Balawant

Reg.No. FTR/ 24/2005

Submitted to

Mokashi College of Food Science and

Technology, Rajmachi. , Tal-Karad, Dist-Satara.

[Affilated to Mahatma Phule Krishi Vidyapeeth,

Rahuri]

M.C.F.T Rajmachi , Karad 1

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

ACKNOWLEDGEMENT

Kolhapur Zilla Sahakari Dudh Utpadak

Sangh Ltd.,

Kolhapur is the best dairy industry . It provides greate

opportunity to learn more about Milk processing and their

products.

We were very fortunate to get support from number

of people to whom we are very thankful .

We are very thankful to Mr. Mahadik (Chairman)

for giving us great opportunity. We are also very thankful to

Mr. R. C. Shah (Dy General Manager) , Mr. Chaudhari , Mr.

Tathe for their valuable support.

We express our sincere thanks to Mr. Shahaji

Magdum, Mr.Bharat Lad , Mr. Khatavkar , Mr. A. A. Amte , Mr.

A . Magdum,

Mr. Suraj Ingavale , Mr. Shankar Patil, Mr. Uday Patil, Mr. A. P.

Patil, Mr. J. D. Patil, Mr. Narinkar for their helpful guidance in

training period.

I am grateful to our Principal Mr. P.T. Patil and

Prof. A.S. Dhane for his able guidance in systematic and

successful completion of training.

Finaly we are thankful to all dairy workers for

giving their moral support during our inplant training.

M.C.F.T Rajmachi , Karad 2

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Kore Purushottam Balawant

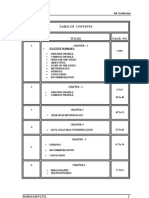

Content

1) Introduction

2) Product line

3) Raw Milk Receiving Dock

4) Milk Processing Section

5) Prepack Section

6) Butter Section

7) Ghee Section

8) Lassi Section

M.C.F.T Rajmachi , Karad 3

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

9) Dahi Section

10) Shrikhand Section

11) Paneer Section

12) Skim milk powder

13) Quality Control

14) Refrigeration Section

15) Boiler Section

16) Mechanical Section

17) CIP Section

18) Effluent Treatment

Plant

M.C.F.T Rajmachi , Karad 4

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

INTRODUCTION

Hisotry & organization

The research has selected following company for research.

Company name:-kolhapur zilla sahakari dudh Uttpadak Sangh.

History of the company

Shri arjun narake; shri anandrao patil & shri sarnaik established GOKUL

DIARY in 1963.the current turnover of this company is approximately_________, the

plant of Gokul Dairy is at GOKUL SHIRGAON ,MIDC.

Different test are done on milk, like fat test,pureness etc.

They use computer billing software for transaction.They daily purchase

litresof milk.the kolhapur district co-operative milk producers Union Ltd. Kolhapur

established on 16th March 1963 under co-operative socities Act

(Regd No-KPR-PRD[A]102) made a moderate beginning by collecting 700 lits of

milk/day from 22 societies. The basic function of Sangh during the formative years were

to produce the milk & supply it to the Govt. Dairy in Tarabai Park , kolhapur.

In 1978the Dairy Development Board included kolhapur distict under

operation flood area & this was beginning of bnew era for the Dudh Sangh the NDDB

constructed a 2LLPD capacity dairy plant at Gokul Shirgaon & two chilling centers

capacity of 75TLPD & 50TLPD at gadinglaj & Bidri respecticely was also installed.

Two more chilling centers at Gagve ( Shahuwadi) and tavarewadi (Chadgad ) have been

proposed under operation flood programme of the NDDB. Expansion during octomber

1992 under the financial assistance from under 11.

M.C.F.T Rajmachi , Karad 5

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

The dairy was commissioned towads the ends of 1985. MCANWHILC; with

the efforts of the NDDB , the Govt. milk scheme in kolhapur was handed over to the

Kolhapur Zilla Dudh Sangh in mid 1985. with commissioning of a new dairy at Gokul

Shirgaon . the Avg milk procrument was 114836 PD with 676.villages level Societes

affiliated to the Dudh sangh.

OBJECTIVES OF THE DUDH SANGH :-

1) Infrastruture for procrument of milk. In rural areas of maharashtra & to to ensure on

assured market for milk producers throughout the year, as wellas the best remunerative

prices.

2) Fulfill the growing needs for milk & milk products of the consumers in the

maharashtra & else where.

3) Organize the co-operative structure of milk at the villages level.

4) Supplement of programme extension input,with particular reference to feed & fodder

production & implements an intensive breeding programme for milah animal to increase

milk production .

5) inparting training for developing human resourses at rural level for effective

leadership , management skills & improvement of services to rural milk producers.

6) Running co-operative development cell to increase awareness & active women

participation for better management of co-operative & their ppositive role in demciation

set up.

AREAS OF OPERATION:-

M.C.F.T Rajmachi , Karad 6

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

The kolhapur Dudh Sangh corses all the 12 talukas

1)KARVIER 2)KAGAL 3)CHANDGAD

4)GADINGLAJ 5)BHUDARGAD 6)AJARA

7)SHIROL 8)GAGANBAVADA 9)SHAHUWADI

10)RADHANAGARI 11)PANHALA 12)HATKANAGALE

However 41 villages from Hatkanagle & panhakla talukas are affiliated to Gokul milk

producers union.

PRODUCT LINE:-

THIS COMPANY PRODUCES:-

1.MILK::-

Standardized Milk

Cow Milk

Toned milk

Double tonned milk.

2. Cooking Butter

3. Table Butter

4. Paneer

5. Dahi.

6. Lassi

7. Ghee

8. Milk Powder

9. Shrikhand

M.C.F.T Rajmachi , Karad 7

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

10 Amrkhand

M.C.F.T Rajmachi , Karad 8

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

GOKUL DAIRY AT A GLANCE

ADDRESS OF DAIRY:- “Gokul plant” , Plot no. B-1, M.I.D.C , BT No.2, Gokul

Shrigaon ,Tal:- Karvier, Dist:- Kolhapur Pin:- 416234

YEAR OF ESTABLISHMENT:-1963

FORM OF ORGANIZATION:- Co-operative society

DISTANCE FROM CITY:- Gokul dairy is 13 Km. Away from Kolhapur city.

TOTAL AREA OF DAIRY:- 25 acres

Cpacity:- 6.5 Lakh litres per Day

Routes:-151 milk routes of 2569 villages

M.C.F.T Rajmachi , Karad 9

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

RAW MILK RECEPTION DOCK

Introduction :

RMRD at Gokul dairy is well equipped with the advanced equipment like

computers and pneumatic sampler, milk testing machinates, electronic weighing system.

There is spacious area in front of the dock to park the vehicles. The dock having two ran

reception lines, so has two units of each equipment like can opener, weighing tank Dump

Tank, can washer, and crate washer.

The process on RMRD starts from unloading the tempos. The cans are conveyed

on Hook chain conveyer. On the way to tilting point auto lid opener opens can lids and

organoleptic tests are conducted. If anything wrong with can then it is detected and such

can is taken out from conveyor. Then these cans are unloaded / emptied in dump tank

manually at tilting point. The cow milk and buffalo milk is collected separately on

RMRD. The suspected / sour milk is not allowed to mix with good / fresh milk. It is

diverted from that line and conveyed to sour milk dump tank. A lab person or chemist

analyses the sample for platform tests such as Fat,SNF,CLR, Acidity, EKOMILK,

(machine) , etc. machine tests are carried out in separate laboratory chamber. Here are

two computer chambers to record the quantitative and qualitative parameters of incoming

milk from the societies. These parameters are fat, CLR and quantity of milk. These

parameters are used to calculate the price of milk per liter.

Sampling is done automatically by pneumatic sampler. Sample from each lot

( Tilting tank) is taken in bottles and carried to the milk testing chamber on a sample

bottle conveyor.

The cans, which are not properly cleaned, are taken to can scrubber and again

loaded to can washer for recleaning.

M.C.F.T Rajmachi , Karad 10

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Tanker Reception :

The milk from the chilling centers located at Boravade (Bidri), Lingnur

(Gadhinglaj), Tavarewadi (Chandgad), Gogave ( Shahuwadi) etc. is transported by road

tankers. These tankers are on hire basis as and when required subjected to procurement of

milk.

As soon as the tanker arrives at the dock containing processed or chilled milk it is

being tested for organoleptic tests and lab tests. After analyzing its quality, it is accepted

for further processing and production.

The reception starts from 8.00 a.m. during morning and 7.00 p.m. at evening and

continues till all the expected milk is received. The milk handling capacity of Gokul is

around 6 lakh lit / day

M.C.F.T Rajmachi , Karad 11

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Milk Reception Flow Line :

Reception of cans on platform

Can conveyor

Auto can Opener

Oraganoleptic Testing

(if doubt then COB testing)

Tilting of Cans

Sour milk

Weighing

Sampling

(Testing CLR and Fat)

Processing Dump tank Reception of milk

from tankers

Empty can

Milk Draining

Can Washer Can Scrubbing

Dispatch

M.C.F.T Rajmachi , Karad 12

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

RMRD Equipment details :

1. Can :

Material of construction = Aluminum

Capacity = 40 Liters.

2. Can Conveyor :

Type = 1. Chain conveyor ( In can washer)

3.Can Opener :

Working = Power driven

1. Principle of operation = Vibration

4.Organoleptic Testing :

At first, milk is well mixed with the help of plunger and following tests are

carried out by experienced persons.

a) Color b) Smell

c) Taste d) Appearance e) Temperature by touch to cans.

5.Tilting of cans :

Mode of operation = Manual

6. Weighing :Weighing balance

Operation = Electrically operated

7 Pneumatic Samplers:

Amount of sample drawn from each lot = 100ml

Operation = Pneumatic

8. RMRD Lab.:

Tests are conducted by advanced machines (EKOMILK) . These tests are for Fat,

SNF, Protien, which are conducted on the platform.

9. Screens &Filters:

Small Pore Size Screens are used to efficiently remove the sediments from the

milk. These are present at weighing tank and dump tank.

M.C.F.T Rajmachi , Karad 13

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

10. Dump Tank:

11. Can Washer:

No. of Can Washers =2

Type =Straight through can washer.

Speed =600Cans/hr.

No. of compartments = 4.

13. Can Scrubber:

Shape = Semi cylindrical open.

Brushes =Nylon hairs.

No. of brushes =2.

CLEANING OF CANS:-

The empty cans are washed in a straight through can washer daily. Once

in a week the cans should be washed manually with schedule programme.

Can Washer Operating Parameters:-

1. Steam pressure 3Kg/.cm2

2. Pre-rinse temp min. 450C

3. Detergent temp min 700C

4. Final rinse temp 80-850C

5. Hot air temp 90-1000C

6. Washing speed 600 can/hr

Can Washer Programme :

1. Pre-rinsing with normal water and draining.

2. Detergent strength at 700 C (For soda + SMS + TSP) 0.5 +/- 0.1 Alkalinity

3. Steam heated hot water at 800 C

4. Hot air drying at 90-1000C.

M.C.F.T Rajmachi , Karad 14

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

CRATE RECEPTION DOCK :

The crates returned from distributors are received here and washed out

in crate washer. This section is located at back to the RMRD.

Above crate washer:

Type = Straight through.

Capacity = 1500 Crates/hr.

No. of compartments = 3.

Crate Washer Programme:

1. Prerinse with normal water at 400C.

2. Drain.

3. Jetting with caustic solution at 750C, of strength 0.6- 0.8 % NaOH, pressure

– 0.75 Kg/cm2 & drain.

4. Hot water heated by steam at 800C & drain.

TANKER CLEANING:-

After every Emptying & before every filling.

-Pre-rinse with water.

-Manul cleaning with hot water, detergent & pads.

-Final rinse with hot water.

-Sterilisation with chlorine150-220 ppm i.e. 150 ml in 40 lits of water

Solution.

- Man hole cover, gaskets, air vents : Brushing with liquid detergent,

flushing

- with hot water, & sterilization with chlorine.

-Valve box steam union : Open valve body, union & clean them with

detergent & hot water.

M.C.F.T Rajmachi , Karad 15

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

PROCESSING SECTION

Introduction :

Processing section is the heart of Dairy industry. The milk received from the

RMRD cannot be instantly processed. So it is first chilled and stored in silo tanks.

Consequently processing is carried out in this section are chilling, storage, pasteurization,

cream separation, filtration, clarification , homogenization, standardization,

reconstitution .

Milk Process:

The eqipments in this section are Chillers, Silos, Tanks, HTST, Pasteurizers,

Duplex filters, Clarifier cum Separators.

Processes carried out in this section are as below :

Chilling :

All the milk received through RMRD is chilled to 5 – 70 C through the plate heat

exchanger type chillers. Chilled water at 1-1.50C is used as cooling agent. Chilled water

pipes are insulated by thermocol. Total 3 chillers of PHE type are in working in the

process section.

Sr Parameter Specification

No

1. Flow rate chiller no 1 18,000 litres /hr.min

2. Flow rate chiller no 2 18,000 litres/ hr. min

3. Flow rate chiller no 3 27,000 litres/hr min

Storage :

The chilled milk is stored in silos at 50 C and then supplied for further processing

steps.

Pasteurization :

M.C.F.T Rajmachi , Karad 16

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

In this section, HTST Pasteurizers ( 3 for milk and 2 for cream ) are

working here. Out of 3 milk Pasteurizers , 2 have the holding tubes . Milk is pasteurized

at a temperature of 78+/-20 C for 15 Sec. The cream pasteurization is carried out at 90 –

980 C for 15 – 16 seconds. Pasteurizers are composed or four regeneration sections in

which the temperature of milk is increased in steps as 350C, 470C , 650C & 80 hence milk

can be sent to separation, homogenization between the regeneration sections. Pasteurizers

are connected to Duplex filter, Westfalia separator and Homogenizer. Flow Diversion

Valve is attached after the holding section. After pasteurization product (Milk or cream)

is instantly cooled to 50 C or below and stored in storage tanks.

Duplex Filters :

The milk from regeneration 4 section of pasteurizer is taken to duplex

filters, which is a closed cylindrical body. The milk enters from top and passes out from

bottom, which is connected, to Westfalia separator. This body consists of two layers of

metallic filters.

Westfalia Separator :

In this type of separator milk is clarified as well separated into cream

and skim milk. The slime is removed manually during cleaning operation. The cream is

pumped to cream pasteurizer while and skim milk returns to pasteurizer .

Homogenizer :

A two stage homogenizer is installed in processing section, which is used for

homogenizing whole milk and it is connected in between regeneration 1 and heating

section .

M.C.F.T Rajmachi , Karad 17

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Milk Pasteurizer:-

Sr Parameter Specification

No.

1. Pasteurizer Temperature 78 ± 2ºc

2. Chilled Milk Temperature ≤04 ºc

≤06ºc (For recombined

milk)

3. Chilled water inlet temperature 02ºc Max.

4. Hot water inlet Temperature 88ºc Max.

5. Flow rate

For past. no 1&2 >8500 LPH

For past. no 3 >14,000 LPH

For past. no 4&5 >18,000 LPH

Cream Pasteurizer:-

Sr Parameter Specification

no.

1. Pasteurizer temperature 92 ± 2ºc

2. Chilled Cream temperature 07 ± 2ºc

3. Flow rate

For CP 01 3,500 LPH

For CP 02 5,500 LPH

Seperators (Westfalia):-

Sr Parameter Specification

No.

1. Air Pressure Min 6 kg/cm2

2. Soft water pressure Min 3 bar

M.C.F.T Rajmachi , Karad 18

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Homoginizer:-

Sr Parameters Specification

no.

1. Pressure 2nd stage Min 500 psi+ 100 psi

2. Pressure 1st Stage

For cow milk Min 1,500 psi + 100 psi

For Recombined milk Min 2,500 psi + 100 psi

Deep Chiller:-

Parameters specifications

Temperature of chilled milk ≤4ºC

Flow Rate 20,000 litres/hrs.max

Glycol Inlet Temperature -5ºC to 0ºC max

Or

Chilled water temperature ≤1.5ºC

FLOW DIAGRAM FOR CHILLING OF RAW MILK:

Raw milk (from dump tank at RMRD)

Chilled water in Chiller Chilled water out

Store in silos

M.C.F.T Rajmachi , Karad 19

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Processing

Flow Chart for Milk Pasteurization :

Milk from silo

Balance tank (Milk temp 10-130C)

Filter Regeneration 1 (Milk inlet temp 10-130C)

(Milk outlet temp 450C)

Cream Seperator

M.C.F.T Rajmachi , Karad 20

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Cream Skim milk Regeneration 2 (Milk inlet temp. 450C)

(Milk outlet temp. 55-600C)

Homogenizer

Regeneration 3 (Milk inltet temp. 600C)

(Milk outlet temp. 650C)

Hot water (850C) Heating Section (Milk inlet temp 650C)

(Milk outlet temp 800C)

Holding tubes or Holding plates (for 15 seconds)

Regeneration 3 (Milk inlet temp.800C)

(Milk outlet temp.650C)

Regeneration 2 (Milk inlet temp.650C)

(Milk outlet temp.450C)

Regeneration 1 (Milk inlet temp.450C)

(Milk outlet temp.250C)

Chilled water (1-20C) Chilling section (Milk inlet temp.250C)

(Milk outlet temp.4-50C)

Pasteurized chilled milk

Storage tank

Flow Chart for Cream Pasteurization :

Cream from cream separator

Cream pasteurizer.

Balance tank

Feed pump.

M.C.F.T Rajmachi , Karad 21

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Flow control valve.

Regeneration ( Inlet temp 50 –550 C

Outlet temp 65 – 700 C)

Hot water ( 90 – 950 C) Heating section (inlet temp 65 – 700 C

Outlet temp 80 – 850 C)

Holding tube (holding for 5 sec.)

Regeneration (Inlet temp 80 – 850 C

Outlet temp 50 – 550 C)

Tap water ( 28 – 380 C ) Cooling ( Inlet temp 50 – 550 C

Outlet temp 25-300 C)

Chilled water temp (1- 20 C ) Chilling ( Inlet temp 25 – 300 C

Outlet temp 7 – 80 C)

Pasteurized chilled cream

Cream storage tank.

MILK STANDARDIZATION

Standardization is an important procedure for the adjustment of fat and SNF as per the

specified standard. The standardization is done by Skim milk or Reconstituted milk for

buffalo milk while buffalo milk for cow milk. The tanks are provided agitators inside for

through mixing continuously. There are different ratios for standardized milk and whole

milk.

Operating parameters for Standardization :

M.C.F.T Rajmachi , Karad 22

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Products Fat [%] SNF[%]

Standardized milk 4.5 8.5

Whole milk 6 9

Cow milk 4 8.5

Flow Diagram of Reconstituted Milk :

Skim milk powder

Hopper

Addition of water

Mixing tank

Agitator (for well mixing )

Pasteurization & homogenization

Reconstituted Milk

BULK MILK DISPATCH THROUGH TANKER :

Daily near about 1,25,000 lit. processed milk is sent to Washi for packaging.

Before the milk is dispatched through tankers, the tankers, the tankers are cleaned

properly as per schedule given previously in the RMRD section. The Pasteurized Whole

milk and Standardized milk is chilled at 1.5 – 2 0 C and filled in tankers and after filling ,

the sample is given for analysis. After satisfactory analysis report, the tanker are

permitted for transportation to Washi for packaging. This is carried out with Glycol

chiller. The cooling medium used in this chilling is Glycol.

M.C.F.T Rajmachi , Karad 23

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

PRE-PACK SECTION

Introduction :

This section is very important as it gives the protection to the product and

improve its attractiveness i.e. contributing for enhancing the acceptance.

This section is located just behind the RMRD. It is in between RMRD & process

section. The washed creates are received in prepack, section for placing the pouch of

M.C.F.T Rajmachi , Karad 24

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

milk and then shifted to cold storage. In this section, there are five fillpack machines.

This section is laterally connected with cold storage.

The milk, which is pasteurized, homogenized or standardized, is received from

storage tanks in overhead balance tank of filpack machine at 40C. This milk flows from

overhead balance tank into the pouch by gravity. Machine operates one electronic and

pneumatic principles. Laboratory takes sample for each size sample for each size of pack

and after clearance regarding chemical analysis, weight and length of pouch, from quality

control laboratory, machine is run for regular production.

The milk is pouched in various capacities with different types of milk. The milk

pouched are Buffalo whole milk, Cow whole milk, Tonned milk. Lassi is also packed in

this section at 40 C. the pouches are filled in crates and stored in cold storage at 10 C in

stacks. Stacks means keeping the crates one over other. 10 crates form a stack. Pouches

are checked for leakage while stacking in cold storage. There are two cold storage for

storing market / pouch milk.

This product needs circulation in market as quickly as possible. After temporary

storage refrigeration at 10 C, pouch milk is dispatched in vehicles / tempos.

Flow Diagram of Pouch Filling :

Milk from storage tank (40 C)

Over head balance tank

Filling cylinder.

M.C.F.T Rajmachi , Karad 25

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Vertical sealing and pouch formation.

Filling of milk and Horizontal sealing

Milk pouch.

Weighing & leakage testing of pouch.

Filling in crates.

Crate coyer.

Cold storage .(0.5 – 1 0 C)

Dispatch.

Details of Packing Machine :

In this section, five packaging machines are working. Packaging material is

polythene film. Roll is fixed on the backside of the machine and it is carried out to the

top of front side mechanically by the nib rollers. It is sterilized by UV light. Vertical

edges of material are sealed to each other by vertical Teflon coated electrode rod at a

temperature of 600 C. then the material comes down and sealed by horizontal electrode

rod at 900 C. The horizontal rod seals first lower end of pouch horizontally and after

filling adjusted amount of milk with the help of pneumatically operated pistons having

adjustable stroke volume, the pouch slips down a specified distance and then its upper

M.C.F.T Rajmachi , Karad 26

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

edge is sealed. Horizontal sealing of upper side of one pouch and lower side of next

pouch & horizontally cutting of filled pouch is carried out in single stroke of horizontal

sealer. Packaging machine and quantity of milk to be packed without leakage

.

Parameters of Packaging Machines :

No. of Units - 05

01 - Power saver (Nichrome )

02 - Nichrome

The milk, which is collected from leaked pouches is sent for reprocessing. Average milk

loss during adjustment & due to leakage is around 6 liters per hour. Air is used as

lubricant in pulling cylinder.

Packaging parameters for Pouch filling machine:-

Sr Parameters Specification

No:-

1. Weight (with pouch)

200ml 210gm ±2gm

500ml 521gm ±3gm

1000ml 1040gm ±5gm

2. Pouch length

200ml 107mm ±3mm

500ml 146mm max.

1000ml 225mm max.

3 Air pressure

M.C.F.T Rajmachi , Karad 27

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

On line 8 kg/cm2

Machine 6 kg/cm2

4. Cooling Water Running

5. Weight & Length Checking From each working head.random checking of

Frequency 20 pouches at every hrAvg. Wt shall confirm

to the specification

6. Weigh Balance To be checked with dead wt. at the start of

each shift

7. Film loss norm 1.5% max. During packing

8. Drop Test 16 samples of filled pouches shall be taken

random from filling line.the sample bags

drawn from machine shall be dropped from

the height of 1.2 meter on a flat, smooth ,

hard surface in 4 ways i.e 1)at vertical seam.

2)at opposite to vertical seam. 3) & 4) at

vertical edges.The samples have deamed to

have the test of 75% of the sample with

stood all the above 4 drops .

Storage of film:-

1) At dry cool & dust free area

2) Keep wrapped until taken for use.

3) Stacking on wooden pallets/ racks

M.C.F.T Rajmachi , Karad 28

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

BUTTER SECTION

Introduction-

In Gokul dairy White Butter as well as Table Butter are manufactured in the

Butter –Section by using cream (40-45% fat) of Buffalo milk or Cow milk or

combination their of. Daily near about Cream is converted into Butter.

White butter :

White butter is produced for the conversion of surplus fat, it is not sold in the

market and used in the production of Ghee. Generally the white butter is prepared by

using continuous butter making machine. But sometimes when bulk of the cream is less,

it may be prepared in tabletop churn.

Flow Diagram for Manufacture : -

Pasteurized and cooled cream

Cream Storage tank

Aging (3 to 4 Hrs. at 10-150 C.)

M.C.F.T Rajmachi , Karad 29

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Continuous Butter Making Machine

(Temp.9-100 C )

Butter Milk

White Butter Chilling

Packed in cartons Butter milk tank

Cold storage

(-10 to -150 C.)

CBMM Operation:-

1.Primary churning cylinder :

In this cylinder the butter grains are formed due to the action of high speed

beaters. This cylinder is provided with chilled water jacket to maintain the tempearture.

2.Secondary churning cylinder :

It consist of single blade dasher, paddle and pitched paddle. There is provision for

butter washing. In this cylinder butter clumps are formed due to the action of dasher

blade, washing and separated from Butter miilk.

3.Working cylinder :

It consist of two working blades with chilled water jacket cylinder. In this part of

CBMM, continuous mass of butter is formed due to action of working blades.

Operating parameters:-

Parametrs Specification

Temperature 9 to 13 ºC

Ageing Time 4 hrs. min

Agitators In working hrs , no oil leakage under blades ,

Sufficient agitation to break froth

System Followed FIFO

M.C.F.T Rajmachi , Karad 30

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Loading and Churning:-

Sr Parameter Table butter White butter

no.

1. Loading of churn Approx ⅓ of drum Approx ⅓ of drum

capacity capacity

2. Churning temperature

Winter 9 - 13ºC 9 - 13ºC

Summer 9 - 10ºC 9 - 13ºC

3. Butter Annato colour

For cow milk 1 ml/kg sterilized fat

input

For buffalo milk 2 ml/kg uniform fat

input

4. Spray water Use chilled water Use chilled water

5. Washing by Chlorinated past. Chlorinated past.

Chille Chilled

d water

water 150 –

150 – 200

200 ppm

ppm <11 ºC

<11 ºC

6. Salt addition As per QP/milk ---

7. Working of Butter Under vaccum ---

Churning efficiency of the CBMM :-

The percentage of the fat present in buttermilk is known as churning

efficiency. it should be less than or equal to 0.7. in Gokul dairy fat percentage of

buttermilk is 12.00 to 1.5 % i.e. churning efficiency is higher. But it is not the matter to

worry because the buttermilk is passed through separator and skim milk obtained is

admixed with skim milk used for the production of powder.

M.C.F.T Rajmachi , Karad 31

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Cleaning of CBMM :

The cleaning of CBMM is done manually by dismantling. All parts are scrubbed

with brush using detergent and caustic, then are washed with water and reassembled.

Table Butter :

The table butter is sold under brand name GOKUL BUTTER. The

production is done as per demand.

Flow diagram for manufacture :-

Cream from storage tank

(10-12 0C)

Loading of churn

Addition of Annato color @0.055%

Churning at 20 rpm for 30 min.

Churning at 16 rpm for 30 min. Butter milk drain

Addition of wash water

Washing at 12 rpm for 30 min Water drain

Addition of salt @2.5%

M.C.F.T Rajmachi , Karad 32

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Working at 6rpm for 1 hr.

Testing sample

Table butter drawn in butter trolley

Packaging

Storage in deep freezer(-5 to –10 0C)

Addition of color –

The annatto color is used to add into the cream,. The quality of

annatto to be added depends upon the fat % of cream and bulk of cream taken in the

churn. As annatto is a fat soluble pigment which does not lost into buttermilk hence

almost all the added annatto comes into butter. Only prerequisite is that the butter should

contain 0.1 % annatto. Therefore annatto to be added can be determined easily as follows

:

Yield of butter = % Fat in cream/ % Fat required in butter (> = 80 % )

∴ Annatto to be added = (Yield of butter) × (% of annatto required in butter )

100

Addition of Salt:-

Addition of salt should be up to 2.5% which is added on the total kg fat in cream

and the %fat in butter. Salt is added is of the High grade TATA SALT. Quantity should

be calculated as follows,

Quantity of salt added = (Total kg fat) × (% salt added )

M.C.F.T Rajmachi , Karad 33

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

% fat in butter

Wrapping and hardening –

The butter prepared is wrapped in polythene film and kept in cartoon box to

conclude the shape. Each box contains 20kg butter. The boxes are then stored at temp. –5

to –100 C for hardening. It is then removed and packed as required.

Packaging of butter –

The butter packaging room is adjacent to production room. Its temperature is

maintained at 4 to 50 C. There are two butter packaging machines in the plant, one for

500gm pack and one for 100gm pack. The machines are completely mechanical. In the

machine hardened butter blocks are placed which are forced forward by screw conveyor

type arrangement through a channel and a piece of it is taken in a groove. It is removed

and wrapped by butter paper by horizontal and vertical rods. The wrapped piece is placed

into outer box manually, it is weight tested and stamped. The boxes are then placed in

cartoons and sent to storage at temperature –18 to –210 C.

Cleaning of churn :-

The churn is filled with hot water and churn is rotated for some time. The water is

drained out and caustic solution is added and again rotated for some time. It is again

washed with hot water.

Cleaning of packaging machine :-

When the packaging is over, hot steam is forced on it until the butter resided on it

is melted off and drained down. Then, after some time it is dried by hot compressed air

spray.

M.C.F.T Rajmachi , Karad 34

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

GHEE SECTION

Introduction :

Gokul Dairy receives bulk amount milk, which is separated in to skim milk and

cream. This cream is used for Butter producing and Butter is used for Ghee manufacture.

The Ghee is produced by creamery butter method.

Flow diagram for Manufacture :

White Butter

Melting

(70-80 0C steam pressure 0.5 kg/cm2)

Cooking

(105-109 0C steam pressure 1.5 kg/cm2)

Dark brown color of Ghee residue

M.C.F.T Rajmachi , Karad 35

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Filtration Ghee Residue

Settling tank Ghee Residue

Pouching (filling & Packing) at 40 0 C

Storage (Ambient Temp.)

Details of manufacture :

1). White Butter :-

It is taken out from deep storage at –18 0 C and emptied in melting vats.

The vats are double jacketed in which steam is used for its melting at 70-800 C.

Formerly, sour butter was mixed with white butter in melting vat for Ghee preparation

but now a days this practice is stopped as it is indulging with quality of product i.e. Ghee

residue is appearing in Ghee due to its lower rate of settling.

Presently separate batch of sour butter Ghee is manufactured.

2). Cooking :-

Melted Butter is taken into Ghee boliling of vats. They are given steam in their

jacket at a pressure of 1.5kg/cm2. Ghee is boiled at 105 – 1090 C till nearly all the

moisture get evaporated and it is detected by dark brown color of Ghee residue.

3) Balance tank :

The prepared Ghee lot is taken to filter balance tanks which consists of

metallic sieve aligned with muslin cloth to extract the Ghee residue from Ghee.

4) Filtration :

M.C.F.T Rajmachi , Karad 36

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Filter is a closed cylindrical body. It consists of metallic screeners with cotton

pads in between them to remove Ghee residue from Ghee. The Ghee is supplied from

bottom and filtered .Ghee is taken out from top of filter and is sent to settling tank.

5) Settling tank :-

The filtered Ghee is stored in settling tank for 4-5 hrs in order to settle down

the Ghee residue. Then Ghee residue is taken out and Ghee sample is sent to lab before

filling and packaging. If sample does not contain Ghee residue and satisfy prescribed

then it is allowed to packaging.

6) Filling & Packaging :-

After settling period of 8-10 hrs. Ghee is filled and packed at 40 0C. If

Ghee is directly taken for filling and packing after filtration , it is to be passed through

cooler (PHE) in order to cool from 970C to 400C.

7) Storage:-

Ghee contains 0.5 % (max.) moisture, so it has good shelf life even at room

temperature.

Ghee packing parameter:-

Parameter Specification

Ghee packing temp. 40 - 45ºC

Speed 500 ml. 800 pph max

Speed 1000 ml. 600 pph max

Air pressure 6 kg/ cm2

Bag length 500 ml pouch 16.5 ± 0.5 cm

Bag length 1000 ml pouch 24.5 ± 0.5 cm

Avg. Wt 500 ml (20 bags) 459 + 3 gm gross wt

Avg. Wt 1000ml (10 bags) 915 + 5 gm gross wt

Film loss during packing & storage 3% max

Packing slip Or printed Stamp Mfg date ,batch no., workers card no.,

gross wt, coding on packing slip pasting at

the point of adhesive tape on the top of

M.C.F.T Rajmachi , Karad 37

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

boxes .

LASSI SECTION

Introduction :

Here Lassi is manufactued out of standardized milk and not from the

buttermilk. Gokul Dairy has set its own standards for Lassi. It is being produced

seasonally, as it has tremendous demand in summer season.

Flow Diagram of Manufacture :

Pasteurized and standardized milk

(5.0 – 5.5 fat, 9.4 - 9.7 SNF)

Preheating (370 C)

Starter Inoculation @ 1.0 –1.5 % of milk

Curd Setting (Upto 0.60 % L. A.)

Sugar addition @ 18 % of milk

Mixing

Batch pasteurization at 780 C

Homogenization

(1st stage =100 psi 2nd Stage = 50 psi

Chilling ( below 4º C)

Temporary Storage

M.C.F.T Rajmachi , Karad 38

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Packing(200ml)

Storage (-180 C)

Lassi manufacturing Parameters:-

A) Curd setting:-

Parameter Specification

Incubation temperature 37 – 40 ºC

Incubation period 4 – 6 hr.

Inoculation of culture 1–2%

B) Batch pasteurization:-

Parameter Specification

Pasteurization temperature 78 + 2 ºC

Pasteurization time Min. 30 min

C) Homoginisation:-

Parameter Specification

Homogenization pressure 1st’ stage,100 psi 2nd’stage,50 psi

Homogenization temperature 60 – 65 ºC

D) chilling & storage:-

Parameter specification

Chilling &storage temperature ≤ 5ºC

E) Packing parameters for pouch filling machine:-

Sr no. Parameter Specification

1. Weight(with pouch) 200 ml 210 gm ± 2 gm

2. Air pressure

On line 8 kg/ cm2

Machine 6 kg /cm2

3. Cooling water Running

M.C.F.T Rajmachi , Karad 39

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

4. Weight checking frequency Random check from each working head.

5. Weigh balance To be checked with dead weight at the

start of each shift.

6. Film loss norm 2% max during packing, storage &

distribution

F) Storage Film:-

1. At dry, Cool and dust free area.

2. Keep wrapped until taking for use.

G) Storage conditions at Hardening room:-

1. Temperature to be maintained. Mentioned hourly

2. Proper Illumination.

3. Air curtain working.

M.C.F.T Rajmachi , Karad 40

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

DAHI SECTION

Introduction :

At Gokul Dairy, Dahi is prepared as per demand, in small batches. Buffalo

milk of fat 6.7 %-6.8% & SNF 9.1% is used for Dahi production. The SNF level is

increased upto 10.1% by adding reconstituted SMP about 1.5% of milk. Also protein

powder is mixed during reconstitution of SMP in the proportion of 1gm protein powder

for 10kg milk i.e. about 0.01% of milk. 30-40kg of Dahi is prepared in each batch.

Generally, two batches of Dahi are prepared per week. Dahi is packed in cups of 100gm

& 250 gm manually.

Milk for Dahi :

BM – Fat - 6.7-6.8%

SNF - 9.1%

Initial temp of milk - 40 C

Inoculation temp - 420 C

Rate of culture addition- 2.5%

Incubation temp - Room temp (370 C)

Incubation period - 3-3.5 hrs.

M.C.F.T Rajmachi , Karad 41

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Flow Chart for Dahi Manufacturing :

Standardisation of Milk

QC Check

Preparation & Pasteurisation & Homoginisation

Storage of batch

culture Storage & increase of temp. of milk

in batch pasteurizer

Transfer of milk

Addition of culture Storage of milk in inoculation tank. Storage of

foil & cup

Packing

Storage in Incubation chember

Storage in cold room.

QC check

Coding

Storage in cold room

Dispatch in insulated van / Shippers

M.C.F.T Rajmachi , Karad 42

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

SHRIKHAND SECTION

Introduction :-

It is semi soft , Sweetish sour ,Whole milk product prepared from

lactic fermented curd.Shrikhand is the most popular product of Gokul dairy. In last few

years many renowned dairy organizations have plunged into the Shrikhand production

but it have shown no effect on effect on the demand for GOKUL SHRIKHAND. This

can be clearly understood by following graph.

Process:-

IN shrikhand pasteurized cow or buffalo milk is inoculated at 37 ºC with

1.0% starter, & kept for setting curd. Time is adujest according to ambient temperature so

that the developed acidity of curd reaches to 0.7- 0.9 % (lactic). The curd is suspended in

muslin cloth until nearly all the whey drained off. The semi dry mass ( chakka) is then

kneaded with sugar 70 % of chakka mass imparts creamish yellow colour.

Chakka:-

Is a white to pale yellow semisolid product of good texture & uniform consistency

obtained by draining of the whey from dahi obtained by lactic fermentation of milk

which has been subjected to minimum heat treatment equivalent to that of pasteurization.

It shall have pleasant dahi like flavor . It shall not contain any ingradient forgien to milk.

It shall be free from moldness & free from sign of fat or water seepage or both. It shall be

smooth & not appeare dry. It shall not contain extraneous colour & flavor.

Manufacturing Parameters:-

Sr Parameter Specification

no.

1. Total solid % by weight Not less than 58

2. Milk fat(on dry basis) % by weight Not less than 8.5

3. Milk protein (on dry basis) % by weight Not less than 9.0

4. Titrable acidity% 1.4 Max.

5. Sugar(sucrose) % by weight Not more than 72.5

6. Total ash % by weight Not more than 0.9

M.C.F.T Rajmachi , Karad 43

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Flow diagram for Shrikhand Manufacture :

Standardized and pasteurized milk.

Preheating(400C).

Inoculation of working culture .

Incubation up to acidity 1 %.

Drainage of whey .

Wrapping in Lyner .

Cold storage (8-12 hrs).

Addition of sugar and other ingredients .

Mixing to homogenize state.

Packaging.

Cup filling Pouching.

Lidding.

Sleeve sealing Sealing

Cartooning.

Storage

PANEER SECTION

M.C.F.T Rajmachi , Karad 44

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Paneer is manufactured from the buffalo milk testing less than 5% fat and 9%

SNF using citric acid as coagulation agent. Draining of whey, moulding, pressing and

packaging follows coagulation.

Flow diagram of Paneer Manufacture :-

Pasteurized & standeredised milk

(fat:-5.0-5.5, SNF :- 9.4 – 9.7)

Heating (at 75 to 800 C)

Holding 10 min.

Addition of citric acid (0.2% at 740 C)

Whey draining(Coagulation)

Filling into hoops

Pressing (for 15 to 20 min)(5 kg/cm2)

Immerse in chilled water (salt 0.1%) For 3 hrs

Storage (2ºC) Overnight

Cutting into cubes

Packing( Vaccum packing 200 gm)

Storage (deep freeze -17ºC)

Process steps:

Sr. Parameter Specification

M.C.F.T Rajmachi , Karad 45

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

no

1 Heating tempature in batch pasteurizer 80+2 c

2 Holding time in batch pasteurizer 10 minuets minimum

3 Coagulation temp 70 to 75 ºC

4 Holding time 10 minuets maximum

5 Pressing of paneer 10 to 20 minutes at air

pressure 4 to 6 kg per

centimeter square.

6 Chilled water temp for putting paneer block 10 ºC maximum(Salt

solution1% Max)

7. Time for putting paneer(blocks in chilled water) 2.5 t0 3 hr

Praparation of citric acid:-

Sr Parameter Specification

no.

1. Hot water temperature 70 – 75 ºC

2. Citric acid quantity 0.2% of milk used

3. Quantity of solution to added 1% of milk used

Control point:-

Coagulation temperature.

Cutting of paneer:-

Use sanitized cutting knife.

Packing & Storage:-

1) Details of packing slip/ Printed stamp- Manufacturing date, batch no , workers

card number , gross weight.

2) Weigh balance shall be checked with dead weight twice in a shift.

3) Weight tolerance 200+ 2g

M.C.F.T Rajmachi , Karad 46

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

4) Pouches shall have batch number & manufacturing date.

5) Stoeage of pack below 10ºC

POWDER SECTION

Introduction :

M.C.F.T Rajmachi , Karad 47

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

There are two powder production units in the dairy.

1) having capacity of about 30 tons powder/day.

2) having capacity of about 10 tons powder/day.

Both units are accompanied with evaporator assemblies. Both the evaporators are of

falling film type. Mainly SMP is manufactured in the dairy. But sometimes WMP and

Dairy Whitener are manufactured.

Flow diagram for Concentrate skim milk :

Skim milk

M.C.F.T Rajmachi , Karad 48

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Preheating in condenser.

Preheating in calendria No.3

Preheating in calendria No 2

Preheating in calendria No 1.

Holding

Evaporation in calendria No.1

Vapour seperator No.1

Evaporation in calendria No.2

Vapour seperator No.2

Evaporation in calendria No.3

Vapour seperator No.3.

Finisher

Concentrate skim milk

Flow diagram for Concentrate skim milk :

Concentrated skim milk balance tank

Mono pump

M.C.F.T Rajmachi , Karad 49

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Air blower

Automizer

Hot filtered air

Hot air and powder particles

1st and 2nd cyclone separator Suction fan

Rotary valve Exhaust hot air

Conveying duct Cool filter air

Transport cyclone Suction fan

Powder hooper Exhaust hot air

Rotary valve

Skim milk powder

Packging

Dry storage

Process Stage Involved In Spray Drying:

Feed

M.C.F.T Rajmachi , Karad 50

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Autimization

(rotary disc)

Spray air contact

(co-current flow chamber, vertical with conical flat base)

Drying of spray

(moisture evaporation)

Dried product separation

(primary discharge from drying chamber 40%,

secondary discharge from cyclone 60%)

Dried product handling

(after drying product cooling, conveying, packing and storage)

A) Manufacturing Parameters ( 10 TPD plant):-

Parameters Specification

Condensing Plant

Steam pressure mainline(kg/cm2) 14 – 15

Thermocompressor pressure(kg/cm2) 6–7

Temp. tubular heater 96 ± 2ºC

Temp. Vapour separator-1 71±2ºC

Temp. Vapour separator-2 60 ± 2ºC

Temp. Vapour separator-3

1. When steam jet ejector is in 41 ± 2 ºC

operation

2. When vaccume pump is in 46 ± 2ºC

operation

Vaccume in separator 3rd -1.0 kg/cm2

Cooling water inlet temperature 27 ± 3ºC

Cooling water outlet temp. 3.5 ± 3ºC

Baume reading 22.5 -23.5

Drying plant

M.C.F.T Rajmachi , Karad 51

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Inlet air temperature 190 ± 5ºC

Outlet air temp. 95 ± 2ºC

Chember vaccume (of water) 10- 15 mm

Amp automizer 20 ± 2

Amp suction fan 43 ± 2

Amp supply fan 25 ± 2

Amp conveying fan 13 ± 1

B) Manufacturing parameters (30TPD):-

Parameter Specification

Condensing plant

Steam pressure mainline(kg/cm2) 10- 14

Thermocompressor pressure(kg/cm2) 7–8

Direct steam injection milk heater temp 95 ± 4ºC

Temp. Vapour separator 1 65 ± 3ºC

Temp. Vapour separator 2 62 ± 3 ºC

Temp. Vapour separator 3 60 ± 3ºC

Temp. Vapour separator 4 52 ± 3ºC

Temp. Vapour separator 5 46 ± 3ºC

Evaporator vaccum 650 – 680 mm Hg

Temp difference between inlet & outlet >5 ºC

condenser water

Baume reading 21 – 24

Drying plant

Inlet air temperature 170 – 200 ºC

Outlet air temp. 90 ± 5 ºC

Chember vaccum(of water) -5 to -10 mmwc

Vibro inlet air temp For hot section(2 stage 95 ± 3ºC

drying)

Vibro inlet air temp For hot section(single Ambient

stage drying)

Vibro exhaust temp.(for single stage) 59 ± 3ºC

Vibro exhaust temp.(for 2 stage) 62 ± 3ºC

Vibro vaccum -10 to – 15 mmwc

Packaging of powder :

M.C.F.T Rajmachi , Karad 52

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Filling of powder is carried out in a separate room in Kraft Paper bags at a

temperature of 35-400 C.The size of KP (Kraft Paper)during filling sample is taken at

regular interval of half an hour to check its moisture sediment. Bulk density etc. The

filled bags are stored at room temperature in finished goods store.

For Pouch filling 25 Kgs KP bags are emptied in hopper of the pouch filling

machine. Powder is packed in pouches of 100 / 500 / 1000 gms.

Sr.No. Capacity of Pouch Weight of Pouch Weight of package

(in gms) (in gms) (in gms)

1) 100 100+2 4.

2) 500 500+5 9.

3) 1000 1000+10 13.

QUALITY CONTROL SECTION

Introduction :

Quality of product is must in order the market. This section controls the quality of

production, packaging material. This section carries out tests on products by keeping the

view of quality control and consumer satisfaction. Effluent plant is of more importance

as far as solution for environmental pollution is considered which comes under Quality

Control Section.

In the laboratory various tests are carried out on samples so as to improve the

product quality. All the standard techniques are followed in appropriate manner.

PFA standards for Milk and Milk products :

A) Raw Milk in Can :

Tests Buffalo Cow Milk

CHEMICAL

Fat 6.0 % (Min.) 3.8 % (Min.)

SNF 9.0 % (Min.) 8.5 %(Min.)

COB Negative Negative

M.C.F.T Rajmachi , Karad 53

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

PHYSICAL

Smell Satisfactory(Min.) Satisfactory(Min.)

B) Pasteurized Milk :

Tests Parameters

BIOCHEMICAL.

MBRT 4 Hrs (Min.).

BACTERIOLOGICAL

SPC 30,000 (Max.)

Coliform Absent.

PCT Negative.

C) Buffalo Milk and Cow Milk :

Tests Buffalo Milk Cow Milk

CHEMICAL

Fat 6.5 –6.8. % 3.8 - 4.2 %

SNF 9.0 - 9.3% 8.5 – 8.7 %

(For standardized Milk Fat % = 4.5 – 4.7 and SNF % = 8.5 – 8.7 % )

Acidity 0.1 – 0.15 % L.A. 0.1 – 0.15 % L.A.

BIOCHEMICAL.

MBRT 4 Hrs (Min.).

PHYSICAL.

Temperature 36 – 40 0 F 36 – 40 0 F

D) Fillpack Milk : B.M.

Tests Parameters

CHEMICAL

Fat 6.5 –6.8. %

SNF 9.0 - 9.3%

Acidity 0.11 – 0.15 % L.A.

M.C.F.T Rajmachi , Karad 54

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

BIOCHEMICAL.

MBRT 4.5 Hrs (Min.).

PHYSICAL.

Temperature 36 – 40 0 F

Keeping Quality 10 Hrs.

F) Milk for LASSI

Tests Parameters

CHEMICAL

Fat 4.9 % (Min.)

SNF 8.6 %(Min.)

G) Milk for CHAKKA

Tests Parameters

CHEMICAL

Fat 3.5 % (Min.)

SNF 9.3 %(Min.)

FOR MILK PRODUCTS

A) CREAM

Tests Parameters

CHEMICAL

Fat 35 % (Min.)

Acidity 0.07 – 0.09 %L.A

B) WHITE BUTTER

Tests Parameters

CHEMICAL

Fat 80 % ( Min.)

M.C.F.T Rajmachi , Karad 55

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Moisture 16 % (Max.)

Acidity

PCT Nil / 10 gm.

C) TABLE BUTTER :

Tests Parameters

CHEMICAL

Fat 80 % ( Min.)

Moisture 16 % (Max.)

Curd 1.5 % (Max.)

Salt 3.0 % (Max.)

D ) GHEE :

Tests Parameters

CHEMICAL

Moisture 0.5 % (Max.)

Baudoilin Test Negative.

Acidity 3 % (Max.)

PHYSICAL

Clour Yellowish White.

Sediment No.

E) CHAKKA :

Tests Parameters

CHEMICAL

T. S. 30.0 % (Min)

Milk Fat 33.0 % (Min)

Protein 37.0 % (Min)

Acidity 2.5 % (Min)

Ash 3.5 % (Min)

M.C.F.T Rajmachi , Karad 56

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

BACTERIOLOGICAL

Y/M 20/gm (Max)

Coliform Absent

F) SHRIKHAND (AMRAKHAND MILK FRUIT DESSERT)

Tests Parameters

CHEMICAL

T. S. 58 % (Min)

Milk Fat 8.5 % (Min)

Protein 10.5 % (Min)

Acidity 1.4 % (Max)

Ash 0.9 % (Max)

BACTERIOLOGICAL

Y/M 20/ gm (max)

Coliform PCT

F) SKIM MILK POWDER :

Tests Parameters

CHEMICAL :

Moisture 4.0 % (Max)

Fat 1.5 % (Max)

Acidity 1.5 % L. A. (Max)

Solubility Index 1.5 ml (Max)

Ash 9.3 % (Max)

BACTERIOLOGICAL

SPC 50.000 (Max)

Coliform Absent in 0.1 gm

G) LASSI :

Tests Parameters

M.C.F.T Rajmachi , Karad 57

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

CHEMICAL :

T. S. 18- 21 %

Fat 1.5 % (Max)

Acidity 0.60 – 0.75 % L. A.

BACTERIOLOGICAL

SPC 10-40 Thousands

PCT Nil

Y/M 1 – 2 (Max.)/ ml

Equipment

1. Milko Tester

2. B.O.D. Incubator

3. Incubator (H.A.O.)

4. Moisture Analyzer

5. Laboratory Centrifuge

6. Gerber Centrifuge

7. Solubility index mixer

8. Electronic Weighing balance

9. Moisture analyzer

10. Hot Water Bath

11. Bulk density apparatus

12. Muffle furnaces

13. Refrigerator

14. Bursting strength tester

15. Sieve Shaker (Table Top)

16. Caliper gauge

17. Distilled water preparation assembly

M.C.F.T Rajmachi , Karad 58

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

18. Autoclave

19. Laminar air flow chamber

Tests conducted for products are as follows:

Tests for raw Milk :

1) Fat 2) SNF 3) Temperature 4) Alcohol 5) COB

6) Neutralizer 7) Organoleptic

Tests for pasteurized milk :

1) Fat 2) SNF 3) Phosphatase 4) M. B. R.T. 5) SPC

6) Coliform

Tests for standardized milk :

1) Fat 2) SNF 3) Acidity 4) Curd 5) SPC

6) Coliform 7) M.B.R.T.

Tests for Table Butter :

1) Fat 2) Moisture 3) Salt 4) Curd 5) SPC

6) Coliform 7) Yeast & Mould.

M.C.F.T Rajmachi , Karad 59

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Tests for White Butter :

1) Fat 2) Moisture 3) Curd

Tests for Ghee :

1) Moisture 2) Acidity

Tests for Powder during manufacturing :

1) Fat 2) Moisture 3) Solubility Index. 4) SPC 5) Coliform

6) Yeast & Mould. 7) Pathogens .

Tests for Powder during Packaging :

1) Fat 2) Moisture 3) Solubility Index. 4) Brown particles.

Tests for Shrikhand :

1) Fat 2) Moisture 3) Salt 4) Protein 5)Ash

6) Coliform 7) Yeast & Mould.

Tests for packaging material:

1)GSM 2)Bursting Strength 3)Puncher Resistance 4)Thickness

M.C.F.T Rajmachi , Karad 60

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

REFRIGERATION SECTION

The general process of refrigeration system is takes place as follows

5

2

Fig: - REFRIGENERATION CYCLE

M.C.F.T Rajmachi , Karad 61

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

1.Compressor.

2.Condessor.

3.Receiver.

4.Expansion valve.

5.Evaporator.

Compressor:-

In Gokul the compressor are made up of the “ SABRO” company which are

screw type compressor , having capacity 225kr , having motor of 350 Hp is used. The

compressor increases the pressure forming vapour mix liquid.

Compressor Screw Type:-

“SABRO” Specification

1. Max operating pressure 28 bar

2. Test pressure 25 bar

3. Max. operating temperature 130 ºC

4. Min operating temperature 0 ºC

5. Volume 600 lit

Condensor:-

Here tube & shell tube type of condenser are used. The chilled water is circulated

through tube whereas, the NH3 is circulated through shell.The cost NH3 is about

50 Rs/lit. In condenser the liquid i.e water is formed having low temperature.

Receiver:-

The receiver , receives the water which is used as a chilled water for different

process.

Vessel Accumulated pump:-

Here the liq. Nh3 or Glycol is separated from the chilled water, & this water is

further subjected to evaporator. Here steam is produced which again subjected to

compressor.

M.C.F.T Rajmachi , Karad 62

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

BOILER SECTION:-

The main function of boiler is to produce steam. In Gokul there are 3 boilers each of

having capacity 5 ton/hr.

Generally 2 types of boilers are used:-

1. Water tube boiler:-

In this the water is circulated inside the tube & smoke is present

outside the tube.

2. Smoke tube boiler:-

In this smoke is present inside the tube & water is circulated outside

the tube.

In GOKUL Smoke tube boiler is used…

a) In Smoke tube boiler furnace oil is used for combustion having burning point 110 ºC.

b) In this there are 3 passes, which are circulating passes.

c) Here steam pressure is maintained between 10 – 12 kg/cm2 . The boiler have oil pump

, oil filter , electric heater which regulates the temp at 110ºC.

d) The water which is used comes through feed pump having feed check valve.

M.C.F.T Rajmachi , Karad 63

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

e) In this section the effiency of boiler is considerd on the basis of the oil consumption,

feed consumption.

MECHANICAL SECTION

As the Gokul dairy is big industry, it consists of much equipment. These

equipment needs repairing, maintenance oiling at regular intervals. Any outbreak in

machines can stop the plant operations so they should be paid attention for their

maintenance. Mechanical section of Gokul dairy is well developed. It has proved its

significance section of Gokul dairy is well developed. It has proved its significance by

saving the amounts by increasing the life of machinaries. Whatever be the fault in dairy,

operators run there and provide their service.

The following are some equipment’s which are given maintenance by

mechanical section.

1) Cans, Can Wahser, Can Conveyor.

2) Pumps, Pneumatic Valves.

3) Pasteurizer (Plates) , Homoginizer, Clarifier Cum Separator.

4) Compressors, Condensers, Valves.

M.C.F.T Rajmachi , Karad 64

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

5) Gear Boxes, Boiler, Steam Radiators.

6) Air Compressors, Butter Churns, Packing Machines.

7) Motors, Planetary Mixtures, Weighing balances.

8) Tankers and Other Equipment’s

Mechanical section provides the services like welding, soldering, filing , cutting,

threading and many more as per requirements. They are supposed to do the job of

regular inspection of machines and do the oiling or greasing as per schedules. They

are also involved in erection of new machinaries. Garage section comes under this

section where the tempos, trucks are serviced at cheaper rates.

CIP SECTION

CIP system is located at right hand side of RMRD. It is having four CIP tanks for

storing different cleaning and sanitizing solutions of various temperatures .These tanks

are connected to processing section through pipelines for cleaning various milk

processing equipment and systems.

Cleaning In Place applied to milk lines. Only cream separator & filters are

cleaned manually after each shift.

CIP of Processing Section:

To maintain the hygenic condition of plant proper cleaning, ventillation and CIP

of milk processing equipment is necessary. For CIP Nitric acid and Caustic Soda are use

in the required proportion. The pasteurizers are cleaned with CIP, while cleaning of

Cream Separator and Duplex Filters is done manually after the 6Hrs in each shift.

M.C.F.T Rajmachi , Karad 65

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

Flow chart for CIP of Processing Section :

Prerinse with hot water

(450C for 10 min.)

Caustic + Syndet powder circulation

(700C for 30 min.)

Hot water rinse

(800C for 10 min.)

Nitric acid circulation

(60-700C for 30 min.)

Hot water rinse

(800C for 10 min./till removal of acid )

Caustic + Syndet powder circulation

(700C for 30 min.)

Hot water rinse

(800C for 10 min./till removal of acid )

Hot water +Byosin (800C for 10 min.)

M.C.F.T Rajmachi , Karad 66

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

CIP programme for Milk Pasteurizers/Cream Seperator :

1.Rinse with warm water for about 8 min.

2.Circulate alkali detergent solution (NaOH solution ). For about 20 min at 750 C

3.Rinse alkaline detergent with hot water at 800C for 10 min.

4.Circulation of Nitric acid (HNO3 ) solution about 15 Min at 700 C

5.Flushing with hot water at 750 C for about 6 min.

6.Disinfections by circulation hot water at 900 C for about 8 min.

7.Gradual cooling with cold water for about 8 min.

CIP Programme for circuit with pipes, tanks & other cold components :

1. Rinsing with water for 3 min.

2. Circulation of an alkaline detergent at about 750 C for about 6 min.

3. Rinsing with hot water at 900 C for 3 min

4. Gradual cooling with cold water for about 7 min

M.C.F.T Rajmachi , Karad 67

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

EFFLUENT TREATMENT PLANT

Schematic flow diagram of ETP Plant:-

Raw Effluent tank Volumetric capacities 100m3

By pump

Fat Removal 80m3 × 2

Unit

M.C.F.T Rajmachi , Karad 68

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

By Gravity

Equalization tank 300m3 × 2

Floating Agetator

By pump

Effluent

Recirculation

UASB

500m3

By gravity

615m3 Aeration tank

(Fixed Aerators)

Sludge

Recirculation By gravity

9 × 9× 1 net

300m3 Sludge drying bed

By gravity

4m3

Treated

Effluent

Tank

M.C.F.T Rajmachi , Karad 69

Kolhapur Zilla Sahakari Dudh Utpadak Sangh Ltd. Kolhapur

The capacity of this ETP plant is about 1400m3/day. The fat obtained in ETP section

is transfer to the soaf industries for further use. The sludge obtained in Different stages of

ETP is used as manure for farming.

M.C.F.T Rajmachi , Karad 70

Das könnte Ihnen auch gefallen

- A PROJECT REPORT On Consumer Satisfaction and Awareness Towards Siddhadhara Milk ProductsDokument68 SeitenA PROJECT REPORT On Consumer Satisfaction and Awareness Towards Siddhadhara Milk ProductsBabasab Patil (Karrisatte)Noch keine Bewertungen

- Commissioning and Qualification ASTM ApproachDokument0 SeitenCommissioning and Qualification ASTM Approachvenki_beeNoch keine Bewertungen

- Amaul Dairy MBA Project Report Prince DudhatraDokument147 SeitenAmaul Dairy MBA Project Report Prince DudhatrapRiNcE DuDhAtRa80% (5)

- Customer Satisfaction at Model DairyDokument88 SeitenCustomer Satisfaction at Model DairyGangadhara RaoNoch keine Bewertungen

- RSD Life PostDokument17 SeitenRSD Life PostSteveEvetsNoch keine Bewertungen

- RMDokument53 SeitenRMVijay GohilNoch keine Bewertungen

- Main ProjectDokument59 SeitenMain Projectravikiran195550% (2)

- Omfed Production ProcessDokument15 SeitenOmfed Production Processawishmirza100% (3)

- Feasibility Study of Concentrate Feed Final ReportDokument45 SeitenFeasibility Study of Concentrate Feed Final ReportIjaaraa SabaaNoch keine Bewertungen

- AAVINDokument31 SeitenAAVINMounesh MouneshNoch keine Bewertungen

- Teste Admitere Clasa V A Liceul Ovidius Constanta PDFDokument22 SeitenTeste Admitere Clasa V A Liceul Ovidius Constanta PDFroxana100% (1)

- AavinDokument73 SeitenAavinSASC_MATHESH94% (18)

- Devbhog Report NewDokument62 SeitenDevbhog Report Newritu lodhi100% (1)

- Verka Project Final435Dokument76 SeitenVerka Project Final435Sanjeev kumarNoch keine Bewertungen

- Internship Report Bawany Sugar Mills LTDDokument41 SeitenInternship Report Bawany Sugar Mills LTDHyder Khan100% (1)

- Sabardairy& BAYERDokument80 SeitenSabardairy& BAYERJaymin Panchal100% (2)

- Summer Training Report On Sudha Ice Creams PDFDokument39 SeitenSummer Training Report On Sudha Ice Creams PDFprafful raghawNoch keine Bewertungen

- Job Satisfaction@Rann Sugar Project Report Mba HRDokument78 SeitenJob Satisfaction@Rann Sugar Project Report Mba HRPrince SharmaNoch keine Bewertungen

- Vimal DairyDokument120 SeitenVimal Dairyrushabhbholo83% (6)

- REPORTDokument59 SeitenREPORTrohini100% (1)

- GokulDokument13 SeitenGokulSamrat Patil50% (2)

- Project Report On DairyDokument76 SeitenProject Report On DairySourav RoyNoch keine Bewertungen

- Consumer Buying Behavior Toeards Milk ProductDokument54 SeitenConsumer Buying Behavior Toeards Milk ProductsuyoganuNoch keine Bewertungen

- Amul Industrial VisitDokument30 SeitenAmul Industrial Visitshivi rastogiNoch keine Bewertungen

- Madhur Dairy, Gandhinagar: V.M. Patel College of Management StudiesDokument70 SeitenMadhur Dairy, Gandhinagar: V.M. Patel College of Management StudiesAditypatel451_548818100% (1)

- Hashu Met Iom Sip ReportDokument43 SeitenHashu Met Iom Sip Reportpritam giri100% (1)

- Mahanand Inplant ProjectDokument57 SeitenMahanand Inplant ProjectfarooqlarziNoch keine Bewertungen

- PDP Project ReportDokument35 SeitenPDP Project Reportbharatpurasharma100% (5)

- GOWARDHANDokument30 SeitenGOWARDHANGauravNoch keine Bewertungen

- Consumer Perception About Verka ProductsDokument34 SeitenConsumer Perception About Verka Productsrobin2day100% (1)

- Industrial Visit Report at AMULDokument9 SeitenIndustrial Visit Report at AMULRushabh ParmarNoch keine Bewertungen

- A Study On Customer Satisfaction of Milma Products With Reference To Piravom MuncipalityDokument58 SeitenA Study On Customer Satisfaction of Milma Products With Reference To Piravom MuncipalityDheeraj KrishnanNoch keine Bewertungen

- SH RadhaDokument43 SeitenSH Radhaharshini hapzNoch keine Bewertungen

- ProjectDokument55 SeitenProjectamithgouda0% (1)

- Analysis of Consumer Behaviour Towards Sudha Ice-CreamDokument56 SeitenAnalysis of Consumer Behaviour Towards Sudha Ice-CreamSupriya_kamna100% (1)

- Distributor Channels of VerkaDokument70 SeitenDistributor Channels of VerkaMEHTANoch keine Bewertungen

- Chetan ReportDokument42 SeitenChetan Reportrohini100% (3)

- Markering Report of Gowrdhan Milk Dairy Munchar, PuneDokument47 SeitenMarkering Report of Gowrdhan Milk Dairy Munchar, Puneatulkhandar100% (7)

- Swati-SIP-Project - Nov 2017Dokument57 SeitenSwati-SIP-Project - Nov 2017Anup PatraNoch keine Bewertungen

- Rahul Raj 'Project Report On Amul'Dokument37 SeitenRahul Raj 'Project Report On Amul'rahul khan93% (15)

- DAIRYDokument41 SeitenDAIRYshrivastav_samir07Noch keine Bewertungen

- Arshi Khan Sohail Khan Bushra AddawalaDokument19 SeitenArshi Khan Sohail Khan Bushra Addawalaakbellegirl60% (1)

- Milma Diary FinalDokument66 SeitenMilma Diary FinalClick Pick100% (2)

- A Project Report ON Amul Dairy: Somlalit Institute of Business AdministrationDokument39 SeitenA Project Report ON Amul Dairy: Somlalit Institute of Business Administrationprathamesh kaduNoch keine Bewertungen

- Summer Training Report ON "Consumer Behavior & Satisfaction" FORDokument69 SeitenSummer Training Report ON "Consumer Behavior & Satisfaction" FORayushdixitNoch keine Bewertungen

- Ost On Visakha DairyDokument25 SeitenOst On Visakha DairyrahulchagantiNoch keine Bewertungen

- Namaste India FRPDokument19 SeitenNamaste India FRPShruti SaxenaNoch keine Bewertungen

- Company Profile Copy To ComDokument45 SeitenCompany Profile Copy To ComRaja Lingam91% (11)

- Sudha Milk DairyDokument62 SeitenSudha Milk Dairyimamitanand83% (6)

- Baroda Dairy (Prom)Dokument22 SeitenBaroda Dairy (Prom)Bhavini UnadkatNoch keine Bewertungen

- Varun Beverage LimitedDokument4 SeitenVarun Beverage LimitedIshan YashviNoch keine Bewertungen

- Project ReportDokument42 SeitenProject ReportmaattitudeNoch keine Bewertungen

- Effectiveness of Amul Chocolates Advertisement On Consumer Behaviour Towards Its SalesDokument50 SeitenEffectiveness of Amul Chocolates Advertisement On Consumer Behaviour Towards Its SalesRajani Gupta KamlapuriNoch keine Bewertungen

- A Report On An Industrial Visit To Havmore Ice CreamDokument23 SeitenA Report On An Industrial Visit To Havmore Ice CreamKeval PatelNoch keine Bewertungen

- Finance Report of Sharekhan LTDDokument85 SeitenFinance Report of Sharekhan LTDjsmith84Noch keine Bewertungen

- Understanding MutualfundsDokument45 SeitenUnderstanding MutualfundsManohar Naik ManuNoch keine Bewertungen

- Industrial Visit Report (2) For StudentsDokument15 SeitenIndustrial Visit Report (2) For StudentsAditya PatelNoch keine Bewertungen

- A Project Report On Organizational Study of Dharwad Milk Union Limited DharwadDokument46 SeitenA Project Report On Organizational Study of Dharwad Milk Union Limited DharwadBabasab Patil (Karrisatte)Noch keine Bewertungen

- Sandy ReportDokument15 SeitenSandy ReportAditya PatelNoch keine Bewertungen

- A Project Report On Organization Study of Dharwad Milk UnionDokument45 SeitenA Project Report On Organization Study of Dharwad Milk UnionBabasab Patil (Karrisatte)Noch keine Bewertungen

- Internship Report PonlaitDokument42 SeitenInternship Report PonlaitDjeoshva Belies DNoch keine Bewertungen

- Training Report. (Simran)Dokument95 SeitenTraining Report. (Simran)Yashoda MahajanNoch keine Bewertungen

- Case Study ReportDokument15 SeitenCase Study Reportsupercoolguy143Noch keine Bewertungen

- Gokul Final ReportDokument34 SeitenGokul Final ReportPranil Yadav0% (1)

- G7 - First Periodical TestDokument11 SeitenG7 - First Periodical TestNoreen Fae T. AguinaldoNoch keine Bewertungen

- Product List of DaburDokument5 SeitenProduct List of DaburNischal Solanki85% (13)

- Fat Metabolism During ExerciseDokument8 SeitenFat Metabolism During ExercisealmaformaNoch keine Bewertungen

- Reading Passage 1: IELTS Practice Test Volume 7Dokument14 SeitenReading Passage 1: IELTS Practice Test Volume 7Minh Nhat ThanNoch keine Bewertungen

- Keto ResearchDokument2 SeitenKeto ResearchNidza DzonsNoch keine Bewertungen

- YashikaDokument24 SeitenYashikaShruti PareekNoch keine Bewertungen

- The Importance of Safe Food Handling Practices and Proper Safety Etiquette Among The Grade 12 Cookery Students in DarssthsDokument34 SeitenThe Importance of Safe Food Handling Practices and Proper Safety Etiquette Among The Grade 12 Cookery Students in DarssthsLloyd Martin PascualNoch keine Bewertungen

- Alloro Dinner MenupdfDokument1 SeiteAlloro Dinner MenupdfAaron McCantsNoch keine Bewertungen

- General Science (Biological Sciences) : Dr. Sanawar IqbalDokument19 SeitenGeneral Science (Biological Sciences) : Dr. Sanawar IqbalAbdullah khalidNoch keine Bewertungen

- Comparative Study of Rate of Fermentation of Fruit JuicesDokument30 SeitenComparative Study of Rate of Fermentation of Fruit JuicesSubrat KumarNoch keine Bewertungen

- MaggiDokument5 SeitenMaggiVishalNoch keine Bewertungen

- Tip Sheet 9 - Foodservice: Allergen ManagementDokument3 SeitenTip Sheet 9 - Foodservice: Allergen ManagementLuis ReisNoch keine Bewertungen

- August 18, 2017 (MONDAY) : Division of Taguig City and Pateros Cluster V Em'S Signal Village Elementary School English - ViDokument2 SeitenAugust 18, 2017 (MONDAY) : Division of Taguig City and Pateros Cluster V Em'S Signal Village Elementary School English - ViCharlotteNoch keine Bewertungen

- Journal of Food Composition and AnalysisDokument10 SeitenJournal of Food Composition and AnalysisLevin Oval Arroyo OviedoNoch keine Bewertungen

- Case Study - How An Effective Manager Handles Precarious Situations "Left or Right"Dokument1 SeiteCase Study - How An Effective Manager Handles Precarious Situations "Left or Right"VAIDIK JOSHINoch keine Bewertungen

- Detailed Liquidity RatioDokument126 SeitenDetailed Liquidity Ratioapi-19931483Noch keine Bewertungen

- Breeding Amazons Captivity: Treasure Island. NotDokument5 SeitenBreeding Amazons Captivity: Treasure Island. NotOjeda BorisNoch keine Bewertungen

- Class 12th Chemistry Project On EsDokument30 SeitenClass 12th Chemistry Project On Esdan jose skNoch keine Bewertungen

- Surat AOCDokument2 SeitenSurat AOCIzzatun NabilahNoch keine Bewertungen

- Wild Ducks: Richard GilbertDokument11 SeitenWild Ducks: Richard GilbertRichard GilbertNoch keine Bewertungen

- Possessive PronounDokument20 SeitenPossessive PronounJerico MarcosNoch keine Bewertungen

- Respiration and Lipid Metabolism - SummaryDokument3 SeitenRespiration and Lipid Metabolism - SummaryxprakashNoch keine Bewertungen

- Cuba Is A Country of The West Indies, The Largest Single Island of TheDokument3 SeitenCuba Is A Country of The West Indies, The Largest Single Island of Themialge2001Noch keine Bewertungen

- RDO No. 80 - Mandaue City, CebuDokument1.113 SeitenRDO No. 80 - Mandaue City, CebuArnold DrilonNoch keine Bewertungen

- 617 - 9 - New Total English Intermediate. SB VideoScriptsDokument19 Seiten617 - 9 - New Total English Intermediate. SB VideoScriptsBruno GarciaNoch keine Bewertungen

- Dossier - The Future of Health DataDokument141 SeitenDossier - The Future of Health Dataigor100% (1)