Beruflich Dokumente

Kultur Dokumente

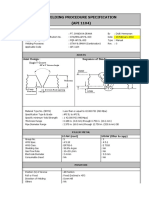

Pictorial Guide To Basic Metallurgy (Notes Correspond To Numbers in The Chart)

Hochgeladen von

shaikz_10 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

125 Ansichten2 SeitenLower Transformation Temperature - (AC1) temperature at which structure begins to change from ferrite and pearlite to austenite if being heated. Upper Transformation Temperature (AC3) temperature at which structure completes change from austenite to ferrite.

Originalbeschreibung:

Originaltitel

Pictorial Guide to Basic Metallurgy

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenLower Transformation Temperature - (AC1) temperature at which structure begins to change from ferrite and pearlite to austenite if being heated. Upper Transformation Temperature (AC3) temperature at which structure completes change from austenite to ferrite.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

125 Ansichten2 SeitenPictorial Guide To Basic Metallurgy (Notes Correspond To Numbers in The Chart)

Hochgeladen von

shaikz_1Lower Transformation Temperature - (AC1) temperature at which structure begins to change from ferrite and pearlite to austenite if being heated. Upper Transformation Temperature (AC3) temperature at which structure completes change from austenite to ferrite.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Pictorial Guide to Basic Metallurgy (Notes correspond to numbers in the chart)

1. Transformation Range - In this range steels undergo internal atomic changes which

affect the properties of the material.

2. Lower Transformation Temperature - (AC1) Temperature at which structure

begins to change from ferrite and pearlite to austenite if being heated, upon

cooling, temperature at which structure completes change from austenite to ferrite

and pearlite.

3. Upper Transformation Temperature - (AC3) Temperature at which structure

completes change from ferrite and pearlite to austenite if being heated, upon

cooling, temperature at which structure begins change from austenite to ferrite and

pearlite.

4. Annealing - Heating steels to slightly above AC3 , holding for austenite to

form, then slowly cooling (usually in a furnace) to produce ferrite and pearlite with

a small grain size, softness, and good ductility.

5. Normalizing - Heating to slightly above AC3 , holding for austenite to form,

then slowly cooling in still air (usually out of the furnace) to produce material with

somewhat higher strength, hardness and less ductility than that produced by

annealing.

6. Forging Range - Usually conducted several hundred degrees above AC3.

Typically in the range of 1800F to 2000F.

7. Burning Range - Results in steels that have to be remelted due to liquation

and other problems.

8. Stress Relieving - Heating to below AC1 and holding sufficiently long to relieve

internal stresses and then slowly cooling.

9. Blue Brittle Range - Loss of ductility while at temperatures from approximately

300F to 700F compared with temperature ranges above and below this range.

10. Preheating for Welding - Recommended temperature range for preheating

steels and alloys to precent cracking while welding. Temperature increases with

the carbon content.

11. Carburizing - Temperatures normally used to carburize steels (dissolving

carbon into the surface of steels using high carbon gaseous atmospheres.)

12. Nitriding - Temperatures normally used to nitride steels (dissolving nitrogen

into steels, usually with an ammonia-based atmosphere).

13. Spherodizing - Heating to just below AC1 sufficiently long for for the cementite

constituent of pearlite to change into globular form. May take many hours to

complete.

Das könnte Ihnen auch gefallen

- Tempil Basic Guide To Ferrous Metallurgy PDFDokument1 SeiteTempil Basic Guide To Ferrous Metallurgy PDFJose Alberto Gamiño Garcia100% (1)

- EAS107 Lab 1Dokument14 SeitenEAS107 Lab 1Mohd Ashraf Mohd Ismail100% (1)

- Lecture Heat TreatmentDokument23 SeitenLecture Heat TreatmentabinmwangiNoch keine Bewertungen

- Anealing TypesDokument29 SeitenAnealing TypesPratheep AddrinNoch keine Bewertungen

- 3 - Heat Treatment & Engineering ApplicationDokument24 Seiten3 - Heat Treatment & Engineering ApplicationHussein SaeedNoch keine Bewertungen

- ME3302 - Lecture-10 - Heat Treatment and Surface Hardening-2Dokument76 SeitenME3302 - Lecture-10 - Heat Treatment and Surface Hardening-2Jesh KeerawellaNoch keine Bewertungen

- Material Science and Engineering Heat TRDokument18 SeitenMaterial Science and Engineering Heat TRSamit NagNoch keine Bewertungen

- 4 - Heat TreatmentDokument29 Seiten4 - Heat TreatmentNomor SatuNoch keine Bewertungen

- Heat TreatmentDokument33 SeitenHeat TreatmentIsrael HailuNoch keine Bewertungen

- Heat TreatmentDokument40 SeitenHeat TreatmentFavour LawrenceNoch keine Bewertungen

- HEAT TREATMENT of SteelDokument33 SeitenHEAT TREATMENT of Steelparamaguru vNoch keine Bewertungen

- Heat TreatmentDokument38 SeitenHeat TreatmentTushar RoyNoch keine Bewertungen

- Modified HT NotesDokument16 SeitenModified HT NotesBeesam Ramesh KumarNoch keine Bewertungen

- Heat Treatment of SteelDokument7 SeitenHeat Treatment of SteelmaadNoch keine Bewertungen

- Heat Treatment LectureDokument58 SeitenHeat Treatment LectureKeith Tanaka Magaka100% (1)

- Anne A Ling and Normalizing of SteelDokument5 SeitenAnne A Ling and Normalizing of SteelTareef HashNoch keine Bewertungen

- Literature ReviewDokument23 SeitenLiterature ReviewRISHAVNoch keine Bewertungen

- Heat Treatment of SteelDokument7 SeitenHeat Treatment of Steelshganesh81gmailcomNoch keine Bewertungen

- Heat TreatmentDokument31 SeitenHeat TreatmentJackNoch keine Bewertungen

- Heat TreatmentDokument31 SeitenHeat TreatmentsureshNoch keine Bewertungen

- Capili Jefferson 12Dokument9 SeitenCapili Jefferson 12Christian Al EncarnacionNoch keine Bewertungen

- Importance of Heat TreatmentDokument5 SeitenImportance of Heat TreatmentArgha DasNoch keine Bewertungen

- HeattreatmentDokument29 SeitenHeattreatmentUJJWAL PRAKASHNoch keine Bewertungen

- Carbon SteelDokument15 SeitenCarbon Steelhirenkumar patelNoch keine Bewertungen

- 54tuhergihnheat TreatmentDokument31 Seiten54tuhergihnheat TreatmentJackNoch keine Bewertungen

- Uhergihnheat TreatmentDokument31 SeitenUhergihnheat TreatmentJackNoch keine Bewertungen

- Jnkjkjklnhjhytguythjbhgvbhvjhbhk Uggsilla Ki Heat TreatmentDokument31 SeitenJnkjkjklnhjhytguythjbhgvbhvjhbhk Uggsilla Ki Heat TreatmentJackNoch keine Bewertungen

- 4Dokument31 Seiten4JackNoch keine Bewertungen

- Hjbjjnkjkjklnhjhytguythjbhgvbhvjh Bhkuggsilla Ki Heat TreatmentDokument31 SeitenHjbjjnkjkjklnhjhytguythjbhgvbhvjh Bhkuggsilla Ki Heat TreatmentJackNoch keine Bewertungen

- Uggsilla Ki Heat TreatmentDokument31 SeitenUggsilla Ki Heat TreatmentJackNoch keine Bewertungen

- Chapter 8 - Heat TreatmentDokument20 SeitenChapter 8 - Heat TreatmentISANoch keine Bewertungen

- Document 7Dokument6 SeitenDocument 7Roy mugendi100% (1)

- Kjklnhjhytguythjbhgvbhvjhbhkugg Silla Ki Heat TreatmentDokument31 SeitenKjklnhjhytguythjbhgvbhvjhbhkugg Silla Ki Heat TreatmentJackNoch keine Bewertungen

- Objectives of Heat TreatmentDokument6 SeitenObjectives of Heat TreatmentAdaitaChowdhury100% (1)

- Jhbhkuggsilla Ki Heat TreatmentDokument31 SeitenJhbhkuggsilla Ki Heat TreatmentJackNoch keine Bewertungen

- Unit 2: Heat Treatment of Iron and SteelsDokument24 SeitenUnit 2: Heat Treatment of Iron and SteelsRahul kumarNoch keine Bewertungen

- Material ScienceDokument20 SeitenMaterial ScienceKushNoch keine Bewertungen

- Theory of Heat TreatmentDokument8 SeitenTheory of Heat Treatmentayie740% (1)

- Changing The Properties of SteelsDokument21 SeitenChanging The Properties of SteelsBHARANINoch keine Bewertungen

- Course No: Experiment No:: Structural Study of Mild Steel After Heat TreatmentDokument13 SeitenCourse No: Experiment No:: Structural Study of Mild Steel After Heat TreatmentRifat KhanNoch keine Bewertungen

- Heat TreatmentDokument21 SeitenHeat TreatmentChernet MerknehNoch keine Bewertungen

- Hjhytguythjbhgvbhvjhbhkuggsilla Ki Heat TreatmentDokument31 SeitenHjhytguythjbhgvbhvjhbhkuggsilla Ki Heat TreatmentJackNoch keine Bewertungen

- Gvbhvjhbhkuggsilla Ki Heat TreatmentDokument31 SeitenGvbhvjhbhkuggsilla Ki Heat TreatmentJackNoch keine Bewertungen

- Heat TreatmentDokument59 SeitenHeat TreatmentINSTECH Consulting100% (1)

- MetallurgyDokument25 SeitenMetallurgyPandu Damay PutraNoch keine Bewertungen

- Heat Treatment: ME 318 Manufacturing TechniquesDokument12 SeitenHeat Treatment: ME 318 Manufacturing Techniquesmayur_mechNoch keine Bewertungen

- Heat TreatmentDokument44 SeitenHeat Treatmentmurari100% (2)

- 1 MatsciDokument20 Seiten1 MatsciCliford AlbiaNoch keine Bewertungen

- Discussion: Ferrous Alloys Specimen 1 (X17)Dokument5 SeitenDiscussion: Ferrous Alloys Specimen 1 (X17)Syahirzabidi100% (1)

- Heat Treatment Steel: ObjectDokument10 SeitenHeat Treatment Steel: ObjectKetut Rizki FirmandanuNoch keine Bewertungen

- Heat Treatment of Ferrous MetalsDokument8 SeitenHeat Treatment of Ferrous Metalsarchangeluriel06Noch keine Bewertungen

- Heat TreatmentDokument26 SeitenHeat TreatmentMirza Shaizad BegNoch keine Bewertungen

- Heat Treatment of Ferrous AlloysDokument11 SeitenHeat Treatment of Ferrous AlloysSyed Mohsin Ali Naqvi100% (2)

- 3rd Class Heat TreatmentDokument19 Seiten3rd Class Heat TreatmentPROMISE JULIUSNoch keine Bewertungen

- HeattreatmentDokument21 SeitenHeattreatmentroyalmechnoNoch keine Bewertungen

- Heat Treatment of Steels (Power Point Presentation)Dokument14 SeitenHeat Treatment of Steels (Power Point Presentation)Armando Lopez Bond75% (4)

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelVon EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNoch keine Bewertungen

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelVon EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelBewertung: 5 von 5 Sternen5/5 (4)

- ThermodynamicsDokument79 SeitenThermodynamicsshaikz_1Noch keine Bewertungen

- Time TablesDokument1 SeiteTime Tablesshaikz_1Noch keine Bewertungen

- FM 920 1172 - Isometric Control SheetDokument1 SeiteFM 920 1172 - Isometric Control Sheetshaikz_1Noch keine Bewertungen

- Contractor Float UtilizationDokument6 SeitenContractor Float Utilizationshaikz_1Noch keine Bewertungen

- DatabaseDokument112 SeitenDatabaseamirulamirNoch keine Bewertungen

- B 928 - 04 - QjkyoaDokument10 SeitenB 928 - 04 - Qjkyoamercab15Noch keine Bewertungen

- Section Guillotine: Title SawDokument4 SeitenSection Guillotine: Title SawIsabel TorresNoch keine Bewertungen

- Draft Wps Astm A 743 GR - Ca6nmDokument2 SeitenDraft Wps Astm A 743 GR - Ca6nmIlham PaneNoch keine Bewertungen

- Agoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Dokument3 SeitenAgoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Anonymous 7vljJzH100% (1)

- Sae Ams 2759-1e-2014Dokument13 SeitenSae Ams 2759-1e-2014Reza NooriNoch keine Bewertungen

- Astm 105Dokument5 SeitenAstm 105JOSEPH REFUERZONoch keine Bewertungen

- Alloy 400 PDFDokument12 SeitenAlloy 400 PDFwasatiah05Noch keine Bewertungen

- CASE STUDY Corrosion of Pump BodyDokument5 SeitenCASE STUDY Corrosion of Pump BodyJeevana Sugandha WijerathnaNoch keine Bewertungen

- Astm A749Dokument9 SeitenAstm A749Felipe De la cruzNoch keine Bewertungen

- Astm B 265-2010Dokument9 SeitenAstm B 265-2010bryan wengNoch keine Bewertungen

- Draft WPS Welder R0Dokument51 SeitenDraft WPS Welder R0R Bernanda Argandhi SaputraNoch keine Bewertungen

- Mstube BrochureDokument8 SeitenMstube Brochuresatish3682Noch keine Bewertungen

- Report Welding ISMA PDFDokument14 SeitenReport Welding ISMA PDFMuhammad NaqiuddinNoch keine Bewertungen

- THE PEROIDIC TABLE Answer Key 2dd55 61635c8cDokument1 SeiteTHE PEROIDIC TABLE Answer Key 2dd55 61635c8cbhagat johnsonNoch keine Bewertungen

- Storz ConnectionsDokument2 SeitenStorz ConnectionsSpinu DanielNoch keine Bewertungen

- 26-Hardox 600 The - Ultimate Wear Plate PDFDokument4 Seiten26-Hardox 600 The - Ultimate Wear Plate PDFlazaroccsNoch keine Bewertungen

- SSD Industrial Training Report Raigarh ChhattisgarhDokument23 SeitenSSD Industrial Training Report Raigarh ChhattisgarhAviNoch keine Bewertungen

- A 709/A 709M - 01b: N 1 - Where ". - ." Appears in This Table, There Is No RequirementDokument1 SeiteA 709/A 709M - 01b: N 1 - Where ". - ." Appears in This Table, There Is No Requirementle hoang vietNoch keine Bewertungen

- Property Name: Die Casting Centrifugal Casting Investment CastingDokument11 SeitenProperty Name: Die Casting Centrifugal Casting Investment CastingjohnblackburnNoch keine Bewertungen

- Study On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelDokument8 SeitenStudy On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelAngga Pamilu PutraNoch keine Bewertungen

- Faculty of Engineering, UNIMASDokument4 SeitenFaculty of Engineering, UNIMASjohnNoch keine Bewertungen

- B462 Plfy402430879val PDFDokument6 SeitenB462 Plfy402430879val PDFCarlosIkedaNoch keine Bewertungen

- Buku Saku Surveyor:Surveyor HandbookDokument4 SeitenBuku Saku Surveyor:Surveyor HandbookHaryadi BakriNoch keine Bewertungen

- Metal Ammine Complexes 1928.Dokument296 SeitenMetal Ammine Complexes 1928.Richard.nlNoch keine Bewertungen

- Experimental Investigation of Deposition Rate in Tig Welding of Grade 304 Stainless SteelDokument3 SeitenExperimental Investigation of Deposition Rate in Tig Welding of Grade 304 Stainless Steelsreejith2786Noch keine Bewertungen

- The Effect of Sodium Citrate As An Additive On Properties of ElectroplatedDokument7 SeitenThe Effect of Sodium Citrate As An Additive On Properties of ElectroplatedCzzhhNoch keine Bewertungen

- USm Nitjsr MFGDokument33 SeitenUSm Nitjsr MFGshaliniNoch keine Bewertungen

- SM53C Datasheet, SM53C Property, SM53C Standard Specification, SM53C Standard DownloadDokument2 SeitenSM53C Datasheet, SM53C Property, SM53C Standard Specification, SM53C Standard Downloadandi suntoroNoch keine Bewertungen

- Investigation Into The Effect of Tool-Chip Contact Length OnDokument5 SeitenInvestigation Into The Effect of Tool-Chip Contact Length OnAbid HussainNoch keine Bewertungen