Beruflich Dokumente

Kultur Dokumente

Benzene

Hochgeladen von

Tee Chee KeongOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Benzene

Hochgeladen von

Tee Chee KeongCopyright:

Verfügbare Formate

Cyclohexanol Caprolactam Nylon 6

KA oil

Polymerization

w-amino acid

Liquid-phase Oxidation

1. + H2O H2N(CH2)5COOH

Hydrogenation: ΔH = -266

2. H2N(CH2)5COOH + [-HN(CH2)5CO-]n

95-120˚C 10atm 95% short contact

Cobalt acetate and orthoboric acid catalyst Nylon 6

250-280˚C

160-220˚C 25-30atm system

*T control is important especially for depolymerization,

Ni/alumina or Ni/Pd which directly proportional to rexn T and water content

Benzene Cyclohexane

Alkylation: Liquid-phase Oxidation

+21/2O2 HOOC(CH2)4COOH + H2O

Cobalt acetate catalyst

40-100˚C 2-8atm AlCl3-HCl

(1st monomer ) (2nd monomer)

Ethylbenzene (Badger Process) Adipic Acid Hexamethylenediamine Nylon 6,6

HOOC(CH2)4COOH H2N(CH2)6NH2

Dehydrogenation

1) Hydrogenation 1,6-hexanediol n HOOC(CH2)4COOH + n H2N(CH2)6NH2

HOOC(CH2)4COOH + 4H2 HO(CH2)6OH + 2H2O

• [OOC(CH2)4COO]n2-+ [H3N(CH2)6NH3]

2) HO(CH2)6OH +2NH3 H2N(CH2)6NH2 + 2H2O • [-CO(CH2)4CONH(CH2)6NH-] +2nH2O

600-700˚C ≤ 1atm Hexamethylenediamine

90%yield@30-40%conversion Hexamethylene diammonium adipate salt

Styrene (Monsanto/Lummus

Crest Process)

Das könnte Ihnen auch gefallen

- Condensate Estimation TemplateDokument2 SeitenCondensate Estimation TemplateTee Chee KeongNoch keine Bewertungen

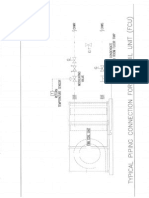

- FCU & AHU Typical Piping ConnectionDokument2 SeitenFCU & AHU Typical Piping ConnectionTee Chee Keong75% (4)

- Read MeDokument1 SeiteRead MeTee Chee KeongNoch keine Bewertungen

- MAXIS Annual Report 2010 (2.8MB)Dokument283 SeitenMAXIS Annual Report 2010 (2.8MB)Tee Chee KeongNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Lifting PermanentmagnetDokument6 SeitenLifting PermanentmagnetShekh Muhsen Uddin Ahmed100% (1)

- Parker HPD Product Bulletin (HY28-2673-01)Dokument162 SeitenParker HPD Product Bulletin (HY28-2673-01)helden50229881Noch keine Bewertungen

- Remedy MidTier Guide 7-5Dokument170 SeitenRemedy MidTier Guide 7-5martin_wiedmeyerNoch keine Bewertungen

- Windows System Shortcut CommandsDokument2 SeitenWindows System Shortcut CommandsVenkatesh YerraNoch keine Bewertungen

- Shaqlawa Technical College: IT DepartmentDokument20 SeitenShaqlawa Technical College: IT Departmentbilind_mustafaNoch keine Bewertungen

- Tourbier Renewal NoticeDokument5 SeitenTourbier Renewal NoticeCristina Marie DongalloNoch keine Bewertungen

- Chapter 24 - The Solar SystemDokument36 SeitenChapter 24 - The Solar SystemHeather Blackwell100% (1)

- What Are The Advantages and Disadvantages of UsingDokument4 SeitenWhat Are The Advantages and Disadvantages of UsingJofet Mendiola88% (8)

- Corporate Restructuring Short NotesDokument31 SeitenCorporate Restructuring Short NotesSatwik Jain57% (7)

- Assignment RoadDokument14 SeitenAssignment RoadEsya ImanNoch keine Bewertungen

- Community Resource MobilizationDokument17 SeitenCommunity Resource Mobilizationerikka june forosueloNoch keine Bewertungen

- Saif Powertec Limited Project "Standard Operating Process" As-Is DocumentDokument7 SeitenSaif Powertec Limited Project "Standard Operating Process" As-Is DocumentAbhishekChowdhuryNoch keine Bewertungen

- Rab Sikda Optima 2016Dokument20 SeitenRab Sikda Optima 2016Julius Chatry UniwalyNoch keine Bewertungen

- 16 Personalities ResultsDokument9 Seiten16 Personalities Resultsapi-605848036Noch keine Bewertungen

- PronounsDokument6 SeitenPronounsHải Dương LêNoch keine Bewertungen

- Flowrox Valve Solutions Catalogue E-VersionDokument16 SeitenFlowrox Valve Solutions Catalogue E-Versionjavier alvarezNoch keine Bewertungen

- Biscotti: Notes: The Sugar I Use in France, Is CalledDokument2 SeitenBiscotti: Notes: The Sugar I Use in France, Is CalledMonica CreangaNoch keine Bewertungen

- Chapter 13Dokument15 SeitenChapter 13anormal08Noch keine Bewertungen

- TAC42055 - HO01 Edition I2.0: Section 1 Module 1 Page 1Dokument69 SeitenTAC42055 - HO01 Edition I2.0: Section 1 Module 1 Page 1matheus santosNoch keine Bewertungen

- Mobile Services: Your Account Summary This Month'S ChargesDokument3 SeitenMobile Services: Your Account Summary This Month'S Chargeskumarvaibhav301745Noch keine Bewertungen

- SahanaDokument1 SeiteSahanamurthyarun1993Noch keine Bewertungen

- Anthony Robbins - Time of Your Life - Summary CardsDokument23 SeitenAnthony Robbins - Time of Your Life - Summary CardsWineZen97% (58)

- Risha Hannah I. NazarethDokument4 SeitenRisha Hannah I. NazarethAlpaccino IslesNoch keine Bewertungen

- Nature of Science-Worksheet - The Amoeba Sisters HWDokument2 SeitenNature of Science-Worksheet - The Amoeba Sisters HWTiara Daniel25% (4)

- Sodexo GermanyDokument13 SeitenSodexo GermanySandeep Kumar AgrawalNoch keine Bewertungen

- SAP HR - Legacy System Migration Workbench (LSMW)Dokument5 SeitenSAP HR - Legacy System Migration Workbench (LSMW)Bharathk KldNoch keine Bewertungen

- Angelo (Patrick) Complaint PDFDokument2 SeitenAngelo (Patrick) Complaint PDFPatLohmannNoch keine Bewertungen

- Auto Turn-Off For Water Pump With Four Different Time SlotsDokument3 SeitenAuto Turn-Off For Water Pump With Four Different Time SlotsKethavath Sakrunaik K100% (1)

- RevlonDokument13 SeitenRevlonSarosh AtaNoch keine Bewertungen

- Jones Et - Al.1994Dokument6 SeitenJones Et - Al.1994Sukanya MajumderNoch keine Bewertungen