Beruflich Dokumente

Kultur Dokumente

Prontuario Vigas

Hochgeladen von

vicvargOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Prontuario Vigas

Hochgeladen von

vicvargCopyright:

Verfügbare Formate

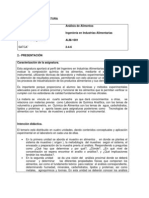

Notas

- P* se refiere a la carga puntual mayorada, para el clculo de esfuerzos y reacciones

- P se refiere a la carga puntual caracterstica, para deformaciones

- q* se refiere a la carga distribuida mayorada, para el clculo de esfuerzos y reacciones

- q se refiere a la carga distribuida caracterstica, para deformaciones

- Fy es el limite elstico del acero (235, 275, 355, 420 460)

- Si introduce un valor de D (dimetro) = 0, se entiende que el perfil es cuadrado o rectangular

- Si D (dimetro) <> 0, se entiende que el perfil es circular, pese a que H y B sean distintos de cero

- H es la altura del perfil (normalmente el canto).

- B es la base del perfil

- Esta hoja de clculo recomendar slo perfiles del tipo de seccin que usted haya introducido.

- Esta hoja de clculo advierte sobre efectos locales considerando que el perfil est sometido a flexin pura.

Para otras combinaciones de carga consultar la Gua de Diseo 2 del CIDECT o el Eurocdigo 3.

Casos Incluidos

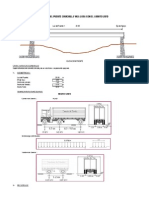

Viga biapoyada con carga puntual

Viga biapoyada con 2 cargas puntuales simtricas

Viga biapoyada con carga uniforme descentrada

Viga biapoyada con carga triangular ascendente

Viga biapoyada con carga triangular descendente

Viga biempotrada con carga puntual

Viga biempotrada con 2 cargas puntuales simtricas

Viga biempotrada con carga uniforme descentrada

Viga biempotrada con carga triangular ascendente

Viga biempotrada con carga triangular descendente

Viga en voladizo con carga puntual

Viga en voladizo con carga uniforme

Viga en voladizo con carga triangular ascendente

Viga en voladizo con carga triangular descendente

Correas continuas de dos tramos

2000, Instituto para la Construccin Tubular

Resultados

Viga biapoyada con carga puntual

Datos

Reacciones

300.0 kN

RA =

P=

210.0 kN

RB =

L=

12.0 m

Cortantes

a=

6.0 m

V(x) =

b=

6.0 m

Vmx =

x=

1.00 m

en x =

P* =

Fy=

355 N/mm2

150.0 kN

MA =

0.0 kNm

150.0 kN

MB =

0.0 kNm

Flectores

150.0 kN

M(x) =

150.0 kNm

150.0 kN

Mmx =

900.0 kNm

6.0 m

en x =

Mdulo Elstico mnimo (Wel) =

6.0 m

2535.21 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

Perfil

H=

600.0 mm

D=

0.0 mm

RHS 600x200x12,5

2558.34

146.83

76750.32

B=

200.0 mm

T=

12.5 mm

RHS 500x400x10

2573.37

135.46

64334.26

Flechas

RHS 400x300x20

2606.99

193.76

52139.86

f(x) =

RHS 450x350x14

2662.16

163.08

59898.70

fmx =

RHS 600x400x8

2689.00

121.87

80669.90

RHS 500x200x20

2717.35

193.76

67933.78

RHS 600x300x10

2722.47

135.46

81674.19

RHS 500x300x14

2757.14

163.08

68928.56

RHS 600x200x14

2807.43

163.08

84222.82

RHS 450x350x16

2965.65

184.30

66727.11

RHS 500x400x12

2995.80

160.19

74895.02

RHS 500x300x16

3070.53

184.30

76763.26

RHS 500x400x12,5

3103.51

166.45

77587.86

RHS 600x200x16

3120.78

184.30

93623.52

RHS 600x300x12

3164.20

160.19

94926.03

RHS 450x350x18

3250.73

204.99

73141.35

RHS 600x300x12,5

3277.53

166.45

98325.84

RHS 600x400x10

3302.70

151.16

99080.85

RHS 500x300x18

3364.56

204.99

84113.98

RHS 600x200x18

3412.92

204.99 102387.75

Err:512

0.0469 m

en x=

6.00 m

= 1/ 255

2000, Instituto para la Construccin Tubular

Resultados

Viga biapoyada con 2 cargas puntuales simtricas

Datos

Reacciones

150.0 kN

RA =

P=

105.0 kN

RB =

L=

12.0 m

Cortantes

a=

4.0 m

V(x) =

6.00 m

Vmx =

355 N/mm2

en x =

P* =

x=

Fy=

150.0 kN

MA =

0.0 kNm

150.0 kN

MB =

0.0 kNm

Flectores

0.0 kN

M(x) =

600.0 kNm

150.0 kN

Mmx =

600.0 kNm

0.0 m

en x =

Mdulo Elstico mnimo (Wel) =

6.0 m

1690.14 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

Perfil

H=

600.0 mm

D=

0.0 mm

RHS 500x300x8

1712.20

96.75

42805.10

B=

200.0 mm

T=

10.0 mm

RHS 400x250x14

1738.11

130.11

34762.24

Flechas

RHS 600x200x8

1754.37

96.75

52631.08

f(x) =

RHS 450x150x18

1756.87

148.47

39529.59

fmx =

RHS 400x200x18

1762.96

148.47

35259.14

RHS 400x300x12

1764.20

122.51

35283.94

RHS 400x300x12,5

1824.43

127.20

36488.52

RHS 500x200x12

1852.48

122.51

46311.98

RHS 500x400x7

1855.09

96.05

46377.25

RHS 450x150x20

1872.92

162.36

42140.79

RHS 500x400x7,1

1879.76

97.38

46994.06

RHS 400x200x20

1884.33

162.36

37686.52

RHS 500x200x12,5

1914.97

127.20

47874.31

RHS 400x250x16

1922.43

146.62

38448.65

RHS 400x300x14

1998.97

141.10

39979.39

RHS 450x350x10

2018.59

119.76

45418.25

RHS 400x250x18

2091.53

162.60

41830.58

RHS 500x300x10

2093.10

119.76

52327.60

RHS 500x200x14

2095.61

141.10

52390.27

RHS 500x400x8

2099.54

109.31

52488.51

Err:512

0.0477 m

en x=

6.00 m

= 1/ 251

2000, Instituto para la Construccin Tubular

Datos

Viga biapoyada con carga uniforme

Resultados

q* =

3.6 kN/m

Reacciones

q=

2.4 kN/m

RA =

L=

6.0 m

RB =

a=

3.0 m

Cortantes

b=

3.0 m

V(x) =

0.0 kN

M(x) =

16.2 kNm

c=

6.0 m

Vmx =

10.8 kN

Mmx =

16.2 kNm

x=

3.00 m

en x =

0.0 m

en x =

Fy=

355 N/mm2

10.8 kN

MA =

0.0 kNm

10.8 kN

MB =

0.0 kNm

Flectores

Mdulo Elstico mnimo (Wel) =

3.0 m

45.63 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

Perfil

H=

180.0 mm

D=

0.0 mm

B=

60.0 mm

T=

6.0 mm

RHS 100x60x8

46.04

16.36

230.18

RHS 110x70x5

46.84

12.84

257.62

Flecha

RHS 140x80x3

47.77

9.90

334.40

f(x) =

RHS 120x60x5

47.83

12.84

286.97

RHS 150x70x3

48.45

9.90

363.39

RHS 160x60x3

48.73

9.90

389.86

RHS 120x80x4

49.10

11.73

294.59

RHS 100x60x10

49.68

19.28

248.41

RHS 140x60x4

50.80

11.73

355.59

RHS 150x50x4

50.85

11.73

381.39

RHS 100x80x6

51.68

15.10

258.39

RHS 110x70x6

53.57

15.10

294.63

RHS 120x60x6

54.67

15.10

328.01

RHS 140x100x3

55.82

10.84

390.71

RHS 150x90x3

57.10

10.84

428.22

RHS 160x80x3

57.98

10.84

463.81

RHS 120x100x4

58.07

12.99

348.43

RHS 180x60x3

58.54

10.84

526.85

RHS 120x80x5

58.86

14.41

353.14

RHS 100x80x8

59.61

18.87

298.06

= 1/ 294

0.0204 m

(NO es flecha mxima)

2000, Instituto para la Construccin Tubular

Resultados

Viga biapoyada con carga triangular ascendente

Datos

Reacciones

50.0 kN/m

RA =

q=

35.0 kN/m

RB =

L=

12.0 m

Cortantes

a=

6.0 m

V(x) =

b=

6.0 m

Vmx =

x=

5.70 m

en x =

q* =

Fy=

355 N/mm2

100.0 kN

MA =

0.0 kNm

50.0 kN

MB =

0.0 kNm

Flectores

-35.4 kN

M(x) =

312.8 kNm

100.0 kN

Mmx =

326.6 kNm

0.0 m

en x =

Mdulo Elstico mnimo (Wel) =

4.9 m

920.00 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

RHS 300x220x12,5

947.51

RHS 400x200x8

RHS 300x200x14

Perfil

H=

400.0 mm

D=

0.0 mm

91.88

14212.72

B=

200.0 mm

T=

16.0 mm

948.72

71.63

18974.42

Flechas

952.49

97.14

14287.30

f(x) =

RHS 450x150x8

956.45

71.63

21520.08

fmx =

RHS 400x300x6

972.34

64.08

19446.79

RHS 350x150x14

977.24

97.14

17101.63

RHS 400x250x7

977.92

68.58

19558.42

RHS 400x250x7,1

990.54

69.51

19810.74

RHS 320x220x12

1009.27

92.36

16148.26

RHS 400x300x6,3

1010.63

66.92

20212.64

RHS 320x220x12,5

1041.10

95.80

16657.62

RHS 300x200x16

1041.11

108.94

15616.67

RHS 350x150x16

1065.65

108.94

18648.85

RHS 400x250x8

1102.41

77.91

22048.12

RHS 400x300x7

1113.08

74.07

22261.56

RHS 300x200x18

1118.66

120.21

16779.87

RHS 400x300x7,1

1127.56

75.09

22551.11

RHS 320x220x14

1131.93

105.93

18110.89

RHS 350x150x18

1142.00

120.21

19984.97

RHS 400x200x10

1150.13

88.36

23002.65

Err:512

0.0445 m

= 1/ 269

2000, Instituto para la Construccin Tubular

Resultados

Viga biapoyada con carga triangular descendente

Datos

Reacciones

50.0 kN/m

RA =

q=

35.0 kN/m

RB =

L=

12.0 m

Cortantes

a=

6.0 m

V(x) =

b=

6.0 m

Vmx =

x=

5.60 m

en x =

q* =

Fy=

355 N/mm2

125.0 kN

MA =

0.0 kNm

25.0 kN

MB =

0.0 kNm

Flectores

-49.3 kN

M(x) =

159.9 kNm

125.0 kN

Mmx =

190.8 kNm

0.0 m

en x =

Mdulo Elstico mnimo (Wel) =

3.6 m

537.53 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

H=

400.0 mm

D=

0.0 mm

RHS 300x200x7

557.72

52.09

8365.75

B=

200.0 mm

T=

12.0 mm

RHS 300x200x7,1

564.67

52.79

8469.98

Flechas

RHS 260x180x10

566.41

63.24

7363.31

f(x) =

RHS 250x150x14

569.16

75.16

7114.53

fmx =

RHS 300x100x14

570.47

75.16

8557.01

RHS 260x140x14

573.13

75.16

7450.64

RHS 320x220x6

574.75

49.01

9195.97

RHS 350x150x7

576.74

52.09

10092.88

RHS 250x200x10

581.27

64.81

7265.84

RHS 350x150x7,1

583.89

52.79

10218.12

RHS 320x220x6,3

595.32

51.10

9525.16

RHS 300x100x16

610.49

83.82

9157.36

RHS 250x150x16

612.79

83.82

7659.83

RHS 260x140x16

616.55

83.82

8015.12

RHS 300x200x8

625.95

59.07

9389.27

RHS 260x180x12

634.23

73.52

8245.01

RHS 350x150x8

646.96

59.07

11321.87

RHS 260x180x12,5

652.50

76.18

8482.47

RHS 250x200x12

652.69

75.41

8158.66

RHS 320x220x7

653.86

56.49

10461.72

Perfil

Err:512

0.0313 m

= 1/ 383

2000, Instituto para la Construccin Tubular

Resultados

Viga biempotrada con carga puntual

Datos

Reacciones

300.0 kN

RA =

P=

210.0 kN

RB =

L=

12.0 m

Cortantes

a=

6.0 m

V(x) =

-150.0 kN

M(x) =

-450.0 kNm

b=

6.0 m

Vmx =

-150.0 kN

Mmx =

-450.0 kNm

x=

12.00 m

en x =

12.0 m

en x =

P* =

Fy=

355 N/mm2

150.0 kN

MA =

-450.0 kNm

150.0 kN

MB =

-450.0 kNm

Flectores

Mdulo Elstico mnimo (Wel) =

12.0 m

1267.61 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

Perfil

H=

450.0 mm

D=

0.0 mm

RHS 450x350x6

1272.83

73.50

28638.69

B=

350.0 mm

T=

6.0 mm

RHS 400x200x12

1312.42

103.67

26248.42

Flechas

RHS 450x150x12

1316.58

103.67

29623.07

f(x) =

RHS 450x350x6,3

1324.80

76.81

29807.93

fmx =

RHS 500x200x8

1324.87

84.19

33121.69

RHS 400x250x10

1340.30

96.21

26805.99

RHS 320x220x18

1340.58

131.51

21449.20

RHS 400x200x12,5

1355.02

107.58

27100.50

RHS 450x150x12,5

1358.65

107.58

30569.68

RHS 450x350x7

1460.75

85.06

32866.92

RHS 400x200x14

1477.25

119.12

29545.09

RHS 450x150x14

1478.94

119.12

33276.11

RHS 450x350x7,1

1479.99

86.23

33299.86

RHS 500x300x7

1514.80

85.06

37869.96

RHS 400x300x10

1530.47

104.06

30609.32

RHS 500x300x7,1

1534.75

86.23

38368.73

RHS 400x250x12

1538.31

113.09

30766.18

RHS 400x250x12,5

1589.73

117.39

31794.51

RHS 500x200x10

1612.84

104.06

40320.93

RHS 450x150x16

1625.62

134.06

36576.49

Err:512

0.0314 m

en x=

6.00 m

= 1/ 381

2000, Instituto para la Construccin Tubular

Resultados

Viga biempotrada con 2 cargas puntuales simtricas

Datos

Reacciones

150.0 kN

RA =

P=

105.0 kN

RB =

L=

12.0 m

Cortantes

a=

6.0 m

V(x) =

1.00 m

Vmx =

355 N/mm2

en x =

P* =

x=

Fy=

150.0 kN

MA =

-450.0 kNm

150.0 kN

MB =

-450.0 kNm

Flectores

150.0 kN

M(x) =

-300.0 kNm

150.0 kN

Mmx =

-450.0 kNm

0.0 m

en x =

Mdulo Elstico mnimo (Wel) =

0.0 m

1267.61 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

Perfil

H=

450.0 mm

D=

0.0 mm

RHS 450x350x6

1272.83

73.50

28638.69

B=

350.0 mm

T=

6.0 mm

RHS 400x200x12

1312.42

103.67

26248.42

Flechas

RHS 450x150x12

1316.58

103.67

29623.07

f(x) =

RHS 450x350x6,3

1324.80

76.81

29807.93

fmx =

RHS 500x200x8

1324.87

84.19

33121.69

RHS 400x250x10

1340.30

96.21

26805.99

RHS 320x220x18

1340.58

131.51

21449.20

RHS 400x200x12,5

1355.02

107.58

27100.50

RHS 450x150x12,5

1358.65

107.58

30569.68

RHS 450x350x7

1460.75

85.06

32866.92

RHS 400x200x14

1477.25

119.12

29545.09

RHS 450x150x14

1478.94

119.12

33276.11

RHS 450x350x7,1

1479.99

86.23

33299.86

RHS 500x300x7

1514.80

85.06

37869.96

RHS 400x300x10

1530.47

104.06

30609.32

RHS 500x300x7,1

1534.75

86.23

38368.73

RHS 400x250x12

1538.31

113.09

30766.18

RHS 400x250x12,5

1589.73

117.39

31794.51

RHS 500x200x10

1612.84

104.06

40320.93

RHS 450x150x16

1625.62

134.06

36576.49

Err:512

0.0314 m

en x=

6.00 m

= 1/ 381

2000, Instituto para la Construccin Tubular

Datos

Viga biempotrada con carga uniforme

Resultados

q* =

25.0 kN/m

Reacciones

q=

17.5 kN/m

RA =

L=

12.0 m

RB =

a=

3.0 m

Cortantes

b=

9.0 m

V(x) =

c=

6.0 m

Vmx =

x=

6.00 m

en x =

Fy=

355 N/mm2

121.9 kN

MA =

-206.3 kNm

28.1 kN

MB =

-93.8 kNm

Flectores

-28.1 kN

M(x) =

75.0 kNm

121.9 kN

Mmx =

-206.3 kNm

0.0 m

en x =

Mdulo Elstico mnimo (Wel) =

0.0 m

580.99 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

H=

250.0 mm

D=

0.0 mm

RHS 250x200x10

581.27

64.81

7265.84

B=

200.0 mm

T=

10.0 mm

RHS 350x150x7,1

583.89

52.79

10218.12

RHS 320x220x6,3

595.32

51.10

9525.16

RHS 300x100x16

610.49

83.82

9157.36

RHS 250x150x16

612.79

83.82

7659.83

RHS 260x140x16

616.55

83.82

8015.12

RHS 300x200x8

625.95

59.07

9389.27

RHS 260x180x12

634.23

73.52

8245.01

RHS 350x150x8

646.96

59.07

11321.87

RHS 260x180x12,5

652.50

76.18

8482.47

RHS 250x200x12

652.69

75.41

8158.66

RHS 320x220x7

653.86

56.49

10461.72

RHS 320x220x7,1

662.10

57.25

10593.58

RHS 300x220x8

671.44

61.58

10071.56

RHS 250x200x12,5

671.76

78.14

8396.99

RHS 260x180x14

703.61

83.95

9146.91

RHS 320x220x8

734.92

64.09

11758.66

RHS 400x200x6

739.47

54.66

14789.35

RHS 450x150x6

747.10

54.66

16809.81

RHS 300x200x10

754.18

72.66

11312.70

Perfil

Flecha

f(x) =

Err:512

= 1/ Err:512

m

(NO es flecha mxima)

2000, Instituto para la Construccin Tubular

Resultados

Viga biempotrada con carga triangular ascendente

Datos

Reacciones

50.0 kN/m

RA =

q=

35.0 kN/m

RB =

L=

12.0 m

Cortantes

a=

6.0 m

V(x) =

b=

6.0 m

Vmx =

x=

9.00 m

en x =

q* =

Fy=

355 N/mm2

108.8 kN

MA =

-240.0 kNm

41.3 kN

MB =

-135.0 kNm

Flectores

-41.3 kN

M(x) =

-11.3 kNm

108.8 kN

Mmx =

-240.0 kNm

0.0 m

en x =

Mdulo Elstico mnimo (Wel) =

0.0 m

676.06 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

H=

260.0 mm

D=

0.0 mm

RHS 260x180x14

703.61

83.95

9146.91

B=

180.0 mm

T=

14.0 mm

RHS 320x220x8

734.92

64.09

11758.66

Flechas

RHS 400x200x6

739.47

54.66

14789.35

f(x) =

RHS 450x150x6

747.10

54.66

16809.81

fmx =

RHS 300x200x10

754.18

72.66

11312.70

RHS 260x180x16

763.31

93.86

9923.00

RHS 400x200x6,3

766.49

57.03

15329.74

RHS 450x150x6,3

773.52

57.03

17404.31

RHS 350x150x10

778.62

72.66

13625.80

RHS 300x220x10

810.27

75.80

12154.03

RHS 400x200x7

842.76

63.08

16855.27

RHS 450x150x7

850.15

63.08

19128.35

RHS 300x200x12

852.52

84.83

12787.83

RHS 400x200x7,1

853.52

63.94

17070.37

RHS 400x250x6

855.90

59.37

17118.07

RHS 450x150x7,1

860.95

63.94

19371.28

RHS 350x150x12

876.51

84.83

15339.00

RHS 300x200x12,5

878.59

87.95

13178.86

RHS 320x220x10

888.11

78.94

14209.76

RHS 400x250x6,3

888.56

61.98

17771.19

Perfil

Err:512

0.0351 m

en x =

5.45 m

= 1/ 341

2000, Instituto para la Construccin Tubular

Resultados

Viga biempotrada con carga triangular descendente

Datos

Reacciones

50.0 kN/m

RA =

q=

35.0 kN/m

RB =

L=

12.0 m

Cortantes

a=

6.0 m

V(x) =

b=

6.0 m

Vmx =

x=

6.00 m

en x =

q* =

Fy=

355 N/mm2

135.0 kN

MA =

-172.5 kNm

15.0 kN

MB =

-4.6 kNm

Flectores

-15.0 kN

M(x) =

37.5 kNm

135.0 kN

Mmx =

-172.5 kNm

0.0 m

en x =

Mdulo Elstico mnimo (Wel) =

0.0 m

485.92 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

H=

320.0 mm

D=

0.0 mm

RHS 320x220x5

486.10

41.10

7777.55

B=

220.0 mm

T=

5.0 mm

RHS 300x200x6

491.35

45.24

7370.23

Flechas

RHS 220x180x12

495.21

65.99

5447.36

f(x) =

RHS 300x200x6,3

508.29

47.14

7624.39

fmx =

RHS 220x180x12,5

508.75

68.33

5596.28

RHS 350x150x6

508.96

45.24

8906.87

RHS 250x150x12

516.63

65.99

6457.90

RHS 300x100x12

520.55

65.99

7808.31

RHS 260x140x12

520.60

65.99

6767.76

RHS 350x150x6,3

525.81

47.14

9201.63

RHS 300x220x6

525.93

47.13

7888.92

RHS 250x150x12,5

530.61

68.33

6632.67

RHS 300x100x12,5

533.97

68.33

8009.59

RHS 260x140x12,5

534.60

68.33

6949.76

RHS 300x200x7

557.72

52.09

8365.75

RHS 300x200x7,1

564.67

52.79

8469.98

RHS 260x180x10

566.41

63.24

7363.31

RHS 250x150x14

569.16

75.16

7114.53

RHS 300x100x14

570.47

75.16

8557.01

RHS 260x140x14

573.13

75.16

7450.64

Perfil

Err:512

0.0184 m

en x =

5.00 m

= 1/ 653

2000, Instituto para la Construccin Tubular

Resultados

Viga en voladizo con carga puntual

Datos

Reacciones

100.0 kN

RA =

P=

70.0 kN

RB =

L=

6.0 m

Cortantes

a=

0.0 m

V(x) =

b=

6.0 m

Vmx =

x=

0.00 m

en x =

P* =

Fy=

355 N/mm2

0.0 kN

MA =

0.0 kNm

100.0 kN

MB =

-600.0 kNm

Flectores

-100.0 kN

M(x) =

0.0 kNm

-100.0 kN

Mmx =

-600.0 kNm

6.0 m

en x =

Mdulo Elstico mnimo (Wel) =

6.0 m

1690.14 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

Perfil

H=

500.0 mm

D=

0.0 mm

RHS 500x300x8

1712.20

96.75

42805.10

B=

400.0 mm

T=

16.0 mm

RHS 400x250x14

1738.11

130.11

34762.24

Flechas

RHS 600x200x8

1754.37

96.75

52631.08

f(x) =

RHS 450x150x18

1756.87

148.47

39529.59

fmx =

RHS 400x200x18

1762.96

148.47

35259.14

RHS 400x300x12

1764.20

122.51

35283.94

RHS 400x300x12,5

1824.43

127.20

36488.52

RHS 500x200x12

1852.48

122.51

46311.98

RHS 500x400x7

1855.09

96.05

46377.25

RHS 450x150x20

1872.92

162.36

42140.79

RHS 500x400x7,1

1879.76

97.38

46994.06

RHS 400x200x20

1884.33

162.36

37686.52

RHS 500x200x12,5

1914.97

127.20

47874.31

RHS 400x250x16

1922.43

146.62

38448.65

RHS 400x300x14

1998.97

141.10

39979.39

RHS 450x350x10

2018.59

119.76

45418.25

RHS 400x250x18

2091.53

162.60

41830.58

RHS 500x300x10

2093.10

119.76

52327.60

RHS 500x200x14

2095.61

141.10

52390.27

RHS 500x400x8

2099.54

109.31

52488.51

Err:512

0.0251 m

en x=

0.00 m

= 1/ 238

2000, Instituto para la Construccin Tubular

Resultados

Viga en voladizo con carga uniforme

Datos

q* =

q=

RA =

10.0 kN/m

RB =

L=

6.0 m

x=

6.00 m

Fy=

Reacciones

15.0 kN/m

0.0 kN

MA =

0.0 kNm

90.0 kN

MB =

-270.0 kNm

Cortantes

V(x) =

355 N/mm

Flectores

-90.0 kN

M(x) =

-270.0 kNm

Vmx =

-90.0 kN

Mmx =

-270.0 kNm

en x =

6.0 m

en x =

Mdulo Elstico mnimo (Wel) =

6.0 m

760.56 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

H=

400.0 mm

D=

0.0 mm

RHS 260x180x16

763.31

93.86

9923.00

B=

200.0 mm

T=

16.0 mm

RHS 400x200x6,3

766.49

57.03

15329.74

Flechas

RHS 450x150x6,3

773.52

57.03

17404.31

f(x) =

0.0000 m

RHS 350x150x10

778.62

72.66

13625.80

fmx =

0.0237 m

RHS 300x220x10

810.27

75.80

12154.03

RHS 400x200x7

842.76

63.08

16855.27

RHS 450x150x7

850.15

63.08

19128.35

RHS 300x200x12

852.52

84.83

12787.83

RHS 400x200x7,1

853.52

63.94

17070.37

RHS 400x250x6

855.90

59.37

17118.07

RHS 450x150x7,1

860.95

63.94

19371.28

RHS 350x150x12

876.51

84.83

15339.00

RHS 300x200x12,5

878.59

87.95

13178.86

RHS 320x220x10

888.11

78.94

14209.76

RHS 400x250x6,3

888.56

61.98

17771.19

RHS 350x150x12,5

902.86

87.95

15800.08

RHS 300x220x12

918.92

88.59

13783.74

RHS 300x220x12,5

947.51

91.88

14212.72

RHS 400x200x8

948.72

71.63

18974.42

RHS 300x200x14

952.49

97.14

14287.30

Perfil

en x=

0.00 m

= 1/ 253

2000, Instituto para la Construccin Tubular

Resultados

Viga en voladizo con carga triangular ascendente

Datos

Reacciones

15.0 kN/m

RA =

q=

10.0 kN/m

RB =

L=

12.0 m

x=

0.00 m

q* =

Fy=

0.0 kN

MA =

0.0 kNm

90.0 kN

MB =

-360.0 kNm

Cortantes

V(x) =

355 N/mm

Flectores

0.0 kN

M(x) =

0.0 kNm

Vmx =

-90.0 kN

Mmx =

-360.0 kNm

en x =

12.0 m

en x =

Mdulo Elstico mnimo (Wel) =

12.0 m

1014.08 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

Perfil

H=

500.0 mm

D=

0.0 mm

RHS 320x220x12,5

1041.10

95.80

16657.62

B=

300.0 mm

T=

14.0 mm

RHS 300x200x16

1041.11

108.94

15616.67

Flechas

RHS 350x150x16

1065.65

108.94

18648.85

f(x) =

0.0478 m

RHS 400x250x8

1102.41

77.91

22048.12

fmx =

0.0478 m

RHS 400x300x7

1113.08

74.07

22261.56

RHS 300x200x18

1118.66

120.21

16779.87

RHS 400x300x7,1

1127.56

75.09

22551.11

RHS 320x220x14

1131.93

105.93

18110.89

RHS 350x150x18

1142.00

120.21

19984.97

RHS 400x200x10

1150.13

88.36

23002.65

RHS 450x150x10

1158.00

88.36

26054.92

RHS 500x200x7

1174.51

74.07

29362.67

RHS 500x200x7,1

1189.74

75.09

29743.39

RHS 320x220x16

1242.28

118.98

19876.46

RHS 400x300x8

1256.09

84.19

25121.83

RHS 450x350x6

1272.83

73.50

28638.69

RHS 400x200x12

1312.42

103.67

26248.42

RHS 450x150x12

1316.58

103.67

29623.07

RHS 450x350x6,3

1324.80

76.81

29807.93

RHS 500x200x8

1324.87

84.19

33121.69

en x=

0.00 m

= 1/ 251

2000, Instituto para la Construccin Tubular

Resultados

Viga en voladizo con carga triangular descendente

Datos

q* =

q=

RA =

10.0 kN/m

RB =

L=

6.0 m

x=

0.00 m

Fy=

Reacciones

15.0 kN/m

0.0 kN

MA =

0.0 kNm

45.0 kN

MB =

-180.0 kNm

Cortantes

V(x) =

355 N/mm

Flectores

0.0 kN

M(x) =

0.0 kNm

Vmx =

-45.0 kN

Mmx =

-180.0 kNm

en x =

6.0 m

en x =

Mdulo Elstico mnimo (Wel) =

6.0 m

507.04 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

H=

400.0 mm

D=

0.0 mm

RHS 300x200x6,3

508.29

47.14

7624.39

B=

250.0 mm

T=

12.5 mm

RHS 220x180x12,5

508.75

68.33

5596.28

Flechas

RHS 350x150x6

508.96

45.24

8906.87

f(x) =

0.0178 m

RHS 250x150x12

516.63

65.99

6457.90

fmx =

0.0178 m

RHS 300x100x12

520.55

65.99

7808.31

RHS 260x140x12

520.60

65.99

6767.76

RHS 350x150x6,3

525.81

47.14

9201.63

RHS 300x220x6

525.93

47.13

7888.92

RHS 250x150x12,5

530.61

68.33

6632.67

RHS 300x100x12,5

533.97

68.33

8009.59

RHS 260x140x12,5

534.60

68.33

6949.76

RHS 300x200x7

557.72

52.09

8365.75

RHS 300x200x7,1

564.67

52.79

8469.98

RHS 260x180x10

566.41

63.24

7363.31

RHS 250x150x14

569.16

75.16

7114.53

RHS 300x100x14

570.47

75.16

8557.01

RHS 260x140x14

573.13

75.16

7450.64

RHS 320x220x6

574.75

49.01

9195.97

RHS 350x150x7

576.74

52.09

10092.88

RHS 250x200x10

581.27

64.81

7265.84

Perfil

en x=

0.00 m

= 1/ 337

2000, Instituto para la Construccin Tubular

Resultados

Correas continuas de dos tramos

Datos

Reacciones

5.8 kN/m

RA =

13.1 kN

q=

4.0 kN/m

RB =

43.5 kN

L=

6.0 m

Fy=

355 N/mm2

q* =

Flectores

M1 =

14.6 kNm

en x =

2.25 m

Mmx =

-26.1 kNm

en x =

6.0 m

Mdulo Elstico mnimo (Wel) =

73.52 cm3

Deformaciones

Perfiles adecuados:

Wel

Peso

Inercia

Designacin

cm

Kg/m

cm

Perfil

H=

160.0 mm

D=

0.0 mm

RHS 140x80x5

73.87

15.98

517.06

B=

80.0 mm

T=

4.0 mm

RHS 180x90x3

74.21

12.25

667.85

Flechas

RHS 150x130x3

74.39

12.72

557.89

fmx =

RHS 150x50x7

74.57

19.12

559.30

RHS 160x80x4

74.71

14.25

597.71

RHS 150x70x5

74.86

15.98

561.45

RHS 200x70x3

74.97

12.25

749.68

RHS 140x60x7

74.99

19.12

524.93

RHS 160x60x5

75.19

15.98

601.52

RHS 180x60x4

75.35

14.25

678.19

RHS 160x120x3

76.47

12.72

611.73

RHS 150x100x4

79.28

14.87

594.60

RHS 120x80x8

79.31

21.39

475.83

RHS 180x100x3

79.43

12.72

714.84

RHS 150x50x8

80.59

21.39

604.42

RHS 120x100x6

80.68

18.87

484.11

RHS 200x80x3

80.79

12.72

807.90

RHS 160x90x4

80.80

14.87

646.39

RHS 140x60x8

81.22

21.39

568.52

RHS 170x80x4

81.79

14.87

695.18

0.0215 m

= 1/ 278

2000, Instituto para la Construccin Tubular

Das könnte Ihnen auch gefallen

- Viga Biapoyada 1cargaDokument1 SeiteViga Biapoyada 1cargaCivil MexNoch keine Bewertungen

- Diseño de columnas por flexocompresión y cortanteDokument7 SeitenDiseño de columnas por flexocompresión y cortanteBryan Chamorro DurandNoch keine Bewertungen

- Memoria de Calculo PerchaDokument14 SeitenMemoria de Calculo PerchaVictor Alfonso Lopez OrtegaNoch keine Bewertungen

- Analisis Sismico EstaticoDokument23 SeitenAnalisis Sismico EstaticoVictor Rene H. R.100% (1)

- DISEÑO DE LOSA - L 30, F'C 280Dokument9 SeitenDISEÑO DE LOSA - L 30, F'C 280Julie WilkinsonNoch keine Bewertungen

- Diseño de placa por corte en estructura sísmicaDokument24 SeitenDiseño de placa por corte en estructura sísmicaCarlos Aniceto100% (1)

- Sesion 02 - Diseño de PlacasDokument27 SeitenSesion 02 - Diseño de PlacasGeison Alexander100% (1)

- Calculo de Locales ResidenciasDokument34 SeitenCalculo de Locales ResidenciasfabiolaNoch keine Bewertungen

- Calculo de Potencia de BombaDokument7 SeitenCalculo de Potencia de BombaJulioAndresRivasplataNoch keine Bewertungen

- Diseño de Cortante VigasDokument3 SeitenDiseño de Cortante Vigaskarob87Noch keine Bewertungen

- 1er Analisis-Análisis Estático 1-2Dokument28 Seiten1er Analisis-Análisis Estático 1-2EduardoNoch keine Bewertungen

- Viga Biempotrada Con 2 CargasDokument1 SeiteViga Biempotrada Con 2 CargasCivil MexNoch keine Bewertungen

- Cálculo y diseño de acueducto colgante de 11m de luzDokument5 SeitenCálculo y diseño de acueducto colgante de 11m de luzwww.riegoscad.blogspot.comNoch keine Bewertungen

- Placas CompressDokument24 SeitenPlacas CompressDick EMNoch keine Bewertungen

- Diseño de placa y muro cortante en nivel ADokument24 SeitenDiseño de placa y muro cortante en nivel AMikel Tito Ramirez100% (1)

- Solución Práctica Calificada Concreto Armado IDokument8 SeitenSolución Práctica Calificada Concreto Armado IDavyLlanosSanchezNoch keine Bewertungen

- Diseno de Puentes Hoja de CalculoDokument31 SeitenDiseno de Puentes Hoja de CalculoIsaias CorzaNoch keine Bewertungen

- Losa y Vigas Longitudinales PDFDokument26 SeitenLosa y Vigas Longitudinales PDFeligioNoch keine Bewertungen

- Diseño de placas y muros de corteDokument27 SeitenDiseño de placas y muros de corteWilliam CamposNoch keine Bewertungen

- Diseño riostras horizontalesDokument12 SeitenDiseño riostras horizontalesmrnicus0% (1)

- Diseño de Elementos EstructuralesDokument24 SeitenDiseño de Elementos EstructuralesDario Manrique GamarraNoch keine Bewertungen

- Calderon Calderon Victor Examen Parcial 2 1Dokument15 SeitenCalderon Calderon Victor Examen Parcial 2 1Victor CcNoch keine Bewertungen

- Ejercicio Viga LosaDokument18 SeitenEjercicio Viga LosapercyNoch keine Bewertungen

- Calculo de Estribos Puente Tipo Viga GrupalxlsxDokument64 SeitenCalculo de Estribos Puente Tipo Viga GrupalxlsxKalimbxNoch keine Bewertungen

- Modulo N°1. Viga de Gran Altura Marzo21Dokument24 SeitenModulo N°1. Viga de Gran Altura Marzo21cristhian martínez espinozaNoch keine Bewertungen

- Memoria de Calculo Columnas y ZapatasDokument25 SeitenMemoria de Calculo Columnas y ZapatasJairo MijangosNoch keine Bewertungen

- Estribo Puente TorsiasDokument11 SeitenEstribo Puente Torsiasduliodav88Noch keine Bewertungen

- Concret oDokument22 SeitenConcret oSergio Andres Vanegas HerreraNoch keine Bewertungen

- Sesion 3-2Dokument24 SeitenSesion 3-2Junior AlReNoch keine Bewertungen

- Losa y Vigas LongitudinalesDokument27 SeitenLosa y Vigas LongitudinalesAndy GonzalezNoch keine Bewertungen

- Ejemplos de Aplicaciòn de Fuerza CortanteDokument9 SeitenEjemplos de Aplicaciòn de Fuerza CortanteRosa ZamudioNoch keine Bewertungen

- Puente Peatonal Tipo Losa-FONCODESDokument20 SeitenPuente Peatonal Tipo Losa-FONCODESMiguel Trinidad AlvaradoNoch keine Bewertungen

- Expo CimentacionesDokument16 SeitenExpo CimentacionesEstrellaNoch keine Bewertungen

- Ejercicios de Diseño de MurosDokument12 SeitenEjercicios de Diseño de MurosKahori Silva SanchezNoch keine Bewertungen

- Diseño Acueducto de 35MDokument8 SeitenDiseño Acueducto de 35MdionivargNoch keine Bewertungen

- Informe de Puentes Acueductos y AlcantarillasDokument11 SeitenInforme de Puentes Acueductos y AlcantarillasHenry Abel CuevasNoch keine Bewertungen

- Mathcad - Alcantarilla 300x300Dokument7 SeitenMathcad - Alcantarilla 300x300Atilio MarcillaNoch keine Bewertungen

- Diseño de EstriboDokument51 SeitenDiseño de EstriboEnriqueGabrielBeraúnCoronel100% (1)

- Diseño de Un PuenteDokument71 SeitenDiseño de Un Puentenaldo1584Noch keine Bewertungen

- Diseño Ductil de Columna ColumnaDokument6 SeitenDiseño Ductil de Columna Columnajamir777Noch keine Bewertungen

- Hoja de Calculo Puente Chuichilla - Diseño de Losa Vigas y DiafragmaDokument85 SeitenHoja de Calculo Puente Chuichilla - Diseño de Losa Vigas y DiafragmaTedder Aquino Yupanqui100% (2)

- Diseño de viga B106 Piso 7Dokument8 SeitenDiseño de viga B106 Piso 7Aldo Greco Nuñonca HerreraNoch keine Bewertungen

- Acero RfzoDokument13 SeitenAcero RfzoBenjamin FloresNoch keine Bewertungen

- Unidad 5Dokument15 SeitenUnidad 5Rodrigo Andrés Maluenda RomeroNoch keine Bewertungen

- Diseño de EstriboDokument27 SeitenDiseño de EstriboFernando Smith TorresNoch keine Bewertungen

- ICHA Manual de Diseño para Estructuras de Acero 2000 TOMO I - Parte246Dokument3 SeitenICHA Manual de Diseño para Estructuras de Acero 2000 TOMO I - Parte246shailaboyNoch keine Bewertungen

- Cálculo de Vigueta y Bov. de Microsoft PowerPointDokument6 SeitenCálculo de Vigueta y Bov. de Microsoft PowerPointGlo RoMaNoch keine Bewertungen

- EJEMPLO Barra Traccionada y Su ConexionDokument5 SeitenEJEMPLO Barra Traccionada y Su ConexionNelson VazquezNoch keine Bewertungen

- Tablero AmaybambaDokument17 SeitenTablero AmaybambaTara CurtisNoch keine Bewertungen

- Segundo Parcial Esfuerzos MaterialesDokument10 SeitenSegundo Parcial Esfuerzos MaterialesValeria MedinaNoch keine Bewertungen

- Zapatas Aislada Z-3Dokument1 SeiteZapatas Aislada Z-3ANGELRAFA23Noch keine Bewertungen

- Plan de Marketing - 1ºparteDokument44 SeitenPlan de Marketing - 1ºpartevicvargNoch keine Bewertungen

- Calculo de Electrificación de ViviendasDokument6 SeitenCalculo de Electrificación de ViviendasDavid HerreraNoch keine Bewertungen

- Fixture Copa America Chile 2015Dokument27 SeitenFixture Copa America Chile 2015vicvargNoch keine Bewertungen

- Torre Fija H 8.00 MDokument1 SeiteTorre Fija H 8.00 MvicvargNoch keine Bewertungen

- Izaje y montaje de columnas de concretoDokument18 SeitenIzaje y montaje de columnas de concretovicvargNoch keine Bewertungen

- Dimencionamiento TuberiasDokument150 SeitenDimencionamiento TuberiasvicvargNoch keine Bewertungen

- Elaboración Del Programa de Mantenimiento Preventivo Centrifugas PomalcaDokument37 SeitenElaboración Del Programa de Mantenimiento Preventivo Centrifugas Pomalcavicvarg50% (2)

- Imco Pets Cald 19Dokument8 SeitenImco Pets Cald 19vicvargNoch keine Bewertungen

- MantenimientoDokument39 SeitenMantenimientovicvargNoch keine Bewertungen

- Aprende A Manejar El Estres en El TrabajoDokument2 SeitenAprende A Manejar El Estres en El TrabajovicvargNoch keine Bewertungen

- Micropilotes: historia y formas de trabajoDokument32 SeitenMicropilotes: historia y formas de trabajoCarlos QuimNoch keine Bewertungen

- MANUAL de PROCEDIMIENTOS Sala de Calderos - SupermixDokument154 SeitenMANUAL de PROCEDIMIENTOS Sala de Calderos - Supermixvicvarg100% (1)

- Aseguramiento de Vigas Con IzajesDokument1 SeiteAseguramiento de Vigas Con IzajesvicvargNoch keine Bewertungen

- Guía para La Preparación de Planes de Trabajo, Informes de Avance E Informes de Autoevaluación para Programas Y Proyectos de Cooperación TécnicaDokument12 SeitenGuía para La Preparación de Planes de Trabajo, Informes de Avance E Informes de Autoevaluación para Programas Y Proyectos de Cooperación TécnicaOmar Ignacio BalcazarNoch keine Bewertungen

- Montaje de estructuras metálicas para nave industrialDokument12 SeitenMontaje de estructuras metálicas para nave industrialvicvargNoch keine Bewertungen

- SoldaduraDokument14 SeitenSoldaduravicvargNoch keine Bewertungen

- Consejos de Un Experto para El Montaje de EstructurasDokument19 SeitenConsejos de Un Experto para El Montaje de EstructurasFelipe Díaz FloresNoch keine Bewertungen

- Informe Final SSMADokument1 SeiteInforme Final SSMAvicvargNoch keine Bewertungen

- Tanque de Almacenamiento de Agua Potable PDFDokument13 SeitenTanque de Almacenamiento de Agua Potable PDFGeLoRa66Noch keine Bewertungen

- Oferta TecnicaDokument37 SeitenOferta TecnicavicvargNoch keine Bewertungen

- Aseguramiento de Vigas Con IzajesDokument1 SeiteAseguramiento de Vigas Con IzajesvicvargNoch keine Bewertungen

- Arequipa: Instalaciones ElectricasDokument12 SeitenArequipa: Instalaciones ElectricasvicvargNoch keine Bewertungen

- Comportamiento Estructuras Soldadas Sometidas A Cargas Dinámicas-EjemplosDokument8 SeitenComportamiento Estructuras Soldadas Sometidas A Cargas Dinámicas-EjemplosvicvargNoch keine Bewertungen

- Curso AtsDokument15 SeitenCurso AtsvicvargNoch keine Bewertungen

- Depósitos cuaternarios: eólicos, aluviales, coluviales y deluvialesDokument2 SeitenDepósitos cuaternarios: eólicos, aluviales, coluviales y deluvialesNoel Escolino Narciso PujayNoch keine Bewertungen

- El AquinateDokument1 SeiteEl AquinateManuel OrtegaNoch keine Bewertungen

- Novocentro Final FinalDokument72 SeitenNovocentro Final FinalLiz BalbinNoch keine Bewertungen

- Fundamentos de Antropologia - Ricardo Yepes Storck - Cap 1-4 - EDITABLEDokument49 SeitenFundamentos de Antropologia - Ricardo Yepes Storck - Cap 1-4 - EDITABLEjorgeirv89% (9)

- Cna 8vo 001 1 - 102001Dokument5 SeitenCna 8vo 001 1 - 102001JOSE LUIS BOHORQUEZ VARGASNoch keine Bewertungen

- Manual de Redes Sociales de UgtDokument40 SeitenManual de Redes Sociales de UgtUGTFSPCabildogcNoch keine Bewertungen

- DETERMINACIÓN de PARÁMETROS FÍSICOS, Quimicos y Bacteriologicos Del Contenido de Las Aguas Del Rio MazanDokument77 SeitenDETERMINACIÓN de PARÁMETROS FÍSICOS, Quimicos y Bacteriologicos Del Contenido de Las Aguas Del Rio MazanArmando GL100% (1)

- Impulsamos el crecimiento económico sostenibleDokument3 SeitenImpulsamos el crecimiento económico sostenibleJeanWillyChotaManahuacoNoch keine Bewertungen

- Estrés Laboral Casos PrácticosDokument17 SeitenEstrés Laboral Casos PrácticosgeodennysNoch keine Bewertungen

- Aun de Noche Alumbra El Sol 2Dokument24 SeitenAun de Noche Alumbra El Sol 2stabiloooNoch keine Bewertungen

- Las Nuevas Tendencias de La Gerencia Moderna ARTICULODokument2 SeitenLas Nuevas Tendencias de La Gerencia Moderna ARTICULODayana PeñaNoch keine Bewertungen

- La Zona ColonialDokument9 SeitenLa Zona Colonialffabriciocollado100% (1)

- Esquemas Psicologia Del Pensamiento PDFDokument21 SeitenEsquemas Psicologia Del Pensamiento PDFJosé Antonio Gómez MateoNoch keine Bewertungen

- La Novela EpistolarDokument5 SeitenLa Novela EpistolargabycifNoch keine Bewertungen

- Infografia Uso Del MovilDokument1 SeiteInfografia Uso Del MovilMaria Fernanda RAMIREZ CRUZNoch keine Bewertungen

- Zoo La Granja BaezaDokument2 SeitenZoo La Granja BaezaDiego Patricio Piñan EgasNoch keine Bewertungen

- Writing FceDokument6 SeitenWriting FceFonsi Arc Rs100% (1)

- OTRA FORMA: Extracción Prefijos y SufijosDokument3 SeitenOTRA FORMA: Extracción Prefijos y SufijosMarcos AntonioNoch keine Bewertungen

- Importancia y utilización del estándar ISA/ANSIDokument26 SeitenImportancia y utilización del estándar ISA/ANSIPaul Ramos CarcaustoNoch keine Bewertungen

- Movimiento Parabólico - Ejercicios Resueltos - FisimatDokument12 SeitenMovimiento Parabólico - Ejercicios Resueltos - FisimatLUISNoch keine Bewertungen

- Cómo Crear Un Negocio de Lectura de Oráculos y Conseguir Clientes Aplicando Los 4 Pasos Del Ciclo CreativoDokument8 SeitenCómo Crear Un Negocio de Lectura de Oráculos y Conseguir Clientes Aplicando Los 4 Pasos Del Ciclo CreativoMérida VRNoch keine Bewertungen

- Fibra Tecnica MaquinariaDokument61 SeitenFibra Tecnica MaquinariaGonzalo Jara Pacori100% (1)

- Informe de Laboratorio de SuperposicionDokument6 SeitenInforme de Laboratorio de SuperposicionFernando Jair HuancaNoch keine Bewertungen

- Correlaciones SPT ensayoDokument16 SeitenCorrelaciones SPT ensayoChris PillajoNoch keine Bewertungen

- 22 Analisisde AlimentosDokument12 Seiten22 Analisisde AlimentosAnalia BachirNoch keine Bewertungen

- Métodos numéricos para la resolución de ecuaciones no linealesDokument36 SeitenMétodos numéricos para la resolución de ecuaciones no linealesBeto Pacichana DominguezNoch keine Bewertungen

- JF 3 3 EspDokument35 SeitenJF 3 3 EspDenzel HernandezNoch keine Bewertungen

- Metodología de La Electroestimulación en El Deporte: Electrostimulation Methodology in SportDokument12 SeitenMetodología de La Electroestimulación en El Deporte: Electrostimulation Methodology in Sportmaria_daniNoch keine Bewertungen

- El Texto Argumentativo-EjercicioDokument3 SeitenEl Texto Argumentativo-EjercicioRoger ArmasNoch keine Bewertungen

- Impacto de La Tecnologia Sobre El Medio AmbienteDokument10 SeitenImpacto de La Tecnologia Sobre El Medio AmbienteScarlet Yanara ValenzuelaNoch keine Bewertungen