Beruflich Dokumente

Kultur Dokumente

Signal Conditioning Failure Modes 2

Hochgeladen von

Raluca EftimoiuOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Signal Conditioning Failure Modes 2

Hochgeladen von

Raluca EftimoiuCopyright:

Verfügbare Formate

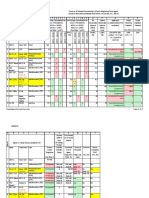

PAGE: 1

PRINT DATE: 12/05/01

FAILURE MODES EFFECTS ANALYSIS (FMEA) -- CIL HARDWARE NUMBER: 03-1-0515 -X

SUBSYSTEM NAME: MAIN PROPULSION REVISION: PART DATA PART NAME VENDOR NAME LRU :SIGNAL CONDITIONER PACIFIC SCIENTIFIC HTL K-WEST DIV. PART NUMBER VENDOR NUMBER MC476-0148-0005 2 07/27/00

EXTENDED DESCRIPTION OF PART UNDER ANALYSIS: SIGNAL CONDITIONER, ULLAGE PRESSURE, GO2/GH2

REFERENCE DESIGNATORS:

QUANTITY OF LIKE ITEMS:

FUNCTION: EACH ULLAGE PRESSURE SIGNAL CONDITIONER (LOCATED IN AFT AVIONICS BAY 4, 5, OR 6) POWERS/MONITORS ONE PAIR OF GO2 AND GH2 ET ULLAGE PRESSURE TRANSDUCERS AND CONTROLS ONE GH2 FLOW CONTROL VALVE (FCV). THE SIGNAL CONDITIONERS TO THE GO2 FLOW CONTROL VALVES HAVE BEEN DISCONNECTED FOR THE FIXED ORIFICE CONFIGURATION. THE SIGNAL CONDITIONER GENERATES FCV CLOSE COMMANDS TO MAINTAIN ET ULLAGE PRESSURE WITHIN A REQUIRED RANGE. ADDITIONALLY, THE SIGNAL CONDITIONERS PROVIDE 0 TO 5 VDC ANALOG SIGNALS FOR GROUND CONTROL OF ET ULLLAGE PRESSURE DURING PROPELLANT LOADING, TELEMETRY, AND COCKPIT ULLAGE PRESSURE DISPLAY/CAUTION AND WARNING. A COCKPIT SWITCH ALLOWS THE CREW TO OVERRIDE GH2 FCV CLOSE COMMANDS FROM THE SIGNAL CONDITIONERS, CAUSING ALL GH2 FCVS TO OPERATE AT HIGH FLOW.

PAGE 2

PRINT DATE: 12/21/01

FAILURE MODES EFFECTS ANALYSIS FMEA -- CIL FAILURE MODE NUMBER: 03-1-0515-02 REVISION#: 1 07/27/00 SUBSYSTEM NAME: MAIN PROPULSION LRU: SIGNAL CONDITIONER CRITICALITY OF THIS ITEM NAME: GO2/GH2 FCVS SIG COND ET ULLAGE PRESS FAILURE MODE: 1R2 FAILURE MODE: INADVERTENT/CONTINUOUS CLOSED COMMAND TO GO2 (FOR ACTIVE CONFIGURATION VALVES ONLY) OR GH2 FLOW CONTROL VALVE. (FCV CLOSED - LOW FLOW). MISSION PHASE: LO LIFT-OFF

VEHICLE/PAYLOAD/KIT EFFECTIVITY:

102 103 104 105

COLUMBIA DISCOVERY ATLANTIS ENDEAVOUR

CAUSE: ELECTRICAL CIRCUIT FAILURE. CRITICALITY 1/1 DURING INTACT ABORT ONLY? NO

REDUNDANCY SCREEN

A) PASS B) PASS C) PASS

PASS/FAIL RATIONALE: A)

B) PASSES B SCREEN BECAUSE FLOW CONTROL COMMANDS ARE REMOVED AT ET SEPARATION DUE TO ZERO INPUT FROM LH2 ULLAGE PRESSURE TRANSDUCER C)

- FAILURE EFFECTS (A) SUBSYSTEM: INADVERTENT COMMAND SIGNAL TO ONE FCV CAUSING IT TO CLOSE/REMAIN CLOSED.

(B) INTERFACING SUBSYSTEM(S):

PAGE: 3

PRINT DATE: 12/21/01

FAILURE MODES EFFECTS ANALYSIS (FMEA) -- CIL FAILURE MODE NUMBER: 03-1-0515-02

FOR NOMINAL MISSIONS, NO EFFECT. REDUNDANT FCVS WOULD COMPENSATE TO MAINTAIN ULLAGE PRESSURE AND NPSP. FOR GH2 AND GO2 SYSTEMS, FCV CLOSE COMMANDS ARE VERIFIED OFF BY LCC PRIOR TO T-9 MINUTES. DURING RTLS ABORTS DUE TO ONE SSME OUT AND THE REMAINING ENGINES AT A 104% RPL, A SUBSEQUENT FCV FAILED TO THE LOW FLOW POSITION WILL CAUSE THE ET LH2 ULLAGE PRESSURE TO FALL BELOW THE REQUIRED CONTROL BAND (32 - 34 PSIA) LATE IN THE MAIN ENGINE OPERATION. TANK MINIMUM STRUCTURAL REQUIREMENTS AND NPSP ARE MAINTAINED.

(C) MISSION: POSSIBLE LAUNCH SCRUB DUE TO LCC VIOLATION.

(D) CREW, VEHICLE, AND ELEMENT(S): NO EFFECT.

(E) FUNCTIONAL CRITICALITY EFFECTS: CASE 1: LH2 SYSTEM 1R/2 2 SUCCESS PATHS. TIME FRAME - ENGINE OPERATION. 1) SIGNAL CONDITIONER FAILURE RESULTING IN INADVERTENT COMMAND SIGNAL TO ONE GH2 FCV CAUSING IT TO CLOSE/REMAIN CLOSED. 2) ONE OF THE FOLLOWING FAILURES ON A PARALLEL PRESSURIZATION LEG: - LOSS OF FCV CLOSE COMMAND HYBRID DRIVER - FCV FAILS IN THE LOW FLOW POSITION - LOSS OF ENGINE PRESSURANT FLOW RESULTS IN INSUFFICIENT PRESSURIZATION GAS TO MAINTAIN LH2 ULLAGE PRESSURE IN THE REQUIRED FLIGHT CONTROL BAND (32 -34 PSIA). POSSIBLE VIOLATION OF TANK MINIMUM STRUCTURAL CAPABILITY REQUIREMENTS AND UNCONTAINED SSME SHUTDOWN DUE TO LOW NPSP. POSSIBLE LOSS OF CREW/VEHICLE CASE 2: LO2 SYSTEM (ACTIVE CONFIGURATION VALVES ONLY) 1R/2 2 SUCCESS PATHS. TIME FRAME - ENGINE OPERATION. 1) SIGNAL CONDITIONER FAILURE RESULTING IN INADVERTENT COMMAND SIGNAL TO ONE GO2 FCV CAUSING IT TO CLOSE/REMAIN CLOSED. 2) ONE OF THE FOLLOWING FAILURES ON A PARALLEL PRESSURIZATION LEG: ET ULLAGE PRESSURE TRANSDUCER FAILURE LOSS OF A SECOND SIGNAL CONDITIONER LOSS OF FCV CLOSE COMMAND HYBRID DRIVER FCV FAILS IN THE LOW FLOW POSITION LOSS OF ENGINE PRESSURANT FLOW

PAGE: 4

PRINT DATE: 12/21/01

FAILURE MODES EFFECTS ANALYSIS (FMEA) -- CIL FAILURE MODE NUMBER: 03-1-0515-02

LOSS OF ET LO2 ULLAGE PRESSURE WILL RESULT IN VIOLATION OF TANK MINIMUM STRUCTURAL CAPABILITY REQUIREMENTS. MASS OF LO2 AND VEHICLE ACCELERATION SHOULD BE SUFFICIENT TO MAINTAIN PROPER ENGINE NPSP, DELAYING UNCONTAINED SSME SHUTDOWN DUE TO LOW NPSP UNTIL LATE IN POWERED FLIGHT. POSSIBLE LOSS OF CREW/VEHICLE.

-DISPOSITION RATIONALE(A) DESIGN: THE ULLAGE PRESSURE SIGNAL CONDITIONER HAS TWO PHYSICALLY AND ELECTRICALLY ISOLATED MODULES MOUNTED ON A 6061-T6 ALUMINUM FRAME; ONE FOR GO2 AND ONE FOR GH2. EACH MODULE CONTAINS A POWER SUPPLY, SIGNAL CONDITIONER, CHECKOUT CIRCUIT, AND FCV COMMAND CIRCUIT IN A 6061-T6 BLACK ANODIZED ALUMINUM HOUSING. DYNAMIC DAMPENING OF THE INTERNALLY MOUNTED COMPONENTS IS ACHIEVED BY ENCAPSULATION IN GLASS RESIN EPOXY. THE COMPONENTS ARE MOUNTED ON SEMIRIGID NICKEL RIBBONS AND ARE HELD IN PLACE BY THE ENCAPSULANT. THE NICKEL RIBBONS ARE CONNECTED TO AN ELECTRICAL INTERFACE CONNECTOR. EACH MODULE IS THEN EXTERNALLY SEALED AFTER CHECKOUT WITH EPOXY SEALANT TO PROVIDE AN ENVIRONMENTAL SEAL. EACH MODULE CONTAINS AN ELECTRICAL INTERFACE CONNECTOR, WHICH IS HERMETICALLY SEALED AND SOLDERED. THE CONNECTOR IS BUILT TO THE MSFC 40M SPECIFICATIONS FOR SPACE VEHICLES. ALL ELECTRONIC COMPONENTS WERE SELECTED SO THAT THEIR USAGE MEETS THE SHUTTLE DERATING REQUIREMENTS. CHECKOUT COMMANDS FROM THE GROUND MDM ARE DISTRIBUTED THROUGH OPTICAL ISOLATION CIRCUITS IN EACH MODULE. FCV CLOSE COMMANDS ARE CONTROLLED ON THE BASIS OF EXCITATION TO TRANSDUCER FEEDBACK VOLTAGE RATIO, REDUCING THE EFFECTS OF EXCITATION VOLTAGE SHIFTS. EXCITATION POWER TO THE ET ULLAGE PRESSURE TRANSDUCER IS LIMITED TO 10 MA BY CURRENT LIMITING CIRCUITRY TO MAINTAIN A SAFE CONFIGURATION IN CASE OF AN EXTERNAL SHORT CIRCUIT. SYSTEM SEPARATE CABLE HARNESSES ARE USED ON THE ORBITER FOR EACH SIGNAL CONDITIONER (EACH POWERED BY A SEPARATE ORBITER MAIN BUS). THE OUTPUTS ARE FED TO SEPARATE MDMS AND VALVE LOAD DRIVERS TO MAINTAIN SIGNAL ISOLATION. TWO CABLE HARNESSES ARE USED ON THE EXTERNAL TANK (ET) FOR CONNECTION TO THE ET TRANSDUCERS. ET AND ORBITER CABLES TO THE TRANSDUCERS ARE SHIELDED WITH A SINGLE GROUND CONNECTION AT THE SIGNAL CONDITIONER TO MINIMIZE RF NOISE PROBLEMS. THE ET MAINTAINS AN EXTRA OUTER SHIELD FOR LIGHTNING PROTECTION WITH MULTIPLE POINT GROUNDS. ET TRANSDUCER FAILURE MODES ARE DOCUMENTED BY THE ET PROJECT.

PAGE: 5

PRINT DATE: 12/21/01

FAILURE MODES EFFECTS ANALYSIS (FMEA) -- CIL FAILURE MODE NUMBER: 03-1-0515-02

(B) TEST: ATP EXAMINATION OF PRODUCT INSULATION RESISTANCE 50 VOLTS DC DIELECTRIC STRENGTH 250 VRMS (60 HZ) THERMAL CYCLE +20 DEG F TO -40 DEG F TO +140 DEG F TO +70 DEG F 60 MINUTES AT EACH TEMPERATURE RANDOM VIBRATION 30 SECONDS FOR EACH OF 3 AXES EXTERNAL LEAKAGE NOT GREATER THAN 1X10-4 SCCS OF HELIUM PERFORMANCE TESTS CERTIFICATION (3 UNITS) VIBRATION 48 MINUTES FOR EACH OF 3 AXES. EXTERNAL LEAKAGE NOT GREATER THAN 1X10-4 SCCS OF HELIUM SHOCK PER MIL-STD-810 BENCH HANDLING DESIGN LIGHTNING PER MF0004-002 EMC PER MF0004-002 AND MIL-STD-462 THERMAL CYCLE 10 CYCLES: +70 TO +105 TO -65 TO +165 TO +70 DEG F 60 MINUTES AT EACH TEMPERATURE THERMAL VACUUM 6 HOURS AT 1X10-6 TORR TEMPERATURE: 160 DEG F

PAGE: 6

PRINT DATE: 12/21/01

FAILURE MODES EFFECTS ANALYSIS (FMEA) -- CIL FAILURE MODE NUMBER: 03-1-0515-02

PERFORMANCE TESTS OPERATING LIFE 1000 HOURS OF CYCLING CYCLE PERIOD: 6 HOURS (POWER ON FOR 3 HOURS, OFF FOR 3 HOURS) DURING THE POWER ON PHASE THE ON/OFF COMMAND IS CYCLED EVERY 5 SECONDS POST TEST INSPECTION GROUND TURNAROUND TEST ANY TURNAROUND CHECKOUT IS ACCOMPLISHED IN ACCORDANCE WITH OMRSD.

(C) INSPECTION: RECEIVING INSPECTION INCOMING PARTS ARE VERIFIED FOR MATERIAL, PHYSICAL CHARACTERISTICS, AND PROCESS CERTIFICATIONS. RECEIVING RECORDS ARE MAINTAINED FOR VERIFICATION. CONTAMINATION CONTROL PROPER CLEANLINESS IN ACCORDANCE WITH ASSEMBLY AND TEST REQUIREMENTS IS INSPECTED AND VERIFIED. ASSEMBLY/INSTALLATION ALL SOLDER AND WELD JOINTS COATED WITH 2850/CAT9 EPOXY ARE INSPECTED. INSPECTION VERIFIES ALL MODULES FILLED WITH XR-5068 ENCAPSULANT AND CURE TIME OF 2 HOURS AT 160 DEG F. TIGHTENED SCREWS AND TORQUE ARE CHECKED TO PRECLUDE STRIPPED SCREWS AND ENSURE PROPER MOUNTING. ALL EXTERIOR SURFACES OF HOUSING AND COVER MACHINED TO 63 RMS ARE CHECKED. GAP BETWEEN COVER AND CASE SEALED WITH 2850/CAT9 AND CURE TIME ARE MONITORED. MANDATORY INSPECTION POINTS ARE INCLUDED IN ASSEMBLY PROCESS. CRITICAL PROCESSES CONFORMAL COATING ON PWB ARE VERIFIED BY INSPECTION. ADHESIVE BONDING OF TYPE GE GLASS EPOXY BOARD TO PWB SURFACE IS CHECKED. WIRE WELDING AND LEAD SOLDERING OF COMPONENTS ARE INSPECTED IN ACCORDANCE WITH APPLICABLE REQUIREMENTS. ASSEMBLY POTTING IS VERIFIED. NONDESTRUCTIVE EVALUATION NOT APPLICABLE TESTING ATP, INCLUDING PERFORMANCE TEST, IS VERIFIED BY INSPECTION. HANDLING/PACKAGING PACKAGING FOR SHIPMENT IS VERIFIED BY INSPECTION.

(D) FAILURE HISTORY: EARLY PRODUCTION UNITS

PAGE: 7

PRINT DATE: 12/21/01

FAILURE MODES EFFECTS ANALYSIS (FMEA) -- CIL FAILURE MODE NUMBER: 03-1-0515-02

DURING ATP (-40 DEG F, 22 VOLT INPUT ANALOG OUTPUT ERROR TEST), THE MODULE DREW EXCESSIVE CURRENT (REFERENCE CAR AC0545). THE INTERMITTENT FAILURE WAS VERIFIED AT LOW TEMPERATURE AND WAS ATTRIBUTED TO A SHORT. END EFFECT (LOSS OF OR ERRONEOUS FCV CLOSE COMMAND, ERRONEOUS PRESSURE INDICATION) DEPENDS ON LOCATION OF THE SHORT. WIRING COULD HAVE BEEN DISPLACED DURING ENCAPSULATION; TEMPERATURE VARIATIONS COULD THEN HAVE CAUSED STRESS ON THE WIRING RESULTING IN AN INTERMITTENT SHORT. CORRECTIVE ACTION WAS TO PERFORM A POST-ENCAPSULATION CONFIDENCE TEST WITH THERMAL CYCLING PRIOR TO ATP. DURING ATP, THE SIGNAL CONDITIONER FAILED THE FREQUENCY RESPONSE TEST BY DRAWING EXCESSIVE CURRENT (REFERENCE CAR A5038). DURING REMOVAL OF THE UNIT FROM THE CASE AND SHIELD, A WELD CONNECTION ON ONE MODULE LOCATED ADJACENT TO THE MODULE DIVIDER SHIELD WAS FOUND TO BE MAKING INTERMITTENT CONTACT WITH THE DIVIDER SHIELD. THE MODULE INTERCONNECTING RIBBON HAD WORN THROUGH THE DIVIDER SHIELD INSULATION DUE TO INSUFFICIENT CLEARANCE BETWEEN THE DIVIDER SHIELD AND MODULES. END EFFECT OF THIS CONDITION (INADVERTENT FCV CLOSE COMMAND, ERRONEOUS PRESSURE INDICATION) DEPENDS ON LOCATION OF THE SHORT. CORRECTIVE ACTION WAS TO CONTROL THE LENGTH OF THE RIBBONS. FOR ASSEMBLED HARDWARE, THE ATP THERMAL CYCLE AND VIBRATION TESTS WERE CONSIDERED SUFFICIENT SCREENING TO INSURE DETECTION OF THE POTENTIAL PROBLEM. SEVERAL SIGNAL CONDITIONER FAILURES (VARIOUS MODES) AT KSC WERE ATTRIBUTED TO MOISTURE RETAINED IN THE GLASS RESIN EPOXY ENCAPSULATION MATERIAL CAUSING MULTIPLE SHORT CIRCUITS WITHIN THE WELDED MODULES (REFERENCE CAR AC4420). ALL UNITS WERE REFURBISHED TO THE -0005 CONFIGURATION TO IMPROVE SEALING AND PRECLUDE INTERNAL MOISTURE. ADDITIONAL EPOXY SEALANT WAS ADDED BETWEEN THE COVER AND HOUSING. THE UNIT IS VACUUM BAKED AFTER THE ENCAPSULANT IS ADDED TO INSURE ABSENCE OF INTERNAL MOISTURE PRIOR TO SEALING OF THE FILL HOLE WITH EPOXY. THE UNIT IS THEN LEAK CHECKED, AND EPOXY IS APPLIED TO SEAL ELECTRICAL CONNECTOR SOLDER JOINT POROSITY IF REQUIRED. CURRENT DATA ON TEST FAILURE, FLIGHT FAILURE, UNEXPLAINED ANOMALIES, AND OTHER FAILURES EXPERIENCED DURING GROUND PROCESSING ACTIVITY CAN BE FOUND IN THE PRACA DATABASE.

(E) OPERATIONAL USE: IF THE LH2 NPSP DROPS BELOW THE PRE-FLIGHT ACCEPTED LEVELS (PER FLIGHT RULES), THE CREW WILL MANUALLY THROTTLE THE ENGINES TO KEEP THE NPSP HIGH ENOUGH TO PREVENT LH2 TURBOPUMP CAVITATION. NO CREW ACTION CAN BE TAKEN FOR LO2 SYSTEM FAILURES.

- APPROVALS S&R ENGINEERING S&R ENGINEERING ITM : W.P. MUSTY : P. A. STENGER-NGUYEN :/S/ W.P. MUSTY :/S/ P.A. STENGER-NGUYEN

PAGE: 8

PRINT DATE: 12/21/01

FAILURE MODES EFFECTS ANALYSIS (FMEA) -- CIL FAILURE MODE NUMBER: 03-1-0515-02

DESIGN ENGINEERING MPS SUBSYSTEM MGR. EPD&C SUBSYSTEM MGR. MOD USA SAM USA ORBITER ELEMENT NASA SR&QA

: HERB WOLFSON : TIM REITH : RICHARD PHAN : JEFF MUSLER : MICHAEL SNYDER : SUZANNE LITTLE : BILL PRINCE

:/S/ :/S/ :/S/ :/S/ :/S/ :/S/ :/S/

HERB WOLFSON TIM REITH RICHARD PHAN JEFF MUSLER MICHAEL SNYDER SUZANNE LITTLE BILL PRINCE

Das könnte Ihnen auch gefallen

- DIGITAL EXCITATION SYSTEM BHEL - EDN , BANGALOREDokument31 SeitenDIGITAL EXCITATION SYSTEM BHEL - EDN , BANGALOREsantoshkumar777Noch keine Bewertungen

- Amm Task Perf Each FlightDokument5 SeitenAmm Task Perf Each Flightbilly100% (1)

- VFD ManualDokument2.629 SeitenVFD ManualJhajjarNoch keine Bewertungen

- IO List MRHSDokument52 SeitenIO List MRHSvinayjoshi2705Noch keine Bewertungen

- PLC - PresDokument30 SeitenPLC - PresSandeep Yadav100% (1)

- LT SWGR Test SCHDokument3 SeitenLT SWGR Test SCHshailesh284Noch keine Bewertungen

- Reliability Based MaintenanceDokument35 SeitenReliability Based MaintenanceManoj PaneriNoch keine Bewertungen

- Ehtc LatestDokument34 SeitenEhtc Latestbharat5100100% (3)

- Specification For Approval: P/N: #REF! Customer P/NDokument7 SeitenSpecification For Approval: P/N: #REF! Customer P/NThiago Andrade RangelNoch keine Bewertungen

- NTPC Simhadri DDCMIS Testing ScheduleDokument19 SeitenNTPC Simhadri DDCMIS Testing ScheduleSandip GaraiNoch keine Bewertungen

- SF6 GCB 24 - 36 KVDokument4 SeitenSF6 GCB 24 - 36 KVMichael Parohinog GregasNoch keine Bewertungen

- EGPM-10-DAS-MOV-01 - Datasheet For MOV ActuatorDokument7 SeitenEGPM-10-DAS-MOV-01 - Datasheet For MOV Actuatordrkongala100% (1)

- Model SS ChecklistDokument30 SeitenModel SS ChecklistAnonymous PeuxGWWy8tNoch keine Bewertungen

- Check List of 6.6kv PanelDokument22 SeitenCheck List of 6.6kv Panelsantoshkumar100% (1)

- GIS Switchgear SpecificationDokument11 SeitenGIS Switchgear SpecificationbonekbenjeNoch keine Bewertungen

- Ocb 283Dokument17 SeitenOcb 283Jason RogersNoch keine Bewertungen

- Gen Trans BackchargingDokument3 SeitenGen Trans BackcharginglrpatraNoch keine Bewertungen

- Capacit LS GBDokument116 SeitenCapacit LS GBdaniel03_181975Noch keine Bewertungen

- Control Philosophy Rafha-18.11.2004Dokument14 SeitenControl Philosophy Rafha-18.11.2004srigirisetty208Noch keine Bewertungen

- Lovato InfoDokument38 SeitenLovato Infolurdhez_moNoch keine Bewertungen

- Switch YardDokument105 SeitenSwitch Yardsiddharth507Noch keine Bewertungen

- ESP Seminar Raipur DT 1.2.11Dokument92 SeitenESP Seminar Raipur DT 1.2.11Tanmoy ChakrabortyNoch keine Bewertungen

- SCR Unit Chapter 3Dokument48 SeitenSCR Unit Chapter 3stashkinvalriy100% (2)

- SEO-Optimized Lighting Transformer TitleDokument8 SeitenSEO-Optimized Lighting Transformer TitleShrikant KajaleNoch keine Bewertungen

- ICF - Control Panel - Manual (1999)Dokument27 SeitenICF - Control Panel - Manual (1999)sangramjitNoch keine Bewertungen

- HCD XGR6Dokument74 SeitenHCD XGR642634560Noch keine Bewertungen

- Measurements: CDG 11 CDG 16Dokument4 SeitenMeasurements: CDG 11 CDG 16girish1950% (2)

- Presentation On "Free Governor Mode Operation"Dokument72 SeitenPresentation On "Free Governor Mode Operation"s_jmi2345Noch keine Bewertungen

- Turbine ProtectionDokument9 SeitenTurbine ProtectionKetan Pathak100% (1)

- Selection of Circuit BreakerDokument47 SeitenSelection of Circuit Breakerconsultnadeem70100% (1)

- Orissa Power Gen. Co. Ltd. 2 X 660 MW (Unit #3 & 4) Ib Thermal Power Station, BanharpaliDokument6 SeitenOrissa Power Gen. Co. Ltd. 2 X 660 MW (Unit #3 & 4) Ib Thermal Power Station, BanharpaliSantoshkumar GuptaNoch keine Bewertungen

- Untitled 04Dokument6 SeitenUntitled 04eoictiNoch keine Bewertungen

- Generator Excitation SystemDokument35 SeitenGenerator Excitation SystemNitin Sakpal100% (1)

- Ata 31Dokument606 SeitenAta 31Tarik BenzinebNoch keine Bewertungen

- CDF G30 G50Dokument46 SeitenCDF G30 G50Luis Arturo Leiva MonjarasNoch keine Bewertungen

- O & M of Sub StationDokument94 SeitenO & M of Sub StationAlbert Sekar100% (2)

- 12 24KV GF1 GF2 Gis Rmu R0Dokument2 Seiten12 24KV GF1 GF2 Gis Rmu R0Mohd Afifi JusohNoch keine Bewertungen

- Stamford PM734F-Wdg 28 4 Pole 6 Wire Technical Data SheetDokument6 SeitenStamford PM734F-Wdg 28 4 Pole 6 Wire Technical Data SheetKVRamananNoch keine Bewertungen

- 220kV and 33kV Circuit Breakers BHEL PDFDokument77 Seiten220kV and 33kV Circuit Breakers BHEL PDFSellappan Muthusamy75% (4)

- 01 - FEWA-EL-SWGR-TS-0111, Rev 1, 2016 XXXDokument34 Seiten01 - FEWA-EL-SWGR-TS-0111, Rev 1, 2016 XXXMuraryspottyNoch keine Bewertungen

- Disjuntor 123-160 KV - ABBDokument2 SeitenDisjuntor 123-160 KV - ABBdmezzavillaNoch keine Bewertungen

- Panasonic+Ct 36l13g+Ct 32sl13g+Ct 36sc13g+Ct 32sc13g+Ct 3663gDokument187 SeitenPanasonic+Ct 36l13g+Ct 32sl13g+Ct 36sc13g+Ct 32sc13g+Ct 3663gwonderboy39Noch keine Bewertungen

- Commissioning Protocol For Stacker Cum Reclaimer - A: Format No: SCR/CMDokument2 SeitenCommissioning Protocol For Stacker Cum Reclaimer - A: Format No: SCR/CMSagar G ReddyNoch keine Bewertungen

- Partbii IIIDokument388 SeitenPartbii IIIsaravananNoch keine Bewertungen

- Specification of Excitation SystemDokument39 SeitenSpecification of Excitation Systemnitin100% (2)

- Gov Simulator 23.12.06Dokument46 SeitenGov Simulator 23.12.06Sam100% (2)

- 34 Samss 634Dokument13 Seiten34 Samss 634naruto256Noch keine Bewertungen

- Design Criteria ElectricalDokument38 SeitenDesign Criteria ElectricalPramod B.Wankhade100% (4)

- Bhelvision-20M: Operation and Maintenance ManualDokument37 SeitenBhelvision-20M: Operation and Maintenance ManualSAROJ100% (2)

- Aviation blade de-icing system descriptionDokument26 SeitenAviation blade de-icing system descriptionJose Carlos Flores SosaNoch keine Bewertungen

- 3 Phase SCR ManualDokument68 Seiten3 Phase SCR Manualfreddy067Noch keine Bewertungen

- Reset CBs to fix ATA 22 faultsDokument76 SeitenReset CBs to fix ATA 22 faultsprsnjt11100% (1)

- YTEK CONTROLS Automatic Control PanelDokument12 SeitenYTEK CONTROLS Automatic Control PanelPritam SinghNoch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- High Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorVon EverandHigh Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorNoch keine Bewertungen

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesVon EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNoch keine Bewertungen

- Protection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsVon EverandProtection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsNoch keine Bewertungen

- 2.4 Avogadro's Hypothesis+ Equivalent MassesDokument12 Seiten2.4 Avogadro's Hypothesis+ Equivalent MassesSantosh MandalNoch keine Bewertungen

- Conceptual FrameworkDokument24 SeitenConceptual Frameworkmarons inigoNoch keine Bewertungen

- 5 Dec2021-AWS Command Line Interface - User GuideDokument215 Seiten5 Dec2021-AWS Command Line Interface - User GuideshikhaxohebkhanNoch keine Bewertungen

- Bandung Colonial City Revisited Diversity in Housing NeighborhoodDokument6 SeitenBandung Colonial City Revisited Diversity in Housing NeighborhoodJimmy IllustratorNoch keine Bewertungen

- IELTS Vocabulary ExpectationDokument3 SeitenIELTS Vocabulary ExpectationPham Ba DatNoch keine Bewertungen

- Um 0ah0a 006 EngDokument1 SeiteUm 0ah0a 006 EngGaudencio LingamenNoch keine Bewertungen

- Singer NM37 57manualDokument266 SeitenSinger NM37 57manualpaulkoby100% (2)

- Emerson Park Master Plan 2015 DraftDokument93 SeitenEmerson Park Master Plan 2015 DraftRyan DeffenbaughNoch keine Bewertungen

- Amar Sonar BanglaDokument4 SeitenAmar Sonar BanglaAliNoch keine Bewertungen

- Active and Passive Voice of Future Continuous Tense - Passive Voice Tips-1Dokument5 SeitenActive and Passive Voice of Future Continuous Tense - Passive Voice Tips-1Kamal deep singh SinghNoch keine Bewertungen

- Computer Portfolio (Aashi Singh)Dokument18 SeitenComputer Portfolio (Aashi Singh)aashisingh9315Noch keine Bewertungen

- Individual Sports Prelim ExamDokument13 SeitenIndividual Sports Prelim ExamTommy MarcelinoNoch keine Bewertungen

- Henny Penny 500-561-600 TM - FINAL-FM06-009 9-08Dokument228 SeitenHenny Penny 500-561-600 TM - FINAL-FM06-009 9-08Discman2100% (2)

- Numerical Methods: Jeffrey R. ChasnovDokument60 SeitenNumerical Methods: Jeffrey R. Chasnov2120 sanika GaikwadNoch keine Bewertungen

- Operation Manual: Auto Lensmeter Plm-8000Dokument39 SeitenOperation Manual: Auto Lensmeter Plm-8000Wilson CepedaNoch keine Bewertungen

- IMT Ghaziabad PGDM Timetable Term II 2020Dokument22 SeitenIMT Ghaziabad PGDM Timetable Term II 2020Ved JhingranNoch keine Bewertungen

- SYNOPSIS - Impact of GST On Small Traders!Dokument21 SeitenSYNOPSIS - Impact of GST On Small Traders!Laxmi PriyaNoch keine Bewertungen

- Paradigm Shift Essay 2Dokument17 SeitenParadigm Shift Essay 2api-607732716Noch keine Bewertungen

- Symmetry (Planes Of)Dokument37 SeitenSymmetry (Planes Of)carolinethami13Noch keine Bewertungen

- Antiquity: Middle AgesDokument6 SeitenAntiquity: Middle AgesPABLO DIAZNoch keine Bewertungen

- Condy LatorDokument11 SeitenCondy LatorrekabiNoch keine Bewertungen

- Weekly Choice - Section B - February 16, 2012Dokument10 SeitenWeekly Choice - Section B - February 16, 2012Baragrey DaveNoch keine Bewertungen

- 5505 SW 138th CT, Miami, FL 33175 ZillowDokument1 Seite5505 SW 138th CT, Miami, FL 33175 Zillowlisalinda29398378Noch keine Bewertungen

- Module 2Dokument42 SeitenModule 2DhananjayaNoch keine Bewertungen

- Budget ControlDokument7 SeitenBudget ControlArnel CopinaNoch keine Bewertungen

- Miami Police File The O'Nell Case - Clemen Gina D. BDokument30 SeitenMiami Police File The O'Nell Case - Clemen Gina D. Barda15biceNoch keine Bewertungen

- Clean Agent ComparisonDokument9 SeitenClean Agent ComparisonJohn ANoch keine Bewertungen

- Biomotor Development For Speed-Power Athletes: Mike Young, PHD Whitecaps FC - Vancouver, BC Athletic Lab - Cary, NCDokument125 SeitenBiomotor Development For Speed-Power Athletes: Mike Young, PHD Whitecaps FC - Vancouver, BC Athletic Lab - Cary, NCAlpesh Jadhav100% (1)

- Colour Ring Labels for Wireless BTS IdentificationDokument3 SeitenColour Ring Labels for Wireless BTS Identificationehab-engNoch keine Bewertungen

- Bluetooth Home Automation Using ArduinoDokument25 SeitenBluetooth Home Automation Using ArduinoRabiNoch keine Bewertungen