Beruflich Dokumente

Kultur Dokumente

Manual Atlas Copco Zrzt110-315

Hochgeladen von

Jairo Promotor LopezCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Manual Atlas Copco Zrzt110-315

Hochgeladen von

Jairo Promotor LopezCopyright:

Verfügbare Formate

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.

qxp

26/09/2005

11:29

Pagina 1

Atlas Copco

ZR/ZT 110-425-FF & ZR/ZT 132-500 VSD-FF

libre de aceite del compresor de tornillo rotativo de la serie

con accionamiento de velocidad variable y variantes Full Feature

MATCHING

ALL NEEDS

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 2

El concepto de ahorro de energia

El camino ms corto para maximizar su rentabilidad es minimizar

los costos operativos. Debido a que el consumo de energa es el factor principal en un

coste del ciclo de vida del compresor, el enfoque en el diseo de los nuevos Atlas Copco

Compresores Z est en el ahorro de energa en todas las formas imaginables. Este enfoque es

que base de un concepto de desarrollo de producto total que abarca todas las etapas

de R& D, fabricacin, instalacin y servicio post-venta.

La evaluacion de las necesidades a fondo

Ahorros reales se basan en hechos. Atlas

Consultores Copco evalan el aire

demanda el perfil de su aplicacin

y sugerir el mejor compresor

Energia

Circular

seleccin para el trabajo.

La tecnologa central derecho

Atlas Copco domina todos los de compresin

principio y proporciona la mayor cantidad de energa

tecnologa eficiente para la necesaria

presin y caudal.

La mejor disposicin de

Mquinas de velocidad fija estn bien cuando pueden

funcionan a plena carga la mayor parte del tiempo. Pero cuando el aire

fluctua, el accionamiento de velocidad variable

puede lograr considerables ahorros de un 35%.

Los accesorios innovadores

El IMD integrado ofrece secador de adsorcion

aire seco de alta calidad con la menor presin

cada y utiliza el calor del compresor

para la regeneracin. Dos caractersticas que

conducen al ahorro de energa significativo.

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 3

Z - La eleccin correcta

Completa

Seguridad

los mas bajos

los costos

de energia

el mas alto de

confiabilidad

ua

ra nt ee

100

oil-free

r

ai

se pueden recuperar y poner a buen

El calor del proceso de compresin

Recuperacin de Energia

uso en los procesos endotrmicos,

calefaccin de edificios, etc

El seguimiento profesional

Un Contrato de servicio Atlas Copco

le asegurar el mantenimiento integral

de prevencin, respuesta inmediata y

repuestos originales ... en todo el mundo.

Seguro

Proceso y el medio ambiente

libre de contaminacin

Simple

100 % aire libre de aceite = no hay filtros necesarios

El sistema completamente optimizado

Una instalacion completa de multiples compresores

se pueden control centralizado, para lograr una

banda a prueba de presin y el menor coste total de energia.

Eficiente

No hay caida de presion del filtro = menos energia

La instalacion sin problemas y

la puesta en marcha

Un Atlas Copco sin aceite Z-compresor es

realmente plug-and-play. Ninguna asamblea

campo especial es necesaria. Ponga la

maquina en un suelo liso, conecte la linea

de alimentacin y la toma de comprimidos

EAIR ... y presionar el boton de inicio.

Aire libre de aceite, una cuestion de sentido comun

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 4

El concepto de fiabilidad total

Una mquina eficiente ahorra dinero slo si funciona de forma fiable durante todo el da.

Y no slo hoy, sino da tras da, ao tras ao, con intervenciones de los servicios mnimos

y prolongados intervalos de revisin.

Desde hace ms de un siglo, Atlas Copco ha sido la construccin de mquinas que

resisten la prueba del tiempo. Con la probada compresores Z, la fiabilidad no ha sido

nunca tan intemporal.

El socio con experiencia

Atlas Copco es lder mundial

en tecnologa de aire comprimido,

con ms de 100 aos de experiencia

Circulo de

fiabilidad

en sistemas de compresin de aire.

El diseo integrado

Tuberas internas, secador de aire integral,

a unidad integrada de velocidad variable,

100% de componentes iguales, controles consolidados ...

la nica manera de garantizar una fiabilidad total.

s truly

y is

La Solucion completa

Compresor, el secador, la unidad, filtros,

sistema de control ... todos llevan la misma

marca de calidad: el logotipo Atlas Copco.

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 5

Empujando los limites de

eficiencia energetica

Pushing the limits in

safety

Pushing the limits in reliability

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 6

Select the perfect match

tailored to your needs

The new generation of Z-compressors provides you with

compressor to your specific needs. All options are perfectly

unprecedented freedom to select the features that add up to

compatible, safeguarding the lowest operational cost and

your perfect match.

the highest reliability.

The wide range of choices allows you to tailor the

The compressor you want is the compressor we build.

Pressure

50 Hz:

7.5 bar

8.6 bar

10 bar

60 Hz:

7 bar / 100 psi

8.6 bar / 125 psi

10.4 bar / 150 psi

Capacity (power)

110 kW (fixed speed)

132 kW (fixed speed & VSD - Variable Speed Drive)

145 kW (fixed speed)

160 kW (fixed speed & VSD - Variable Speed Drive)

200 kW (fixed speed)

250 kW (fixed speed & VSD - Variable Speed Drive)

275 kW (fixed speed)

300 kW (fixed speed)

315 kW (fixed speed & VSD - Variable Speed Drive)

355 kW (fixed speed)

400 kW (fixed speed & VSD - Variable Speed Drive)

425 kW (fixed speed)

500 kW (VSD - Variable Speed Drive)

Cooling

ZR: watercooled

ZT: aircooled (up to 315 kW)

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

Z

Z

26/09/2005

11:29

Motor drive

Pagina 7

Fixed Speed Drive

Variable Speed Drive (VSD) saving up to 35 % in energy costs

Dryer

MD dryer for dry air at no energy cost:

integrated IMD for Z 110-275 and Z 132-315 VSD

free-standing MD for ZR 300-415 and ZR 400-500 VSD

BD/XD dryer for very dry air

Compressor without dryer

Z

Z

In/outdoor

Standard package for indoor use

Outdoor variant mounted in a standard container

(up to 315 kW)

Ambient temperature

Standard machine: operating range between

0 and 40 C

HAT (High Ambient Temperature) version: operating

range between 0 and 50 C

Winterization option: temperatures to -20 C

... Select additional options

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

Proven Z-technology

in one package

11:29

Pagina 8

ZR/ZT 110-425-FF and ZR/ZT 132-500 VSD-FF

Capacity range (50 & 60 Hz)

ZR 110-425-FF

ZR 132-500 VSD-FF

ZT 110-275-FF

ZT 132-315 VSD-FF

Excellence is achieved in all aspects of the design

and manufacturing of the new oil-free ZR/ZT 110-500

range. The result is top quality and high reliability.

Within this range, the ZR/ZT 132-500 VSD-FF

120

7

250

260

15

550

1320 l/s

80 m3/min

2800 cfm

ZT: Aircooled / ZR: Watercooled / VSD: Variable Speed Drive / FF: Full Feature

See data pages for range details

compressors take the Total Energy Concept to its full

potential, combining two of the biggest energy savers

Watercooled ZR 160 VSD-FF

within the Full Feature VSD compressor package itself:

Integrated VSD, Full Feature version with IMD dryer

the (I)MD dryer and the Variable Speed Drive.

Excellence by design

Completely oil-free no risk of oil-contaminated air

No oil in the condensate

Watercooled ZR-FF: air/oil/coolant flow

Completely ready-to-use package

Easy, low cost installation no foundations

Elemento de

baja presin

Air and watercooled versions

Filtro de aire

Entrada de aire

Elemento de alta

presin

Low cooling water consumption with watercooled variant

Proven reliability

True performance as per ISO 1217, Annex C, Ed. 3

Flexible as a base load or a top load machine

Consistent performance over the lifetime of the compressor

Operator and service friendly

Silenced package

Refrigerador Intermedio

Very low vibration level

Energy saving Variable Speed Drive & Full Feature

Refrigerador posterior

Salida de aire seco

versions available

Integrated IMD dryer in FF version

secador IMD

aire

agua

aceite

(with

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 9

Complete scope

suiting all needs

Complete ZR/ZT range

Many features are included as standard. Some applications

may also need or benefit from additional options.

ZR 55-750

ZR 90-900 VSD

ZT 55-275

ZT 90-315 VSD

Standard

Air intake filter and silencer

1000

500

30

1060

60

2120

1500

90

3180

2000

2500 l/s

150 m3/min

5300 cfm

120

4240

Air intake flexible

Stainless steel inter and aftercooler cores *

Inter and aftercooler water traps and electronic drains

Outlet air silencer

Six sided silencing canopy

Terminal expansion joints air and water side

Aircooled ZT 160 VSD-FF

Outlet air flange

Integrated VSD, Full Feature version with IMD dryer

Complete water circuit *

Single point inlet and outlet cooling water connection *

Back-flush arrangement for cooler cleaning *

Complete oil circuit pre-piped

Built-in oil breather system

AGMA class 13, DIN class 5 gears

Electric IP 55 motors pre-mounted **

Starters **

Pre-mounted electrical and VSD cubicles

Skid with no need for foundations

Suppression of emissions/harmonic distortions in VSD

Options

Aircooled ZT: air/oil/coolant flow

Energy recovery *

Automatic water shut-off valve *

Air filter

Anti-condensation heater for motor

Air in

PT1000s in motor windings

Low pressure

element

High pressure

element

PT1000s in motor bearings

Witness performance test

Material certificates

IT network for VSD

Pre-filter for air inlet

Separate air intake

Oversized motor (no use of Service Factor)

Thermostatic water valve for ZR VSD

Aftercooler

(with pre-cooler)

Bypass over IMD

PDp filter after IMD

Air out

Oilcooler

Intercooler

(with pre-cooler)

Pressure dewpoint sensor after IMD

SPM (shock pulse measurement) monitoring

er

* only for watercooled versions

** standard on LV, optional on MV

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 10

Superior design in every detail

In every detail Atlas Copco Z-compressors are

designed and manufactured to the highest standards

of quality and reliability. There are no hidden extras or

complicated installation requirements: every unit is

Proven Z-technology

delivered as a complete and integrated package,

unique Z-seal design guarantees

ready to run.

Watercooled

Oil-free screw

compression element

ZR 425

Superior element bearings

100 % oil-free air

high stability under varying

operation far below

load conditions

critical speed

easily adapts to changing loads

high overall efficiency

no need for pre-lubrication/

no oil clean up problems

stabilisation time

Advanced Elektronikon

control and monitoring system

Inlet compensators

standard on all

piping connections

Coolers &

water separator

Water separator

the labyrinth design efficiently separates the condensate from the

compressed air

electronic drains are offered as standard

low moisture carry-over protects downstream equipment

better dryer performance

Oil-free screw

compression element

IMD dryer

Watercooled

ZR 315 VSD-FF

field proven design

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 11

Advanced Elektronikon control and monitoring system

overall system performance status with pro-active service indications,

alarms for malfunctions and safety shutdowns

High precision gears

multi-language selectable display

according to AGMA Q13/DIN

Efficient filtration of

all monitoring and control functions via one interface

Class 5

the intake air

wide communication possibilities

long lifetime

machine mounted,

low transmission losses

easy to maintain

low noise and vibration

minimum intake losses

Gearbox breathing system

Inlet valve

integration possible in many process control systems (field bus system)

High efficiency cooling (watercooled ZR compressor)

efficient filter combined with

air operated diaphragm

coolers with tubes of special corrosion resistant stainless steel (R249)

venturi system

lowest unloaded power

star profile increases heat transfer

keeps the oil inside the

positive interlock with unload

very low approach temperatures

gearbox

valve

nearly perfect intercooling saves energy

no oil fumes in the atmosphere

nearly perfect aftercooling enhances dryer performance

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 12

Why Variable Speed Drive (VSD) compressors ?

Because a VSD compressor precisely follows the

Direct energy savings of up to 35 %

varying air demand that is typical in most production

Unload losses are reduced to a minimum

facilities, it dramatically reduces the energy bill and

No blow-off of compressed air to the atmosphere

provides many additional benefits. The result is a fast

Load/no load transition losses are eliminated

payback of the investment and huge yearly savings long

The precise pressure control of the VSD compressor allows

after that.

for a tighter pressure band and a lower average working

pressure, resulting in reduced energy consumption

Because energy constitutes the biggest portion of the

life cycle cost of a compressor, these savings have a

significant impact on the operational costs of your

compressed air system.

STABLE SYSTEM PRESSURE

Pressure - Standard load-unload - 0.5 bar

Pressure - turbo-modulating - 0.2 bar

Pressure - VSD - 0.1 bar

investment

energy savings with VSD

maintenance

0.5

bar

energy

Predicting your savings

Process pressure

Indirect savings

Call upon the expertise of Atlas Copco specialists and have

The lowered system pressure obtained by the VSD

an assessment carried out in your factory.

compressor provides additional yearly savings:

A detailed report will show your current operation and

the achievable savings when adding a VSD solution to your

compressed air system.

other base-load compressors will consume up to

5 % less energy

leak losses - always present in compressed air systems are significantly reduced: e.g. leakage at 6 bar(e) is

13 % less than at 7 bar

most compressed air applications consume less air

at a reduced pressure

In addition to the direct savings, the combination of above

elements could add up to another 10 % energy savings on

the complete compressed air installation.

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 13

Additional VSD benefits

The stable system pressure provides stability for all

NO CURRENT PEAKS

processes using compressed air.

Current peaks during start-up are eliminated

VSD compressors can be started and stopped without

limitation

starting the compressor no longer leads to current peak

800

% Full load current

Star Delta

DOL

Soft Starter

400

VSD

penalties

Often, smaller transformers, breakers, fuses and cables can

0

10

be used, saving on the electrical installation costs.

20

Seconds

Integrated VSD - The only way

All Atlas Copco VSD compressors are EMC tested and certified. External

sources do not influence the compressor operation, nor does the compressor

The Elektronikon system controls the compressor

disturb other equipment via emissions or via the power supply line.

and the integrated converter; this ensures

maximum machine safety and allows for easy

networking of the compressor.

Mechanical enhancements are made to ensure

that gears and bearings receive proper

lubrication at all speeds and that all components

operate well below critical vibrations.

The electric motor is specifically designed for

VSD operation. Bearings are protected against

induced bearing currents and both motor and

converter are perfectly tuned to obtain the best

efficiency over the entire speed range. Cooling

air flow to the motor is optimized over the

complete range.

The machine is tested for the complete speed

range to eliminate all "speed windows" that can

COMBINED MOTOR/CONVERTER EFFICIENCY

jeopardize the energy savings and the stable

100 %

system pressure.

OPERATING RANGE

non-integrated solution

integrated VSD

non-integrated VSD

Atlas Copco integrated solution

speed windows

minimum

maximum

Flow

minimum

maximum

Motor speed

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 14

The Full Feature compressor

a compact, all-in-one quality air solution

The Full Feature concept is a total installation,

providing dry compressed air out of the box. Integrating

the IMD dryer and its Variable Speed Drive on VSD

models, this compact package offers high quality air at

The IMD drying principle

the lowest cost with the highest reliability:

Dry air

Hot unsaturated air

The IMD adsorption dryer eliminates the moisture before

it enters the air net, ensuring a reliable process and an

impeccable end product. No external energy is needed for

Drying

section

Regeneration

section

the IMD to dry the air, resulting in large savings over the

lifetime of the compressor.

The pressure drop through the dryer is minimal, which

again cuts down the operating cost.

Reduced floor space thanks to the efficient integration of the

dryer into the compressor canopy.

The Full Feature compressor is a pre-wired and

pre-piped solution, ready to use.

Aircooled

ZT 315 VSD-FF

Cold saturated air

Hot saturated air

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 15

Energy savings with Full Feature

Advanced control and monitoring

Direct Savings

One integrated control system for compressor and dryer

Monitoring of the IMD dryer includes:

The IMD drying process requires no external energy; over time

this results in large savings.

Temperature readings of

80 000

regeneration air inlet and outlet

mix air inlet

Pressure dewpoint after the IMD (option)

Loading reporting of dryer

IMD

Refrigerant dryer

Heat reactivated dryer

Heatless dryer

70 000

60 000

IMD Savings

Energy savings* (/$/year)

IMD dryer inlet and outlet

50 000

40 000

30 000

20 000

10 000

Flow

0

0

500

1060

1000

2120

1500

3180

2000 l/s

4240 cfm

* Assumptions: 1kWh = 0.05 /$ 8000 h/year

Indirect Savings

Other than direct energy input, the pressure drop in dryers

causes indirect energy consumption as well. IMD dryers have a

very low pressure drop, which leads to a further reduction in

energy cost.

4000

Yearly savings* (/$)

3500

3000

2500

2000

1500

Savings

1000

Savings

for each 0.1 bar (1.4 psi) pressure drop

500

Flow

0

0

Watercooled

ZR 160 VSD-FF

500

1060

1000

2120

1500

3180

2000

4240

2500

5300

3000 l/s

6360 cfm

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 16

Reliable technology for tough conditions

HAT version keeps cool in hot spots

Operating air compressors in very hot environments

has been a challenge to plant engineers for many years.

Often, the only solution was to order custom built units,

at high additional expense and with long and

unpredictable delivery times.

Standard solution

With the new High Ambient Temperature (HAT) compressors,

Atlas Copco offers an off-the-shelf standard solution.

HAT compressors operate comfortably at high intake and

cooling air/water temperatures of up to 50 C.

Reliable operation is ensured by...

enhanced mechanical design

optimized cooling

proper motor sizing

The HAT compressor is a thoroughly tested package to prevent

any uncertainties and surprises.

ContainAIR is out there

Be it for a temporary need or simply because there

is no room inside your factory, Atlas Copco ContainAIR

delivers air wherever you need it. Installed in a 20 ft.

container, ContainAIR has all the features of its stationary

oil-free relatives, but adds flexibility and mobility.

ContainAIR is available for all compressor

configurations, VSD and FF versions (up to 315 kW).

Totally self-contained and rugged, it runs around

the clock. Winterized versions are optional.

When the going gets tough, ContainAIR gets going.

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

True performance

11:29

Pagina 17

Global presence

Local service

When specifying the true performance of an air

compressor, at least three parameters must be considered:

Capacity

The standard to which the capacity is measured

Working pressure

The point where the delivery pressure is measured

Power consumption

The compressor package power required at an effective

working pressure (including all internal losses from inlet

to outlet) and the drive motor efficiency

Atlas Copco offers a complete portfolio of Aftermarket

products, unrivalled in todays compressed air industry.

High quality service is delivered locally: Atlas Copco

Intake volume - l/s - m3/min - cfm

is present in 150 countries around the world.

Intake volume

Inlet flow referred to

compressor element inlet

conditions. Seal leakages and

inlet losses should not deprive

you the air you paid for.

A sophisticated logistics concept brings genuine parts

to your doorstep in record times, across the globe.

External leakages

Service Plans perfectly meet the needs of your business

and ensure a constant productivity at peak level.

Atlas Copco Z-compressors are measured according to

Three levels are available: Total Responsibility Plan,

ISO 1217, Annex C, Edition 3, stipulating the FAD

Preventative Maintenance Plan and Inspection Plan.

measurement at the outlet of the package, net of all losses.

Consultancy services and on-site measurements help

Atlas Copco specifications correspond to the capacity and

optimizing the complete air net, minimizing leak losses

pressure which the customer receives, not to what the

and maximizing energy savings. Following packages

compressor sucks in. Differences can be substantial.

can be included individually or combined:

in-depth system audits based on

actual measurements

remote monitoring via the Internet

FAD - l/s - m3/min - cfm

energy savings via system control

Delivered volume

FAD according to ISO 1217,

Annex C, Edition 3.

A Z-compressor truly

gives what is promised.

and management.

Site

conditions

External leakages

Net usable

air

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 18

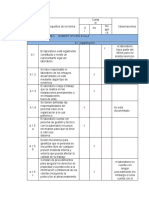

Technical data

ZR 110-425 and ZR 132-500 VSD compressors - 50 Hz

ZR

watercooled

Pack (w/o IMD Dryer)

FF (with IMD Dryer)

Pack (w/o IMD Dryer)

FF (with IMD Dryer)

Pack (w/o IMD Dryer)

FF (with IMD Dryer)

Type

50 Hz - 7.5 bar(e)

ZR 110

ZR 132

ZR 145

ZR 160

ZR 200

ZR 250

ZR 275

ZR 110

ZR 132

ZR 145

ZR 160

ZR 200

ZR 250

ZR 275

ZR 300

ZR 315

ZR 355

ZR 400

ZR 425

50 Hz - 8.6 bar(e)

ZR 110

ZR 132

ZR 132 VSD

ZR 145

ZR 160

ZR 160 VSD

ZR 200

ZR 250

ZR 250 VSD

ZR 275

ZR 315 VSD

ZR 110

ZR 132

ZR 132 VSD

ZR 145

ZR 160

ZR 160 VSD

ZR 200

ZR 250

ZR 250 VSD

ZR 275

ZR 300

ZR 315

ZR 315 VSD

ZR 355

ZR 400

ZR 400 VSD

ZR 425

ZR 500 VSD

50 Hz - 10 bar(e)

ZR 110

ZR 132

ZR 132 VSD

ZR 145

ZR 160

ZR 160 VSD

ZR 200

ZR 250

ZR 250 VSD

ZR 275

ZR 315 VSD

ZR 110

ZR 132

ZR 132 VSD

ZR 145

ZR 160

ZR 160 VSD

ZR 200

ZR 250

ZR 250 VSD

ZR 275

ZR 300

ZR 315

ZR 315 VSD

ZR 355

ZR 400

ZR 400 VSD

ZR 500 VSD

Free air delivery (1)

Installed

motor

Cooling

water

consumption (2)

Pressure

dewpoint (3)

Sound pressure

level (4)

Weight

Dimensions

l/s

m3/min

cfm

kW

l/s

w/o duct

dB(A)

with duct

dB(A)

kg

A

mm

B

mm

C

mm

318

367

394

471

607

726

780

318

367

394

471

607

726

780

775

855

949

1049

1162

19.1

22.0

23.6

28.3

36.4

43.6

46.8

19.1

22.0

23.6

28.3

36.4

43.6

46.8

46.5

51.3

56.9

62.9

69.7

674

778

835

998

1286

1538

1653

674

778

835

998

1286

1538

1653

1642

1812

2011

2223

2462

110

132

160

160

200

250

275

110

132

160

160

200

250

275

315

315

355

400

450

3.5

4.1

4.2

4.4

5.1

5.8

6.2

1.7

1.9

2.0

2.3

3.0

3.7

4.1

4.0

4.4

4.8

5.4

6.2

-28

-29

-30

-25

-25

-28

-30

-

70

70

70

67

67

67

67

67

67

67

67

67

67

67

70

71

71

71

72

68

68

68

66

66

66

66

65

65

66

66

66

66

66

69

69

69

70

70

3265

3390

3530

4705

5365

5360

5560

2635

2760

2900

3795

3995

3990

4190

6650

6650

6950

7050

7250

3440

3440

3440

4340

4340

4340

4340

2540

2540

2540

3140

3140

3140

3140

3700

3700

3700

3700

3700

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2400

2400

2400

2400

2400

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

2120

2120

2120

2120

2120

285

326

364

362

435

431

553

691

721

723

836

285

326

369

362

435

434

553

691

721

723

723

798

836

886

978

1114

1081

1318

17.1

19.6

21.8

21.7

26.1

25.9

33.2

41.5

43.3

43.4

50.2

17.1

19.6

22.1

21.7

26.1

26.0

33.2

41.5

43.3

43.4

43.4

47.9

50.2

53.2

58.7

66.9

64.9

79.1

604

691

771

767

922

913

1172

1464

1528

1532

1771

604

691

782

767

922

920

1172

1464

1528

1532

1532

1691

1771

1877

2072

2361

2291

2793

110

132

132

160

160

160

200

250

250

275

315

110

132

132

160

160

160

200

250

250

275

315

315

315

355

400

425

450

525

3.1

3.5

3.9

3.9

4.2

4.2

4.8

5.6

5.8

5.8

6.8

1.5

1.7

1.9

1.9

2.2

2.2

2.8

3.5

3.7

3.8

4.1

4.5

4.3

4.9

5.4

6.4

6.2

7.6

-28

-29

-28/-32

-30

-25

-28/-32

-25

-28

-25/-30

-30

-25/-30

-

70

70

68-72

70

67

68-74

67

67

63-73

67

63-73

67

67

62-68

67

67

62-70

67

67

63-73

67

71

72

63-73

72

72

68-75

73

68-76

68

68

66-69

68

66

66-71

66

66

62-71

66

62-71

65

65

61-66

66

66

61-66

66

66

62-71

66

70

70

62-71

72

71

66-73

71

66-74

3265

3390

3500

3530

4705

3500

5365

5360

6080

5560

6080

2635

2760

2870

2900

3795

2870

3995

3990

4710

4190

6650

6650

4710

6950

7050

8350

7250

8350

3440

3440

3440

3440

4340

3440

4340

4340

4340

4340

4340

2540

2540

2540

2540

3140

2540

3140

3140

3140

3140

3700

3700

3140

3700

3700

4060

3700

4060

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2400

2400

2000

2400

2400

2470

2400

2470

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

2120

2120

1650

2120

2120

2120

2120

2120

265

313

330

334

402

392

504

629

648

689

746

265

313

333

334

402

394

504

629

648

689

689

765

746

846

939

979

1150

15.9

18.8

19.8

20.0

24.1

23.5

30.2

37.7

38.9

41.3

44.8

15.9

18.8

20.0

20.0

24.1

23.6

30.2

37.7

38.9

41.3

41.3

45.9

44.8

50.8

56.3

58.7

69.0

562

663

699

708

852

831

1068

1333

1373

1460

1581

562

663

706

708

852

835

1068

1333

1373

1460

1460

1621

1581

1793

1990

2074

2437

110

132

132

160

160

160

200

250

250

315

315

110

132

132

160

160

160

200

250

250

315

315

315

315

355

400

425

525

3.3

3.8

4.1

4.1

4.3

4.4

4.9

5.6

5.8

6.0

6.7

1.6

1.8

1.9

1.9

2.3

2.1

2.9

3.6

3.7

4.0

4.2

4.5

4.3

4.9

5.4

5.7

7.6

-28

-29

-28/-32

-30

-25

-28/-32

-25

-28

-25/-30

-30

-25/-30

-

70

70

68-72

70

67

68-74

67

67

67-73

67

67-73

67

67

62-68

67

67

62-70

67

67

64-70

67

71

72

63-73

73

73

69-76

69-77

68

68

66-69

68

66

66-71

66

66

65-71

66

65-71

65

65

61-66

66

66

61-66

66

66

65-68

66

70

70

62-71

71

71

66-73

66-74

3265

3390

3500

3530

4705

3500

4905

5360

6080

5560

6080

2380

2440

2590

2580

3795

2590

3995

3990

4710

4190

6650

6650

4710

6950

7050

8350

8350

3440

3440

3440

3440

4340

3440

4340

4340

4340

4340

4340

2540

2540

2540

2540

3140

2540

3140

3140

3140

3140

3700

3700

3140

3700

3700

4060

4060

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2400

2400

2000

2400

2400

2470

2470

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

2120

2120

1650

2120

2120

2120

2120

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 19

Technical data

ZT 110-275 and ZT 132-315 VSD compressors - 50 Hz

ZT

aircooled

Type

Pack (w/o IMD Dryer)

FF (with IMD Dryer)

Pack (w/o IMD Dryer)

FF (with IMD Dryer)

Pack (w/o IMD Dryer)

FF (with IMD Dryer)

50 Hz - 7.5 bar(e)

ZT 110

ZT 132

ZT 145

ZT 160

ZT 200

ZT 250

ZT 275

ZT 110

ZT 132

ZT 145

ZT 160

ZT 200

ZT 250

ZT 275

50 Hz - 8.6 bar(e)

ZT 110

ZT 132

ZT 132 VSD

ZT 145

ZT 160

ZT 160 VSD

ZT 200

ZT 250

ZT 250 VSD

ZT 275

ZT 315 VSD

ZT 110

ZT 132

ZT 132 VSD

ZT 145

ZT 160

ZT 160 VSD

ZT 200

ZT 250

ZT 250 VSD

ZT 275

ZT 315 VSD

50 Hz - 10 bar(e)

ZT 110

ZT 132

ZT 132 VSD

ZT 145

ZT 160

ZT 160 VSD

ZT 200

ZT 250

ZT 250 VSD

ZT 275

ZT 315 VSD

ZT 110

ZT 132

ZT 132 VSD

ZT 145

ZT 160

ZT 160 VSD

ZT 200

ZT 250

ZT 250 VSD

ZT 275

ZT 315 VSD

(1)

Free air delivery (1)

Installed

motor

Installed

fan motor

Pressure

dewpoint (3)

Sound pressure

level (4)

Weight

Dimensions

l/s

m3/min

cfm

kW

kW

w/o duct

dB(A)

with duct

dB(A)

kg

A

mm

B

mm

C

mm

312

360

386

457

557

695

729

314

362

388

457

557

695

729

18.7

21.6

23.2

27.4

33.4

41.7

43.7

18.8

21.7

23.3

27.4

33.4

41.7

43.7

661

763

818

968

1180

1473

1545

665

767

822

968

1180

1473

1545

110

132

160

160

200

250

275

110

132

160

160

200

250

275

4.8

4.8

4.8

8.8

8.8

8.8

18.5

4.8

4.8

4.8

8.8

8.8

8.8

8.8

-28

-29

-30

-30

-25

-28

-30

-

72

73

73

77

77

77

77

71

72

72

77

77

77

77

70

70

71

75

75

75

75

70

70

70

75

75

75

75

4095

4220

4360

5625

6285

6280

6630

3585

3710

3850

5185

5385

5380

5580

4040

4040

4040

5040

5040

5040

5040

4040

4040

4040

5040

5040

5040

5040

2000

2000

2000

2100

2100

2100

2100

2000

2000

2000

2100

2100

2100

2100

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

281

322

349

357

422

404

510

661

690

696

778

281

322

354

357

422

410

510

661

690

696

778

16.9

19.3

20.9

21.4

25.3

24.2

30.6

39.7

41.4

41.8

46.7

16.9

19.3

21.2

21.4

25.3

24.6

30.6

39.7

41.4

41.8

46.7

595

682

739

756

894

856

1081

1401

1462

1475

1648

595

682

750

756

894

869

1081

1401

1462

1475

1648

110

132

132

160

160

160

200

250

250

275

315

110

132

132

160

160

160

200

250

250

275

315

4.8

4.8

4.8

4.8

8.8

4.8

8.8

8.8

18.5

18.5

18.5

4.8

4.8

4.8

4.8

8.8

4.8

8.8

8.8

8.8

8.8

8.8

-28

-29

-25/-30

-30

-30

-25/-30

-25

-28

-25/-30

-30

-25/-30

-

72

73

67-71

73

77

67-74

77

77

70-77

77

70-78

71

72

67-74

72

77

67-74

77

77

70-77

77

70-78

70

70

66-70

71

75

66-71

75

75

68-75

75

68-76

70

70

66-71

70

75

66-71

75

75

68-75

75

68-76

4095

4220

4330

4360

5625

4330

6285

6280

6660

6630

6660

3585

3710

3820

3850

5185

3820

5385

5380

6130

5580

6130

4040

4040

4040

4040

5040

4040

5040

5040

5040

5040

5040

4040

4040

4040

4040

5040

4040

5040

5040

5040

5040

5040

2000

2000

2000

2000

2100

2000

2100

2100

2100

2100

2100

2000

2000

2000

2000

2100

2000

2100

2100

2100

2100

2100

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

260

307

316

327

383

370

485

605

610

667

702

261

309

320

329

383

384

485

605

610

667

702

15.6

18.4

19.0

19.6

23.0

22.2

29.1

36.3

36.6

40.0

42.1

15.7

18.5

19.2

19.7

23.0

23.0

29.1

36.3

36.6

40.0

42.1

551

650

670

693

812

784

1028

1282

1293

1413

1487

553

655

678

697

812

814

1028

1282

1293

1413

1487

110

132

132

160

160

160

200

250

250

315

315

110

132

132

160

160

160

200

250

250

315

315

4.8

4.8

4.8

4.8

8.8

4.8

8.8

8.8

18.5

18.5

18.5

4.8

4.8

4.8

4.8

8.8

4.8

8.8

8.8

8.8

8.8

8.8

-28

-29

-25/-30

-30

-30

-25/-30

-30

-28

-25/-30

-30

-25/-30

-

72

73

67-71

73

78

67-74

78

78

71-78

78

71-79

71

72

67-71

72

78

67-74

78

78

71-78

78

71-79

70

70

66-70

70

76

66-71

76

76

69-76

76

69-77

70

70

66-70

70

76

66-71

76

76

69-76

76

69-77

4095

4220

4330

4360

5625

4330

5825

6280

6660

6630

6660

3560

3700

4050

3850

5185

4050

5385

5380

6130

5580

6130

4040

4040

4040

4040

5040

4040

5040

5040

5040

5040

5040

4040

4040

4040

4040

5040

4040

5040

5040

5040

5040

5040

2000

2000

2000

2000

2100

2000

2100

2100

2100

2100

2100

2000

2000

2000

2000

2100

2000

2100

2100

2100

2100

2100

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

Reference Conditions:

- Dry air

- Absolute inlet pressure 1 bar(a)

- Cooling and air intake temperature 20 C

- Nominal working pressure:

- 7 bar(e) for 7, 7.5 and 8.6 bar(e) variants

- 9 bar(e) for 10 and 10.4 bar(e) variants

- Z VSD: 5 % derating for 380V nets

- Capacity of the compressor package measured

according to ISO 1217, Third Edition, Annex C

(2)

Cooling water temp. rise of 15 C (10 C for FF)

(3)

Pressure dewpoint is specified for

- 20 C cooling air/water temperature

- relative humidity of 60 %

- nominal working pressure

- load level of minimum 50 %

(4)

3 dB(A) according to ISO 2151:2004 and using ISO 9614-2

Conversions

- 1 kg = 2.2 lbs

- 1 mm = 0.039 inch

- F = C x 9/5 + 32

C

A

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 20

Technical data

ZR 110-400 and ZR 132-500 VSD compressors - 60 Hz

ZR

watercooled

Free air delivery (1)

Installed

motor

Cooling

water

consumption (2)

Pressure

dewpoint (3)

Pack (w/o IMD) FF (with IMD)

FF (with IMD Dryer)

Pack (w/o IMD Dryer)

FF (with IMD Dryer)

Pack (w/o IMD Dryer)

Weight

Dimensions

l/s

m3/min

cfm

HP

l/s

w/o duct

dB(A)

with duct

dB(A)

kg

A

mm

B

mm

C

mm

352

463

574

667

752

352

463

574

667

752

21.1

27.8

34.4

40.0

45.1

21.1

27.8

34.4

40.0

45.1

746

981

1216

1413

1593

746

981

1216

1413

1593

150

200

250

300

350

150

200

250

300

350

3.9

4.4

4.9

5.4

5.9

1.9

2.3

2.9

3.4

3.8

-28

-25

-25

-28

-30

-

70

67

67

67

67

67

67

67

67

67

68

66

66

66

66

65

66

66

66

66

3265

4695

5305

5515

5635

2635

3785

3935

4145

4265

3440

4340

4340

4340

4340

2540

3140

3140

3140

3140

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

318

364

398

419

431

516

619

721

726

836

318

369

398

419

434

516

619

721

726

755

850

836

955

1043

1114

1318

19.1

21.8

23.9

25.1

25.9

31.0

37.1

43.3

43.6

50.2

19.1

22.1

23.9

25.1

26.0

31.0

37.1

43.3

43.6

45.3

51.0

50.2

57.3

62.6

66.9

79.1

674

771

843

888

913

1093

1312

1528

1538

1771

674

782

843

888

920

1093

1312

1528

1538

1600

1801

1771

2024

2210

2361

2793

150

175

200

200

215

250

300

335

350

423

150

175

200

200

215

250

300

335

350

350

400

423

450

500

570

703

3.8

3.9

4.1

4.4

4.2

4.6

5.2

5.8

5.8

6.8

1.7

1.9

2.1

2.1

2.2

2.6

3.1

3.7

3.7

4.1

4.6

4.3

5.1

5.6

6.4

7.6

-28

-28/-32

-30

-25

-28/-32

-25

-28

-25/-30

-30

-25/-30

-

70

68-72

70

67

68-74

67

67

63-73

67

63-73

67

62-68

68

67

62-70

67

67

63-73

67

71

72

63-73

72

72

68-75

68-76

68

66-69

68

66

66-71

66

66

62-71

66

62-71

65

61-66

66

66

61-66

66

66

62-71

66

70

70

62-71

70

71

66-73

66-74

3265

3500

3530

4695

3500

5305

5515

6080

5635

6080

2635

2870

2900

3785

2870

3935

4145

4710

4265

6550

6550

4710

6950

7050

8320

8320

3440

3440

3440

4340

3440

4340

4340

4340

4340

4340

2540

2540

2540

3140

2540

3140

3140

3140

3140

3700

3700

3140

3700

3700

4060

4060

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2400

2400

2000

2400

2400

2470

2470

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

2120

2120

1650

2120

2120

2120

2120

287

330

336

375

392

459

548

648

641

746

287

333

336

375

394

459

548

648

641

677

762

746

858

945

979

1150

17.2

19.8

20.2

22.5

23.5

27.5

32.9

38.9

38.5

44.8

17.2

20.0

20.2

22.5

23.6

27.5

32.9

38.9

38.5

40.6

45.7

44.8

51.5

56.7

58.7

69.0

608

699

712

795

831

973

1161

1373

1358

1581

608

706

712

795

835

973

1161

1373

1358

1434

1615

1581

1818

2002

2074

2437

150

175

200

200

215

250

300

335

350

423

150

214

200

200

215

250

300

335

350

350

400

423

450

500

570

703

3.5

3.9

4.1

4.4

4.2

4.7

5.2

5.8

5.7

6.7

1.7

1.9

2.0

2.2

2.1

2.6

3.1

3.7

3.6

4.3

4.6

4.3

5.1

5.5

5.7

7.6

-28

-28/-32

-30

-25

-28/-32

-25

-28

-25/-30

-30

-25/-30

-

70

68-72

70

67

68-74

67

67

67-73

67

67-73

67

62-68

67

67

62-70

67

67

64-70

67

71

72

63-73

73

73

69-76

69-77

68

66-69

68

66

66-71

66

66

65-71

66

65-71

65

61-66

66

66

61-66

66

66

65-68

66

70

70

62-71

71

71

66-73

66-74

3265

3500

3530

4695

3500

4845

5515

6080

5635

6080

2635

2590

2900

3785

2590

3935

4145

4710

4265

6550

6550

4710

6950

7050

8350

8350

3440

3440

3440

4340

3440

4340

4340

4340

4340

4340

2540

2540

2540

3140

2540

3140

3140

3140

3140

3700

3700

3140

3700

3700

4060

4060

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2400

2400

2000

2400

2400

2470

2470

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

2120

2120

1650

2120

2120

2120

2120

Type

60 Hz - 7 bar(e)

ZR 110

ZR 160

ZR 200

ZR 250

ZR 275

ZR 110

ZR 160

ZR 200

ZR 250

ZR 275

60 Hz - 8.6 bar(e)

ZR 110

ZR 132 VSD

ZR 145

ZR 160

ZR 160 VSD

ZR 200

ZR 250

ZR 250 VSD

ZR 275

ZR 315 VSD

ZR 110

ZR 132 VSD

ZR 145

ZR 160

ZR 160 VSD

ZR 200

ZR 250

ZR 250 VSD

ZR 275

ZR 300

ZR 315

ZR 315 VSD

ZR 355

ZR 400

ZR 400 VSD

ZR 500 VSD

60 Hz - 10.4 bar(e)

ZR 110

ZR 132 VSD

ZR 145

ZR 160

ZR 160 VSD

ZR 200

ZR 250

ZR 250 VSD

ZR 275

ZR 315 VSD

ZR 110

ZR 132 VSD

ZR 145

ZR 160

ZR 160 VSD

ZR 200

ZR 250

ZR 250 VSD

ZR 275

ZR 300

ZR 315

ZR 315 VSD

ZR 355

ZR 400

ZR 400 VSD

ZR 500 VSD

Sound pressure

level (4)

C

A

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

26/09/2005

11:29

Pagina 21

Technical data

ZT 110-275 and ZT 132-315 VSD compressors - 60 Hz

ZT

aircooled

Type

Pack (w/o IMD Dryer)

FF (with IMD Dryer)

Pack (w/o IMD)

FF (with IMD)

60 Hz - 8.6 bar(e)

ZT 110

ZT 132 VSD

ZT 145

ZT 160

ZT 160 VSD

ZT 200

ZT 250

ZT 250 VSD

ZT 275

ZT 315 VSD

ZT 110

ZT 132 VSD

ZT 145

ZT 160

ZT 160 VSD

ZT 200

ZT 250

ZT 250 VSD

ZT 275

ZT 315 VSD

60 Hz - 10.4 bar(e)

ZT 110

ZT 132 VSD

ZT 145

ZT 160

ZT 160 VSD

ZT 200

ZT 250

ZT 250 VSD

ZT 275

ZT 315 VSD

ZT 110

ZT 132 VSD

ZT 145

ZT 160

ZT 160 VSD

ZT 200

ZT 250

ZT 250 VSD

ZT 275

ZT 315 VSD

(1)

Free air delivery(1)

Installed

motor

Installed

fan motor

Pressure

dewpoint (3)

Sound pressure

level (4)

Weight

Dimensions

l/s

m3/min

cfm

HP

HP

w/o duct

dB(A)

with duct

dB(A)

kg

A

mm

B

mm

C

mm

312

349

391

410

404

500

596

690

699

778

314

354

392

410

410

500

596

690

699

778

18.7

20.9

23.5

24.6

24.2

30.0

35.8

41.4

41.9

46.7

18.8

21.2

23.5

24.6

24.6

30.0

35.8

41.4

41.9

46.7

661

739

828

869

856

1059

1263

1462

1481

1648

665

750

831

869

869

1059

1263

1462

1481

1648

150

175

200

200

215

250

300

335

350

423

150

175

200

200

215

250

300

335

350

423

6.5

6.5

6.5

12.3

6.5

12.3

12.3

24.8

24.8

24.8

6.5

6.5

6.5

12.3

6.5

12.3

12.3

12.3

12.3

12.3

-28

-25/-30

-30

-30

-25/-30

-25

-28

-25/-30

-30

-25/-30

-

72

67-71

73

77

67-74

77

77

70-77

77

70-78

71

67-74

72

77

67-74

77

77

70-77

77

70-78

70

66-70

70

75

66-71

75

75

68-75

75

68-76

70

66-71

70

75

66-71

75

75

68-75

75

68-76

4095

4330

4360

5615

4330

6225

6435

6660

6705

6660

3585

3820

3850

5175

3820

5325

5535

6130

5655

6130

4040

4040

4040

5040

4040

5040

5040

5040

5040

5040

4040

4040

4040

5040

4040

5040

5040

5040

5040

5040

2000

2000

2000

2100

2000

2100

2100

2100

2100

2100

2000

2000

2000

2100

2000

2100

2100

2100

2100

2100

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

282

316

329

359

370

438

526

610

616

702

283

320

331

359

384

438

526

610

616

702

16.9

19.0

19.7

21.5

22.2

26.3

31.6

36.6

37.0

42.1

17.0

19.2

19.9

21.5

23.0

26.3

31.6

36.6

37.0

42.1

598

670

697

761

784

928

1115

1293

1305

1487

600

678

701

761

814

928

1115

1293

1305

1487

150

175

200

200

215

250

300

335

350

423

150

175

200

200

215

250

300

335

350

423

6.5

6.5

6.5

12.3

6.5

12.3

12.3

24.8

24.8

24.8

6.5

6.5

6.5

12.3

6.5

12.3

12.3

12.3

12.3

12.3

-28

-25/-30

-30

-30

-25/-30

-30

-28

-25/-30

-30

-25/-30

-

72

67-71

73

78

67-74

78

78

71-78

78

71-79

71

67-71

72

78

67-74

78

78

71-78

78

71-79

70

66-70

70

76

66-71

76

76

69-76

76

69-77

70

66-70

70

76

66-71

76

76

69-76

76

69-77

4095

4330

4360

5615

4330

5765

6435

6660

6705

6660

3585

4050

3850

5175

4050

5325

5535

6130

5655

6130

4040

4040

4040

5040

4040

5040

5040

5040

5040

5040

4040

4040

4040

5040

4040

5040

5040

5040

5040

5040

2000

2000

2000

2100

2000

2100

2100

2100

2100

2100

2000

2000

2000

2100

2000

2100

2100

2100

2100

2100

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

1650

Reference Conditions:

- Dry air

- Absolute inlet pressure 1 bar(a)

- Cooling and air intake temperature 20 C

- Nominal working pressure:

- 7 bar(e) for 7, 7.5 and 8.6 bar(e) variants

- 9 bar(e) for 10 and 10.4 bar(e) variants

- Z VSD: 5 % derating for 380V nets

- Capacity of the compressor package measured

according to ISO 1217, Third Edition, Annex C

(2)

Cooling water temp. rise of 15 C (10 C for FF)

(3)

Pressure dewpoint is specified for

- 20 C cooling air/water temperature

- relative humidity of 60 %

- nominal working pressure

- load level of minimum 50 %

(4)

3 dB(A) according to ISO 2151:2004 and using ISO 9614-2

Conversions

- 1 kg = 2.2 lbs

- 1 mm = 0.039 inch

- F = C x 9/5 + 32

C

A

26/09/2005

11:29

Pagina 22

The face of innovation

2935 x466 13_ZRZT110-315_TALENVERSIES_v1.1.qxp

Atlas Copco se distingue como empresa por nuestra

conviccin de que slo podremos destacar en lo que hacemos si,

ofrecemos la mejor experiencia tecnolgica posible para ayudar

realmente a nuestros clientes a producir, crecer y triunfar.

Slo hay una forma de conseguirlo - nosotros lo llamamos

simplemente el Estilo Atlas Copco. Se basa en la interaccin,

las relaciones a largo plazo y la participacin en los procesos,

ISO 9001

Nuestra calidad constante nos

ha otorgado el liderazgo de

la industria y la confianza de

nuestros clientes

necesidades y objetivos de los clientes. Significa que debemos

ser flexibles para adaptarnos a los variados requisitos de las

personas que confan en nosotros.

El compromiso con el negocio de nuestros clientes dirige

nuestro esfuerzo para aumentar su productividad mediante

mejores soluciones. Un compromiso que comienza prestando

continuamente. Pero no nos detenemos aqu, concebimos

realizamos avances tecnolgicos a travs de la innovacin

Atlas Copcos

Environmental Management

System forms an integral part

of each business process.

No por simple amor a la tecnologa, sino pensando en los

resultados y en la tranquilidad de nuestros clientes.

As es como Atlas Copco se esforzar por seguir siendo la

primera eleccin, atraer nuevos negocios y mantener nuestra

posicion como lider de la industria.

Never use compressed air

as breathing air without

prior purification in

accordance with local

legislation and standards.

2935 0466 13 - Printed in Belgium - Subject to alterations without prior notice

ISO 14001

www.atlascopco.com

Das könnte Ihnen auch gefallen

- Planeacion DelipostresDokument8 SeitenPlaneacion Delipostressandra carolina pinzonNoch keine Bewertungen

- LYC-P-80 Criterios SSYMA para Proveedores V5Dokument9 SeitenLYC-P-80 Criterios SSYMA para Proveedores V5Ceslyp Lisseth Bautista FernándezNoch keine Bewertungen

- C#5 Responsabilidad Social y Ética AdministrativaDokument19 SeitenC#5 Responsabilidad Social y Ética AdministrativaRif JoestarNoch keine Bewertungen

- Costos y PresupuestosDokument10 SeitenCostos y PresupuestosEvelyn SotoNoch keine Bewertungen

- Lecciones de Hermenéutica JuridicaDokument11 SeitenLecciones de Hermenéutica JuridicaAlonso ForeroNoch keine Bewertungen

- Capilla El ÁngelDokument7 SeitenCapilla El Ángelthaidy rojasNoch keine Bewertungen

- Simulador Financiero FinalDokument114 SeitenSimulador Financiero FinalVillarreal Maricelita LindaNoch keine Bewertungen

- Guia Historia IIM 2semDokument4 SeitenGuia Historia IIM 2semCarlos Alberto SotoNoch keine Bewertungen

- Capítulo 16 MacroeconomiaDokument15 SeitenCapítulo 16 MacroeconomiaAgustinNoch keine Bewertungen

- Informe NESTLE 2.0Dokument7 SeitenInforme NESTLE 2.0Ronal Franco Alejo PariNoch keine Bewertungen

- La Responsabilidad Social Empresarial y El Rol Del Ingeniero Industrial en La Gestión IntegralDokument4 SeitenLa Responsabilidad Social Empresarial y El Rol Del Ingeniero Industrial en La Gestión IntegralLiyibethNoch keine Bewertungen

- Caso Contaminacion en El Agustino MepsaDokument3 SeitenCaso Contaminacion en El Agustino MepsaEdson HurtadoNoch keine Bewertungen

- Ta 2 AuditoriaDokument16 SeitenTa 2 AuditoriaCamila Ramos FarajNoch keine Bewertungen

- Taller Normatividad NiifDokument24 SeitenTaller Normatividad Niiffelipe julaNoch keine Bewertungen

- Para Hacer La ComparacionDokument22 SeitenPara Hacer La ComparacionJUAN DAVID SERNA VALDERRAMANoch keine Bewertungen

- Ty CAplazoDokument12 SeitenTy CAplazoDm MotionsNoch keine Bewertungen

- Ejerciciosmc - Rafael Bravo Karen MarielaDokument11 SeitenEjerciciosmc - Rafael Bravo Karen MarielaKaren RafaelNoch keine Bewertungen

- Ebook Conaltura Comprar Sobre PlanosDokument30 SeitenEbook Conaltura Comprar Sobre PlanosWilson VargasNoch keine Bewertungen

- Caso 2 Final No Copiar Otra SeccionDokument19 SeitenCaso 2 Final No Copiar Otra SeccionLuis Maldonado SepulvedaNoch keine Bewertungen

- 1 Carta de Visita GuiadaDokument2 Seiten1 Carta de Visita Guiadaperezleo_002Noch keine Bewertungen

- Ley Servicio Civil GuatemalaDokument30 SeitenLey Servicio Civil GuatemalaChes AlcazarNoch keine Bewertungen

- Compraventa Codigo CivilDokument14 SeitenCompraventa Codigo CivilCesar Augusto GuerraNoch keine Bewertungen

- Análisis de localización y diseño de proceso productivo para planta apícolaDokument7 SeitenAnálisis de localización y diseño de proceso productivo para planta apícolaemy natalyNoch keine Bewertungen

- Diagnostico y JustificacionDokument2 SeitenDiagnostico y JustificacionSanndy Zcon100% (1)

- Construcción de IndicadoresDokument5 SeitenConstrucción de Indicadoresmilton martinez batistaNoch keine Bewertungen

- Sistema Nacional de Fiscalización: Actores y funcionesDokument11 SeitenSistema Nacional de Fiscalización: Actores y funcionesLuisa GutierrezNoch keine Bewertungen

- Silabo CON115 Desarrollo Sistemas Información EmpresarialDokument5 SeitenSilabo CON115 Desarrollo Sistemas Información EmpresarialSussyNoch keine Bewertungen

- Parcial - Escenario 4 - SEGUNDO BLOQUE-TEORICO - PRACTICO - FINANZAS CORPORATIVAS - (GRUPO5)Dokument8 SeitenParcial - Escenario 4 - SEGUNDO BLOQUE-TEORICO - PRACTICO - FINANZAS CORPORATIVAS - (GRUPO5)JENNY MARCELA MAMBUSCAY BAUTISTANoch keine Bewertungen

- Aa21 - Lista de ChequeoDokument18 SeitenAa21 - Lista de ChequeoRobert AyalaNoch keine Bewertungen

- Administración - de - Proyectos - Enfoque - Por - Competencias A2018Dokument205 SeitenAdministración - de - Proyectos - Enfoque - Por - Competencias A2018Ing.sergio sanchez100% (1)