Beruflich Dokumente

Kultur Dokumente

Table of Diameter of Screw Low Hole (Low Anchor)

Hochgeladen von

api-3848892Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Table of Diameter of Screw Low Hole (Low Anchor)

Hochgeladen von

api-3848892Copyright:

Verfügbare Formate

〔Technical Data〕 〔Technical Data〕

Table of Diameter of Screw Low Hole (Low Anchor) Correct Tightening Axial Force and Correct Tightening Torque for Bolts

1.Meter coarse thread ■The tightening tension and fatigue limit when clamping with bolts

Minimum dimensions Maximum dimensions Minimum dimensions Maximum dimensions

Nominal size of thread Nominal size of thread

Grade 2, Grade 3 Grade 2 Grade 3 Grade 2, Grade 3 Grade 2 Grade 3 ・The calculation of the correct tightening torque when tightening bolts is to be within the elastic region, and a maximum of 70% of the standard yield strength under the Torque Method.

M 1 × 0.25 0.73 0.78 − M 16 × 1.5 14.38 14.68 14.75 ・The fatigue limit from repeated loads on the bolt should not exceed the allowable value. The Torque Method, the Torque Gradient Method,

M 1.1 × 0.25 0.83 0.89 − M 16 × 1 14.92 15.15 15.22 the Turn-of-Nut Method, and the Stretch

M 1.2 × 0.25 0.93 0.98 − ・The flange of a bolt or nut should not be sunk into the clamped surface.

Measurement Method can all be used as the method

M 1.4 × 0.3 1.08 1.14 − M 17 × 1.5 15.38 15.68 15.75 ・The surface to be clamped should not be damaged through the tightening of bolts. of bolt tightening, but the Torque Method is relatively

M 1.6 × 0.35 1.22 1.32 − M 17 × 1 15.92 16.15 16.22

simple and is widely used.

■Calculation of the tightening axial force and tightening torque

M 1.7 × 0.35 1.33 1.42 −

M 1.8 × 0.35 1.42 1.52 − M 18 × 2 15.84 16.21 16.31

M 2 × 0.4 1.57 1.67 − M 18 × 1.5 16.38 16.68 16.75

M 2.2 × 0.45 1.71 1.84 − M 18 × 1 16.92 17.15 17.22

M 2.3 × 0.4 1.87 1.97 − The relationship of the tightening axial force Ff is expressed in formula(1). k : torque coefficient

M 2.5 × 0.45 2.01 2.14 − M 20 × 2 17.84 18.21 18.31

M 2.6 × 0.45 2.12 2.23 − M 20 × 1.5 18.38 18.68 18.75

Ff=0.7×σy×As……(1) d :nominal bolt diameter[cm]

M 20 × 1 18.92 19.15 19.22 The tightening torque TfA, is expressed in formula(2). Q :tightening coefficient

M 3 × 0.5 2.46 2.60 2.64 2

M 3.5 × 0.6 2.85 3.01 3.05 M 22 × 2 19.84 20.21 20.31 TfA=0.35k

(1+1/Q)

σy・As・d……(2) σy :yield strength(112 kgf/mm when strength category is 12.9)

M 4 × 0.7 3.24 3.42 3.47 M 22 × 1.5 20.38 20.68 20.75 2

As : effective bolt area

[mm ]

M 22 × 1 20.92 21.15 21.22

M 4.5 × 0.75

M 5 × 0.8

3.69

4.13

3.88

4.33

3.92

4.38 M 24 × 2 21.84 22.21 22.31

■Calculation Example

M 6× 1 4.92 5.15 5.22 M 24 × 1.5 22.38 22.68 22.75

M 24 × 1 22.92 23.15 23.22

M 7× 1 5.92 6.15 6.22 The correct torque and axial force is required to clamp two pieces of soft steel(strength category of 12.9)with a socket head cap screw M6 in a lubricated state.

M 8 × 1.25 6.65 6.91 6.98 M 25 × 2 22.84 23.21 23.31 ・The correct torque is shown using formula (2) ・The correct axial tension is shown using formula (1)

M 9 × 1.25 7.65 7.91 7.98 M 25 × 1.5 23.38 23.68 23.75

M 10 × 1.5 8.38 8.68 8.75 M 25 × 1 23.92 24.15 24.22 TfA=0.35k(1+1/Q) σy・As・d ・Ff=0.7×σy×As

M 11 × 1.5 9.38 9.68 9.75

TA =0.35・0.17

(1+1/1.4)112・20.1・0.6 ・Ff=0.7×112×20.1

M 26 × 1.5 24.38 24.68 24.75

M 12 × 1.75 10.11 10.44 10.53 TA =138[kgf・cm] ・Ff=1576

[kgf]

M 14 × 2 11.84 12.21 12.31 M 27 × 2 24.84 25.21 25.31

M 16 × 2 13.84 14.21 14.31 M 27 × 1.5 25.38 25.68 25.75

M 18 × 2.5 15.29 15.74 15.85 M 27 × 1 25.92 26.15 26.22 ■Torque coefficient by combining the surface treatment of the bolt, the surface to be clamped, and the female screw.■The standard values of tightening coefficient Q

M 20 × 2.5 17.29 17.74 17.85 Bolt Torque Combining Tightening

coefficient Tightening method

Surface state

Lubrication state

Bolt Nut

(a)

M 28 × 2 25.84 26.21 26.31

Surface treatment coefficient Material of surface to be clamped−Material of female screw Q

M

M

22 × 2.5

24 × 3

19.29

20.75

19.74

21.25

19.85

21.38

M 28 × 1.5

M 28 × 1

26.38

26.92

26.68

27.15

26.75

27.22

Lubricant k (a) (b) (b)

1.25 Torque wrench Manganese phosphate

M 27 × 3 23.75 24.25 24.38 0.145 SCM−FC FC−FC SUS−FC Torque wrench Lubricated or

M 30 × 3.5 26.21 26.77 26.92 M 30 × 3 26.75 27.25 27.38

0.155 S10C−FC SCM−S10C SCM−SCM FC−S10C FC−SCM 1.4 Non-treated or phosphate

M 33 × 3.5 29.21 29.77 29.92 M 30 × 2 27.84 28.21 28.31 Ratchet wrench Non-treated or phosphate MoS2 paste

M 30 × 1.5 28.38 28.68 28.75 Steel bolts 0.165 SCM−SUS FC−SUS AL−FC SUS−S10C SUS−SCM SUS−SUS 1.6 Impact wrench

M 36 × 4 31.67 32.27 32.42 M 30 × 1 28.92 29.15 29.22

M 39 × 4 34.67 35.27 35.42

Black oxide coating 0.175 S10C−S10C S10C−SCM S10C−SUS AL−S10C AL−SCM Torque wrench

Lubricated 0.185 SCM−AL FC−AL AL−SUS 1.8 Non-treated or phosphate Non-treated Not lubricated

M 42 × 4.5 37.13 37.80 37.98 M 32 × 2 29.84 30.21 30.31 Ratchet wrench

M 45 × 4.5 40.13 40.80 40.98 M 32 × 1.5 30.38 30.68 30.75 0.195 S10C−AL SUS−AL

M 48 × 5 42.59 43.30 43.49 Expressing strength categories

M 33 × 3 29.75 30.25 30.38 0.215 AL−AL

Example 1 2 . 9

M 33 × 2 30.84 31.21 31.31 0.25 S10C−FC SCM−FC FC−FC

2.Meter fine thread M 33 × 1.5 31.38 31.68 31.75 Steel bolts 0.35 S10C−SCM SCM−SCM FC−S10C FC−SCM AL−FC Yield strength:90% of the minimum tensile strength

Minimum dimensions Maximum dimensions Black oxide coating

Nominal size of thread M 35 × 1.5 33.38 33.68 33.75 The minimal tensile strength is 1220N/mm2{124kgf/mm2}

Grade 2, Grade 3 Grade 2 Grade 3 Not lubricated

0.45 S10C−S10C SCM−S10C AL−S10C AL−SCM

例 1 0 . 9

M 2.5 × 0.35 2.12 2.22 − 0.55 SCM−AL FC−AL AL−AL

M 36 × 3 32.75 33.25 33.38 Yield strength:90% of the minimum tensile strength

M 36 × 2 33.84 34.21 34.31 S10C: Non heat-treated steel SCM:Heat-treated steel(35HRC) FC:Cast iron(FC200) AL:Aluminum SUS:Stainless(SUS304)

M 3 × 0.35 2.62 2.72 −

M 3.5 × 0.35 3.12 3.22 −

M 36 × 1.5 34.38 34.68 34.75 The minimal tensile strength is 1040N/mm2{106kgf/mm2}

M 4 × 0.5

M 4.5 × 0.5

3.46

3.96

3.60

4.10

3.64

4.14 M 38 × 1.5 36.38 36.68 36.75 ■Initial tightening strength and torque

M 5 × 0.5 4.46 4.60 4.64

M 39 × 3 35.75 36.25 36.38 Effective Strength category

M 5.5 × 0.5 4.96 5.10 5.14

5.19 5.38 M 39 × 2 36.84 37.21 37.31 bolt area 12.9 10.9 8.8 4.8

Bolt size

M 6 × 0.75 5.42

Yield load Initial tightening strength Tightening torque Yield load Initial tightening strength Tightening torque Yield load Initial tightening strength Tightening torque Yield load Initial tightening strength Tightening torque

M 39 × 1.5 37.38 37.68 37.75

As

M

M

7 × 0.75

8× 1

6.19

6.92

6.38

7.15

6.42

7.22

M 40 × 3 36.75 37.25 37.38 mm2 kgf kgf kgf・cm kgf kgf kgf・cm kgf kgf kgf・cm kgf kgf kgf・cm

M 40 × 2 37.84 38.21 38.31

M 8 × 0.75 7.19 7.38 7.42

M 40 × 1.5 38.38 38.68 38.75

M 3 ×0.5 5.03 563 394 17 482 338 15 328 230 10 175 122 5

M 9× 1 7.92 8.15 8.22

M 4 ×0.7 8.78 983 688 40 842 589 34 573 401 23 305 213 12

M 42 × 4 37.67 38.27 38.42

M 9 × 0.75 8.19 8.38 8.42 M 5 ×0.8 14.20 1590 1113 81 1362 953 69 927 649 47 493 345 25

M 42 × 3 38.75 39.25 39.38

M 10 × 1.25 8.65 8.91 8.98

M 42 × 2 39.84 40.21 40.31 M 6 ×1 20.10 2251 1576 138 1928 1349 118 1313 919 80 697 488 43

8.92 9.15 M 42 × 1.5 40.38 40.68 40.75 M 8 ×1.25 36.60 4099 2869 334 3510 2457 286 2390 1673 195 1270 889 104

M 10 × 1 9.22

M 10 × 0.75 9.19 9.38 −

M 45 × 4 40.67 41.27 41.42 M10 ×1.5 58.00 6496 4547 663 5562 3894 567 3787 2651 386 2013 1409 205

9.92 10.15 M 45 × 3 41.75 42.25 42.38 M12 ×1.75 84.30 9442 6609 1160 8084 5659 990 5505 3853 674 2925 2048 358

M 11 × 1 10.22

10.19 10.38 M 45 × 2 42.84 43.21 43.31

M 11 × 0.75 10.42 M14 ×2 115.00 12880 9016 1840 11029 7720 1580 7510 5257 1070 3991 2793 570

M 45 × 1.5 43.38 43.68 43.75

M 12 × 1.5 10.38 10.68 10.75 M16 ×2 157.00 17584 12039 2870 15056 10539 2460 10252 7176 1670 5448 3814 889

M 12 × 1.25 10.65 10.91 10.98 M 48 × 4 43.67 44.27 44.42

M 48 × 3 44.75 45.25 45.38 M18 ×2.5 192.00 21504 15053 3950 18413 12889 3380 12922 9045 2370 6662 4664 1220

M 12 × 1 10.92 11.15 11.22

M 48 × 2 45.84 46.21 46.31 M20 ×2.5 245.00 27440 19208 5600 23496 16447 4790 16489 11542 3360 8502 5951 1730

12.38 12.68 M 48 × 1.5 46.38 46.68 46.75

M 14 × 1.5 12.75 M22 ×2.5 303.00 33936 23755 7620 29058 20340 6520 20392 14274 4580 10514 7360 2360

M 14 × 1 12.92 13.15 13.22

M 50 × 3 46.75 47.25 47.38 M24 ×3 353.00 39536 27675 9680 33853 23697 8290 23757 16630 5820 12249 8574 3000

13.38 13.68 M 50 × 2 47.84 48.21 48.31

M 15 × 1.5 13.75

M 15 × 1 13.92 14.15 14.22

M 50 × 1.5 48.38 48.68 48.75 (Notes)・ Tightening conditions:The use of a torque wrench (lubrication, torque coefficient k= 0.17, tightening coefficient Q= 1.4)

・ The torque coefficient changes depending on conditions of use, so please use this table as an indication only.

・ This table is an edited excerpt from a catalogue from KYOKUTO MFG.CO., Ltd

1133 1134

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Surface Roughness by Different Processing MethodsDokument1 SeiteSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- Socket Head Cap ScrewsDokument1 SeiteSocket Head Cap Screwsapi-3848892100% (5)

- Fit Selection BasicDokument1 SeiteFit Selection Basicapi-3848892100% (2)

- SI (System International D Unit's)Dokument1 SeiteSI (System International D Unit's)api-3848892100% (1)

- Surface RoughnessDokument1 SeiteSurface Roughnessapi-3848892100% (2)

- Surface RoughnessDokument1 SeiteSurface Roughnessapi-3848892100% (2)

- Greek Symblos-Atomic SymbolsDokument1 SeiteGreek Symblos-Atomic Symbolsapi-3848892Noch keine Bewertungen

- Examples of Applicable Steels For Typical ProductsDokument1 SeiteExamples of Applicable Steels For Typical Productsapi-3848892Noch keine Bewertungen

- Calculation of Beam DeflectionDokument1 SeiteCalculation of Beam Deflectionapi-3848892100% (2)

- Calculation of Beam DeflectionDokument1 SeiteCalculation of Beam Deflectionapi-3848892100% (2)

- Conversion Table of HardnessDokument1 SeiteConversion Table of Hardnessapi-3848892100% (2)

- Greek Symblos-Atomic SymbolsDokument1 SeiteGreek Symblos-Atomic Symbolsapi-3848892Noch keine Bewertungen

- Claculation of Area, Center of Gravity and Sectional Secondary MomentDokument1 SeiteClaculation of Area, Center of Gravity and Sectional Secondary Momentapi-3848892Noch keine Bewertungen

- Solidworks Tutorial 07nov06Dokument13 SeitenSolidworks Tutorial 07nov06Robin SanjayaNoch keine Bewertungen

- Prepare For IELTSDokument170 SeitenPrepare For IELTSevilinside_me96% (23)

- Solid Works Drawing and DetailingDokument69 SeitenSolid Works Drawing and Detailingapi-3848892100% (1)

- Mastercam Tutorial Surface ModelingDokument4 SeitenMastercam Tutorial Surface Modelingapi-3848892100% (1)

- Cosmos SWDokument52 SeitenCosmos SWRicardo Vargas GraciaNoch keine Bewertungen

- English TestDokument23 SeitenEnglish Testapi-3848892100% (1)

- Solid Works AssemblyDokument46 SeitenSolid Works Assemblyapi-3848892Noch keine Bewertungen

- PLC Basic Programme BookDokument45 SeitenPLC Basic Programme Bookapi-384889275% (4)

- Sach Hoc Tieng AnhDokument269 SeitenSach Hoc Tieng Anhapi-26623512100% (1)

- Ug Nx3 TutorialDokument235 SeitenUg Nx3 TutorialAJAYKRISHNAA92% (13)

- English Test 2Dokument26 SeitenEnglish Test 2api-3848892Noch keine Bewertungen

- Surface RoughnessDokument1 SeiteSurface Roughnessapi-3848892100% (2)

- Socket Head Cap ScrewsDokument1 SeiteSocket Head Cap Screwsapi-3848892100% (5)

- Surface Roughness by Different Processing MethodsDokument1 SeiteSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- Critical Thinking Skills Success in 20 Minutes A Day - Lauren StarkeyDokument182 SeitenCritical Thinking Skills Success in 20 Minutes A Day - Lauren StarkeyAustin Higgins97% (61)

- SI (System International D Unit's)Dokument1 SeiteSI (System International D Unit's)api-3848892100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- E SN752Dokument3 SeitenE SN752hasan_676489616Noch keine Bewertungen

- Residual Strength A N D Crack Propagation Tests O N C-130 Airplane Center Wings With Service-Imposed Fatigue DamageDokument69 SeitenResidual Strength A N D Crack Propagation Tests O N C-130 Airplane Center Wings With Service-Imposed Fatigue DamagemilindshettiNoch keine Bewertungen

- Process Simulation of Ethanol Production From Biomass Gasification and Syngas Fermentation PDFDokument33 SeitenProcess Simulation of Ethanol Production From Biomass Gasification and Syngas Fermentation PDFramesh pokhrelNoch keine Bewertungen

- Jazan Refinery and Terminal ProjectDokument3 SeitenJazan Refinery and Terminal ProjectkhsaeedNoch keine Bewertungen

- Beam Tutorial 1Dokument23 SeitenBeam Tutorial 1aikalessNoch keine Bewertungen

- Currrent Electricity FinalDokument30 SeitenCurrrent Electricity FinalSaadullah Shahid100% (1)

- Taka Gas Spring CatalogueDokument14 SeitenTaka Gas Spring CatalogueAdem YıldızhanNoch keine Bewertungen

- Sikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarDokument3 SeitenSikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarSulaim Al KautsarNoch keine Bewertungen

- SurtecDokument7 SeitenSurtecbrahymNoch keine Bewertungen

- MacReburBrochure WebDokument16 SeitenMacReburBrochure WebYarSakawatuNoch keine Bewertungen

- KELEN HB 07 eDokument40 SeitenKELEN HB 07 enhblinh100% (2)

- GE Black Light Brochure 1970Dokument16 SeitenGE Black Light Brochure 1970Alan MastersNoch keine Bewertungen

- CAE-ECM System For Electrochemical Technology of Parts and ToolsDokument7 SeitenCAE-ECM System For Electrochemical Technology of Parts and Toolsdavid2404Noch keine Bewertungen

- Mic10 PDFDokument2 SeitenMic10 PDFteperiniNoch keine Bewertungen

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDokument1 Seite4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFabdullah amanullah0% (1)

- Operation of The First HIsmelt Plant in ChinaDokument8 SeitenOperation of The First HIsmelt Plant in ChinaJJNoch keine Bewertungen

- Cardinal Weigh BridgeDokument24 SeitenCardinal Weigh Bridgegriff19884942Noch keine Bewertungen

- 4R70W Ford Transmission Service Manual PDFDokument206 Seiten4R70W Ford Transmission Service Manual PDFFabricio Vilela100% (2)

- Engineering Standards SAEC Waste Disposal LandfillsDokument17 SeitenEngineering Standards SAEC Waste Disposal LandfillsAhmad RazaNoch keine Bewertungen

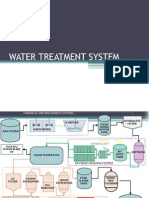

- Water Treatment 3Dokument16 SeitenWater Treatment 3kukukrunchNoch keine Bewertungen

- Chemical & Process Technology - Determine Latent Heat For Multi-Component and Relieving Area Using Rigorous Method in HYSYSDokument6 SeitenChemical & Process Technology - Determine Latent Heat For Multi-Component and Relieving Area Using Rigorous Method in HYSYSAnonymous q95lwCgNoch keine Bewertungen

- Mechatronics Electronic Control Systems in Mechanical and Electrical EngineeringDokument19 SeitenMechatronics Electronic Control Systems in Mechanical and Electrical EngineeringTanNoch keine Bewertungen

- CSA C22 No.131Dokument1 SeiteCSA C22 No.131metin yurtseverNoch keine Bewertungen

- Draka 2Dokument260 SeitenDraka 2Sakinah Cik KinoNoch keine Bewertungen

- Yarde Metals Shapes CatalogDokument493 SeitenYarde Metals Shapes Catalogdncz69Noch keine Bewertungen

- Chemical Kinetics Mcqs Group 1Dokument11 SeitenChemical Kinetics Mcqs Group 1zafarchem_iqbalNoch keine Bewertungen

- Hybrid Geosynthetic Paving Mat For Highway ApplicationsDokument4 SeitenHybrid Geosynthetic Paving Mat For Highway ApplicationsmithileshNoch keine Bewertungen

- HP Transformer OilsDokument2 SeitenHP Transformer OilsNoble Jose KunhiparaNoch keine Bewertungen

- Approved Supplier of IFR For IOCL Solapur Tender.Dokument2 SeitenApproved Supplier of IFR For IOCL Solapur Tender.rohitNoch keine Bewertungen

- Frictional Losses in Circular PipeDokument5 SeitenFrictional Losses in Circular PipeVrushiket PatilNoch keine Bewertungen