Beruflich Dokumente

Kultur Dokumente

Formation of Polythionic Acid in Process Equipments

Hochgeladen von

nishank soniOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Formation of Polythionic Acid in Process Equipments

Hochgeladen von

nishank soniCopyright:

Verfügbare Formate

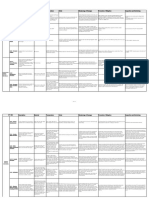

Polythionic acid SCC

Susceptible materials: Environmental conditions: Description

Austenitic stainless steels, e.g. Type 300-series Steel in sensitised and stressed condition; sulphides

Polythionic acids (i.e. H2SxO6 where x=2-5, e.g. sulphurous acid), are formed by the decomposition of sulphides in the presence of oxygen and water, e.g. shutdown equipment that carry H 2S/H2 at elevated temperature. A requirement for Polythionic Acid Stress Corrosion Cracking (PASCC) is that a stainless steel is in a sensitised and stressed condition (either residual or applied). Sensitisation describes a steel that has formed chromium carbides along the grain boundaries, producing adjacent chromium-depleted regions that are susceptible to corrosion. This occurs after long-term service within the 370 - 815C temperature range, dependent on the grade and prior thermomechanical history. In itself, sensitisation does not affect mechanical properties. Methods of avoidance During shutdowns, displace process fluids with flushing oil followed by a nitrogen purge; Use low carbon, e.g. Type 316L, or stabilised stainless steel grades, e.g. Type 347 with Nb; Alloy 801 for heaters in desulphurization units, Alloy 800 for feed/effluent exchangers; and Solution anneal to dissolve carbides, e.g. 1100 C, followed by a water quench. Further reading NACE RP0170-93: "Protection of austenitic stainless steels and other austenitic alloys from polythionic acid stress corrosion cracking during shutdown of refinery equipment", National Association of Corrosion Engineers, Houston, 1993

Das könnte Ihnen auch gefallen

- 571 SummaryDokument3 Seiten571 SummarySimbu Arasan100% (1)

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkVon EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNoch keine Bewertungen

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicVon EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNoch keine Bewertungen

- Hydrogen Cracking MechanismsDokument1 SeiteHydrogen Cracking MechanismsvenkateaNoch keine Bewertungen

- Prevention of Polythionic Acid Stress Corrosion Cracking of Austenitic Stainless Steel Equipment EG 19-7-1.2Dokument2 SeitenPrevention of Polythionic Acid Stress Corrosion Cracking of Austenitic Stainless Steel Equipment EG 19-7-1.2aminNoch keine Bewertungen

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonVon EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNoch keine Bewertungen

- Heat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingVon EverandHeat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingBewertung: 1 von 5 Sternen1/5 (1)

- AVESTA How To Weld Duplex SteelDokument20 SeitenAVESTA How To Weld Duplex SteelGMacella100% (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonVon EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNoch keine Bewertungen

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksVon EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksNoch keine Bewertungen

- Stress CorrosionDokument13 SeitenStress CorrosionAbhinav GuptaNoch keine Bewertungen

- API 571 Notes ImportantDokument6 SeitenAPI 571 Notes ImportantMalik Ansar Hayat100% (1)

- Material SelectionDokument44 SeitenMaterial SelectionFebbyOktaviaNoch keine Bewertungen

- Hydrogen in Material SelectionDokument4 SeitenHydrogen in Material SelectionAsad Bin Ala Qatari0% (1)

- Tool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforVon EverandTool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforNoch keine Bewertungen

- Corrosion and Materials Selection For Amine ServiceDokument5 SeitenCorrosion and Materials Selection For Amine Servicedj22500100% (1)

- SCC of Ss in NAOHDokument9 SeitenSCC of Ss in NAOHKarna2504Noch keine Bewertungen

- Dga Hic Sohic PDFDokument16 SeitenDga Hic Sohic PDFEur-Ing Nicola GalluzziNoch keine Bewertungen

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelVon EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNoch keine Bewertungen

- Stress Corrosion CrackingDokument2 SeitenStress Corrosion CrackingrenatobellarosaNoch keine Bewertungen

- Damage Mechanisms For API 653Dokument10 SeitenDamage Mechanisms For API 653Saran KumarNoch keine Bewertungen

- Concept of Post Weld Heat Treatment PDFDokument2 SeitenConcept of Post Weld Heat Treatment PDFsridharchebrolu100% (2)

- Prepare by Nasrizal Mohd Rashdi Senior Lecturer Welding & Quality Inspection Universiti Kuala LumpurDokument39 SeitenPrepare by Nasrizal Mohd Rashdi Senior Lecturer Welding & Quality Inspection Universiti Kuala LumpurFaiz IshakNoch keine Bewertungen

- Secondary Steel MakingDokument13 SeitenSecondary Steel Makingsatish_trivedi100% (1)

- Grade 316 316LDokument9 SeitenGrade 316 316LvsajuNoch keine Bewertungen

- Materials Selection For Corrosion PreventionDokument61 SeitenMaterials Selection For Corrosion PreventionJeremy Coleman100% (1)

- Hydrogen in Material SelectionDokument5 SeitenHydrogen in Material SelectionrajaNoch keine Bewertungen

- Polythionic Acid Stress Corrosion CrackingDokument3 SeitenPolythionic Acid Stress Corrosion Crackingvajidqc100% (1)

- Chloride - Stress Corrosion Cracking (CL-SCC) : DescriptionDokument6 SeitenChloride - Stress Corrosion Cracking (CL-SCC) : DescriptionAylaa DuhaimiNoch keine Bewertungen

- Article - Stress Relieving Heat Treatments For Austenitic Stainless SteelsDokument2 SeitenArticle - Stress Relieving Heat Treatments For Austenitic Stainless Steelsabhishek198327Noch keine Bewertungen

- API Self NotesDokument13 SeitenAPI Self NotesOwais AlamNoch keine Bewertungen

- Welding of Austenitic Stainless Steel - Part 2 - TWIDokument6 SeitenWelding of Austenitic Stainless Steel - Part 2 - TWISumantaNoch keine Bewertungen

- Article - Selection of Stainless Steels For Handling Sulphuric Acid (H2SO4)Dokument4 SeitenArticle - Selection of Stainless Steels For Handling Sulphuric Acid (H2SO4)gbuckley9630Noch keine Bewertungen

- Carbon Steels (1 000, 11 00, 1 200, and 1500 Series)Dokument18 SeitenCarbon Steels (1 000, 11 00, 1 200, and 1500 Series)Kerem Cengiz KılıçNoch keine Bewertungen

- Polythionic Acid Stress Corrosion CrackingDokument4 SeitenPolythionic Acid Stress Corrosion CrackingpmkarNoch keine Bewertungen

- Polythionic Acid Stress Corrosion CrackingDokument2 SeitenPolythionic Acid Stress Corrosion CrackingVajid MadathilNoch keine Bewertungen

- Pickling and PassivationDokument2 SeitenPickling and PassivationKalpesh JainNoch keine Bewertungen

- Stress RelievingDokument1 SeiteStress RelievingManjadi MaverickNoch keine Bewertungen

- Amines PDFDokument1 SeiteAmines PDF최승원Noch keine Bewertungen

- High Temperature Stainless Steels - Pubs - 91981742Dokument16 SeitenHigh Temperature Stainless Steels - Pubs - 91981742OttoKumpuNoch keine Bewertungen

- Stainless Steels For H2SO4Dokument4 SeitenStainless Steels For H2SO4Marshel LeninNoch keine Bewertungen

- Materials and Design: Steven A. Bradley, Mark W. Mucek, Hiroyuki Anada, Takahiro OsukiDokument8 SeitenMaterials and Design: Steven A. Bradley, Mark W. Mucek, Hiroyuki Anada, Takahiro Osukiqueno1Noch keine Bewertungen

- CPHFD 011Dokument7 SeitenCPHFD 011Napoleon DasNoch keine Bewertungen

- Stainless SteelDokument8 SeitenStainless SteelEdgarDavidDiazCampos100% (1)

- Soldadura SawDokument18 SeitenSoldadura SawanselmoNoch keine Bewertungen

- Stainless SteelDokument6 SeitenStainless SteelNiko NištićNoch keine Bewertungen

- Research Notes On Sulfide Stress CrackingDokument5 SeitenResearch Notes On Sulfide Stress CrackingaladinsaneNoch keine Bewertungen

- 7steel and Heat TreatmentDokument19 Seiten7steel and Heat TreatmentManoj BallaNoch keine Bewertungen

- 10208-15101387124325secondary Steel Making OverviewDokument13 Seiten10208-15101387124325secondary Steel Making OverviewOmar TahaNoch keine Bewertungen

- Polythionic Acid Stress Corrosion CrackingDokument9 SeitenPolythionic Acid Stress Corrosion CrackingMedina EldesNoch keine Bewertungen

- Steel Properties (Notes)Dokument27 SeitenSteel Properties (Notes)ellesor macalamNoch keine Bewertungen

- Heat Treatment of Welded JointsDokument4 SeitenHeat Treatment of Welded JointskingstonNoch keine Bewertungen

- Sensitization: Definition - What Does Sensitization Mean?Dokument2 SeitenSensitization: Definition - What Does Sensitization Mean?Kanzul FadhilNoch keine Bewertungen

- SG Materials Selection SS 316Dokument4 SeitenSG Materials Selection SS 316rkukgNoch keine Bewertungen

- X-Cor Boiler Plates and Pressure Vessel Steels en PDFDokument8 SeitenX-Cor Boiler Plates and Pressure Vessel Steels en PDFIgor GrujićNoch keine Bewertungen

- RA151 28pgDokument31 SeitenRA151 28pgpipedown456Noch keine Bewertungen

- Stainless SteelsDokument16 SeitenStainless SteelsGnobelNoch keine Bewertungen

- Acid Pickling of Carbon SteelDokument10 SeitenAcid Pickling of Carbon SteelAnoop KizhakathNoch keine Bewertungen