Beruflich Dokumente

Kultur Dokumente

NC CNC DNC FMS Theory

Hochgeladen von

kamleshyadavmoneyOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

NC CNC DNC FMS Theory

Hochgeladen von

kamleshyadavmoneyCopyright:

Verfügbare Formate

10/1/2011

NC,CNC&Robotics

WhatisNC/CNC?

NC is an acronym for Numerical Control and CNC is an acronym for Computer Numerical Control.

BySKMondal

WhatisthedifferencebetweenNCandCNC?

The difference between NC and CNC is one of age and capability. The earliest NC machines performed limited functions and movements controlled by punched tape or punch cards. cards As the technology evolved, the machines were equiped with increasingly powerful microprocessors (computers) with the addition of these computers, NC machines become CNC machines. CNC machines have far more capability than their predecessor. contd..

WhatisthedifferencebetweenNCandCNC?

Some of the enhancements that came along with CNC include: Canned Cycles, Sub Programming, Cutter Compensation, Work coordinates, Coordinate system rotation, automatic corner rounding, chamfering, and B spline interpolation.

WheredidCNCgetstarted?

1940 Jhon Parson developed first machine able to drill holes at specific coordinates programmed on punch cards. 1951 MIT developed servomechanism 1952 MIT developed first NC machines for milling. 1970 First CNC machines came into picture Nowadays modified 1970s machines are used.

IsitnecessarytohaveaCAD/CAM systemtoprogramaCNCmachine?

No, yes, may be. It all depends on the kind of work you are doing, your customers requirements and your staffs capability. CAM system give the programmer a tool for creating set up sheets and process drawings.

10/1/2011

DoallmachinesspeakthesameCNC language

No, while there is fairly standard set of G and M codes, there is some variation in their application. For example a G0 or G00 command is universally regarded as the command for rapid travel. Some older machines do not have a G00 command. On these machines, rapid travel is commanded by using the F (feed) word address.

WhatisaConversationalControl

CNC machine tool builders offer an option what is known as the conversational control. This control lets the operator/programmer use simple descriptive

language to program the part. The control then displayed a graphical representation of the instructions so the operator/programmer can verify the tool path.

AreCNCmachinesfasterthan conventionalmachines?

Yes, No, Sometimes. When it comes to making a single, simple part it is hard to beat a conventional mill or lathe. lathe CNC machines move faster in rapid travel than conventional machines.

AreCNCmachinesmoreaccurate thanconventionalmachines?

Yes, they can be. But like anything else it depends on who i running th machine, h h is i the hi how well th machines h ll the hi has been maintained, quality of setup and so on.

NC/CNCMachinesAdvantages

High Repeatability and Precision e.g. Aircraft parts Volume of production is very high Complex contours/surfaces need to be machined. E.g. Turbines Flexibility in job change, automatic tool settings, less scrap More safe, higher productivity, better quality Less paper work, faster prototype production, reduction in lead times

NC/CNCMachinesDisadvantages

Costlysetup,skilledoperators Computers,programmingknowledgerequired Maintenanceisdifficult

10/1/2011

NC/CNC/DNC

Direct Numerical Control is a system that uses a central computer to control several machines at the same time Distributed Numerical Control (DNC): the central computer downloads complete programs to the CNC t d l d l t t th machines, which can be workstations or PCs, and can get the information for the machine operations. The speed of the system is increased, large files can be handled and the number of machine tools used is expanded.

13

Directnumericalcontrol

14

DNC

BasicLengthUnit(BLU)

In NC machine, the displacement length per one pulse output from machine is defined as a Basic Length Unit (BLU). In the CNC computer each bit (binary digit) represents 1 BLU. BLU Bit = BLU Example: If one pulse makes a servo motor rotate by one degree and the servo motor moves the table by 0.0001 mm, one BLU will be 0.0001 mm. The lead of a ball screw is related to the displacement unit of the machine tool table.

15

StepperMotor

The stepper motor is special type of synchronous motor which is designed to rotate through a specific angle (Called step) for each electrical pulse received from the control unit.

10/1/2011

ControlSystemspossibleinCNCMachine

Point to point mode:

Pointtopointstraightlinemode

Coordinatesystem

All the machine tool use Cartesian Coordinate system. The first axis to be identified is the Z axis, This is followed by X and Y axes respectively.

Righthandcoordinatesystems

10/1/2011

5axesCNCverticalaxismachiningcentreconfiguration

Absolute and Incremental Coordinate System

Thefollowingarethestepstobefollowed whiledevelopingtheCNCpartprograms.

Processplanning Axesselection Toolselection Cuttingprocessparametersplanning Jobandtoolsetupplanning Machiningpathplanning Partprogramwriting Partprogramproving

Absolute Coordinate System

Incremental Coordinate System

10/1/2011

BasicCNCPrinciples

For a CNC machine control unit (MCU) decides cutting speed, feed, depth of cut, tool selection , coolant on off and tool paths. The MCU issues commands in form of numeric data to motors that position slides and tool accordingly.

PartProgramming

FANUCCONTROLL SIEMENSCONTROLL

CNCprogramming

Importantthingstoknow:

CoordinateSystem Units,incrementalorabsolutepositioning Coordinates:X,Y,Z,RX,RY,RZ Feedrateandspindlespeed CoolantControl:On/Off,Flood,Mist ToolControl:Toolandtoolparameters

ProgrammingKeyLetters

O Programnumber(Usedforprogramidentification) N Sequencenumber(Usedforlineidentification) G Preparatoryfunction X Xaxisdesignation Y Yaxisdesignation g Z Zaxisdesignation R Radiusdesignation F Feedratedesignation S Spindlespeeddesignation H Toollengthoffsetdesignation D Toolradiusoffsetdesignation T ToolDesignation M Miscellaneousfunction

ExplanationofcommonlyusedGcodes

G00 Preparatory code to control final position

of the tool and not concerned with the path that is followed in arriving at the final destination. G01 Tool is required to move in a straight line connecting current position and final position. Used for tool movement without any machining point to point control. (linear interpolation) G02 Tool path followed is along an arc specified by I, J and K codes.( circular interpolation)

10/1/2011

CNCProgrammingBasics

Each letter address relates to a specific machine function. G and M letter addresses are two of the most common. A G letter specifies certain machine preparations such as inch or metric modes, or absolutes versus incremental modes. A M letter specifies miscellaneous machine functions and work like on/off switches for coolant flow, tool changing, or spindle rotation. Other letter addresses are used to direct a wide variety of other machine commands.

TableofImportantGcodes

G00RapidTransverse G01LinearInterpolation G02CircularInterpolation,CW G03CircularInterpolation,CCW G17XYPlane,G18XZPlane,G19YZPlane G XYPl G XZPl G YZPl G20/G70Inchunits G21/G71MetricUnits G40Cuttercompensationcancel G41Cuttercompensationleft G42Cuttercompensationright

TableofImportantGcodes

G43Toollengthcompensation(plus) G44Toollengthcompensation(minus) G49Toollengthcompensationcancel G80Cancelcannedcycles G81Drillingcycle G82Counterboringcycle G83Deepholedrillingcycle G90Absolutepositioning G91Incrementalpositioning

Rapidtraverse:G00

G00:

tomakethemachinemoveatmaximumspeed. Itisusedforpositioningmotion. G90G00X20.0Y10.0 G90G00X20 0Y10 0

G90: absolute coordinate s

Start End

(20,10) (10,10)

(0,0)

Linearinterpolation:G01

G01:

linearinterpolationatfeedspeed. G91G0lX200.0Y100.0F200.0

G91: incremental coordinates Y 100.0 End

Circularinterpolation:G02,G03

G02,G03: Forcircularinterpolation,thetooldestinationandthecircle centerareprogrammedinoneblock G02isclockwiseinterpolation,G03iscounterclockwise interpolation

G 02 R G17 X __ Y __ G 03 I __ G 02 R G18 X __ Z __ G 03 I __ G 02 R G19 Y __ Z __ G 03 J __ F __; J __ F __; K __ F __; K __

Start

200.0

End point

Circlecenter,radius

10/1/2011

Circularinterpolation:G02,G03

Y X R=-50mm End

Circularinterpolation:G02,G03

Y End

SpecifyCenterwithI,J,K

I,J,Karetheincremental distancefromthestartof thearc; Start Viewingthestartofarcas theorigin,I,J,Khave positiveornegativesigns.

SpecifyRwith signbeforeit:

180 +R >180 R

Start

R=50mm

Center i G91G02X60.0Y20.0R50.0 F300.0 G91G02X60.0Y20.0R50.0 F300.0

Circularinterpolation:G02,G03

N0010G92X200.0Y40.0Z0; N0020G90G03X140.0Y100.0I60.0F300 N0030G02X120.0Y60.0I 50.0

Or G92: Todefineworking coordinate

Circularinterpolation:G02,G03

AnnotationforCircularInterpolation

I0.0,J0.0,andK0.0canbeomitted. IfX,Y,Zareallomittedintheprogram,thatmeans startandendofarcaresamepoints. startandendofarcaresamepoints

N0020G02I20.0(afullcircle)

N0010G92X200.0Y40.0Z0 N0010G92X200 0Y40 0Z0 N0020G90G03X140.0Y100.0R60.0F300 N0030G02X120.0Y60.0R50.0

G90: absolute coordinates

Y 100 60 40 O

IfI,J,K,andRallappearsincircularinterpolation instruction,RisvalidandI,J,andKareinvalid

R50 R60 X

90 120 140

200

ToolCompensation

ToolRadiusCompensation

LefthandG41 RighthandG42 CanceltoolradiuscompensationG40 C l l di i G

ToolRadiusCompensation

Toolradiuscompensationsmakeitpossibleto programdirectlyfromthedrawing,andthuseliminate thetooloffsetcalculation

G41(G42)H

H:theradiusoftooltocompensateissavedinamemoryunitthat H th di ft lt t i di itth t isnamedH G41/G42isdirectlyrelatedwithdirectionoftoolmovementand whichsideofpartiscut.

ToolHeightCompensation

PositiveG43 NegativeG44 CanceltoolheightcompensationG49

10/1/2011

CancelToolCompensation:G40

Notethedifferencebetweentwoways

N0060G40G01 X2.000Y1.700M02 N0060G01 X2.000Y1.700 7 4 N0070G40 M02

ToolHeightCompensation

G43(G44)H

H:specifiedmemoryunitusedtosaveheight compensationoftool. Positivecompensation(G43):

realposition=specifiedposition+valuesavedinH

Negativecompensation(G44):

realposition=specifiedposition valuesavedinH

rampoffblock effectivetotheendpoint

ToolHeightCompensation

Example:

N0010G91G00X12.0Y80.0 N0020G44Z32.0H02 Ifweput0.5mmintoH02, realposition=32.0 0.5=32.5

G91: incremental coordinates

TableofImportantMcodes

M00Programstop M01Optionalprogramstop M02Programend M03Spindleonclockwise M04Spindleoncounterclockwise M05Spindlestop M06Toolchange M08Coolanton M09Coolantoff M10Clampson M11Clampsoff M30Programstop,resettostart

Canceltoolheightcompensation:G49

Rulesforprogramming

Block Format N135 G01 X1.0 Y1.0 Z0.125 F5 Sample Block Restrictions on CNC blocks Each may contain only one tool move Each may contain any number of non-tool move G-codes Each may contain only one feed rate Each may contain only one specified tool or spindle speed The block numbers should be sequential Both the program start flag and the program number must be independent of all other commands (on separate lines) The data within a block should follow the sequence shown in the above sample block

ExampleofCNC Programming

WhatMustBeDoneToDrillAHoleOnACNC VerticalMillingMachine g

10/1/2011

ToolHome

Top View

Top View

2.)ZAxisRapidMove JustAboveHole 3.)TurnOnCoolant 4.)TurnOnSpindle ) O i dl

1.)X&YRapidToHolePosition

Front View

Front View

.100

Top View

5 5.)ZAxisFeedMoveto DrillHole

Top View

6.)RapidZAxisMove OutOfHole

Front View

Front View

HeresTheCNCProgram!

ToolAtHome

Top View

7.)TurnOffSpindle 8.)TurnOffCoolant 9.)X&YAxisRapid MoveHome

Top View

Front View

Front View

O0001 N005G54G90S600M03 N010G00X1.0Y1.0 N015G43H01Z.1M08 N020G01Z.75F3.5 N025G00Z.1M09 N030G91G28X0Y0Z0 N035M30

10

10/1/2011

ToolAtHome

ToolAtHome

Top View

O0001

O0001 NumberAssignedtothisprogram

Top View

O0001 N005G54G90S600M03

N005 G54 G90 S600 M03 SequenceNumber FixtureOffset AbsoluteProgrammingMode SpindleSpeedsetto600RPM SpindleoninaClockwiseDirection

Front View

Front View

Top View

O0001 N005G54G90S600M03 N010G00X1.0Y1.0

G00 G X1.0 Y1.0 RapidMotion R idM i XCoordinate1.0in.fromZero YCoordinate1.0in.fromZero

Top View

O0001 N005G54G90S600M03 N010G00X1.0Y1.0 N015G43H01Z.1M08

G43 H01 Z.1 M08 ToolLengthCompensation SpecifiesToollengthcompensation ZCoordinate.1in.fromZero FloodCoolantOn

Front View

Front View

Top View

O0001 N005G54G90S600M03 N010G00X1.0Y1.0 N015G43H01Z.1M08 N020G01Z.75F200

G01 Z.75 F200 StraightLineCuttingMotion ZCoordinate.75in.fromZero FeedRatesetto200mm/min.

Top View

O0001 N005G54G90S600M03 N010G00X1.0Y1.0 N015G43H01Z.1M08 N020G01Z.75F3.5 N025G00Z.1M09

G00 Z.1 M09 RapidMotion ZCoordinate.1in.fromZero CoolantOff

Front View

Front View

11

10/1/2011

Top View

O0001 N005G54G90S600M03 N010G00X1.0Y1.0 N015G43H01Z.1M08 N020G01Z.75F3.5 75 3 5 N025G00Z.1M09 N030G91G28X0Y0Z0

G91 IncrementalProgrammingMode G28 ZeroReturnCommand X0,Y0,Z0 X,Y,&ZCoordinatesatZero

Top View

Front View

Front View

O0001 N005G54G90S600M03 N010G00X1.0Y1.0 N015G43H01Z.1M08 N020G01Z .75F3.5 N020G01Z.75F3.5 N025G00Z.1M09 N030G91G28X0Y0Z0 N035M30

M30 EndofProgram

APTLanguage

APT (Automatically Programmed Tools) TheAPTlanguageconsistsofmanydifferenttypesof statementsmadeupofthefollowingvalidletters,numerals andpunctuationmarks. Letters: ABCDEFGHIJKLMNOPQRSTWWXYZ Numerals: 0123456789 / Aslashdividesastatementintotwosections.eg., GO/PAST, , Acommaisusedasaseparatorbetweentheelementsin astatementgenerallytotherightoftheslash. = Anequalsisusedforassigninganentitytoasymbolic name,e.g.,CI=CIRCLE/25,50,30.

Words

The words to be used in the statements are built up from one to six letters or numerals with the first one being a letter. No special character is allowed in the words.

ThecompleteAPTpartprogramconsistsof thefollowingfourtypesofstatements

Geometry Motion Postprocessor Compilationcontrol

12

10/1/2011

APTLanguage

Additionalstatements:

MACHIN/DRILL, 2 COOLNT/ p Forexample: COOLNT/MIST COOLNT/FLOOD COOLNT/OF FEDRAT/ SPINDL/ Forexample: SPINDL/ON SPINDL/1250, CCLW TOOLNO/ TURRET/ END

APTLanguage

OthercapabilitiesofAPT,themacrofacility,withusevariableargumentasina FORTRANsubroutine,forexample:

P0 = POINT/0.0, 0.3, 0.1 FROM/P0 CALL/DRILL, X=1.0, Y=1.0, Z=0.1, DEPTH=0.7 CALL/DRILL, X=2.0, Y=1.0, Z=0.1, DEPTH=0.7 GOTO/P0

whenthedefinitionofthemacroDRILLis:

DRILL = MACRO/X, Y, Z, DEPTH GOTO/X,Y,Z GODLTA/0,0, -DEPTH GODLTA/0,0, DEPTH TARMAC

73

74

OtherPartProgramming Languages

Point (POINT)

PTA = POINT/ 3,4,5

y (3, 4, 5) PTA z

ADAPT (ADaptationAPT)wasthefirstattempttoadaptAPT programmingsystemforsmallercomputers AUTOSPOT (AUTOmaticSytemforPOsitioningTools)was developedbyIBMandfirstintroducedin1962 EXAPT (EXtendedsubsetofAPT)wasdevelopedjointlyin Germaninabout1964byseveraluniversitiestoadaptAPTfor Europeanuse.ItiscompatiblewithAPTandthuscanusethe E I i ibl i hAPT d h h sameprocessorasAPT COMPACT wasdevelopedbyManufacturingDataSystems,Inc. (MDSI) SPLIT (SundstrandProcessingLanguageInternallyTranslated) wasdevelopedbySundstrandCorporation,intendedforitsown machinetools MAPT (MicroAPT)isasubsetofAPT,toberunonthe microcomputers

75

Point (POINT)

PTB = POINT/ INTOF, LIN1, LIN2

Point (POINT)

PTD = POINT/ YSMALL, INTOF, LIN3, C1 PTD = POINT/ XSMALL, INTOF, LIN3, C1 PTC = POINT/ YLARGE, INTOF, LIN3, C1 PTC = POINT/ XLARGE, INTOF, LIN3, C1 y

PTC

LIN2

LIN3 PTB LIN1 PTD C1

13

10/1/2011

Point (POINT)

PTE = POINT/ YLARGE, INTOF, C1, C2 PTE = POINT/ XLARGE, INTOF, C1, C2 PTF = POINT/ YSMALL, INTOF, C1, C2 PTF = POINT/ XSMALL, INTOF, C1, C2

Point (POINT)

PT7 = POINT/ CENTER, C6

y

y PTE C6

C1

PT7

PTF

C2

Line (LINE)

LIN1 = LINE/ P1, P2

y

Line (LINE)

LIN4 = LINE/ PT6, 15, -30, 3

y PT6 P2

P1 L4 LIN1 x x (15,30,3)

Line (LINE)

L12 = LINE/ PT4, ATANGL, 20, XAXIS L14 = LINE/ PT1, ATANGL, 40 L15 = LINE/ 32, -3, 2, ATANGL, -15, XAXIS L16 = LINE/ PT3, ATANGL, 40, YAXIS

y PT3 40 L16 PT1 PT4 L14 L L12

Line (LINE)

LIN = LINE/ POINT, ATANGL, ANGLE (in degrees), LINE

y LINE2

P1

30

LINE1

LINE2=LINE/P1,ATANGL,30,LINE1

40 L15 20 15 (32,3,2) x

x

14

10/1/2011

Line (LINE)

LIN = LINE/ SLOPE, SLOPE VALUE, INTERC, MODIFIER, d where the slope value is y/x. The modifier options are [XAXIS, YAXIS], and d is the corresponding intercept value on the selected axis (i.e., modifier).

y

Line (LINE)

LIN = LINE/ ATANGL, DEGREES, INTERC, MODIFIER, d The modifier options are [XAXIS, YAXIS], and d is the corresponding intercept value on the selected axis (i.e., modifier).

LINE1

LINE1

LINE1=LINE/SLOPE,1,INTERC,xaxis,6

=30 x

LINE1=LINE/ATANGL,30,INTERC,d

x

(6,0)PointofXIntercept

Line (LINE)

The LEFT & RIGHT modifier indicates whether the line is at the left or right tangent point, depending on how one looks at the circle from the point. L1 = LINE/ PT51, LEFT, TANTO, C11

Line (LINE)

L2 = LINE/ PT51, RIGHT, TANTO, C11 L3 = LINE/ PT40, RIGHT, TANTO, C11 L4 = LINE/ PT40, LEFT, TANTO, C11

L3 Right

L1 L1 C11 PT51 PT51 Right L2 Left Left L4

PT40

Line (LINE)

LN3 = LINE/ PNT6, PARLEL, LN15 LN4 = LINE/ PNT5, PERPTO, LN13

y PNT6 LN3 LN4 PNT5

Plane (PLANE)

LN5 = LINE/ INTOF, PLAN1, PLAN2

LN5

LN15

LN13

PLAN1 PLAN2

15

10/1/2011

Plane (PLANE)

PLAN10 = PLANE/ PT6, PT12, PT15

Plane (PLANE)

PLAN14 = PLANE/ PT4, PARLEL, PLAN10 PLAN14 = PLANE/ PARLEL, PLAN10, YSMALL, 3.0

PLAN10 PT15 PT15 PLAN10

PT6 y

PT12 3.0 y PT6 PT12 3.0

PT4 z PLAN14 z

PT4

PLAN14 x

Circle (CIRCLE)

Circle (CIRCLE)

C3 = CIRCLE/ CENTER, PT6, TANTO, LN4 C7 = CIRCLE/ CENTER, PT8, PT5

y C1 4.3 PT3 (3,6,5) LN4 PT5 y

C1 = CIRCLE/ 3, 6, 5, 4.3 C1 = CIRCLE/ CENTER, PT3, RADIUS, 4.3

y

PT6 C3

PT8 C7

The Machining Plan:

Contouring: Part surface: the surface on which the end of the tool is riding. Drive surface: the surface against which the edge of the tool rides. Check surface: a surface at which the current tool motion is to stop.

The Machining Plan

Drivesurface

y

Checksurface

cutter

x

Directionof cuttermotion

Partsurface

16

10/1/2011

The Machining Plan

The Machining Plan

Motion commands:

CS

CS

CS

GOLFT/ GORGT/ GOUP/

: Move left along the drive surface : Move right along the drive surface : Move up along the drive surface : Move forward from a tangent position

DS

DS

DS

GODOWN/ : Move down along the drive surface GOFWD/ GOBACK/ : Move backward from a tangent position

TO

ON

PAST

Machining Specifications

Postprocessor commands for a particular machine tool are: MACHIN/ : used to specify the machine tool and call the postprocessor for that tool: , MACHIN/ DRILL, 3 COOLNT/ : allows the coolant fluid to be turned on or off: COOLNT/ MIST COOLNT/ FLOOD COOLNT/ OFF

Machining Specifications

FEDRAT/ : specifies the feed rate for moving the tool along the part surface in inches per minute: FEDRAT/ 4.5 SPINDL/ : gives the spindle rotation speed in revolutions per minute: SPINDL/ 850 TURRET/ : can be used to call a specific tool from an automatic tool changer: TURRET/ 11

Machining Specifications

TOLERANCE SETTING: Nonlinear motion is accomplished in straight-line segments, and INTOL/ and OUTTOL/ statements dictate the number of straight-line segments to be generated. INTOL/ 0.0015 OUTTOL/ 0.001

Machining Specifications

PARTNO: identifies the part program and is inserted at the start of the program. CLPRINT: indicates that a cutter location printout is desired. CUTTER: specifies a cutter diameter for offset (rough versus finish p ( g cutting). If a milling cutter is 0.5 in. in diameter and we have CUTTER/ 0.6 then the tool will be offset from the finish cut by 0.05 in.

17

10/1/2011

Machining Specifications

FINI: specifies the end of the program.

APT Program

MACHIN/ MILL P0 = POINT/ 0, 0, 3 P1 = POINT/ 1, 0 L1 = LINE/ P1, SLOPE, 0 L2 = LINE/ P1, SLOPE, 90 L3 = LINE/ PARLEL, L1, YLARGE, 2 L4 = LINE/ (POINT/ 4, 2), SLOPE, 1, L3 L5 = LINE/ (POINT/ 6, 4), ATANGL, 270, L4 10, 0), PEPTO, L6 = LINE/ (POINT/ 10 0) PEPTO L3 P2 = POINT/ INTOF, L3, L4 P3 = POINT/ INTOF, L4, L5 P4 = POINT/ INTOF, L5, L3 PL = PLANE/ P1, P2, P3 CUTTER/ 60 TOLER/ 0.1 SPINDL/ 200 COOLNT/ ON FEDRAT/ 20 P0 L2 P1 L1 L3 L4 P2 P3 L5 P4 L3 L6

APT Program

MACHIN/ MILL P0 = POINT/ 0, 0, 3 P1 = POINT/ 1, 0 L1 = LINE/ P1, SLOPE, 0 L2 = LINE/ P1, SLOPE, 90 L3 = LINE/ PARLEL, L1, YLARGE, 2 L4 = LINE/ (POINT/ 4, 2), SLOPE, 1, L3 L5 = LINE/ (POINT/ 6, 4), ATANGL, 270, L4 L6 = LINE/ (POINT/ 10, 0), PEPTO, L3 10 0) PEPTO P2 = POINT/ INTOF, L3, L4 P3 = POINT/ INTOF, L4, L5 P4 = POINT/ INTOF, L5, L3 PL = PLANE/ P1, P2, P3 CUTTER/ 60 TOLER/ 0.1 SPINDL/ 200 COOLNT/ ON FEDRAT/ 20 P0 L6 L1 L5 L4 L3 L2

APT Program

FROM/ P0 GOTO/ L1, TO, PL, TO, L2 GOFWD/ P1, PAST, L3 GORGT/ L3, TO, P2 GOLFT/ P2, TO, P3 GORGT/ P3, TO, P4 GORGT/ P4, PAST, L6 GORGT / L6, PAST, L1 GORGT / L1, TO, P1 COOLNT/ OFF END FINI P0 L2 P1 L1 L3 L4 P2 P3 L5 P4 L3 L6

APTLanguage Example:

APTLanguage Answer:

FROM/SP GO/TO, L1, TO, PS, ON, L6 GORGT/L1, PAST, L2 GORGT/L2, TANTO, C1 GOFWD/C1, TANTO, L3 GOFWD/L3, PAST, L4 GOLFT/L4, PAST, L5 GOLFT/L5, PAST, L6 GOLFT/L6, PAST, L1 GOTO/SP

107 108

18

10/1/2011

APTLanguage Example1:

APTLanguage Answer:

P0 = POINT/0.0, 3.0, 0.1 P1 = POINT/1.0, 1.0, 0.1 P2 = POINT/2.0, 1.0, 0.1 FROM/P0 GOTO/P1 GODLTA/0, 0, -0.7 GODLTA/0, 0, 0.7 GOTO/P2 GODLTA/0, 0, -0.7 GODLTA/0, 0, 0.7 GOTO/P0

109 110

APTLanguage

OtherMotionstatements:

GO/{TO}, Drive surface, {TO} Part surface, {TO}, Check surface Or GO/{TO}, Drive surface, {TO} Part surface, {TANTO}, Check surface AndthesamewithPASTorONinsteadofTO GOLFT/ GORGT/ GOUP/ GODOWN/ GOFWD/ GOBACK/ Forexample: GO/TO, L1, TO, PS, TANTO, C1 GO/PAST, L1, TO, PS, TANTO, C1

111

APTLanguage Example2:

112

APTLanguage Answer:

FROM/SP GO/TO, L1, TO, PS, ON, L4 GORGT/L1, PAST, L2 GOLFT/L2, PAST, L3 GOLFT/L2 PAST GOLFT/L3, PAST, C1 GOLFT/C1, PAST, L3 GOLFT/L3, PAST, L4 GOLFT/L4, PAST, L1 GOTO/SP

113

19

10/1/2011

20

10/1/2011

21

Das könnte Ihnen auch gefallen

- Imindmap 11Dokument3 SeitenImindmap 11ahmustNoch keine Bewertungen

- Heidenhain FK-Programming TNC 530iDokument83 SeitenHeidenhain FK-Programming TNC 530itonybullough100% (1)

- Log4j2 Users Guide PDFDokument212 SeitenLog4j2 Users Guide PDFKavyaNoch keine Bewertungen

- 13 Internal Audit Procedure Integrated Preview enDokument3 Seiten13 Internal Audit Procedure Integrated Preview enBogdan CorneaNoch keine Bewertungen

- DMG-iTNC530 MillProgManual (533 190-23) PDFDokument789 SeitenDMG-iTNC530 MillProgManual (533 190-23) PDFMACKAY9999Noch keine Bewertungen

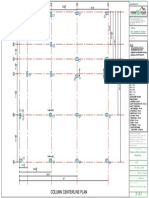

- 1 Column Centerline PlanDokument1 Seite1 Column Centerline PlankamleshyadavmoneyNoch keine Bewertungen

- Network ModelsDokument32 SeitenNetwork ModelsWesal RefatNoch keine Bewertungen

- CNC - Machines PresentationDokument31 SeitenCNC - Machines PresentationSascha SchranzNoch keine Bewertungen

- CNC Technology: Amasidda R ChinagundiDokument27 SeitenCNC Technology: Amasidda R Chinagundiabhijit biswasNoch keine Bewertungen

- The Use of Variables, Macros and Subroutines and Compatibility With FANUC Parametric Programming ......................... 3Dokument10 SeitenThe Use of Variables, Macros and Subroutines and Compatibility With FANUC Parametric Programming ......................... 3Jérôme GRANGENoch keine Bewertungen

- Programming MillDokument81 SeitenProgramming MillEddy ZalieNoch keine Bewertungen

- CNC Basic & Prog.Dokument89 SeitenCNC Basic & Prog.Christine BrownNoch keine Bewertungen

- (Lecture Notes in Computer Science 4488) JeongHee Cha, GyeYoung Kim, HyungIl Choi (auth.), Yong Shi, Geert Dick van Albada, Jack Dongarra, Peter M. A. Sloot (eds.)-Computational Science – ICCS 2007_ 7.pdfDokument1.284 Seiten(Lecture Notes in Computer Science 4488) JeongHee Cha, GyeYoung Kim, HyungIl Choi (auth.), Yong Shi, Geert Dick van Albada, Jack Dongarra, Peter M. A. Sloot (eds.)-Computational Science – ICCS 2007_ 7.pdfGaboGagNoch keine Bewertungen

- Ch-11 NC CNC DNC FMS Automation and RoboticsDokument143 SeitenCh-11 NC CNC DNC FMS Automation and RoboticsshafiqNoch keine Bewertungen

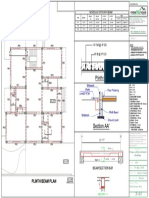

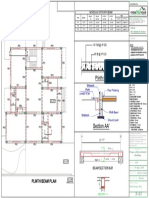

- 6 Plinth Beam PlanDokument1 Seite6 Plinth Beam PlankamleshyadavmoneyNoch keine Bewertungen

- Lecture Cad CamDokument84 SeitenLecture Cad Camismail_69Noch keine Bewertungen

- Post Processor ManualDokument16 SeitenPost Processor ManualVagner Aux CadNoch keine Bewertungen

- Toilet Detail DrawingsDokument1 SeiteToilet Detail Drawingskamleshyadavmoney100% (1)

- S.No1 CCIE-RS-BC-RevDokument230 SeitenS.No1 CCIE-RS-BC-RevMithilesh SharmaNoch keine Bewertungen

- 11 Cad Cam CNC Programming MVVDokument37 Seiten11 Cad Cam CNC Programming MVVbassem smatiNoch keine Bewertungen

- Overview of New and Modified Software Functions: NC Software 34059x-02 To 34059x-11Dokument133 SeitenOverview of New and Modified Software Functions: NC Software 34059x-02 To 34059x-11Langer MexicoNoch keine Bewertungen

- Heidenhain TNC 620 User ManualDokument48 SeitenHeidenhain TNC 620 User ManualBombacı MülayimNoch keine Bewertungen

- Milling Programming ManualDokument207 SeitenMilling Programming ManualAhmad Suffian IsmailNoch keine Bewertungen

- Remote Procedure CallsDokument104 SeitenRemote Procedure CallsxenonyodaNoch keine Bewertungen

- Project Synopsis RakeshDokument4 SeitenProject Synopsis RakeshRakesh Chopra100% (2)

- 6 Plinth Beam Plan PDFDokument1 Seite6 Plinth Beam Plan PDFkamleshyadavmoneyNoch keine Bewertungen

- Computer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentDokument43 SeitenComputer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentSreedhar PugalendhiNoch keine Bewertungen

- CNC Programmer Job Description PostingDokument2 SeitenCNC Programmer Job Description Postingsmith9krNoch keine Bewertungen

- FANUC G Code of LatheDokument2 SeitenFANUC G Code of Latheteam1 M y B100% (1)

- CNC1Dokument91 SeitenCNC1Revana KadurNoch keine Bewertungen

- Comparative Study of CNC Controllers Used in CNC Milling MachineDokument9 SeitenComparative Study of CNC Controllers Used in CNC Milling MachineAJER JOURNALNoch keine Bewertungen

- Introduction of CNC Milling To First-Year Engineering Students With Interests inDokument10 SeitenIntroduction of CNC Milling To First-Year Engineering Students With Interests ineliiiiiiNoch keine Bewertungen

- CNC Codes and LettersDokument48 SeitenCNC Codes and LettersIvo DimitrovNoch keine Bewertungen

- Touch Probe Cycles: Product InformationDokument6 SeitenTouch Probe Cycles: Product Informationsonnv_hcmuteNoch keine Bewertungen

- Mba-058-En 02 1310 Cert Education MedDokument12 SeitenMba-058-En 02 1310 Cert Education Medchristian111Noch keine Bewertungen

- CNC HistoryDokument26 SeitenCNC HistoryBas RamuNoch keine Bewertungen

- CNC Common Terms PDFDokument2 SeitenCNC Common Terms PDFShaival JhaNoch keine Bewertungen

- Jyoti CNCDokument46 SeitenJyoti CNCAmit Vora100% (1)

- Part Programming Manual PDFDokument80 SeitenPart Programming Manual PDFTejas KumarNoch keine Bewertungen

- Program Structure of CNC Machines According To PALDokument16 SeitenProgram Structure of CNC Machines According To PALmanuel_plfNoch keine Bewertungen

- CNC Mill ProgrammingDokument24 SeitenCNC Mill ProgrammingZahidah AmaninaNoch keine Bewertungen

- CNC Milling Sample ProgramDokument16 SeitenCNC Milling Sample ProgramjayyadavvpcNoch keine Bewertungen

- DIN ISO Programming USer Manual 2010Dokument618 SeitenDIN ISO Programming USer Manual 2010Reymondo BundocNoch keine Bewertungen

- iTNC 530: User's Manual Heidenhain Conversational ProgrammingDokument729 SeiteniTNC 530: User's Manual Heidenhain Conversational ProgrammingCarlos Aguilar MontemayorNoch keine Bewertungen

- CNC TurningDokument13 SeitenCNC TurningJAMES JUDYNoch keine Bewertungen

- CNC Lab ManualDokument40 SeitenCNC Lab ManualPavaniNoch keine Bewertungen

- CNCDokument98 SeitenCNCRohit SinghNoch keine Bewertungen

- Unit 7 - CNC - Lecture 1Dokument20 SeitenUnit 7 - CNC - Lecture 1RakshithNoch keine Bewertungen

- Invo MillingDokument8 SeitenInvo MillingOvidiu StoianNoch keine Bewertungen

- MTM Lab PresentationDokument26 SeitenMTM Lab PresentationMuhammad WaseemNoch keine Bewertungen

- VericutDokument20 SeitenVericutStanko Radovanovic0% (1)

- My CNC TurningDokument7 SeitenMy CNC Turningde_stanszaNoch keine Bewertungen

- APT (Programming Language) - Wikipedia, The Free EncyclopediaDokument3 SeitenAPT (Programming Language) - Wikipedia, The Free EncyclopediaAhmed JahaNoch keine Bewertungen

- Introduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1Dokument11 SeitenIntroduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1BabuRaoThellaNoch keine Bewertungen

- Cutting Force of End Cutting Tool Milling MachiningDokument24 SeitenCutting Force of End Cutting Tool Milling MachiningGabryel BogdanNoch keine Bewertungen

- Deep Hole Machining ENGDokument150 SeitenDeep Hole Machining ENGCristian Fuentes100% (1)

- Cam Lab ManualDokument14 SeitenCam Lab Manualelangandhi0% (1)

- CNC RoboticsDokument17 SeitenCNC RoboticsKunal DuttNoch keine Bewertungen

- HMC BasicDokument14 SeitenHMC BasicShashankNoch keine Bewertungen

- Cim Lab Exam Q SDokument17 SeitenCim Lab Exam Q SMohammed ImranNoch keine Bewertungen

- Design and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050Dokument8 SeitenDesign and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050The ash Designe GalaryNoch keine Bewertungen

- Common G Codes and M Codes For CNC Machine ControlsDokument2 SeitenCommon G Codes and M Codes For CNC Machine ControlsVidyut KumarNoch keine Bewertungen

- CNC CodexDokument10 SeitenCNC CodexAmar AshrafNoch keine Bewertungen

- Ch4capp AptDokument28 SeitenCh4capp AptRajesh VermaNoch keine Bewertungen

- CNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inDokument4 SeitenCNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inKhateeb Ul Islam QadriNoch keine Bewertungen

- 01 Introduction To CNC TechnologyDokument46 Seiten01 Introduction To CNC TechnologyNeil RobertsNoch keine Bewertungen

- Feed Rate CalculationsDokument4 SeitenFeed Rate CalculationsJesus Said Mercado VegaNoch keine Bewertungen

- Economics of Metal Cutting OperationsDokument64 SeitenEconomics of Metal Cutting OperationsrohanNoch keine Bewertungen

- Machine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryVon EverandMachine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Ch-11 NC CNC DNC FMS Automation and RoboticsDokument143 SeitenCh-11 NC CNC DNC FMS Automation and RoboticsShafiq AhmadNoch keine Bewertungen

- NC - CNC - DNCDokument99 SeitenNC - CNC - DNCsanjeevani rawatNoch keine Bewertungen

- Sub:Risk Assumption Letter: Insured Vehicles DetailsDokument4 SeitenSub:Risk Assumption Letter: Insured Vehicles DetailskamleshyadavmoneyNoch keine Bewertungen

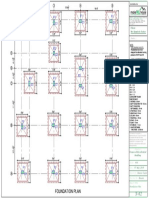

- Foundation ScheduleDokument1 SeiteFoundation SchedulekamleshyadavmoneyNoch keine Bewertungen

- Croma - Campus - Ceaser II Training CurriculumDokument3 SeitenCroma - Campus - Ceaser II Training CurriculumkamleshyadavmoneyNoch keine Bewertungen

- Client Mr. Kamlesh Yadav: NotesDokument1 SeiteClient Mr. Kamlesh Yadav: NoteskamleshyadavmoneyNoch keine Bewertungen

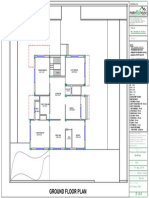

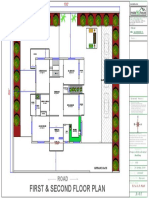

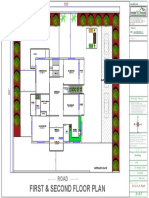

- F.F. & S.F. Kamlesh Yadav Triplex Complete Set-Plan-1Dokument1 SeiteF.F. & S.F. Kamlesh Yadav Triplex Complete Set-Plan-1kamleshyadavmoneyNoch keine Bewertungen

- Terrace Slab DetailsDokument1 SeiteTerrace Slab DetailskamleshyadavmoneyNoch keine Bewertungen

- Column Centerline PlanDokument1 SeiteColumn Centerline PlankamleshyadavmoneyNoch keine Bewertungen

- FF Slab Details PDFDokument1 SeiteFF Slab Details PDFkamleshyadavmoneyNoch keine Bewertungen

- SF Slab DetailsDokument1 SeiteSF Slab DetailskamleshyadavmoneyNoch keine Bewertungen

- FF Column Plan PDFDokument1 SeiteFF Column Plan PDFkamleshyadavmoneyNoch keine Bewertungen

- Staircase DetailsDokument1 SeiteStaircase DetailskamleshyadavmoneyNoch keine Bewertungen

- Plant Design and Management System PDMS - An Overview PDFDokument9 SeitenPlant Design and Management System PDMS - An Overview PDFkamleshyadavmoneyNoch keine Bewertungen

- Client Mr. Kamlesh Yadav: NotesDokument1 SeiteClient Mr. Kamlesh Yadav: NoteskamleshyadavmoneyNoch keine Bewertungen

- Mr. Kamlesh - Yadav-10. Section A-A'Dokument1 SeiteMr. Kamlesh - Yadav-10. Section A-A'kamleshyadavmoneyNoch keine Bewertungen

- Evdt 219 Wdu 1901 PDFDokument1 SeiteEvdt 219 Wdu 1901 PDFkamleshyadavmoneyNoch keine Bewertungen

- GF Slab DetailsDokument1 SeiteGF Slab DetailskamleshyadavmoneyNoch keine Bewertungen

- Tank DesignDokument2 SeitenTank DesignkamleshyadavmoneyNoch keine Bewertungen

- Mr. Kamlesh - Yadav-18. G. Floor Electrical LayoutDokument1 SeiteMr. Kamlesh - Yadav-18. G. Floor Electrical LayoutkamleshyadavmoneyNoch keine Bewertungen

- First & Second Floor Plan: Client Mr. Kamlesh YDokument1 SeiteFirst & Second Floor Plan: Client Mr. Kamlesh YkamleshyadavmoneyNoch keine Bewertungen

- Client Mr. Kamlesh Yadav: NotesDokument1 SeiteClient Mr. Kamlesh Yadav: NoteskamleshyadavmoneyNoch keine Bewertungen

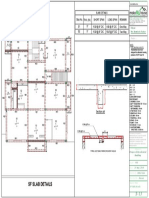

- Company Name/logo: REV Description Drn. Date Chkd. AppdDokument1 SeiteCompany Name/logo: REV Description Drn. Date Chkd. AppdkamleshyadavmoneyNoch keine Bewertungen

- 6 SWR Drainage SystemDokument4 Seiten6 SWR Drainage SystemkamleshyadavmoneyNoch keine Bewertungen

- S.N. Tag Number Instrument Type Service LocationDokument6 SeitenS.N. Tag Number Instrument Type Service LocationkamleshyadavmoneyNoch keine Bewertungen

- Gr.A 1 Flat Bar 25 X 3 THK. X 470m LG. IS-2062 Gr. B GR.B 1 Square Bar 5 X 5 X 420 M Lg. IS-2062 Gr. B Total Weight (KG.)Dokument2 SeitenGr.A 1 Flat Bar 25 X 3 THK. X 470m LG. IS-2062 Gr. B GR.B 1 Square Bar 5 X 5 X 420 M Lg. IS-2062 Gr. B Total Weight (KG.)kamleshyadavmoneyNoch keine Bewertungen

- Designation:-Stack Detail Drg No 460SK1 Rev No φ1600 Tot Wt (Kgs) S. No. Description Item No QtyDokument28 SeitenDesignation:-Stack Detail Drg No 460SK1 Rev No φ1600 Tot Wt (Kgs) S. No. Description Item No QtykamleshyadavmoneyNoch keine Bewertungen

- Proyek Robotika - Mobile Robot MechanismDokument14 SeitenProyek Robotika - Mobile Robot MechanismSatriyoAriezNoch keine Bewertungen

- What Are The Undecidable Problems in TOCDokument7 SeitenWhat Are The Undecidable Problems in TOCsudulagunta aksharaNoch keine Bewertungen

- Indian National Olympiad in Informatics, 2015Dokument6 SeitenIndian National Olympiad in Informatics, 2015Fian IlhamNoch keine Bewertungen

- Csit EssayDokument4 SeitenCsit Essayapi-311617581Noch keine Bewertungen

- Laplace Transform Table: Appendix DDokument4 SeitenLaplace Transform Table: Appendix DHKVMVPVPV021511Noch keine Bewertungen

- Courier Delivery ExectiveDokument3 SeitenCourier Delivery ExectiveKarthikeyan TNoch keine Bewertungen

- 2.1 WorkbookDokument33 Seiten2.1 Workbookbaroliy775Noch keine Bewertungen

- Caterpillar Engine Delivery Service Record: Filling InstructionsDokument4 SeitenCaterpillar Engine Delivery Service Record: Filling InstructionsIgnacio Alejandro Jose Helo VarelaNoch keine Bewertungen

- Mesh Intro 18.0 WS4.1 CFD Workshop Instructions Local Mesh ControlsDokument33 SeitenMesh Intro 18.0 WS4.1 CFD Workshop Instructions Local Mesh Controlsrodrigoq1Noch keine Bewertungen

- Data Visualization Flyer - Protiviti - 230817Dokument1 SeiteData Visualization Flyer - Protiviti - 230817Ashwin LeonardNoch keine Bewertungen

- Introduction To DVB-T2Dokument142 SeitenIntroduction To DVB-T2arsenaldoNoch keine Bewertungen

- Adobe Photoshop Multiple-Choice Questions (MCQS)Dokument31 SeitenAdobe Photoshop Multiple-Choice Questions (MCQS)Harshal ThakurNoch keine Bewertungen

- Comp 2Dokument2 SeitenComp 2Giovanni de los SantosNoch keine Bewertungen

- Sfswmso13 Part 03Dokument156 SeitenSfswmso13 Part 03Gustavo Tromper Trimpis100% (1)

- Sarscape For EnviDokument44 SeitenSarscape For EnviMaria DiamantopoulouNoch keine Bewertungen

- Additional MathematicsDokument5 SeitenAdditional MathematicsAdam NaqibNoch keine Bewertungen

- 12 Creating and Deploying Administrative TemplatesDokument26 Seiten12 Creating and Deploying Administrative TemplatesAlexandreAntunesNoch keine Bewertungen

- 1 PBDokument9 Seiten1 PBrisnandarama123Noch keine Bewertungen

- Image File FormatsDokument22 SeitenImage File FormatsAyano MiyuzakiNoch keine Bewertungen

- PCI and RSI Collisions-Rodrigo Verissimo Extended AbstractDokument8 SeitenPCI and RSI Collisions-Rodrigo Verissimo Extended Abstractfatemeh sameniNoch keine Bewertungen

- IDS I10 User Manual Rev DDokument276 SeitenIDS I10 User Manual Rev DRoy LuoNoch keine Bewertungen