Beruflich Dokumente

Kultur Dokumente

Fixings

Hochgeladen von

api-132751606Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fixings

Hochgeladen von

api-132751606Copyright:

Verfügbare Formate

1

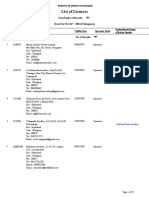

FIXINGS

Nothing sets off a well designed and executed piece of jewellery as hand made fastenings. Once you have learnt the basic principles it is simply a matter of giving your imagination free rein. Considerations: Strength of metal Strength of solder Suitability Ease of use (e.g. opening) Does it add to or detract from the overall design

JUMP RINGS I would try to use 1mm wire upwards (either round or square). 0.8mm is a bit too fragile, so only use it if the design really indicates, or if you are making very small jump rings. The larger the jump ring, the thicker the wire to use. If you are making a few try jamming your wire and an old nail or drill bit into a vice and wind it around the nail as many times as required. Not only does this mean all your jump rings will be the same size, but you can use the nail as a brace as you saw through the jump rings.

If you want the jumps to lie perfectly you should really wind half of the rings one way around the nail and after you have cut them, wind the wire the other way around the nail. Solder using Hard Solder. N.B. Always open and close jump rings sideways, not by pulling them apart, or pushing them together.

Imogen Waitt

January, 2007

EARRINGS Post Style Always use 0.8mm round wire to go through the ear (unless you are making for someone who has worn heavy earrings in the past and stretched the hole through the ear. If this is the case, a larger gauge wire can disguise this.) Cut your wire to achieve a finished length of 11mm. Round off the end to go through the ear. Then, a short way down from this, use a backward cut with your piercing saw to make a small groove right around the circumference of the wire (this will allow the butterfly back to click into place.) At the other end (where you are going to solder it to your earring) take a small file to spread out the metal (you can put it in a vice and try to hammer it slightly, but this is difficult.) When you come to solder it on, you need to put a small amount of solder and flux on the earring, but only flux onto the earring peg. Heat the earring whilst holding the earring post in a pair of insulated reverse action tweezers. As you reach melting point, hold the earring post in place and the solder will jump onto it. N.B. Use the highest grade solder you can, bearing mind which solders you have already used on the front of the earring.

The butterfly back to accompany the above is constructed thus:

Imogen Waitt

January, 2007

Anneal, and then use round nose pliers to bend thus:

Shepherd Crook style earring fixings Again use 0.8mm round wire. There is no solder joint here as with dangly earrings it is considered safest to leave at least one joint that can come apart in case of them getting snagged. Simply use round nose pliers as the metal is so thin it is unlikely that you will need to anneal. This is the basic shape to aim for:

Imogen Waitt

January, 2007

4 In this example a small section of the round wire has been forged with a hammer before twisting.

In this final example a small length of very fine sterling silver wire (0.4mm or 0.5mm) has been wrapped around the front part of the fixing.

FASTENINGS TO BRACELETS & NECKLACES I favour the Serpentine style of fixing. It can be made or round or square wire (I have made some using square wire that I have pre-twisted.) Again, I would not use anything less than 1mm thick and you can make them much more chunky if it would sit better with the design of the main piece of jewellery. They can be made as large or small as you desire. This is the basic shape to aim for:

Imogen Waitt

January, 2007

For the example above, I have run a ball up either end of the wire using some flux and a gentle blow torch flame. This should be done prior to bending the metal. In the following example I have shown both ends of the wire forged out prior to bending into shape and soldering.

In this final example a bezel (with base) has been soldered on to join the Serpentine in place of a simple solder joint:

A jump ring (or rings) should then be soldered onto the closed loop of the Serpentine and attached onto the necklace or bracelet. For the other side of the necklace or bracelet you will need to have one or more jump rings.

Imogen Waitt

January, 2007

Toggle Style Fixings One side is made from a piece of wire where a ball has been run up as described before. The other end of the wire is bent into a circle using round pliers and hard soldered. The other piece is made from a larger circle of metal (hard soldered) that has been bent into shape so that the ball can slip through the centre part, but be held tight as the edges. Again you will attach this to the piece of jewellery using jump rings.

Conventional Toggle

Try to use hard solder as much as possible. The next picture is of the most basic type of toggle bar to fit through the toggle ring. Make sure you cut the toggle bar long enough so that it will not slip through the ring by accident when being worn. It should just be able to slip through at an angle when held at the centre point. The toggle below is held by one circle of hard soldered metal that has been twisted so that it is tight enough to grip the bar securely before you solder it together.

Imogen Waitt

January, 2007

The example below is constructed in exactly the same way as above, but a decorative wire edge has been soldered around the circumference of each end.

In the final example a bezel (without base) has been soldered at each end of the toggle bar. If you are going to do this it looks best on a round wire bar (as opposed to square).

Imogen Waitt

January, 2007

8 CUFFLINKS Swivel bar cufflinks are complex to construct as they require a spring mechanism. Most men seem to prefer good old fashioned bar and chain fastenings, shown below, as they are easier to do up. It is possible to buy special cufflink chain that is stronger than average chain of its weight. If you just want to use up left over bits of chain you already have, and then make sure that it is strong and that the links are sound. Make a bar out of round or square wire that is a minimum of 2mm thick. It may seem obvious, but make sure the shape you use for the decorative side will not slip through the shirt hole and that the bar will pass through the hole, but be robust enough not to slip out. It is possible to use any style mentioned in the previous section in place of a basic bar. To attach the chain to the bar and the decorative top, use a fairly low heat solder to avoid melting your chain, but obviously the higher grade the better. Grip the D or U joining metal in your reverse action insulated tweezers thus. Try to drape the rest of the chain over the back of the tweezers to avoid them falling forward onto the solder joint. It is often helpful to use the cooling gel on the chain, but if you get any on the Joint the solder will not flow.

Instead of using a U shape piece of wire, try using a jump ring; flatten with snipe pliers into a D shape. This gives a larger surface for a stronger joint.

Imogen Waitt

January, 2007

BROOCH FIXINGS It is particularly important to work out how the brooch is to be worn at the start of the design process. If the fixing is not correctly positioned the brooch may lie badly when worn. It is important to assess the weight of the brooch to decide what type of Back to put on. Here are some basic ideas. I use 1mm wire for making this one. It is just a variation on the traditional nappy pin Please note that the circular twist on the left hand side is raised up from where the solder will run to allow for spring (reverse pressure when the brooch is closed will hold it in place in the keep.

This is a variation on the above. Use it if you have piercing work on the brooch so that the pin does not show through.

I have shown a reverse U curve on the base of both pieces. This will give you a larger area for the solder to catch. The following is a basic stick pin with a reverse curve to allow for ease of use and spring.

Imogen Waitt

January, 2007

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Actual Test 9Dokument4 SeitenActual Test 9KilONoch keine Bewertungen

- Bis Licensee DetailsDokument52 SeitenBis Licensee Detailssantosh kumarNoch keine Bewertungen

- Project On TanishqDokument58 SeitenProject On TanishqAdish Jain50% (4)

- Rub Over SettingDokument28 SeitenRub Over Settingapi-132751606Noch keine Bewertungen

- Perspective 2Dokument1 SeitePerspective 2api-132751606Noch keine Bewertungen

- Bead ShapesDokument85 SeitenBead Shapesapi-132751606Noch keine Bewertungen

- Perspective 1Dokument1 SeitePerspective 1api-132751606Noch keine Bewertungen

- Setting in FlushDokument7 SeitenSetting in Flushapi-132751606Noch keine Bewertungen

- Inlay Techniques - BasicDokument3 SeitenInlay Techniques - Basicapi-132751606Noch keine Bewertungen

- Basic Design ElementsDokument1 SeiteBasic Design Elementsapi-132751606Noch keine Bewertungen

- Finishing Process BeginnersDokument1 SeiteFinishing Process Beginnersapi-132751606Noch keine Bewertungen

- Soldering BeginnersDokument5 SeitenSoldering Beginnersapi-132751606Noch keine Bewertungen

- Doming and SwagingDokument1 SeiteDoming and Swagingapi-132751606Noch keine Bewertungen

- HallmarkingDokument2 SeitenHallmarkingapi-132751606Noch keine Bewertungen

- Hinge ConstructionDokument5 SeitenHinge Constructionapi-132751606Noch keine Bewertungen

- Annealing BeginnersDokument1 SeiteAnnealing Beginnersapi-132751606Noch keine Bewertungen

- Decorative Finishes: Imogen Waitt © May, 2010Dokument5 SeitenDecorative Finishes: Imogen Waitt © May, 2010api-132751606Noch keine Bewertungen

- Mokune GaneDokument3 SeitenMokune Ganeapi-132751606Noch keine Bewertungen

- SmithingDokument8 SeitenSmithingapi-132751606Noch keine Bewertungen

- Annealing TutDokument3 SeitenAnnealing Tutapi-132751606Noch keine Bewertungen

- Noble Metals MasterDokument3 SeitenNoble Metals Masterapi-132751606Noch keine Bewertungen

- The Periodic Table - As It Applies To UsDokument4 SeitenThe Periodic Table - As It Applies To Usapi-132751606Noch keine Bewertungen

- RivetingDokument7 SeitenRivetingapi-132751606Noch keine Bewertungen

- Keum BooDokument3 SeitenKeum Booapi-1327516060% (1)

- CastingDokument3 SeitenCastingapi-132751606Noch keine Bewertungen

- Metal PointsDokument1 SeiteMetal Pointsapi-132751606Noch keine Bewertungen

- Fashion History of Clothing Conversation Topics Dialogs Oneonone Activities Re - 9099Dokument4 SeitenFashion History of Clothing Conversation Topics Dialogs Oneonone Activities Re - 9099Marilyn MellowdroneNoch keine Bewertungen

- ESFP Full Report TruityDokument28 SeitenESFP Full Report TruityRobert KhouryNoch keine Bewertungen

- IGI Report 485169Dokument1 SeiteIGI Report 485169rodneyNoch keine Bewertungen

- Ancient Greek JewelryDokument67 SeitenAncient Greek JewelryIshtar AmalNoch keine Bewertungen

- Collection Review: Key Materials & Details - Footwear & Accessories S/S 22Dokument9 SeitenCollection Review: Key Materials & Details - Footwear & Accessories S/S 22Raquel MantovaniNoch keine Bewertungen

- Coloured Diamonds - Women's Jewellery - How To Spend ItDokument6 SeitenColoured Diamonds - Women's Jewellery - How To Spend ItOwm Close CorporationNoch keine Bewertungen

- Diamond Earrings, 0.60 CTDokument1 SeiteDiamond Earrings, 0.60 CTGuido De Gregorio TorriniNoch keine Bewertungen

- Etched Carnelian Intaglios PDFDokument1 SeiteEtched Carnelian Intaglios PDFMax BergerNoch keine Bewertungen

- Blood JadeDokument11 SeitenBlood JadePhone Hlaing0% (1)

- BST11 Chap 1 WorksheetDokument2 SeitenBST11 Chap 1 WorksheetNEONTechNoch keine Bewertungen

- BeadsDokument8 SeitenBeadsMukesh MonuNoch keine Bewertungen

- Kwitansi Toko EmasDokument4 SeitenKwitansi Toko EmasFrizky AriaNoch keine Bewertungen

- Özcan Gümüş CatalogueDokument52 SeitenÖzcan Gümüş CatalogueTeo AdamescuNoch keine Bewertungen

- Design Brief OmnequeDokument5 SeitenDesign Brief OmnequeMouad ElghazouaniNoch keine Bewertungen

- Grade 10 Tle Quart'er ExamDokument3 SeitenGrade 10 Tle Quart'er ExamJovelyn TakilidNoch keine Bewertungen

- Brand Values: Things You Didn't Know AboutDokument1 SeiteBrand Values: Things You Didn't Know AboutSabid KanakkayilNoch keine Bewertungen

- Slinky Bracelet & EarringsDokument4 SeitenSlinky Bracelet & EarringsLepota SvetaNoch keine Bewertungen

- History of Fashion AccessoriesDokument6 SeitenHistory of Fashion AccessoriesMonique ElegarcoNoch keine Bewertungen

- Diamond Report - 03122019Dokument2 SeitenDiamond Report - 03122019sudiptoghosh1977Noch keine Bewertungen

- La Mode Design and Suitability of Dress - Marie Eugenie Jobin - 1920Dokument726 SeitenLa Mode Design and Suitability of Dress - Marie Eugenie Jobin - 1920Kassandra M JournalistNoch keine Bewertungen

- Beadwork - June July 2018Dokument92 SeitenBeadwork - June July 2018Mary008100% (7)

- Reviewer CPAR Grade 12 Stem First SemesterDokument5 SeitenReviewer CPAR Grade 12 Stem First SemesterhendazayaciaNoch keine Bewertungen

- DIC Jewelry Catalogue 2018 PDFDokument138 SeitenDIC Jewelry Catalogue 2018 PDFFrancisco BtaNoch keine Bewertungen

- Jewellery Industry in Hong KongDokument6 SeitenJewellery Industry in Hong KongDvd LavanyaNoch keine Bewertungen

- Bebina Milovanovic - AnodosDokument19 SeitenBebina Milovanovic - AnodosMorriganNoch keine Bewertungen

- Chapter 4 - AccessoriesDokument6 SeitenChapter 4 - AccessoriesKashien Arianna Reglos100% (3)

- Mikimoto America PearlsDokument15 SeitenMikimoto America Pearlshaiducadrian100% (2)