Beruflich Dokumente

Kultur Dokumente

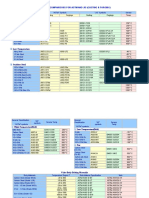

Material Specification

Hochgeladen von

Praveen DodamaniOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Material Specification

Hochgeladen von

Praveen DodamaniCopyright:

Verfügbare Formate

~

::t- .."

l-"

.-

i

MATERIAL PROPERTIES

_."

-'

f" ;:.~~.--'-

_.

.....-

- -.

---

Fe360

Fe 4f(t

Hot Rolled Steel plates. sheets. strips and flats for f1enging

and forming operation (fS 5936 : 1992)

Fe 330

I CHEMICAL

.-.:.';'"

..

High strength low carbon hot rolled

steel sheets and plates (SS 4012 A)

Fe 510

E34

Cold Rolled low carbon steel sheets and strips

(IS 513: 1994)

Hot rolled carbon steel sheets and strips (IS 1079: 199.4)

E'38

HRO

HRD

HROO

HREOD

CRO

CRO

CRDD

CREDO

COMPOSmON

!Carbon (C) %

0.17 Max

0.17 Max

0.20 Max

0.20 Max

0.10 Max

0.10 Max

. 0.15 Max

0.12 Max

0.10 Max

O.O&M~

0.15 Max

0.12 Max

0.10 Max

'Mangane.e

1.00 Max

1.20 Max

1.30 Max

1.50 Max

0.70 Max

1.00 Max

0.60 Max

0..50 Max

0.40 Max

0.40 Max

0.60 Max

0.50 Max

0.45 Max

0.045 Max

0.045 Max

0.045 Max

0.045 Max

0.03 Max

0.03 Max

0.055 Max

0.035 Max

0.030 Max

0.0.55 Max

0.040 Max

0.035 Max

0.030 Max

0.Q35 Max

0.030 Max

(Mn) %

Phoaphorus (P) %

Sulphur (S) %

0.045 Max

0.045 Max

Aluminium (AI) %

0.01 Mln

0.01 Min

SIEcon (Sf) %

0.03Mln

/-job/um (Nb) %

TItanium (TI) %

0.40 Max

0.045 Max

0.03 Max

0.03 Max

0.055 Max

0.040 Max

0.035 Max

0.030 Max

0.055 Max

0.01 Min

0.91 Min

0.02-0.05

0.02-0.05

0.Q1 Mln

0.01Mln

0.01 Mln

0.01Min

0.0$-0.20

0.06-0.20

0.06-0.20

0.06-0.20

0.03 Min

0.03Mln

0.03 Min

0.20 Max

0.40 Max

0.03 Mln

0.03Min

0.03Mln

O.O~Mln

0.10Mln

0.10Mln

0.10Min

0.10 Mln

O.2DMax

0.20 Max

0.20 Max

0.20 Max

0.055 Max

0.055 Max

0.20 Max

0.20 Max

0.20 Max

0.20 Max

0.20 Max

0.20 Max

0.20 Max

0.20 Max

0.20 Max

0.20 Max

0.20 Max

0.20 Max

0.045 Max

0.045 Max

.0.20 Max

. 0.20 Max

0.20 Max

O.2QMax

0.20 Mal(

0.20 Max

0.20 Max

0.20 Max

0.20 Max

0.045 Max

0.20M.x

0.20 Max

0.20M.x

0.20 Max

Boron"

0.001 Max

0.001 M.x

0.001 Max

Nitrogen %

0.012 MIIX

0.012 Max

Copper (Cu) %

0.17-0.38

0.17-0.38

0.0515Max

0..095 Max

0.20 Max

0.20 Max

0.20 Max

0.20 Max

0.006 Max

'0.005 MIIX

0.10 ~IIX

0.10 Max

0.10 Max

0.10 Max

0.012 Max

0.012 Max

0.012M.x

0.007 Max

0.007 Max

0.007 Max

0.007 Max

0.17,.0.38

0.17-0.3&

0.17-0.38

0.17-0.3&

0.17-0.38

0.17-0.38

0.17-0.3&

240-300

260-390

260380

270-410

270-370

270-350

280 Max

250 Max

220 Max

28M!n

32M!n

23Min

28Min

32Mln

0.20 Max.

0.20Mu

a.20Max

0.001 Max

0.006 Max

O.ooe

M,x

0.012 Max

0.012 Max

0.012 Max

0.17-0.3&

0.17-0.38

0.17-0.38

PROPERTIES

Tensile strength Mpe"N/mm2

330-440

360-470

410-520

51~20

390-490

441-559

Yield stress Mpa.

205Mln

235Mln

255Min

355Min

335-410

372-460

27 min

25mln

'4 Elongation

Up to 3 mm thk.

1&Min

18Mln

17Mln

16Mln

Over 3mm tIlk

25Min

25Mln

23Min

20Mln

25Min

..

HARDNESS (HBS)

...

Up to & Incl. 12

2t

2t

Above 12

2t

2t

3t

3t

0.5t (Up to 7mm thk)

65

57

50

..

r

INTERNAL DIAMETER FOR BEND TEST

WELOABIUTY

0.040 Max

VanadlumM%

MECHANICAl

. 0.040 Max

0.08 Max

0.5t

2t

Clo.e

Clo

FI.t

. Flat

Flat.

The materlal.hall

be .ult,ble,for gas welding rc weldlng,

.pot wedin; and roller aetm welding

NOTE: SHADED PROPERTIES ARE APPUCABLE

WHEN THE STEEL ISl<ILLEO WITH ALUMiNIUM OR SIUCON OR BOTH OR WITH COPPER BEARING QUAUTY

Das könnte Ihnen auch gefallen

- Saph 440Dokument1 SeiteSaph 440rinkumax2003100% (1)

- IRON AND STEEL Standard EquivalentsDokument5 SeitenIRON AND STEEL Standard Equivalentsvmls1973100% (6)

- CRCA (Cold Rolled Close Annealed Coils) Specifications: As Per IsDokument2 SeitenCRCA (Cold Rolled Close Annealed Coils) Specifications: As Per Isray_k_9177100% (9)

- Steel (TSL) Specification Chemical-Physical270109Dokument55 SeitenSteel (TSL) Specification Chemical-Physical270109dyutimanhazra88% (8)

- Hot Rolled CoilDokument8 SeitenHot Rolled Coilrobin regoNoch keine Bewertungen

- RFQ of C45 SteelDokument3 SeitenRFQ of C45 Steelnhirpara1Noch keine Bewertungen

- Al. Alloy Chemical CompositionDokument9 SeitenAl. Alloy Chemical Compositionketan1965Noch keine Bewertungen

- JIS To SAE Steel EquivalentsDokument2 SeitenJIS To SAE Steel EquivalentsScott Kramer100% (2)

- CRCA Technical Notes - 2018Dokument11 SeitenCRCA Technical Notes - 2018Sajib Chandra RoyNoch keine Bewertungen

- STEEL 30NiCrMo16 30NCD16 FDMA - 1 - GBDokument2 SeitenSTEEL 30NiCrMo16 30NCD16 FDMA - 1 - GBAdnan ColoNoch keine Bewertungen

- C 45Dokument10 SeitenC 45mohsen_267Noch keine Bewertungen

- 1018 Mechanical PropertiesDokument2 Seiten1018 Mechanical PropertiesjangaswathiNoch keine Bewertungen

- En9 070M55Dokument1 SeiteEn9 070M55Tridib DeyNoch keine Bewertungen

- Indian Standard Designation of SteelsDokument1 SeiteIndian Standard Designation of Steelssushil.vgi75% (4)

- NON Metallic Inclusions in SteelDokument68 SeitenNON Metallic Inclusions in SteelDeepak PatelNoch keine Bewertungen

- CR StandardsDokument6 SeitenCR Standardsalpha_beta48Noch keine Bewertungen

- EN42JDokument1 SeiteEN42Jpavan_joshi_5Noch keine Bewertungen

- 50 Casting DefectsDokument49 Seiten50 Casting DefectsmohammadNoch keine Bewertungen

- Nisshin Steel Cold Rolled Special Steel StripDokument28 SeitenNisshin Steel Cold Rolled Special Steel StripekopujiantoeNoch keine Bewertungen

- Is2062 E350Dokument12 SeitenIs2062 E350Sowmen ChakrobortyNoch keine Bewertungen

- Hardenability of SteelDokument59 SeitenHardenability of SteelKhaula M RausyanNoch keine Bewertungen

- AISI 1026 Carbon SteelDokument2 SeitenAISI 1026 Carbon Steelmateimaniac100% (1)

- Equivalent Steel GradesDokument3 SeitenEquivalent Steel GradesBhushan Verma73% (11)

- Development of New Etchant For High Manganese Steel CastingDokument9 SeitenDevelopment of New Etchant For High Manganese Steel CastingShankhaPathakNoch keine Bewertungen

- Is 1730Dokument11 SeitenIs 1730maheshkbandari0% (1)

- ForgingDokument19 SeitenForgingSarthakNoch keine Bewertungen

- Gating-Risering Sec2Dokument35 SeitenGating-Risering Sec2jagan_4u100% (1)

- Role of Vanadium in Microalloyed Steels - Lagneborg PDFDokument86 SeitenRole of Vanadium in Microalloyed Steels - Lagneborg PDFYogi173Noch keine Bewertungen

- Annexure Rolling DefectDokument32 SeitenAnnexure Rolling Defectamit gajbhiye100% (2)

- SAE J434 1986 Automotive Ductile Iron Castings Nodular Iron CastingsDokument10 SeitenSAE J434 1986 Automotive Ductile Iron Castings Nodular Iron Castingsvinicius_bacellarNoch keine Bewertungen

- High Carbon Steel 15B25Dokument1 SeiteHigh Carbon Steel 15B25Sundara Rajan Ramakrishnan100% (1)

- EN24 Steel PropertiesDokument1 SeiteEN24 Steel Propertieskanha15102003100% (1)

- Mold Oscillation and Negative Strip Time PDFDokument14 SeitenMold Oscillation and Negative Strip Time PDFPrakash SarangiNoch keine Bewertungen

- Steckel Mill 1 PDFDokument178 SeitenSteckel Mill 1 PDFSomnathNaskarNoch keine Bewertungen

- Steel Defect GuideDokument15 SeitenSteel Defect Guidegrd4100% (3)

- Dissimilar Metal WeldingDokument30 SeitenDissimilar Metal Weldingdselvakuu100% (1)

- Hot Rolled Carbon Steel Strip and Sheet (IS: 1079-1968)Dokument1 SeiteHot Rolled Carbon Steel Strip and Sheet (IS: 1079-1968)H & H GRSENoch keine Bewertungen

- Steel CleanlinessDokument22 SeitenSteel CleanlinessfondershellNoch keine Bewertungen

- Is 1079 - 2009Dokument10 SeitenIs 1079 - 2009Shradha SinghaniaNoch keine Bewertungen

- Cross Index MaterialDokument4 SeitenCross Index MaterialioancNoch keine Bewertungen

- Heat Treatment ChartDokument9 SeitenHeat Treatment ChartTashrif YusufNoch keine Bewertungen

- Comparison of Aluminum Casting AlloysDokument2 SeitenComparison of Aluminum Casting Alloyszoran100% (1)

- Analysis On The Cause of Longitudinal Crack On The Hot-Rolled Ribbed Bar SurfaceDokument5 SeitenAnalysis On The Cause of Longitudinal Crack On The Hot-Rolled Ribbed Bar SurfaceTanjidul IslamNoch keine Bewertungen

- Carbon and Alloy Steel PDFDokument52 SeitenCarbon and Alloy Steel PDFmaz234100% (3)

- ISO - TC 17 - SC 11 - Steel CastingsDokument2 SeitenISO - TC 17 - SC 11 - Steel CastingsNilesh MistryNoch keine Bewertungen

- Is 3930Dokument19 SeitenIs 3930IPSITNoch keine Bewertungen

- TTT and CCT DiagramDokument24 SeitenTTT and CCT DiagramArun Raj A C100% (2)

- List of Copper AlloysDokument8 SeitenList of Copper AlloysspahicdaniloNoch keine Bewertungen

- A597 Standard Specification For Cast Tool Steel1Dokument2 SeitenA597 Standard Specification For Cast Tool Steel1tsliaNoch keine Bewertungen

- Astm A297Dokument3 SeitenAstm A297rams789Noch keine Bewertungen

- Is 1367 Part 7Dokument3 SeitenIs 1367 Part 7Otavio1230% (1)

- Rolling Defects ReportDokument4 SeitenRolling Defects ReportMohamed AlkharashyNoch keine Bewertungen

- Metals HandbookDokument33 SeitenMetals HandbookAlexandre Sp50% (4)

- Material Cross Reference TableDokument3 SeitenMaterial Cross Reference TableLuis Pol SistiNoch keine Bewertungen

- Valve Material SpecificationDokument5 SeitenValve Material Specificationapi-9572051Noch keine Bewertungen

- Aerospace Materials: Aircraft Applications of Steel. Aircraft Applications of Steel. Advantages and DisadvantagesDokument55 SeitenAerospace Materials: Aircraft Applications of Steel. Aircraft Applications of Steel. Advantages and DisadvantagesJASHANPREET SinghNoch keine Bewertungen

- Assessment of Welding ConsumablesDokument17 SeitenAssessment of Welding Consumablesmahmoud_allam3Noch keine Bewertungen

- Forged Engineering DataDokument4 SeitenForged Engineering DataretrogradesNoch keine Bewertungen

- New 4130 Alloy SteelDokument3 SeitenNew 4130 Alloy SteelfsijestNoch keine Bewertungen

- 2005 Carbon SteelDokument65 Seiten2005 Carbon SteelmageshkumarNoch keine Bewertungen

- Theory of Elasticity - TIMOSHENKODokument2 SeitenTheory of Elasticity - TIMOSHENKOPraveen DodamaniNoch keine Bewertungen

- ScribdDokument1 SeiteScribdPraveen DodamaniNoch keine Bewertungen

- Visvesvaraya Technological University, Belgaum Scheme of Teaching and ExaminationDokument5 SeitenVisvesvaraya Technological University, Belgaum Scheme of Teaching and ExaminationPraveen DodamaniNoch keine Bewertungen

- GD 1Dokument1 SeiteGD 1Praveen DodamaniNoch keine Bewertungen

- Number Key Answer Number Key Answer Number Key Answer Number Key AnswerDokument1 SeiteNumber Key Answer Number Key Answer Number Key Answer Number Key AnswerPraveen DodamaniNoch keine Bewertungen

- Number Key Answer Number Key Answer Number Key Answer Number Key AnswerDokument1 SeiteNumber Key Answer Number Key Answer Number Key Answer Number Key AnswerPraveen DodamaniNoch keine Bewertungen

- Fund GD&TDokument3 SeitenFund GD&TPraveen DodamaniNoch keine Bewertungen

- 3 GDokument1 Seite3 GPraveen DodamaniNoch keine Bewertungen

- Ms WordDokument3 SeitenMs WordPraveen DodamaniNoch keine Bewertungen

- Fundamentals of GDandTDokument75 SeitenFundamentals of GDandTanjaiah_19945100% (4)

- BadveDokument2 SeitenBadvePraveen DodamaniNoch keine Bewertungen

- CATIA V5 Training ManualDokument118 SeitenCATIA V5 Training ManualAdi BerariNoch keine Bewertungen

- Sahyadri ProfileDokument6 SeitenSahyadri ProfilePraveen DodamaniNoch keine Bewertungen

- Stainless 20Dokument45 SeitenStainless 20k_sivakumar16Noch keine Bewertungen

- BadveDokument2 SeitenBadvePraveen DodamaniNoch keine Bewertungen

- Stainless 20Dokument45 SeitenStainless 20k_sivakumar16Noch keine Bewertungen

- National Training ProgrammesDokument8 SeitenNational Training ProgrammesPraveen DodamaniNoch keine Bewertungen

- H.v.series ClampsDokument4 SeitenH.v.series ClampsPraveen DodamaniNoch keine Bewertungen

- Stainless Steel AISI Grades For PM ApplicationsDokument16 SeitenStainless Steel AISI Grades For PM ApplicationsAxtronNoch keine Bewertungen

- New CPDokument1 SeiteNew CPPraveen DodamaniNoch keine Bewertungen

- All Blocks ModelDokument1 SeiteAll Blocks ModelPraveen DodamaniNoch keine Bewertungen

- All Blocks ModelDokument1 SeiteAll Blocks ModelPraveen DodamaniNoch keine Bewertungen

- ReleasenotesDokument19 SeitenReleasenotesPraveen DodamaniNoch keine Bewertungen

- MRM Aug11Dokument4 SeitenMRM Aug11Praveen DodamaniNoch keine Bewertungen

- Study of Constituents of AlloysDokument17 SeitenStudy of Constituents of AlloysPrakash Giri100% (2)

- 1278 - Filler Rods For Gas WeldingDokument20 Seiten1278 - Filler Rods For Gas WeldingKaushik SenguptaNoch keine Bewertungen

- TKBG Hoa Hoc 9 Tap 1Dokument236 SeitenTKBG Hoa Hoc 9 Tap 1Tạp Chí Hóa Học - www.hoahoc.orgNoch keine Bewertungen

- Pipe Supports z4Dokument5 SeitenPipe Supports z4alla malikNoch keine Bewertungen

- Test No 5Dokument3 SeitenTest No 5Muhammad AsimNoch keine Bewertungen

- Application Datasheet: Standard Designation For Wrought Copper AlloysDokument72 SeitenApplication Datasheet: Standard Designation For Wrought Copper AlloysQuality teamNoch keine Bewertungen

- Astm E350-95Dokument1 SeiteAstm E350-95ippon_osotoNoch keine Bewertungen

- Extraction of MetalsDokument5 SeitenExtraction of MetalsFatema KhatunNoch keine Bewertungen

- Carbon and Low-Alloy SteelsDokument46 SeitenCarbon and Low-Alloy SteelsSuphi YükselNoch keine Bewertungen

- Deca Catalogo GB e D PDFDokument88 SeitenDeca Catalogo GB e D PDFJoséRoldánGarcíaNoch keine Bewertungen

- Material Comparisons For Studs Astm and JisDokument3 SeitenMaterial Comparisons For Studs Astm and JisguluuNoch keine Bewertungen

- h1 PDFDokument124 Seitenh1 PDFMuhammad AminNoch keine Bewertungen

- HTG Katalog 2022 Mail PDFDokument132 SeitenHTG Katalog 2022 Mail PDFemre akhanNoch keine Bewertungen

- WSRC Ms 2001 00544Dokument25 SeitenWSRC Ms 2001 00544arjun prajapatiNoch keine Bewertungen

- Commonly Used Material ChartDokument1 SeiteCommonly Used Material Chartsantosh_ms_kumar2827Noch keine Bewertungen

- Metals - July 20 2018Dokument1 SeiteMetals - July 20 2018Tiso Blackstar GroupNoch keine Bewertungen

- Nominal Size 25mm (1in) : Flange TablesDokument1 SeiteNominal Size 25mm (1in) : Flange TablesReşat DEMİRNoch keine Bewertungen

- TOPIC The Differences Between Pure Metals and Alloys. Content: Pure Metals: - Concept - Physical Property - Uses of Pure MetalsDokument31 SeitenTOPIC The Differences Between Pure Metals and Alloys. Content: Pure Metals: - Concept - Physical Property - Uses of Pure MetalsSinh LeNoch keine Bewertungen

- Astm A959-16Dokument10 SeitenAstm A959-16dadadatony98Noch keine Bewertungen

- Welders List For VesselDokument9 SeitenWelders List For VesselHanuman RaoNoch keine Bewertungen

- HRC enDokument7 SeitenHRC enĐình Khoa PhanNoch keine Bewertungen

- WPS 02Dokument2 SeitenWPS 02ZaidiNoch keine Bewertungen

- Aws 1208Dokument80 SeitenAws 1208ndrarlyNoch keine Bewertungen

- Casting AlloysDokument2 SeitenCasting Alloysgalvaosilva100% (1)

- Gold Trading How To ReadDokument6 SeitenGold Trading How To ReadpaulshhanNoch keine Bewertungen

- Sap 5Dokument22 SeitenSap 5reza noviyantiNoch keine Bewertungen

- QW 442 A Number PDFDokument1 SeiteQW 442 A Number PDFMadidj_2014Noch keine Bewertungen

- Surfacote Surfasit: Beautiful SurfacesDokument8 SeitenSurfacote Surfasit: Beautiful SurfacesChoice OrganoNoch keine Bewertungen

- Pinnacle Alloys ER2594Dokument2 SeitenPinnacle Alloys ER2594Federico Quintana100% (1)

- Equi. MaterialsDokument1 SeiteEqui. MaterialsParameswararao BillaNoch keine Bewertungen