Beruflich Dokumente

Kultur Dokumente

Concrete

Hochgeladen von

Lulu DeabakOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Concrete

Hochgeladen von

Lulu DeabakCopyright:

Verfügbare Formate

1

Aggregates

Crushed Rock: low workability, high strength due to high friction. Rounded aggregate: low friction. High workability, low strength. Found in riverbeds, etc. Expanded clay: not strong. Highly porous. Made by heating in a kiln, where the air inside it expands. Styrofoam beads: lightweight. Absorbs shocks by deforming instead of cracking. Air entrained: Allows water through. Good insulation properties.

Expanded clay and styrofoam beads can be used in combination.

Common aws in concrete

Air voids: lead to lower strength. Honeycombing: loss of strength, ugly appearance. Can be reduced by compacting the concrete. Segregation of aggregates: occurs when concrete is overworked. Less strength on the side with ner aggregate.

Tests

Slump test: used to determine the workability of the concrete. Cube test (compression test): used to nd the compressive strength of the concrete. Ultrasound test: non-destructive method to estimate strength.

Reinforcements

Rounded bar: concrete doesnt hold onto this well as it is smooth; hence it is used as distribution steel. Ribbed bars: ribs mean that it doesnt sleep or pull out of concrete. Shear links: stop shear failure. Hanger bar: also stops shear failure but offers less resistance to it than the shear links.

Spacer wheels1 : maintain the cover distance.

Other stuff

Concrete is usually tested at 7 and 28 days. If more tests are needed after concrete is in place, a core is drilled out, smoothed on top and tested. To avoid cutting the steel reinforcements, cover meters are used to detect the steel. The cover distance is the distance between steel reinforcement bars.

I think. I didnt get the name off him.

Das könnte Ihnen auch gefallen

- Tube Expander Design UsageDokument19 SeitenTube Expander Design UsageJaroslaw PoplawskiNoch keine Bewertungen

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesVon EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNoch keine Bewertungen

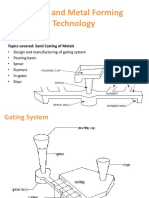

- Unit 2 Sand Moulding PART 2Dokument20 SeitenUnit 2 Sand Moulding PART 2mahammad kamaluddeenNoch keine Bewertungen

- Masonry Loadbearing Wall .NOT!Dokument61 SeitenMasonry Loadbearing Wall .NOT!qazalbash1109588Noch keine Bewertungen

- Laboratory Manual of Glass-BlowingVon EverandLaboratory Manual of Glass-BlowingBewertung: 5 von 5 Sternen5/5 (1)

- Engineering Materials: HITEC University TaxilaDokument26 SeitenEngineering Materials: HITEC University Taxilanasir khanNoch keine Bewertungen

- Module 2Dokument82 SeitenModule 2Nishan K NichuNoch keine Bewertungen

- Presentation 1Dokument5 SeitenPresentation 1mayuresh barbarwarNoch keine Bewertungen

- Tube Expander Design & Usage: © 2017 Elliott Tool TechnologiesDokument20 SeitenTube Expander Design & Usage: © 2017 Elliott Tool TechnologiesELIECER SANCHEZNoch keine Bewertungen

- Sand Casting of Metals - Gating System For CastingDokument31 SeitenSand Casting of Metals - Gating System For CastingAmruta Rane100% (1)

- Sampling Tools and SamplersDokument13 SeitenSampling Tools and SamplersalafdilscaffoldingNoch keine Bewertungen

- Bolting Course Day 1-3Dokument13 SeitenBolting Course Day 1-3marceloNoch keine Bewertungen

- Planejamento de Lavra A Céu Aberto OPEN PITDokument88 SeitenPlanejamento de Lavra A Céu Aberto OPEN PITJohnPereiraNoch keine Bewertungen

- Reinforced Concrete Design Lecture 01 Fundamentals PDFDokument22 SeitenReinforced Concrete Design Lecture 01 Fundamentals PDFAbdul HafeezNoch keine Bewertungen

- Chapter 1Dokument92 SeitenChapter 1Arun NesamNoch keine Bewertungen

- Well Foundation PDFDokument41 SeitenWell Foundation PDFpeterNoch keine Bewertungen

- Recent Advances in Pile Foundation - BCM SeminarDokument15 SeitenRecent Advances in Pile Foundation - BCM Seminarapi-19915731Noch keine Bewertungen

- Introduction To Reinforced ConcreteDokument29 SeitenIntroduction To Reinforced ConcreteDarlene Kate MonterdeNoch keine Bewertungen

- Brick MasonryDokument32 SeitenBrick MasonrygeethaNoch keine Bewertungen

- PrestressDokument2 SeitenPrestressGaddiel AguilarNoch keine Bewertungen

- Bms PCC and RCC PDFDokument27 SeitenBms PCC and RCC PDFKeshav SethiNoch keine Bewertungen

- Destructive Examination & TestingDokument31 SeitenDestructive Examination & TestingMau Atenas PerezNoch keine Bewertungen

- Shikha Bricks Presentation Final 1Dokument11 SeitenShikha Bricks Presentation Final 1Janhvi GoswamiNoch keine Bewertungen

- Lecture 8 - Bond, Anchorage, - Development Length, Bar Splice - Reinforcement CurtailmentDokument33 SeitenLecture 8 - Bond, Anchorage, - Development Length, Bar Splice - Reinforcement CurtailmentMuhammad SulemanNoch keine Bewertungen

- Sheet Metal Process: UNIT-4Dokument11 SeitenSheet Metal Process: UNIT-4Pratheep AddrinNoch keine Bewertungen

- Form Work MethodologyDokument77 SeitenForm Work MethodologyDagnachew TassewNoch keine Bewertungen

- Metalcastingprocess 110925103638 Phpapp02 PDFDokument51 SeitenMetalcastingprocess 110925103638 Phpapp02 PDFramesh tNoch keine Bewertungen

- Reporter 16 Concrete Pavement Behavior and CharacteristicsDokument25 SeitenReporter 16 Concrete Pavement Behavior and CharacteristicsVINCENT NICOLO PALMA BULURANNoch keine Bewertungen

- 16 Different Types of Slabs in ConstructionDokument19 Seiten16 Different Types of Slabs in ConstructionshakeelNoch keine Bewertungen

- Destructive Test MethodsDokument33 SeitenDestructive Test MethodsAvalcwiNoch keine Bewertungen

- Reinforcement PDFDokument102 SeitenReinforcement PDFZairah Ann BorjaNoch keine Bewertungen

- Masonry: AdvantagesDokument27 SeitenMasonry: AdvantagesMadhavi LathaNoch keine Bewertungen

- Concrete Lesson 1Dokument16 SeitenConcrete Lesson 1Cebo QinisoNoch keine Bewertungen

- BrickmasonryDokument27 SeitenBrickmasonryAnonymous r63bVFCcNoch keine Bewertungen

- Construction and Material DAA-601: JANVI TALREJA (2001101) SOMYA AGARWAL (2001120)Dokument27 SeitenConstruction and Material DAA-601: JANVI TALREJA (2001101) SOMYA AGARWAL (2001120)SOMYA AGARWALNoch keine Bewertungen

- Pile Foundation AssignmentDokument15 SeitenPile Foundation AssignmentathavanNoch keine Bewertungen

- DT Internal Assement: Hardness of Metals Experiment DesignDokument8 SeitenDT Internal Assement: Hardness of Metals Experiment DesignAmaury Fayd'herbeNoch keine Bewertungen

- Types of Slabs in ConstructionDokument21 SeitenTypes of Slabs in ConstructionJerico Flores100% (1)

- AggregatesDokument27 SeitenAggregatesManish KumarNoch keine Bewertungen

- Destructive Examination & TestingDokument33 SeitenDestructive Examination & TestingMallesh KaruparthyNoch keine Bewertungen

- 4.4 Bricks and Blocks (Construction 1) (Slides) PDFDokument77 Seiten4.4 Bricks and Blocks (Construction 1) (Slides) PDFMary GuinnessNoch keine Bewertungen

- Soil Exploration-1Dokument24 SeitenSoil Exploration-1naman.h.cogniNoch keine Bewertungen

- Formwork Yash TayalDokument18 SeitenFormwork Yash TayalYash TayalNoch keine Bewertungen

- Cladding: Skin Curtain Wall - Glass + Metal SystemsDokument40 SeitenCladding: Skin Curtain Wall - Glass + Metal SystemsSakshi Mayank SaxenaNoch keine Bewertungen

- 15 Introduction To MasonryDokument87 Seiten15 Introduction To MasonryMark WilliamsNoch keine Bewertungen

- Drilling Bit Introduction and Bit Selection (Part 2)Dokument32 SeitenDrilling Bit Introduction and Bit Selection (Part 2)Ali AlakariNoch keine Bewertungen

- Foundry and CastingDokument72 SeitenFoundry and CastingGreethu BabyNoch keine Bewertungen

- Kombolcha Institute of Technology: Construction Materials IDokument36 SeitenKombolcha Institute of Technology: Construction Materials Iking girmaNoch keine Bewertungen

- Cone BitsDokument32 SeitenCone Bitsamin peyvandNoch keine Bewertungen

- Basic StructureDokument6 SeitenBasic StructurezazabanazaNoch keine Bewertungen

- Wire Drawing Shearing Processes FinalDokument19 SeitenWire Drawing Shearing Processes FinalJairam AtluriNoch keine Bewertungen

- Short Notes Civil EngineeringDokument31 SeitenShort Notes Civil Engineeringsomeshshinde8855Noch keine Bewertungen

- Stone/CHB/Cement: RE200 - AR161Dokument36 SeitenStone/CHB/Cement: RE200 - AR161magne veruNoch keine Bewertungen

- Assignment 1Dokument32 SeitenAssignment 1sharifah atiqahNoch keine Bewertungen

- 7-Properties of Hard ConcreteDokument62 Seiten7-Properties of Hard ConcreteZELALEMNoch keine Bewertungen

- BricksDokument99 SeitenBricksSantosh Kumar M100% (1)

- 01 - Deep FoundationDokument14 Seiten01 - Deep FoundationRekha ojhaNoch keine Bewertungen

- Foundry and Metal CastingDokument53 SeitenFoundry and Metal CastingAndrey MedranoNoch keine Bewertungen

- 18) UC203x203x46toUC254x254x73-B2CF - MCDokument125 Seiten18) UC203x203x46toUC254x254x73-B2CF - MCAsaru DeenNoch keine Bewertungen

- Mil H 6875GDokument29 SeitenMil H 6875Gfordsho95Noch keine Bewertungen

- Constants and ConversionsDokument32 SeitenConstants and ConversionsTan TanNoch keine Bewertungen

- Vykon HvacDokument284 SeitenVykon HvacJose RodriguezNoch keine Bewertungen

- Processing of Bopp FilmDokument49 SeitenProcessing of Bopp FilmHassan Ali Khan75% (8)

- Cool Machines CV Series Insulation Removal VacuumDokument3 SeitenCool Machines CV Series Insulation Removal Vacuumbrooklynarmstrong487Noch keine Bewertungen

- MET01 - Research WorkDokument12 SeitenMET01 - Research WorkJeremae EtiongNoch keine Bewertungen

- Brochure Siemens Gas-Turbine SGT-700 MDDokument4 SeitenBrochure Siemens Gas-Turbine SGT-700 MDJohn_J2012Noch keine Bewertungen

- Chemistry 10th Edition Zumdahl Test Bank 1Dokument52 SeitenChemistry 10th Edition Zumdahl Test Bank 1christopher100% (37)

- Fracture Mechanics Practical FileDokument21 SeitenFracture Mechanics Practical Filesubashish100% (1)

- 1f Multi Voltage Multi Circuit Transmission Tower PDFDokument7 Seiten1f Multi Voltage Multi Circuit Transmission Tower PDFmulualemNoch keine Bewertungen

- Week 13Dokument27 SeitenWeek 13josewilliam85Noch keine Bewertungen

- Tickling Test of RC1536 With Z&S Water Based Ink Rev05Dokument10 SeitenTickling Test of RC1536 With Z&S Water Based Ink Rev05casanovaNoch keine Bewertungen

- DQE SimplifiedDokument8 SeitenDQE SimplifiedBen100% (1)

- Surface & Coatings Technology: SciencedirectDokument8 SeitenSurface & Coatings Technology: SciencedirectVikrant Saumitra mm20d401Noch keine Bewertungen

- Basic InstrumentationDokument59 SeitenBasic Instrumentationjudegj100% (1)

- Physics Study MaterialDokument54 SeitenPhysics Study MaterialCh V S RajuNoch keine Bewertungen

- 436 33 Powerpoint Slides CHAPTER 1Dokument69 Seiten436 33 Powerpoint Slides CHAPTER 1Anonymous PeFQLw19Noch keine Bewertungen

- PricelistDokument136 SeitenPricelistCervantesquijoteNoch keine Bewertungen

- Galvanizing For Corrosion Protection (AGA)Dokument18 SeitenGalvanizing For Corrosion Protection (AGA)Abrianto AkuanNoch keine Bewertungen

- Seismic Design of Water TanksDokument17 SeitenSeismic Design of Water TanksJeevan ReddyNoch keine Bewertungen

- WavesDokument4 SeitenWavesMark ProchaskaNoch keine Bewertungen

- 13 30 Minhaal Kalyan Chevron.8569Dokument19 Seiten13 30 Minhaal Kalyan Chevron.8569Rohan DangareNoch keine Bewertungen

- R N Peb Structures PVT LTD-25.8.22Dokument28 SeitenR N Peb Structures PVT LTD-25.8.22Shashank DimriNoch keine Bewertungen

- Flow Through NozzlesDokument13 SeitenFlow Through NozzlesBharat SharmaNoch keine Bewertungen

- Problem Set 3Dokument5 SeitenProblem Set 3xxvvNoch keine Bewertungen

- Science8 q1 Mod6 Heat-And-temperature FINAL07282020Dokument22 SeitenScience8 q1 Mod6 Heat-And-temperature FINAL07282020kiannatherese andradaNoch keine Bewertungen

- Hydrological Fluvial Coastal Limestone EnvironmentsDokument52 SeitenHydrological Fluvial Coastal Limestone EnvironmentsDharam Jagroop100% (1)

- Procast Manual PDFDokument471 SeitenProcast Manual PDFPhan Dinh Sy0% (2)

- Asme PTC 1986Dokument4 SeitenAsme PTC 1986AmalAhmed0% (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyVon EverandSodium Bicarbonate: Nature's Unique First Aid RemedyBewertung: 5 von 5 Sternen5/5 (21)

- An Applied Guide to Water and Effluent Treatment Plant DesignVon EverandAn Applied Guide to Water and Effluent Treatment Plant DesignBewertung: 5 von 5 Sternen5/5 (4)

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Guidelines for Chemical Process Quantitative Risk AnalysisVon EverandGuidelines for Chemical Process Quantitative Risk AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- The Perfumed Pages of History: A Textbook on Fragrance CreationVon EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationBewertung: 4 von 5 Sternen4/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Mastering Biochemistry: A Comprehensive Guide to ExcellenceVon EverandMastering Biochemistry: A Comprehensive Guide to ExcellenceNoch keine Bewertungen

- Piping Engineering Leadership for Process Plant ProjectsVon EverandPiping Engineering Leadership for Process Plant ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersVon EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNoch keine Bewertungen

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlVon EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlBewertung: 4 von 5 Sternen4/5 (4)

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsVon EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottBewertung: 4 von 5 Sternen4/5 (6)

- Fun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksVon EverandFun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksNoch keine Bewertungen

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersVon EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersBewertung: 4.5 von 5 Sternen4.5/5 (2)

- A New Approach to HAZOP of Complex Chemical ProcessesVon EverandA New Approach to HAZOP of Complex Chemical ProcessesNoch keine Bewertungen

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesVon EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesBewertung: 5 von 5 Sternen5/5 (1)

- Distillation Design and Control Using Aspen SimulationVon EverandDistillation Design and Control Using Aspen SimulationBewertung: 5 von 5 Sternen5/5 (2)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsVon EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNoch keine Bewertungen

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksVon EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNoch keine Bewertungen

- Biochemical and Photosynthetic Aspects of Energy ProductionVon EverandBiochemical and Photosynthetic Aspects of Energy ProductionAnthony San PietroNoch keine Bewertungen

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionVon EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionNoch keine Bewertungen

- Bioinspired Materials Science and EngineeringVon EverandBioinspired Materials Science and EngineeringGuang YangNoch keine Bewertungen

- Fundamentals of Risk Management for Process Industry EngineersVon EverandFundamentals of Risk Management for Process Industry EngineersNoch keine Bewertungen

- Sustainable Plastics: Environmental Assessments of Biobased, Biodegradable, and Recycled PlasticsVon EverandSustainable Plastics: Environmental Assessments of Biobased, Biodegradable, and Recycled PlasticsNoch keine Bewertungen