Beruflich Dokumente

Kultur Dokumente

Speed Sensing Governor

Hochgeladen von

snowman1579Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Speed Sensing Governor

Hochgeladen von

snowman1579Copyright:

Verfügbare Formate

The speed sensing governor consists essentially of a rotating pilot valve, the flyweights, and the flyweight head.

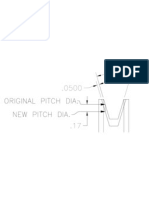

The engine speed signal is transmitted from the engine-driven drive shaft through a gear train to the centrifugal-type flyweight governor. This governor controls movement of the speed servo (3-D cam) by displacing the rotating pilot valve from its hydraulic null position. When the speed changes, the flyweight force varies and the pilot valve is displaced, causing motion of the speed servo. This motion of the speed servo repositions the pilot valve, through the action of a feedback lever working on a spring, until the speed sensing governor returns to null at the new speed servo position. The position of the speed servo is, therefore indicative of actual engine speed. The 3-D cam is contoured to protect against the condition of a broken speed sensing drive shaft. In the event of such a failure, the speed servo bottoms in its bore while the push rod on the speed servo bottoms on an adjustable stop, set near the zero speed position, to eliminate feedback to the speed governor pilot valve. The 3-D cam then places the limiting linkage at the Wf/Ps4 ratio corresponding to the value selected for this failure condition. (5) Acceleration control is provided by adjustment of the roller positioning linkage. This

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Rototiller Parts ManualDokument48 SeitenRototiller Parts Manualsnowman1579Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Rototiller ManualDokument220 SeitenRototiller Manualsnowman1579Noch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Technical Information: Helix Angles Formula To Calculate ChainDokument1 SeiteTechnical Information: Helix Angles Formula To Calculate Chainsnowman1579Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Craftsman 3.7 Cu - in 24 Inch Guide Bar Chain SawDokument30 SeitenCraftsman 3.7 Cu - in 24 Inch Guide Bar Chain Sawsnowman1579100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Pablo Zaragoza PFCDokument67 SeitenPablo Zaragoza PFCsnowman1579Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Full Page PrintDokument1 SeiteFull Page Printsnowman1579Noch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- List of ElementsDokument38 SeitenList of Elementssnowman1579Noch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Oring SealsizesDokument35 SeitenOring Sealsizessnowman1579Noch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A 076 Series ValvesDokument8 SeitenA 076 Series Valvessnowman1579Noch keine Bewertungen

- Pulley ModelDokument1 SeitePulley Modelsnowman1579Noch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)