Beruflich Dokumente

Kultur Dokumente

Boiler Water Treatment

Hochgeladen von

Rommel Cena NepalarOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Boiler Water Treatment

Hochgeladen von

Rommel Cena NepalarCopyright:

Verfügbare Formate

Boiler Water Treatment It is necessary for the water in the boiler be treated to achieve great steam production at a lower

cost. Another reason is that the water has chemical elements it that must be controlled to limit and eliminate the formation of scaling, corrosion and entrainment in the boiler. Scaling may cause low heat transfer at the point of deposits. Some of the more common scale forming constituents are silica, iron, oil, hardness and sugar. Corrosion causes development of weak spots which could lead to failure. Corrosion may be due to chloride, iron, sugar, oil and dissolved gases such as oxygen. Entrainment is often caused by variety f soluble and suspended solids. Chemicals were put in the high pressure and low pressure chemical injection tank to control the formation of the chemical elements that is carried by the water to the boiler.

Dosing points Low Pressure Line Chemical Tank High Pressure Line Chemical Tank

Boilers 1 and 2 Chemical Dillution Diclean B-901 = 2.1 kg Oxynon S-340FG = 2.4 kg Dillute to 200 L water Caustic Soda = 2kg Diclean B-562 = 900g Dillute to 200 L water

Boiler 3 Chemical Dillution Diclean B-901 = 1.4 kg Oxynon S-340FG = 1.6 kg Dillute to 200 L water Caustic Soda = 2kg Diclean B-562 = 900g Dillute to 200 L water

The figure above indicates the chemicals and the dosage required. Dosage will vary depending on the result after the test has been done by the Q.A. in the water sample. the turbine tender gets water sample from the feedwater, continuous blowdown of the three boilers. Below is the table indicating the boiler water treatment control parameters.

Das könnte Ihnen auch gefallen

- Chlorine: International Thermodynamic Tables of the Fluid StateVon EverandChlorine: International Thermodynamic Tables of the Fluid StateNoch keine Bewertungen

- Boiler Water Treatment in OIL MILLSDokument9 SeitenBoiler Water Treatment in OIL MILLSRenford SuraltaNoch keine Bewertungen

- Training ReportPDF PDFDokument42 SeitenTraining ReportPDF PDFAman RajNoch keine Bewertungen

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasVon EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNoch keine Bewertungen

- BoilerpptDokument11 SeitenBoilerpptFarhan SiddiquiNoch keine Bewertungen

- Cheema Boiler Limited: Presented To: MR - Deepak Bhandari (Dokument32 SeitenCheema Boiler Limited: Presented To: MR - Deepak Bhandari (angenious100% (1)

- Role of Hydrazine:reducing Agent To Develop The Magnetite Protective Layer in Boiler? - Nikhilesh MuDokument5 SeitenRole of Hydrazine:reducing Agent To Develop The Magnetite Protective Layer in Boiler? - Nikhilesh Mumini2018Noch keine Bewertungen

- Nexguard: DR 900 Analytical ProcedureDokument4 SeitenNexguard: DR 900 Analytical Procedurewulalan wulanNoch keine Bewertungen

- Boiler Blow Down: Workshop On Efficient Operation & Maintenance of BoilersDokument3 SeitenBoiler Blow Down: Workshop On Efficient Operation & Maintenance of Boilerskcp1986Noch keine Bewertungen

- Pump Manual - Single Plunger AmbicaDokument24 SeitenPump Manual - Single Plunger AmbicaHimTex /JaswinderNoch keine Bewertungen

- Calcium Phosphate Scale Formation From Simulated Milk Ultrafiltrate SolutionsDokument8 SeitenCalcium Phosphate Scale Formation From Simulated Milk Ultrafiltrate SolutionssegundosoporteNoch keine Bewertungen

- Reduction of Chemical Effects of Swelling and ShrinkageDokument22 SeitenReduction of Chemical Effects of Swelling and ShrinkageAkshay SetlurNoch keine Bewertungen

- Tds Contro Heat RecoverylDokument31 SeitenTds Contro Heat RecoverylHélder PascoalNoch keine Bewertungen

- Boiler Dissolved Oxygen ControlDokument12 SeitenBoiler Dissolved Oxygen ControltrieuNoch keine Bewertungen

- 4 - Silica in BoilerDokument3 Seiten4 - Silica in BoilerKrishnan ManiNoch keine Bewertungen

- Boiler Afbc PDFDokument101 SeitenBoiler Afbc PDFdika wahyuNoch keine Bewertungen

- Bhatia Gummidipoondi WHRSG O&m Manual FinalDokument224 SeitenBhatia Gummidipoondi WHRSG O&m Manual Finalt_syamprasadNoch keine Bewertungen

- Boiler Water TreatmentDokument38 SeitenBoiler Water TreatmentMahmoud MahmoudmNoch keine Bewertungen

- Boiler TroublesDokument12 SeitenBoiler TroublesHARSH CHAUHAN 20SCSE1010094Noch keine Bewertungen

- Boiler Internal & External TreatmentDokument62 SeitenBoiler Internal & External Treatmentmdnor100% (1)

- ME6701-Power Plant EngineeringDokument16 SeitenME6701-Power Plant EngineeringNizam MANoch keine Bewertungen

- CFBC Boiler Training ManualDokument4 SeitenCFBC Boiler Training ManualGusti Prasetyo Rendy AnggaraNoch keine Bewertungen

- SCHROEDAHL Automatic Recirculation ValveDokument12 SeitenSCHROEDAHL Automatic Recirculation ValveJaebeom YiNoch keine Bewertungen

- Ferrocare LVDH Oil Cleaning MachineDokument2 SeitenFerrocare LVDH Oil Cleaning Machinessheart_mindNoch keine Bewertungen

- High Silica After Overhaul of Fouled TurbineDokument3 SeitenHigh Silica After Overhaul of Fouled Turbineak_thimiriNoch keine Bewertungen

- Boiler Mounting & AccessoriesDokument14 SeitenBoiler Mounting & Accessoriesshiraj36100% (1)

- Design and Thermal Analysis of A Supercritical CFB BoilerDokument89 SeitenDesign and Thermal Analysis of A Supercritical CFB Boilerbharathkumar0310Noch keine Bewertungen

- Boilers Basic Components (Att. VIII)Dokument28 SeitenBoilers Basic Components (Att. VIII)Vijay RajNoch keine Bewertungen

- Cathotic ProtectionDokument5 SeitenCathotic Protectionkrishna_swaroop99Noch keine Bewertungen

- Boiler Cleaning Technologies - Water Lance VsDokument3 SeitenBoiler Cleaning Technologies - Water Lance VsDSGNoch keine Bewertungen

- Boiler Water High PresureDokument43 SeitenBoiler Water High PresureVinod SindhavNoch keine Bewertungen

- Is.10392.1982 Feed Water BoilerDokument11 SeitenIs.10392.1982 Feed Water BoilerAngelina YunitaNoch keine Bewertungen

- CBD IbdDokument2 SeitenCBD Ibdpremk20100% (5)

- DeaeratorDokument3 SeitenDeaeratorfirojaga13100% (1)

- Boiler Water Chemistry: 1. Formation of Scales & Deposits On The Boiler TubesDokument4 SeitenBoiler Water Chemistry: 1. Formation of Scales & Deposits On The Boiler TubesKumaraswamyNoch keine Bewertungen

- Monitoring Update Defect UPDATEDokument268 SeitenMonitoring Update Defect UPDATEGita RushenantoNoch keine Bewertungen

- Economizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorDokument10 SeitenEconomizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorknsaravanaNoch keine Bewertungen

- Slides On Boiler FundamentalsDokument21 SeitenSlides On Boiler FundamentalsBianca Clarice DalistanNoch keine Bewertungen

- Boiler EfficiencyDokument24 SeitenBoiler EfficiencyAmit ChauhanNoch keine Bewertungen

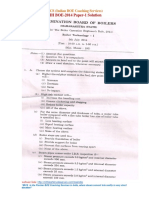

- Indian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionDokument7 SeitenIndian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionAlok DoshiNoch keine Bewertungen

- 6 - Presentation - Boiler Water ChemistryDokument100 Seiten6 - Presentation - Boiler Water Chemistrymuks1308100% (1)

- The Concept of AlkalinityDokument12 SeitenThe Concept of AlkalinityDimas Eko PrasetyoNoch keine Bewertungen

- Boiler Safety Program Boiler ProgramDokument8 SeitenBoiler Safety Program Boiler Programsalman akbarNoch keine Bewertungen

- Flue Gas AnalysisDokument12 SeitenFlue Gas AnalysisMadhavanIceNoch keine Bewertungen

- Whrs ManualDokument41 SeitenWhrs ManualAKHLESH JHALLARENoch keine Bewertungen

- Boiler Tube Cleaning (Fire Tube)Dokument2 SeitenBoiler Tube Cleaning (Fire Tube)Randy AnanthaNoch keine Bewertungen

- MH BOE 2014 Paper 1 SolutionDokument15 SeitenMH BOE 2014 Paper 1 SolutionPratima MondalNoch keine Bewertungen

- DLT 5054-1996Dokument245 SeitenDLT 5054-1996ecsuperalNoch keine Bewertungen

- Hydrazine Oxygen Sacnger LLDokument0 SeitenHydrazine Oxygen Sacnger LLak_thimiriNoch keine Bewertungen

- BoilersDokument46 SeitenBoilersGurvir Singh MaviNoch keine Bewertungen

- Blow Down Calculation For BoilerDokument3 SeitenBlow Down Calculation For BoilerCarla RodriguesNoch keine Bewertungen

- Reducing Steam Header PressureDokument1 SeiteReducing Steam Header Pressuresj_scribdNoch keine Bewertungen

- Sulphuric Acid PlantsDokument16 SeitenSulphuric Acid PlantsSekar.SNoch keine Bewertungen

- Super Critical BoilerDokument46 SeitenSuper Critical BoilerParveen NakwalNoch keine Bewertungen

- Boiler Feed Water Specifications - Specifications of Boiler WaterDokument9 SeitenBoiler Feed Water Specifications - Specifications of Boiler WaterJean YureNoch keine Bewertungen

- Boiler CirculationDokument7 SeitenBoiler CirculationaruntpeNoch keine Bewertungen

- Pi Bond Collodial Silica in Power Plant Water ChemistryDokument4 SeitenPi Bond Collodial Silica in Power Plant Water Chemistryak_thimiriNoch keine Bewertungen

- Wet Lay Up in BoilerDokument5 SeitenWet Lay Up in BoilersprotkarNoch keine Bewertungen

- Water Treatment Training Dakhni Expansion Project P J Sulfur Recovery UnitDokument15 SeitenWater Treatment Training Dakhni Expansion Project P J Sulfur Recovery Unitnasir_engrNoch keine Bewertungen

- Sully: The Untold Story Behind the Miracle on the HudsonVon EverandSully: The Untold Story Behind the Miracle on the HudsonBewertung: 4 von 5 Sternen4/5 (103)

- The Future of Geography: How the Competition in Space Will Change Our WorldVon EverandThe Future of Geography: How the Competition in Space Will Change Our WorldBewertung: 4 von 5 Sternen4/5 (6)

- The Fabric of Civilization: How Textiles Made the WorldVon EverandThe Fabric of Civilization: How Textiles Made the WorldBewertung: 4.5 von 5 Sternen4.5/5 (58)

- Hero Found: The Greatest POW Escape of the Vietnam WarVon EverandHero Found: The Greatest POW Escape of the Vietnam WarBewertung: 4 von 5 Sternen4/5 (19)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterVon EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNoch keine Bewertungen

- System Error: Where Big Tech Went Wrong and How We Can RebootVon EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootNoch keine Bewertungen

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationVon EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationBewertung: 4.5 von 5 Sternen4.5/5 (46)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureVon EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureBewertung: 5 von 5 Sternen5/5 (125)

- The End of Craving: Recovering the Lost Wisdom of Eating WellVon EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellBewertung: 4.5 von 5 Sternen4.5/5 (83)

- Pale Blue Dot: A Vision of the Human Future in SpaceVon EverandPale Blue Dot: A Vision of the Human Future in SpaceBewertung: 4.5 von 5 Sternen4.5/5 (588)

- Four Battlegrounds: Power in the Age of Artificial IntelligenceVon EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceBewertung: 5 von 5 Sternen5/5 (5)

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachVon EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachBewertung: 3.5 von 5 Sternen3.5/5 (6)

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreVon EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreBewertung: 4.5 von 5 Sternen4.5/5 (33)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestVon EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestBewertung: 4 von 5 Sternen4/5 (28)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaVon EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNoch keine Bewertungen

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyVon EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNoch keine Bewertungen

- Mini Farming: Self-Sufficiency on 1/4 AcreVon EverandMini Farming: Self-Sufficiency on 1/4 AcreBewertung: 4 von 5 Sternen4/5 (76)

- Packing for Mars: The Curious Science of Life in the VoidVon EverandPacking for Mars: The Curious Science of Life in the VoidBewertung: 4 von 5 Sternen4/5 (1396)

- Highest Duty: My Search for What Really MattersVon EverandHighest Duty: My Search for What Really MattersNoch keine Bewertungen

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (54)

- The Book of the Moon: A Guide to Our Closest NeighborVon EverandThe Book of the Moon: A Guide to Our Closest NeighborBewertung: 4.5 von 5 Sternen4.5/5 (11)

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)