Beruflich Dokumente

Kultur Dokumente

Line Follower

Hochgeladen von

Sruthi PsOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Line Follower

Hochgeladen von

Sruthi PsCopyright:

Verfügbare Formate

LINE FOLLOWER ROBOT

ACKNOWLEDGEMENT

Words are of few to express our gratitude to those forces in making this effort a success with their splendid support and guidance rendered to us. We would like to thank everybody who played a part in making this project happen and spent their valuable time effort. We express our deep sense of gratitude and sincere thanks to those who helped us in developing this project LINE FOLLOWER ROBOT . It is impossible To point out or classify assistance provided by each and everyone. However small assistance,it is the feeling that matter and not the values. We have extreme pleasure in acknowledging the service and corporation rendered by our PRINCIPAL, HOD of ECE Dept. & Our coordinators teacher Mrs. Nisha S, Mrs.Pournamy S, Mr.Arunlal & Mr. Sreehari S. We take immense pleasure in thanking the our parents &friends for their help and corporation through out the preparation and completion of our project LINE FOLLOWER ROBOT. We express our heartiest gratitude towards all who have assisted us in all possible ways for smooth conduct of our project . Especially we would like to thank our teacher Mrs. Nisha S for her immense help in developing this project. Finally we extend our sincere thanks to staff of the ECE Dept. and other staff of the institution for the help provided for the project.

Dept. of ECE, VKCET

LINE FOLLOWER ROBOT

ABSTRACT

In this project work, we attempt to construct a small and simple line follower robot, which uses a sensor, a pwm unit & motor unit to follow a path, the path can be visible like a black line on a white surface (or vice-versa) or it can be invisible like a magnetic field. The primary aim of this project is to learn in details about how a sensor senses a line on the path and to understand to concepts involved in the making of a line follower. The secondary aim is to fabricate a simple circuit model to show how the system works. The main activities involved in this project are the search done on how the line follower robot works, sketching a detailed circuit of the gates, programming & then fabrication of circuit and finally the product.

We were able to learn a lot from this project such as team work, innovation & concept staught in class into a practical object.

Dept. of ECE, VKCET

LINE FOLLOWER ROBOT

CONTENTS

SL.NO. NO.

1.

CHAPTER

PAGE 01 01 02 02 02 02 03 04 07 08 11 11 12 13 16 16 17 19 23 24 26 27

INTRODUCTION 1.1.ABOUT LINE FOLLOWER 1.2.NEED FOR BUILDING LINE FOLLOWER 1.3.DIFFERENT TYPES OF LINE FOLLOWER 1.4.BACK GROUND 1.5.PRE-REQUISITES

2.

BLOCK DIAGRAM 2.1.BLOCK DIAGRAM DESCRIPTION CIRCUIT DIAGRAM 3.1.CIRCUIT DIAGRAM DESCRIPTION DETAILED COMPONENT DESCRIPTION 4.1. LM 747 4.2. uA741 4.3. NE555 4.4. IRF520 4.5. REFLECTIVE SENSOR 4.6. 7805 VOLTAGE REGULATOR 4.7. ZENER DIODE 4.8. CAPACITORS 4.9. RESISTORS 4.10.9 V DC MOTOR 4.11.5 K VARIABLE

3.

4.

5.

WORKING

Dept. of ECE, VKCET

LINE FOLLOWER ROBOT

SL.NO .

6. 7. 8. 9.

CHAPTER 30 34

PAGE

PCB PREPARATION COMPONENTS LIST APPLICATION CONCLUSION 11.1. CIRCUIT DIAGRAM 11.2. CIRCUIT SCHEMATIC 11.3. COMPONENT LAYOUT 11.3. SOLDERING LAYER 11.4. PCB LAYOUT

35 36

10. APPENDIX

11. DATA SHEET 12. REFERENCE

Dept. of ECE, VKCET

LINE FOLLOWER ROBOT

CHAPTER 1 INTRODUCTION

1.1. LINE FOLLOWER ROBOT

The line follower is a self operating robot that detects and follows a line that is drawn on the floor. The path consists of a black line on a white surface ( or it may be reverse of that ) or it can be invisible like a magnetic field. The control system used must sense a line and maneuver the robot to stay on course. The robot is designed to follow black lines. The path is a black line on a white background with width of 3 cm (except at bends where a little variation may be present).

Dept. of ECE, VKCET

LINE FOLLOWER ROBOT

1.2.NEED FOR BUILDING LINE FOLLOWER Sensing a line and maneuvering the robot to stay on course, while constantly correcting wrong moves using feedback mechanism forms a simple yet effective closed loop system. As a programmer you get an opportunity to teach the robot how to follow the line thus giving it a human-like property of responding to stimuli.

Practical applications of a line follower : Automated cars running on roads with embedded magnets; guidance system for industrial robots moving on shop floor etc.

1.3.TYPES OF LINE FOLLOWER

1. Sandwich 2. Sweet 3. Kabo

1.4. BACK GROUND

Line following robots have been around for years, so many people have had chances to attack this sort of problem. Line following robots can be very basic or very sophisticated depending on the hardware used, efficiency wanted, and programming capabilities. In the history of line following robots the differential steering system is the most widely used way of keeping the robot on course. Infrared (IR) sensors are used more frequently in line following robots then any other sensor.

1.5. PRE-REQUISITES

Knowledge of basic digital and analog electronics. (A course on Digital Design and Electronic Devices & Circuits would be helpful)

CHAPTER 2

Dept. of ECE, VKCET 6

LINE FOLLOWER ROBOT

BLOCK DIAGRAM

PWM CIRCUIT DC MOTOR

SENSO R CIRCUIT

I-V CONVERTER

Dept. of ECE, VKCET

LINE FOLLOWER ROBOT

2.1. BLOCK DIAGRAM DESCRIPTION

1. SENSOR CIRCUIT IR reflective sensors have one emitter (IR LED) and one receiver (PhotoTransistor or photo diode.If we have white surface it reflects the light and it will sensed by the receiver,similarly if we have black surface it absorbs the light and receiver can not sense light .

Dept. of ECE, VKCET

LINE FOLLOWER ROBOT

When a light emitted from the diode is reflected off an object and back into the phototransistor, output current is produced, depending on the amount of infrared light, which triggers the base current of the phototransistor. In this case, the amount of light reflected off a black line is much less than that of a white background, so we can detect the black line somehow by measuring the current. (This current is converted to voltage.)

2. I-V CONVERTER The current developed on account of the amount of light reflected off a black line is converted into voltage by the use of an IC LM 747 as voltage converter and an amplifier.

3. PWM CIRCUIT This circuit consists of two parts: PWM (Pulse Width Modulation) part and a sensor part. First, we take a look at the sensor part. The photodiode turns on the phototransistor and then the output current is converted to output voltage through the first op-amp circuit. The R6 is a variable resistor, so that we can tune the scale of output voltage. The second op-amp circuit is added to change the polarity of voltage. (Positive CV is necessary later.) One thing we should know is that Vcc to Vcc of voltage rail is needed, not from 0 to Vcc. In the circuit built-up, LM747 Dual Operational Amplifiers were used. Second, in the PWM section, two 555 timers (LM555) are used to produce a pulsewidth modulated train of pulses. The timer on the left works in astable mode to generate regular square-wave pulses. The frequency is fixed by the values of R1, R2 and C1 here. Then, this output Q1 is connected to the trigger pin of the second timer that works in monostable mode this time. As you can see in the diagram, at a falling edge of Q1, a pulse is triggered and stays

Dept. of ECE, VKCET

LINE FOLLOWER ROBOT

high during some time. The time (width of a pulse) is purely determined by the value of R3 and C3 if CV (Control Voltage) pin is not connected at all. (Look at the pulse diagrams of Q1 and Q2 at the bottom of the circuit diagram.) CV plays a role of changing the threshold level of a timer. (Without CV, threshold = 2/3 * Vcc) CV just becomes the triggering voltage level. Therefore, the higher the CV is, the longer it takes time until discharge. In this way, the duty cycle of output pulses Q2 can be controlled. Back to my circuit, the output voltage of the sensor part provides CV. For instance, if any sensor senses a black line, the current from the photodiode decreases, the CV drops, the duty cycle gets low and the motor slows down. Third, the PWM pulses are supplied to the gate of a power MOSFET (IRF520) to switch the DC motor on and off. Then, the DC motor only sees the average voltage proportional to the duty cycle of the pulses. When CV is high, so is the duty cycle and the motor turns fast. In this robot, the distance between sensors and the ground is fixed. So, when a sensor is off the black line (The sensor sees white paper.), CV keeps its maximum value and both motors keep turning in a constant speed. As soon as the sensor enters the black line part, CV drops down and thus duty cycle decreases, which means the slowdown of a wheel.

DC MOTOR Instead of applying a constant voltage across a DC motor, we repeat switching on and off the motor with a fixed voltage (Vcc) applied to the motor. This is done by sending a train of PWM (Pulse Width Modulation) pulses to a power MOSFET in order to turn it on and off. Then, the motor sees the average voltage while it depends on duty cycle of PWM pulses. The speed of rotation is proportion to this average voltage. By PWM method, its easier to control the DC motor than by directly controlling the voltage across it. All we have to do is to modulate pulse width, in order words, a duty cycle. Also, a power MOSFET consumes only negligible power in switching.

Dept. of ECE, VKCET

10

LINE FOLLOWER ROBOT

CHAPTER 3 CIRCUIT DIAGRAM

Dept. of ECE, VKCET

11

LINE FOLLOWER ROBOT

3.1. CIRCUIT DIAGRAM DESCRIPTION

Circuit consists of two parts: PWM (Pulse Width Modulation) part an d a sensor part. The sensor part , photodiode turns on the phototransistor and then the output current is converted to output voltage through the first op -amp circuit. added to change the polarity of Amplifiers were used. Second, in the PWM section, two 555 timers (L M555) are used to produce a pulse - width modulated train of pulses. The timer on the le ft works in a s table mode to generate regular Square- wave pulses. The frequency is fixed by the values of R1, R2 and C1 here. Then, this output Q1 is connected to the trigger pin of the second timer that works in monostable mode this time. As you can see in the diagram, at a falling edge of Q1, a pulse is triggered and stays high during some time. The time (width of a pulse) is purely determined by the value of R3 and C3 if CV (Control Voltage) pin is not connected at all. CV play s a role of changing the threshold level of a timer . CV just becomes the triggering voltage level. Therefore, the higher the CV is, the longer it takes time until discharge. In t his way, t h e duty cycle of output pulses Q2 can be controlled. In the circuit, the output voltage of the sensor part provides CV. For instance, if any sensor senses a black line, the current from the photodiode decreases, the CV drop s, the dut cycle gets low and the motor slows down. Third, the PWM pulses are supplied to the gate of a power MOSFET (IRF520) to the switch the DC motor on and off. Then, the DC motor only sees the average to the and duty cycle of the pulses. When CV is high, so is the motor turns fast. duty cycle voltage proportional The R 6 is a variable Operational resistor, so that we can tune the scale of output voltage. The second op-amp circuit is voltage. In the circuit , LM747 Dual

In my robot, the distance between sensors and the ground is fixed. So, when a sensor is off the black line (The sensor sees white paper. ), CV keeps its maximum value and

Dept. of ECE, VKCET 12

LINE FOLLOWER ROBOT

both motors keep turning in a constant speed. As soon as the sensor enters the black line part, CV drops down and thus duty cycle decreases, which means the slowdown of a wheel.

A sensor is a device which measures a physical quantity and converts it into a signal which can be read by an observer or by an instrument. They are used to provide feedback from the external environment

Dept. of ECE, VKCET

13

LINE FOLLOWER ROBOT

Dept. of ECE, VKCET

14

LINE FOLLOWER ROBOT

CHAPTER 4 DETAILED COMPONENT DESCRIPTION

3.1. LM 747

Dual Operational Amplifier Features No frequency compensation required Short-circuit protection Wide common-mode and differential voltage ranges Low power consumption No latch-up Balanced offset null

The LM747 is a general purpose dual operational amplifier. The two amplifiers share a common bias network and power supply leads. Otherwise, their operation is completely independent. Additional features of the LM747 are: no latch-up when input common mode range is exceeded, freedom from oscillations, and package flexibility. The LM747C/LM747E is identical to the LM747/LM747A except that the LM747C/LM747E has its specifications guaranteed over the temperature range from 0C to +70C instead of -55C to +125C.

Dept. of ECE, VKCET

15

LINE FOLLOWER ROBOT

3.2.

uA 741

OPERATIONAL AMPLIFIER

An operational amplifier ("op-amp") is a DC-coupled high-gain electronic voltage amplifier with a differential input and, usually, a single-ended output. An opamp produces an output voltage that is typically hundreds of thousands times larger than the voltage difference between its input terminals. Op-amps are among the most widely used electronic devices today, being used in a vast array of consumer, industrial, and scientific devices. Many standard IC op-amps cost only a few cents in moderate production volume; however some integrated or hybrid operational amplifiers with special performance specifications may cost over $100 US in small quantities. Op-amps may be packaged as components, or used as elements of more complex integrated circuits. The op-amp is one type of differential amplifier. Other types of differential amplifier include the fully differential amplifier (similar to the op-amp, but with two outputs), the instrumentation amplifier (usually built from three op-amps), the isolation amplifier (similar to the instrumentation amplifier, but with tolerance to common-mode voltages that would destroy an ordinary op-amp), and negative feedback amplifier (usually built from one or more op-amps and a resistive feedback network).

CIRCUIT NOTATION

Dept. of ECE, VKCET

16

LINE FOLLOWER ROBOT

Circuit diagram symbol for an op-amp The circuit symbol for an op-amp is shown, where: : Non-inverting input : inverting input : Output : Positive power supply : Negative power supply The power supply pins ( and ) can be labeled in different ways. Despite

different labeling, the function remains the same to provide additional power for amplification of the signal. Often these pins are left out of the diagram for clarity, and the power configuration is described or assumed from the circuit.

3.3.

NE 555

The 555 timer IC is an integrated circuit (chip) used in a variety of timer, pulse generation, and oscillator applications. The 555 can be used to provide time delays, as an oscillator, and as a flip-flop element. Derivatives provide up to four timing circuits in one package.

Dept. of ECE, VKCET 17

LINE FOLLOWER ROBOT

Introduced in 1971 by Signetics, the 555 is still in widespread use, thanks to its ease of use, low price and good stability, and is now made by many companies in the original bipolar and also in low-power CMOS types. As of 2003, it was estimated that 1 billion units are manufactured every year.[1]

Pinout diagram

The connection of the pins for a DIP package is as follows: Pin Name 1 2 3 GND TRIG OUT Ground, low level (0 V) OUT rises, and interval starts, when this input falls below 1/3 VCC. This output is driven to +VCC or GND.

18

Purpose

Dept. of ECE, VKCET

LINE FOLLOWER ROBOT

4 5 6 7 8

RESET A timing interval may be interrupted by driving this input to GND. CTRL "Control" access to the internal voltage divider (by default, 2/3 VCC). THR DIS The interval ends when the voltage at THR is greater than at CTRL. Open collector output; may discharge a capacitor between intervals.

V+, VCC Positive supply voltage is usually between 3 and 15 V.

The 555 has three operating modes:

Monostable mode: in this mode, the 555 functions as a "one-shot" pulse generator. Applications include timers, missing pulse detection, bouncefree switches, touch switches, frequency divider, capacitance measurement, pulsewidth modulation (PWM) and so on.

Astable: free running mode: the 555 can operate as an oscillator. Uses include LED and lamp flashers, pulse generation, logic clocks, tone generation, security alarms, pulse position modulation and so on. Selecting a thermistor as timing resistor allows the use of the 555 in a temperature sensor: the period of the output pulse is determined by the temperature. The use of a microprocessor based circuit can then convert the pulse period to temperature, linearize it and even provide calibration means.

Bistable mode or Schmitt trigger: the 555 can operate as a flip-flop, if the DIS pin is not connected and no capacitor is used. Uses include bounce-free latched switches.

3.4.

IRF 520

Power MOSFET: This N-Channel enhancement mode silicon gate power fieldeffect transistor is and advanced power MOSFET designed,tested, and guaranteed to withstand a specified level ofenergy in the breakdown avalanche mode of operation. All of these power

Dept. of ECE, VKCET 19

LINE FOLLOWER ROBOT

MOSFETs are designed for applications suchas switching regulators, switching convertors, motor drivers,relay drivers, and drivers for high power bipolar switching transistors requiring high speed and low gate drive power.These types can beoperated directly from integratedcircuits. Formerly developmental type TA09594.

3.5.

REFLECTIVE SENSOR

IR reflective sensors have one emitter (IR LED) and one receiver (PhotoTransistor or photo diode.If we have white surface it reflects the light and it will sensed by the receiver,similarly if we have black surface it absorbs the light and receiver can not sense light .

Dept. of ECE, VKCET

20

LINE FOLLOWER ROBOT

When a light emitted from the diode is reflected off an object and back into the phototransistor, output current is produced, depending on the amount of infrared light, which triggers the base current of the phototransistor. In this case, the amount of light reflected off a black line is much less than that of a white background, so we can detect the black line somehow by measuring the current. (This current is converted to voltage.)

3.6.

7805 VOLTAGE REGULATOR

The 7805 voltage regulators employ built-in current limiting, thermal shutdown, and safe-operating area protection which make them virtually immune to damage from output overloads. 7805 is a three-terminal positive voltage regulator. With adequate heat sinking, it can deliver in excess of 0.5A output current. Typical applications would include local (on-card) regulators which can eliminate the noise and degraded performance associated with single-point regulation

7805 regulator comes from the 78xx family of self-contained fixed linear voltage regulator integrated circuits. The 78xx family is a very popular choice for many electronic circuits which require a regulated power supply, due to their ease of use and relative cheapness. When specifying individual ICs within this family, the xx is replaced with a two-digit number, which indicates the output voltage the particular

Dept. of ECE, VKCET 21

LINE FOLLOWER ROBOT

device is designed to provide (for example, the 7805 voltage regulator has a 5 volt output, while the 7812 produces 12 volts). The 78xx line are positive voltage regulators, meaning that they are designed to produce a voltage that is positive relative to a common ground. There is a related line of 79xx devices which are complementary negative voltage regulators. 78xx and 79xx ICs can be used in combination to provide both positive and negative supply voltages in the same circuit, if necessary Pin No 1 2 3 Function Input voltage (5V-18V) Ground (0V) Regulated output; 5V (4.8V-5.2V) Name Input Ground Output

7805 series ICs have built-in protection against a circuit drawing too much power. They also have protection against overheating and short-circuits, making them quite robust in most applications. In some cases, the current-limiting features of the 7805 devices can provide protection not only for the 7805 itself, but also for other parts of the circuit it is used in, preventing other components from being damaged as well.

3.7.

ZENER DIODE

A zener diode is a special kind of diode which allows current to flow in the forward direction in the same manner as an ideal diode, but will also permit it to flow in the reverse direction when the voltage is above a certain value known as the breakdown voltage, "zener knee voltage" or "zener voltage." The device was named after Clarence Zener, who discovered this electrical property. Many diodes described as "zener" diodes rely instead on avalanche breakdown as the mechanism. Both types are used. Common applications include providing a reference voltage for voltage regulators, or to protect other semiconductor devices from momentary voltage pulses.

Dept. of ECE, VKCET

22

LINE FOLLOWER ROBOT

OPERATION A conventional solid-state diode will not allow significant current if it is reversebiased below its reverse breakdown voltage. When the reverse bias breakdown voltage is exceeded, a conventional diode is subject to high current due to avalanche breakdown. Unless this current is limited by circuitry, the diode will be permanently damaged due to overheating. A zener diode exhibits almost the same properties, except the device is specially designed so as to have a greatly reduced breakdown voltage, the so-called zener voltage. By contrast with the conventional device, a reverse-biased zener diode will exhibit a controlled breakdown and allow the current to keep the voltage across the zener diode close to the zener breakdown voltage. For example, a diode with a zener breakdown voltage of 3.2 V will exhibit a voltage drop of very nearly 3.2 V across a wide range of reverse currents. The zener diode is therefore ideal for applications such as the generation of a reference voltage (e.g. for an amplifier stage), or as a voltage stabilizer for low-current applications.[1] Another mechanism that produces a similar effect is the avalanche effect as in the avalanche diode. [1] The two types of diode are in fact constructed the same way and both effects are present in diodes of this type. In silicon diodes up to about 5.6 volts, the zener effect is the predominant effect and shows a marked negative temperature coefficient. Above 5.6 volts, the avalanche effect becomes predominant and exhibits a positive temperature coefficient.[2] In a 5.6 V diode, the two effects occur together and their temperature coefficients nearly cancel each other out, thus the 5.6 V diode is the component of choice in temperature-critical applications. Modern manufacturing techniques have produced devices with voltages lower than 5.6 V with negligible temperature coefficients, but as higher voltage devices are encountered, the temperature coefficient rises dramatically. A 75 V diode has 10 times the coefficient of a 12 V diode.

Dept. of ECE, VKCET 23

LINE FOLLOWER ROBOT

All such diodes, regardless of breakdown voltage, are usually marketed under the umbrella term of "zener diode". Uses

Zener diode shown with typical packages. Reversecurrent

is shown.

Zener diodes are widely used as voltage references and as shunt regulators to regulate the voltage across small circuits. When connected in parallel with a variable voltage source so that it is reverse biased, a zener diode conducts when the voltage reaches the diode's reverse breakdown voltage. From that point on, the relatively low impedance of the diode keeps the voltage across the diode at that value.[3]

In this circuit, a typical voltage reference or regulator, an input voltage, UIN, is regulated down to a stable output voltage UOUT. The breakdown voltage of diode D is stable over a wide current range and holds UOUT relatively constant even though the input voltage may fluctuate over a fairly wide range. Because of the low impedance of the diode when operated like this, resistor R is used to limit current through the circuit.

Dept. of ECE, VKCET 24

LINE FOLLOWER ROBOT

In the case of this simple reference, the current flowing in the diode is determined using Ohm's law and the known voltage drop across the resistor R. IDiode = (UIN - UOUT) / R The value of R must satisfy two conditions:

1.

R must be small enough that the current through D keeps D in reverse

breakdown. The value of this current is given in the data sheet for D. For example, the common BZX79C5V6[4] device, a 5.6 V 0.5 W zener diode, has a recommended reverse current of 5 mA. If insufficient current exists through D, then UOUT will be unregulated, and less than the nominal breakdown voltage (this differs to voltage regulator tubes where the output voltage will be higher than nominal and could rise as high as UIN). When calculating R, allowance must be made for any current through the external load, not shown in this diagram, connected across UOUT.

2.

R must be large enough that the current through D does not destroy the

device. If the current through D is ID, its breakdown voltage VBand its maximum power dissipation PMAX, then .

A load may be placed across the diode in this reference circuit, and as long as the zener stays in reverse breakdown, the diode will provide a stable voltage source to the load. Zener diodes in this configuration are often used as stable references for more advanced voltage regulator circuits.

Shunt regulators are simple, but the requirements that the ballast resistor be small enough to avoid excessive voltage drop during worst-case operation (low input voltage concurrent with high load current) tends to leave a lot of current flowing in the diode much of the time, making for a fairly wasteful regulator with high quiescent power dissipation, only suitable for smaller loads.

These devices are also encountered, typically in series with a base-emitter junction, in transistor stages where selective choice of a device centered around the avalanche or

Dept. of ECE, VKCET 25

LINE FOLLOWER ROBOT

zener point can be used to introduce compensating temperature co-efficient balancing of the transistor PN junction. An example of this kind of use would be a DC error amplifier used in a regulated power supply circuit feedback loop system. Zener diodes are also used in surge protectors to limit transient voltage spikes. Another notable application of the zener diode is the use of noise caused by its avalanche breakdown in a random number generator that never repeats.

3.8.

CAPACITORS

A capacitor (formerly known as condenser) is a device for storing electric charge. The forms of practical capacitors vary widely, but all contain at least two conductors separated by a non-conductor. Capacitors used as parts of electrical systems, for example, consist of metal foils separated by a layer of insulating film. A capacitor is a passive electronic component consisting of a pair of conductors separated by a dielectric (insulator). When there is a potential difference (voltage) across the conductors, a static electric field develops across the dielectric, causing positive charge to collect on one plate and negative charge on the other plate. Energy is stored in the electrostatic field. An ideal capacitor is characterized by a single constant value, capacitance, measured in farads. This is the ratio of the electric charge on each conductor to the potential difference between them.

Capacitors are widely used in electronic circuits for blocking direct current while allowing alternating current to pass, in filter networks, for smoothing the output of power supplies, in the resonant circuits that tune radios to particular frequencies and for many other purposes.

Dept. of ECE, VKCET 26

LINE FOLLOWER ROBOT

The capacitance is greatest when there is a narrow separation between large areas of conductor; hence capacitor conductors are often called "plates", referring to an early means of construction. In practice the dielectric between the plates passes a small amount of leakage current and also has an electric field strength limit, resulting in a breakdown voltage, while the conductors and leads introduce an undesired inductance and resistance

3.9.

RESISTORS

A resistor is a passive two-terminal electrical component that implements electrical resistanceas a circuit element. The current through a resistor is in direct proportion to the voltage across the resistor's terminals. Thus, the ratio of the voltage applied across a resistor's terminals to the intensity of current through the circuit is called resistance. This relation is represented by Ohm's law:

Fig:Resistor where I is the current through the conductor in units of amperes, V is the potential difference measured across the conductor in units of volts, and R is the resistance of the conductor in units of ohms. More specifically, Ohm's law states that the R in this relation is constant, independent of the current. Resistors are common elements of electrical networks and electronic circuits and are ubiquitous in electronic equipment. Practical resistors can be made of various compounds and films, as well as resistance wire (wire made of a high-resistivity alloy, such as nickel-chrome). Resistors are also implemented within integrated circuits, particularly analog devices, and can also be integrated into hybrid and printed circuits.

Dept. of ECE, VKCET

27

LINE FOLLOWER ROBOT

The electrical functionality of a resistor is specified by its resistance: common commercial resistors are manufactured over a range of more than nine orders of magnitude. When specifying that resistance in an electronic design, the required precision of the resistance may require attention to the manufacturing tolerance of the chosen resistor, according to its specific application. The temperature coefficient of the resistance may also be of concern in some precision applications. Practical resistors are also specified as having a maximum power rating which must exceed the anticipated power dissipation of that resistor in a particular circuit: this is mainly of concern in power electronics applications. Resistors with higher power ratings are physically larger and may require heat sinks. In a high-voltage circuit, attention must sometimes be paid to the rated maximum working voltage of the resistor. Practical resistors have a series inductance and a small parallel capacitance; these specifications can be important in high-frequency applications. In a low-noise amplifier or pre-amp, the noise characteristics of a resistor may be an issue. The unwanted inductance, excess noise, and temperature coefficient are mainly dependent on the technology used in manufacturing the resistor. They are not normally specified individually for a particular family of resistors manufactured using a particular technology.[1] A family of discrete resistors is also characterized according to its form factor, that is, the size of the device and the position of its leads (or terminals) which is relevant in the practical manufacturing of circuits using them.

3.10.

9 V DC MOTOR

As the name suggests, a motor which uses a DC (Direct Current) power Can run in both directions Speed Controllable DC Motors are highspeed, low-torque devices.

Dept. of ECE, VKCET

28

LINE FOLLOWER ROBOT

3.11.

5 K VARIABLE(POT)

A common element in electronic devices is a three-terminal resistor with a continuously adjustable tapping point controlled by rotation of a shaft or knob. These variable resistors are known as potentiometers when all three terminals are present, since they act as a continuously adjustable voltage divider. A common example is a volume control for a radio receiver. Accurate, high-resolution panel-mounted potentiometers (or "pots") have resistance elements typically wire wound on a helical mandrel, although some include a conductive-plastic resistance coating over the wire to improve resolution. These typically offer ten turns of their shafts to cover their full range. They are usually set with dials that include a simple turns counter and a graduated dial. Electronic analog

Dept. of ECE, VKCET 29

LINE FOLLOWER ROBOT

computers used them in quantity for setting coefficients, and delayed-sweep oscilloscopes of recent decades included one on their panels.

Dept. of ECE, VKCET

30

LINE FOLLOWER ROBOT

CHAPTER 5 WORKING

The robot has two sensors installed underneath the front part of the body, and two DC motors drive wheels moving forward. A circuit inside takes an input signal from two sensors and controls the speed of wheels rotation. The control is done in such a way that w hen a sensor senses a black line, the motor slows down or even stops. Then the difference of rotation speed makes it possible to make turns. F o r instance, in the figure on the right, if the sensor somehow senses a black line, the wheel on that side slows down an d the robot will make a right turn.

The basic operations of the line follower are as follows:

1.

Capture line position with optical sensor s mounted at front end of the

robot. For this a combination of IR LEDs and Photo Transistor called an opto-couple is used . The line sensing process requires high resolution and high robustness. 2. Steer robot to track the line with any steering mechanism. To achieve this we use two motors governing wheels motion.

The photodiode turns on the phototransistor and then the output current is converted to output voltage through the first op -amp circuit. added to change the polarity of voltage. In the PWM section, two 555 timers (L M555) are used to produce a pulse width modulated train of pulses. The timer on the left works in astable mode to generate regular Square- wave pulses. The frequency is fixed by the values of R1, R2 and C1 here. Then, this output Q1 is connected to the trigger pin of the second timer

Dept. of ECE, VKCET 31

The R 6 is a variable

resistor, so that we can tune the scale of output voltage. The second op-amp circuit is

LINE FOLLOWER ROBOT

that works in monostable mode this time. As you can see in the diagram, at a falling edge of Q1, a pulse is triggered and stays high during some time. The time (width of a pulse) is purely determined by the value of R3 and C3 if CV (Control Voltage) pin is not connected at all. CV play s a role of changing the threshold level of a timer. CV just becomes the triggering voltage level. Therefore , the higher the CV is, the longer it takes time until discharge. In t his way, t h e duty cycle of output pulses Q2 can be controlled. In the circuit, the output voltage of the sensor part provides CV. For instance, if any sensor senses a black line, the current from the photodiode decreases, the CV drop s, the duty cycle gets low and the motor slows down. Then PWM pulses are supplied to the gate of a power MOSFET (IRF520) to switch the DC motor on and off. Then, the DC motor only sees the average voltage proportional to the duty cycle of the pulses. When CV is high, so is the duty cycle and the motor turns fast. In this robot, the distance between sensors and the ground is fixed. So, when a sensor is off the black line (The sensor sees white paper. ), CV keeps its maximum value and both motors keep turning in a constant speed. As soon as the sensor enters the black line part, CV drops down and thus duty cycle decreases, which means the slowdown of a wheel.

CHAPTER 6 PCB PREPARATION TECHNIQUES

Dept. of ECE, VKCET

32

LINE FOLLOWER ROBOT

You need to generate a positive UV translucent artwork film. You will never get a good artwork, so it is important to get the possibly quality at this stage. The most important thing is to get a clear sharp image with a very solid opaque black. Now a day, artwork is drawn using either a dedicated PCB CAD program or a suitable drawing /graphics package. It is absolutely essential that your PCB software prints holes in the middle of pads, which will act as center marks when drilling. Media Artwork quality is very dependent on both the output device and the media used. It is not necessary to use a transparent artwork medium-as long as it is reasonably translucent to UV, its fine-less translucent materials may need a slightly longer exposure time. Line definitions, black opaqueness and toner/ink retention are much more important. Output Devices Laser printers offer the best all-round solution. These are affordable, fast and good quality. The printer used must have at least 600dpi resolution for all but the simplest PCBs as you will usually working in multiples of 0.06cm. 600dpi divides into 40, so you get consistent spacing and line width. It is very important that the printer produces a good solid black with no toner pinholes. If youre planning to buy a printer for PCB use, do some test prints on tracing paper to check the quality first. If the printer has a density control, set it to the blackest. Photo resist PCB Laminates Always use good quality, pre-coated photo resist fiber glass board. Check carefully for scratches in the protective covering and on the surface after peeling off the covering. You dont need darkroom or subdued lighting when handling boards, as long as you avoid direct sunlight, minimize unnecessary exposure and develop immediately after UV exposure. Exposure

Dept. of ECE, VKCET

33

LINE FOLLOWER ROBOT

The photo resist board needs to be exposed to UV light through the artwork, using a UV exposure box. UV exposures units can easily be made using standard fluorescent lamp ballasts and UV tubes. For small PCBs two or four 8 watt, 30.5cm tubes will be adequate. For larger units, four 38cm tubes are ideal. Developing Does not use sodium hydroxide for developing photo resist laminates. It is a completely and utterly dreadful stuff for developing PCBs. Apart from its causticity, it is very sensitive to both temperature and concentration, and made-up solution doesnt last long. When its too weak it doesnt develop at all, and when too strong it strips all the resist off. It is almost impossible to get reliable and consistent result, especially when making PCBs in an environment with large temperature variations. A much better developer is a silicate-based product that comes as a liquid concentrate. You can leave the board in it for several times the normal developing time without noticeable degradation .This also means that it is not temperature critical no risk of stripping at warmer temperatures. Made- up solution also has a very long shelf-life and lasts until its used up. You can make the solution up really strong for very fast developing. Etching Ferric chloride etchant is a messy stuff, but easily available and cheaper than most alternatives. It attacks any metal including stainless steel. So when setting up a PCB etching area, use a plastic or ceramic sink, with plastic fittings and screws wherever possible, and seal any metal screws with silicone. Copper water pipes may get splashed or dripped-on, so sleeve or cover them in plastic; heat sink sleeving is great if youre installing new pipes. Tin Plating Tin-plating a PCB makes it a lot easier to solder, and is pretty much essential for surface mount boards. Unless you have access to a roller tinning machine, chemical tinning is the only option. Unfortunately, tin-plating chemicals are expensive but the results are usually worth it. If you dont tinplate the board, either leave the photo resist coating on o spray the board with rework flux to prevent the copper from oxidizing.

Dept. of ECE, VKCET 34

LINE FOLLOWER ROBOT

Room temperature tin-plating crystals produce a good finish in a few minutes. There are other tinning chemicals available, some of which require mixing with acid or high temperature use. Drilling If you have fiber glass board, you must use tungsten carbide drill bits. Fiber glass eats normal high speed steel bits very rapidly, although HSS drills are all right for odd larger sizes. Carbide drill bits are expensive and the thin ones snap very easily. When using carbide drill bits below 1mm, you must use a good vertical drill stand, you will break very quickly without one. Carbide drill bits are available as straight-shank or thick shank. In straight shank, the whole bit is the diameter of the hole, and in thick shank, a standard size shank tapers down to the hole size. Cutting A small guillotine is the easiest way to cut fiber glass laminate. Ordinary saws ill be blunted quickly unless these are carbide tipped, and the dust can cause sink irritation. A carbide tail-saw blade in a jig saw might be worth a tray. It is also easy to accidently scratch through protective film when sawing, causing photo resist scratches and broken teaks on finished boards. A sheet metal guillotine is also excellent for cutting boards provided the blade is fairly sharp. To make cut outs, drill a series of small holes, punch out and file to size. Alternatively, use after saw or small hack saw, but be prepared to replace blade often. With practice it is possible to do corner cut outs with a guillotine but you have to be vey careful that you dont over cut. Soldering Soldering is the joining together of two metals to give physical bonding and good electrical conductivity. It is use primarily in electrical and electronic circuitry. Solder is a combination of a metal, which are solid at normal room temperature and became liquid at between 1800 and 2000c. Solder bonds well to varies metals and extremely well to copper. Soldering is a necessary skill you need to learn to successfully build the electronics circuit. It is a primary way how electronics

Dept. of ECE, VKCET 35

LINE FOLLOWER ROBOT

components are connected to circuit boards, and sometimes directly to other components. For soldering we can use the soldering iron.

PCB LAYOUT

CHAPTER 7 COMPONENTS LIST

SL NO.

01 02

COMPONENT NAME

R1 R2

COMPONENT

RESISTOR RESISTOR

36

COMPONENT SPECIFICATION

6 1 K K

Dept. of ECE, VKCET

LINE FOLLOWER ROBOT

03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20

R3 R4 R5 R6 R7 C1 C2 C3 IC1 IC2 IC3 IC4 IC5 IC6 U7 M D1 VCC

RESISTOR RESISTOR RESISTOR VARIABLE RESISTOR RESISTOR CAPACITOR CAPACITOR CAPACITOR NE 555 NE 555 IRF 520 LM 747 uA 741 7805 REFLECTIVE SENSOR MODULE DC MOTOR ZENER DIODE BATTERY

20 K 10 K 82 K 5 K

2.2 K 1 uF

0.1 uF 0.1 uF TIMER IC TIMER IC NPN MOSFET DUAL OP-AMP OP-AMP REGULATOR

9V 9V 9V

CHAPTER 8 APPLICATIONS

Automated cars running on roads with embedded magnets; guidance system for industrial robots moving on shop floor etc. It can act as maze solver. Basically it follows a line, therefore it can be used in mining where the robots are used to find the way out of the mine.

Dept. of ECE, VKCET

37

LINE FOLLOWER ROBOT

If we implement a robotic arm along with the line follower then it can be used to pick and place the objects in its way and can be very useful in our day to day life.

Apparatus to control the automatic placing of material along a junction between surfaces with reference to the form and position of the junction including a tool controllably movable to deposit material progressively along the junction in response to a control signal.

An imager linked to the movement of the tool to produce an image of the surfaces.

By modifying the position of the sensors, same principle can be used in obstacle avoidance and edge detection

CHAPTER 9 CONCLUSION

The aim of the project is to make a LINE FOLLOWER ROBOT. For this project we use IC 7805, uA 741 , LM 747,NE 555 and IRF 520. This circuit is very stable and can be repeatedly used for many times without any failure. The mini project was successful.

Dept. of ECE, VKCET

38

LINE FOLLOWER ROBOT

CHPTER 10 APPENDIX

10.1. CIRCUIT DIAGRAM

Dept. of ECE, VKCET

39

LINE FOLLOWER ROBOT

Dept. of ECE, VKCET

40

LINE FOLLOWER ROBOT

10.2.

CIRCUIT SCHEMATIC

Dept. of ECE, VKCET

41

LINE FOLLOWER ROBOT

10.3. COMPONENT LAYER

10.3. SOLDER LAYER

Dept. of ECE, VKCET 42

LINE FOLLOWER ROBOT

10.4. PCB LAYOUT

Dept. of ECE, VKCET

43

LINE FOLLOWER ROBOT

CHAPTER 11 DATA SHEET

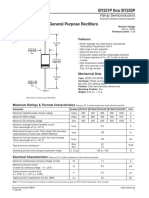

11.1. LM 747

Dept. of ECE, VKCET 44

LINE FOLLOWER ROBOT

11.2. uA 741 11.3. NE 555 11.4. IRF 520 11.5. IC 7805

Dept. of ECE, VKCET

45

LINE FOLLOWER ROBOT

BIBLIOGRAPHY

http://www.wrighthobbies.net/bots/mini/mini.htm http://anusorn.sirin.ac.th/file.php/1/NEWS/building-a-line-following-robot.pdf http://www.robotroom.com/Sandwich.html http://www.kmitl.ac.th/~kswichit/ROBOT/Follower.pdf http://online.physics.uiuc.edu/courses/phys405/P405_Projects/Fall2005/Robot_ project_jaseung_.pdf http://robotika.yweb.sk/skola/AVR/visionrobo%20com/Line%20Follower %20tutorial%20v1.1.pdf Linear Integrated Circuits- D Roy Choudhary & S .B . Jain- 3 Age Techno Pub;lications

rd

Edition- New

Dept. of ECE, VKCET

46

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Journal of Alloys and Compounds: Wei Li, Zhijun Xu, Ruiqing Chu, Peng Fu, Guozhong ZangDokument4 SeitenJournal of Alloys and Compounds: Wei Li, Zhijun Xu, Ruiqing Chu, Peng Fu, Guozhong ZangSamah SamahNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- JY01 V3.5 2018-EnglishDokument12 SeitenJY01 V3.5 2018-Englishveerakumars100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Application Manua: RX-8801SA/JEDokument34 SeitenApplication Manua: RX-8801SA/JEildefonsoNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Edc QB Final LatestDokument15 SeitenEdc QB Final LatestrajeshadktNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Vlsi SyllabusDokument3 SeitenVlsi SyllabusmadhurNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- BY251P Thru BY255P: FeaturesDokument2 SeitenBY251P Thru BY255P: Featureskwagga125Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Band Theory-1 PDFDokument65 SeitenBand Theory-1 PDFKamaljit RajkumarNoch keine Bewertungen

- Electrical Fault FindingDokument4 SeitenElectrical Fault FindingAlexTrantranBertranNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- (Dennis L. Feucht) Transistor Amplifiers PDFDokument439 Seiten(Dennis L. Feucht) Transistor Amplifiers PDFspyeagleNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Quotation CT PT VCB SF6 HT Panel Isolator DO Fuse Set AB Switch Horn Gap Transmission LineDokument11 SeitenQuotation CT PT VCB SF6 HT Panel Isolator DO Fuse Set AB Switch Horn Gap Transmission LineShokautNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Koehler ADokument126 SeitenKoehler AKavita UpadhyayNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Seminar Presentation ONDokument16 SeitenSeminar Presentation ONanon_486451846Noch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Chapter8 CompleteDokument39 SeitenChapter8 CompletegrieverslhNoch keine Bewertungen

- Physics Semiconductors Project PDFDokument25 SeitenPhysics Semiconductors Project PDFAman BindNoch keine Bewertungen

- Furneaux Riddall Catalogue 2017Dokument120 SeitenFurneaux Riddall Catalogue 2017Martin SmithNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- MEMRISTOR 473 UnsecureDokument32 SeitenMEMRISTOR 473 UnsecureFaiz AhmedNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- AIC Selection GuideDokument7 SeitenAIC Selection GuideWerner LouwNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- 400kv Substation Training ReportDokument31 Seiten400kv Substation Training ReportShailendra Yadav85% (26)

- Fundamental STADokument47 SeitenFundamental STAsatNoch keine Bewertungen

- CMP Controls Catalogue 2014-15 (English Version)Dokument147 SeitenCMP Controls Catalogue 2014-15 (English Version)John EvangelistaNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- EASA Electrical Fundamentals 1Dokument28 SeitenEASA Electrical Fundamentals 1Marty008100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- Paper I: Electrical Engineering Syllabus For IES ExamDokument9 SeitenPaper I: Electrical Engineering Syllabus For IES ExamSrinivasu RajuNoch keine Bewertungen

- Successive Approximation ADC - ECE TutorialsDokument5 SeitenSuccessive Approximation ADC - ECE Tutorialsbraddlely nyakatangureNoch keine Bewertungen

- DatasheetDokument86 SeitenDatasheetOnsirin N NuchsopaNoch keine Bewertungen

- RF Device DataDokument1.388 SeitenRF Device Datasergecheshut100% (2)

- MultiCore ArchitectureDokument44 SeitenMultiCore ArchitectureNabendu Karmakar100% (2)

- Another Simple MK484 RadioDokument2 SeitenAnother Simple MK484 Radiorftek100% (2)

- Alstom Grid - Bushings - PNO LIGHT - UK - WEB PDFDokument8 SeitenAlstom Grid - Bushings - PNO LIGHT - UK - WEB PDFjtcool74Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- LNK304 PDFDokument20 SeitenLNK304 PDFnourtal2013Noch keine Bewertungen

- CastingDokument56 SeitenCastingTushar Prakash ChaudhariNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)