Beruflich Dokumente

Kultur Dokumente

Kitchen Stove Parkerizing

Hochgeladen von

jbtam99Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Kitchen Stove Parkerizing

Hochgeladen von

jbtam99Copyright:

Verfügbare Formate

Kitchen Stove Parkerizing

By Dick Culver NOTE:

I originally gave this formula to an interested individual when we were posting on the Ohio site, but it was lost in the transfer. I publish it again here with the disclaimer that I dont wanna be responsible for anyone ruining a $1000 part or becoming a vegetable from inhaling the fumes from some noxious brew. Ive done it on numerous occasions with no ill effect (some will differ in their opinion of my mental state of course) but if you choose to play around with chemical formulas, you are strictly on your own!

INSTRUCTIONS FOR HOME-BREW PARKERIZING:

You need a number of things to do a home-brew Parker-job, but only 4 ingredients. 1. Phosphoric Acid (the active ingredient in Naval Jelly) usually procured at a chemical supply house. 2. Powdered Manganese Dioxide (a very dense and heavy dark gray to black powder) also available at any chemical supply house. 3. Distilled water (Ive used tap water, but the distilled stuff gives more consistent results.) 4. A biscuit of steel wool (dont use soap pads or Brillo pads!) I used to do this on the kitchen stove (I wasnt married in those days) in a one gallon Pyrex beaker (these little beasts are expensive, so be careful with them). Metal pots dont work as well (if at all) I understand, but then I never used anything else but Pyrex.

Proceed as follows: 1. Use one whiskey jigger (yeah, this is really scientific, right?) of phosphoric acid added to the water. Remember your high school chemistry, ALWAYS add the acid to the water, and it is best done by pouring it down a glass rod! 2. Use one whiskey jigger of the (powdered) Manganese Dioxide in the solution. 3. Bring the solution to an extremely slooowwww rolling boil. 4. Now add your biscuit of steel wool. I used wooden sticks placed across the top of the beaker and suspended the parts in the solution using steel or iron machinists wire or some such. DONT use painted coat hangers or any wire with grease on it! You can usually get this stuff from a machine shop or from Brownells. The parts should be totally immersed in the solution, being careful that anywhere the wire touches the part wont show on the finished part (usually easy to do - like in the firing pin hole of a bolt). The part(s) to be Parkerized should be totally de-greased and sand or bead blasted prior to finishing

(depending on the texture you desire on the finished part). Once you have bead blasted the part, you should handle the part with gloves (never greasy hands) and store them wrapped in clean paper towels awaiting the Parker Bath. Any grease on the parts or wire will cause what can only be politely called a variation in color (the parts come out streaked and spotted like a paint horse). I usually let the part remain in the solution for a total of 20 minutes so thats what I used and it worked marvelously). When you withdraw the part, immediately rinse it in hot running water to get the solution off of it. Use extremely hot water, and the part will dry itself. Let it dry (and get cool enough to touch) on some clean paper towels, spray on some lubricant and viola you are done! Rumor control said that if you immersed the freshly rinsed and still hot part in Cosmoline, it would give the sometimes sought after gray-green tint to it. I have never tried it. Cosmoline is still available from Brownells if you are adventurous! The original formula called for iron filings vice steel wool, but since I didnt have any floating around, and didnt want to file on the cast iron stove, I found that the steel wool worked just fine. What you get is a chemical reaction that causes an iron phosphate to form on the metal (steel phosphate I suppose, using steel wool). I have found that the resultant finish is just as durable as the Arsenal finishes and has exactly the same appearance! an attractive dark gray, almost black. Some say that adding more manganese dioxide causes a darker finish, but Ive never tried it, as I was happy with what I got! We often used this technique when finishing .45s built on early Essex frames that needed a lot of fitting, thus often requiring the removal of offending metal. I used to checker the front straps (also violating the finish in a rather spectacular fashion) and the resultant finish worked great and showed little or no wear even with extensive use much like the official GI finish. Im still using a wadcutter gun I performed the magic on back in the 70s and it still looks new. A couple of cautions: 1. Always be careful of any sort of acid, even such an innocuous acid as phosphoric, I certainly would never deliberately inhale the fumes (although there is no gret odor to the process that I could tell, but then I smoke cigars). I started doing this back in the early to mid70s and still have no twitch that I can directly attribute to Parkerizing on the kitchen stove. Just use common sense, WEAR GLOVES AND EYE PROTECTION ANYTIME YOU ARE PLAYING AROUND WITH BOILING SOLUTIONS (with or without acids being involved). 2. Be very careful not to cause any splashes with the boiling solution (of course the same can be said of boiling corn). 3. Prepare your area and your parts before hand, dont try to do this on the spur of the moment. 4. Send your wife to see Gone With the Wind or Titanic or some other movie that whiles away a number of hours. If you ever want to do this again, make sure the kitchen is spiffy when she returns! In Glorias case, she would be attaching the parts, but then Im just lucky in that respect

5. Once you have allowed the solution to cool, you are DONE! Re-heating it dont cut it, It simply doesnt work (Ive tried it on several occasions). Have everything that you want to Parkerize ready to go when you fire up the solution. You can keep Parkerizing as long as the solution is hot, but allowing it to get cold kills it youve gotta brew up a new solution and start from scratch. 6. Do not name me in any divorce proceedings! Good luck!

Das könnte Ihnen auch gefallen

- Super Cool Science and Engineering Activities: with Max Axiom Super ScientistVon EverandSuper Cool Science and Engineering Activities: with Max Axiom Super ScientistNoch keine Bewertungen

- Gun BluingDokument10 SeitenGun BluingMichael Doll50% (2)

- Gun BluingDokument10 SeitenGun Bluingesparancito cordobaNoch keine Bewertungen

- How To Make VinegarDokument2 SeitenHow To Make VinegarnightclownNoch keine Bewertungen

- Bar ShampooDokument10 SeitenBar ShampooKathy Kemmis O'Driscoll100% (1)

- How To Distill Moonshine PDFDokument9 SeitenHow To Distill Moonshine PDFGerbenNoch keine Bewertungen

- How To Distill MoonshineDokument9 SeitenHow To Distill MoonshineRestore AmericaNoch keine Bewertungen

- TATP SynthesisDokument4 SeitenTATP SynthesisSalim Khutu100% (7)

- Easy, Economical, Ecological DistillationDokument13 SeitenEasy, Economical, Ecological DistillationPappa Anton FlorinNoch keine Bewertungen

- How To Brew Beer: April JohnsonDokument5 SeitenHow To Brew Beer: April Johnsonapi-278329775Noch keine Bewertungen

- A Pyros CookbookDokument8 SeitenA Pyros Cookbooknate100% (1)

- A Complete MDMA Synthesis For The First Time Chemist: Compilation and Editorial by Bright StarDokument14 SeitenA Complete MDMA Synthesis For The First Time Chemist: Compilation and Editorial by Bright StarAdrien G. S. Wald100% (3)

- Make Your Own Eco Friendly Soldering FluxDokument7 SeitenMake Your Own Eco Friendly Soldering FluxCiprian ChisegaNoch keine Bewertungen

- Oil Furnace BurnersDokument45 SeitenOil Furnace Burnersdavidkibm100% (1)

- Cuthulu 4Dokument2 SeitenCuthulu 4nafnlausNoch keine Bewertungen

- Acetone PeroxideDokument2 SeitenAcetone Peroxidehappylm100% (1)

- Milk Paint, Tempera, Casein Plastic, Bakers Clay and GessoDokument3 SeitenMilk Paint, Tempera, Casein Plastic, Bakers Clay and GessoStephen MurtaughNoch keine Bewertungen

- Antique FinishesDokument20 SeitenAntique FinishesRic SoNoch keine Bewertungen

- Soy Candles: How to Make Good-for-the-Earth, Long-Lasting CandlesVon EverandSoy Candles: How to Make Good-for-the-Earth, Long-Lasting CandlesNoch keine Bewertungen

- DMTDokument7 SeitenDMTkfx746ndq20% (1)

- ShakeDokument4 SeitenShakesafak100% (2)

- Mace, Pepperspray, Tear Gas, and Smoke Bomb Recipe GuideDokument14 SeitenMace, Pepperspray, Tear Gas, and Smoke Bomb Recipe GuidearesvonsoulgenNoch keine Bewertungen

- Making Ice Cream Without An Ice Cream MakerDokument12 SeitenMaking Ice Cream Without An Ice Cream MakerindramuniNoch keine Bewertungen

- 5 Experiments 1 Final (AWIN)Dokument8 Seiten5 Experiments 1 Final (AWIN)Kristian GatchalianNoch keine Bewertungen

- Getting Started With EpoxyDokument5 SeitenGetting Started With EpoxyelmicakNoch keine Bewertungen

- Полный Синтез MdmaDokument12 SeitenПолный Синтез Mdmacdn.offers100% (1)

- MDMA SynthesisDokument12 SeitenMDMA Synthesisjajcab100% (1)

- Glassware CleaningDokument3 SeitenGlassware CleaningSiti Nurazlin FariddunNoch keine Bewertungen

- Laborator Chimie DIYDokument11 SeitenLaborator Chimie DIYotonel100% (1)

- Bakelite Testing A Bit of HistoryDokument10 SeitenBakelite Testing A Bit of HistoryAbdulwaheedNoch keine Bewertungen

- Bright Star S Mdma Synthesis For The First Time ChemistDokument10 SeitenBright Star S Mdma Synthesis For The First Time ChemistSCRUPEUSSNoch keine Bewertungen

- How To Make Soap and Safety When Soap MakingDokument7 SeitenHow To Make Soap and Safety When Soap Makinglancasterpd100% (1)

- Liver of Sulfur Tips and Tricks With Katie BaumDokument2 SeitenLiver of Sulfur Tips and Tricks With Katie BaumbeadysamNoch keine Bewertungen

- Centrifugal Spin Casting Jewelry Production ExplainedDokument12 SeitenCentrifugal Spin Casting Jewelry Production ExplainedMohammad HassanNoch keine Bewertungen

- Beginner Soapmaking Instructions and Recipes Revised PDFDokument37 SeitenBeginner Soapmaking Instructions and Recipes Revised PDFstefanovicsanjaNoch keine Bewertungen

- Cast Iron Care MistakesDokument6 SeitenCast Iron Care MistakesBrian WarrenNoch keine Bewertungen

- Make Soap Out of Guava Leaf Extract For A Science Investigatory Project 12Dokument6 SeitenMake Soap Out of Guava Leaf Extract For A Science Investigatory Project 12Johnmartin Caballero100% (1)

- MolecularDokument130 SeitenMolecularBianca Díaz100% (3)

- The Text For The Instructions For Use With The Kits I Supply Is Written in RedDokument20 SeitenThe Text For The Instructions For Use With The Kits I Supply Is Written in RedsalmazzNoch keine Bewertungen

- SEEP Resepte en ProsesseDokument31 SeitenSEEP Resepte en ProsesseCora MarieNoch keine Bewertungen

- 10 Tips 2.0 SMALLDokument11 Seiten10 Tips 2.0 SMALLShamalaRathinavel50% (2)

- Catalyzed KNSU Propellant (PP)Dokument6 SeitenCatalyzed KNSU Propellant (PP)Chingyg100% (1)

- Japanning 103, Traditional Japanning, The BlacDokument8 SeitenJapanning 103, Traditional Japanning, The BlacFredy Alvarez LucasNoch keine Bewertungen

- Blackened and Antiqued Hard..Dokument6 SeitenBlackened and Antiqued Hard..Robin Hughes100% (1)

- Beer Making ClassDokument5 SeitenBeer Making ClassMichael BernierNoch keine Bewertungen

- Alles Over ZeepDokument20 SeitenAlles Over ZeepDjarkasi RoxaneNoch keine Bewertungen

- Household Hacks: 150+ Do It Yourself Home Improvement & DIY Household Tips That Save Time & MoneyVon EverandHousehold Hacks: 150+ Do It Yourself Home Improvement & DIY Household Tips That Save Time & MoneyBewertung: 3.5 von 5 Sternen3.5/5 (4)

- Expt 1NDokument4 SeitenExpt 1NmaggieNoch keine Bewertungen

- Making Soap From WoodDokument6 SeitenMaking Soap From WoodmastabloidNoch keine Bewertungen

- Amphetamine SynthesisDokument5 SeitenAmphetamine Synthesisashish_singh_8Noch keine Bewertungen

- Gunny PasteDokument2 SeitenGunny PastejpesNoch keine Bewertungen

- Solid Dishwashing BrickDokument19 SeitenSolid Dishwashing BrickClara StiniNoch keine Bewertungen

- Lost Wax Casting InstructionsDokument5 SeitenLost Wax Casting InstructionsCary BriefNoch keine Bewertungen

- Basic Processes of AlchemyDokument8 SeitenBasic Processes of AlchemyDonna KennedyNoch keine Bewertungen

- Urea PurificationDokument9 SeitenUrea PurificationAFLAC ............Noch keine Bewertungen

- Wikijunior:Big Book of Fun Science ExperimentsDokument9 SeitenWikijunior:Big Book of Fun Science Experiments@jazNoch keine Bewertungen

- Bright Star's MDMA Synthesis For The First Time Chemist - (WWWDokument7 SeitenBright Star's MDMA Synthesis For The First Time Chemist - (WWWSCRUPEUSSNoch keine Bewertungen

- C-Nav Worksheets StepsDokument32 SeitenC-Nav Worksheets Stepsjbtam99Noch keine Bewertungen

- Celestial Navigation in 60 MinDokument20 SeitenCelestial Navigation in 60 Minjbtam990% (1)

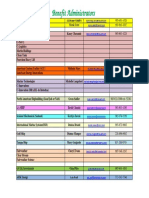

- Edison Chouest Benefits AdministratorsDokument1 SeiteEdison Chouest Benefits Administratorsjbtam99Noch keine Bewertungen

- POF USA2009manualDokument24 SeitenPOF USA2009manualjbtam99Noch keine Bewertungen

- Tees CatalogueDokument6 SeitenTees CatalogueTanzila SharifliNoch keine Bewertungen

- TLE 9 CookeryDokument2 SeitenTLE 9 Cookerypltte dee bee100% (1)

- The 2024 Uber Lost & Found IndexDokument7 SeitenThe 2024 Uber Lost & Found IndexJulie MorenoNoch keine Bewertungen

- Introduction To BakingDokument19 SeitenIntroduction To Bakingapi-320755856Noch keine Bewertungen

- Mazowe Hotel Product ProfileDokument7 SeitenMazowe Hotel Product ProfileMubako VictorNoch keine Bewertungen

- Miniature Golf RubricDokument8 SeitenMiniature Golf Rubricphschemguy0% (1)

- Build My Gallows High - Geoffrey HomesDokument154 SeitenBuild My Gallows High - Geoffrey Homesbrondavid100% (3)

- Countableuncountable-Nouns 23794Dokument3 SeitenCountableuncountable-Nouns 23794Rungthip Kumkaew100% (1)

- Brands and Types of Insulin - Rapid-Acting, Long-Acting, and MoreDokument4 SeitenBrands and Types of Insulin - Rapid-Acting, Long-Acting, and MoreRaul Fernando Vasquez WoddensonNoch keine Bewertungen

- Clatronic Pekac - HrvatskiDokument15 SeitenClatronic Pekac - HrvatskiAnaNoch keine Bewertungen

- Zero ConditionalDokument7 SeitenZero ConditionalnikitetNoch keine Bewertungen

- Bad Meets Evil Feat. Bruno Mars - "Lighters" LyricsDokument4 SeitenBad Meets Evil Feat. Bruno Mars - "Lighters" LyricsSafarina LutfiNoch keine Bewertungen

- All Bran Fruit CakeDokument6 SeitenAll Bran Fruit CakeStephen PritchardNoch keine Bewertungen

- Irmas Sandwich ShopDokument14 SeitenIrmas Sandwich ShopDavid Dtm100% (1)

- Analysis On Dabur India & It's Subsidiary Brand REALDokument22 SeitenAnalysis On Dabur India & It's Subsidiary Brand REALAbhishek Roy ChoudhuryNoch keine Bewertungen

- Calcium TestDokument7 SeitenCalcium Testtata_77Noch keine Bewertungen

- Teaching Plan Healthy PregnancyDokument10 SeitenTeaching Plan Healthy PregnancyDan Gerald Alcido Salunga44% (9)

- +125 Fruit Infused Detox Water Recipes PDFDokument127 Seiten+125 Fruit Infused Detox Water Recipes PDFsethu100% (1)

- Tescom Technical Training - Pressure Regulators Explained - Ver1.1Dokument19 SeitenTescom Technical Training - Pressure Regulators Explained - Ver1.1Amod DeshpandeNoch keine Bewertungen

- Grade 4 Word Problems Mixed Addition Subtraction eDokument3 SeitenGrade 4 Word Problems Mixed Addition Subtraction eRanda MuhammedNoch keine Bewertungen

- ThinTea Eating PlanDokument10 SeitenThinTea Eating Planpatriciagarciarr100% (1)

- Red Chilli PowderDokument2 SeitenRed Chilli PowderRohan MaliNoch keine Bewertungen

- Information Management LastDokument41 SeitenInformation Management LastNipuna Bandara WeerakoonNoch keine Bewertungen

- RulebookDokument228 SeitenRulebookadlard_matthewNoch keine Bewertungen

- Assignment - 2 Sem - 1Dokument4 SeitenAssignment - 2 Sem - 1Manikant SAhNoch keine Bewertungen

- Mymul KarthikDokument80 SeitenMymul KarthikKarthik K J50% (2)

- Ted Lasso 1x01 - PilotDokument40 SeitenTed Lasso 1x01 - PilotVishnu Sinha100% (1)

- CASE 1 1: Starbucks-Going Global FastDokument4 SeitenCASE 1 1: Starbucks-Going Global FastPooja ShahNoch keine Bewertungen

- Business Proposal 1 4 PPDokument32 SeitenBusiness Proposal 1 4 PPKatrin Ellaine Dimla71% (14)

- Final Order FormDokument2 SeitenFinal Order FormhiteshcparmarNoch keine Bewertungen