Beruflich Dokumente

Kultur Dokumente

DN - 1154 Smoke Detector

Hochgeladen von

don121don121Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DN - 1154 Smoke Detector

Hochgeladen von

don121don121Copyright:

Verfügbare Formate

DN-1154:A I-110

1451

2-Wire and 4-Wire Ionization Smoke Detector

Conventional Initiating Devices

General

The System Sensor 400 Series plug-in ionization smoke detectors respond quickly to both fast flaming and slow smoldering fires as required by UL 268. Unipolar dual chamber sensor has the sensitivity needed to quickly detect smoke, and the stability needed to avoid false alarms.

Features

Unique dual unipolar sensor: Provides exceptional stability. Factory preset at 1.9% nominal sensitivity. Stable operation up to 1,200 feet per minute (6 meters per second) air velocities. Removable cover for field cleaning. Two visible LEDs blink in standby. Sealed against dirt, insects, and back pressure. Three-year limited warranty. Field metering of detector sensitivity. Built-in test switch. Low standby current. Built-in tamper-resistant feature. Designed for direct surface or electrical box mounting. 360 field viewing angle of the visual alarm LEDs. Insect-resistant screening (0.020"/0.508 mm openings). Easy plug-in of the head to base. SEMS screws for easy wiring. Optional recess mounting. Field-adjustable sensitivity.

1451 Ionization Detector shown with B401B Base

to install and maintain, this detector is designed for direct surface mounting (using one of the B400 Series bases listed below). Easy-to-wire screw terminals allow fast and simple field wiring of IN, OUT, and remote annunciator connections. Consult Notifier control panel specifications for the maximum allowable loop resistance for the particular control panel to be used. To prevent wiring mistakes, observe polarities and make certain that each conductor is identifiable. A copy of Installation and Maintenance Instructions is packaged with each detector. For further information, refer to NFPA 72 Standard on Automatic Fire Detectors. A Mounting Base Selection Guide is included on page 2 of this document. Junction Box Selection Guide: Box depth is contingent on base and wire size. Refer to National Electrical Code or local applicable codes for appropriate recommendations. Bases B401 and B401B can utilize a single-gang, 3-1/2" (88.9 mm) octagonal, 4" (101.6 mm) octagonal, or 4" square junction box. Bases B402B and B406B can utilize a single-gang, 3-1/2" octagonal, 4" octagonal, 4" square, 50 mm, 60 mm, or 75 mm junction box. Base B404B can utilize a 4" octagonal or 4" square junction box.

Applications

Use to contribute to life safety, fire protection, and property conservation. Superior to photoelectric detectors in detecting fast-flaming fires. Superior to bipolar detectors in avoiding false alarms.

Construction & Operation

All 400 Series plug-in ionization smoke detectors contain a unique dual-source, dual unipolar chamber detection design which will sense the presence of smoke particles produced by fast combustion as well as slow smoldering fires. Additional key features include a blinking LED standby status indicator, an easily visible alarm indication, and provision for convenient field test and metering. The back of the detector is sealed to block back-pressure air flow. The chamber is protected by a fine mesh (0.020"/0.508 mm) screen to minimize problems with dust, dirt, and insects. If cleaning is required, it is easy to remove the cover (with a special tool) and obtain access to the screen and chamber to perform a thorough cleaning.

General Specifications

Operating voltage: mounting base dependent (see chart below). Standby current: 120 micro amps. Sensitivity: 1.9% nominal. Weight: 0.6 pounds (272 grams). Size: 3.2" (81.28 mm) high; 4.0" (101.6 mm) diameter with unflanged bases, or 6.2" (157.48 mm) diameter with flanged bases. Construction: Flame-retardant white Noryl plastic. Temperature: 32F to 120F (0C to 49C).

Installation

Model 1451 detectors are intended for use with Notifier ULlisted control panels. Maximum number of detectors per zone is listed in the installation manual for each control panel. Easy

DN-1154:A 6/4/08 Page 1 of 4

1154pho.jpg

Humidity range: 10 to 93% R.H. (non-condensing). Maximum air velocity: 1,200 feet per minute (6 meters per second).

Agency Listings and Approvals

These listings and approvals apply to the modules specified in this document. In some cases, certain modules or applications may not be listed by certain approval agencies, or listing may be in process. Consult factory for latest listing status. UL Listed: S911 ULC Listed: S911 (1451A) MEA Listed: 427-91-E Vol. III FM Approved CSFM: 7271-1653:108 BSA: 1202-88-SA Maryland State Fire Marshal Certificate: #2185

B401(B) Wiring Diagram

5578d1.wmf

Product Line Information

1451: Ionization Detector. Must be mounted to one of the B400 Series Bases listed below. RA400Z: Remote Annunciator for 2- or 4-wire applications. Use with any System Sensor 400 Series plug-in detector. Fits standard U.S. single-gang electrical box. MOD400R: Field Test module for all of the System Sensor 400 Series Smoke Detectors.

B402B Wiring Diagram

5578d4.wmf

5578d3.wmf

B406B Wiring Diagram B404B Wiring Diagram

5578d2.wmf

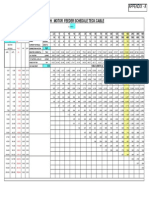

Mounting Base Selection Guide

Base Model Number (A)

B401 & B401B (A) B402B (A) B404B (A) B406B (A)

Version

Loop Type

2-wire* 4-wire 4-wire 2-wire*

Current Limit Resistor

No Yes Yes No

Alarm Contact Type

Form-A & -C Form-A & -C/A Supervisory Form-C

Nominal Voltage

12/24 VDC 24 VDC 120 VAC 24 VDC

Standby Voltage

8.5 to 35 VDC 17 to 32 VDC 120 VAC 15 to 32 VDC

Current Draw on Alarm

10 to 100 mA** 14 to 39 mA 75 mA AC maximum 12 to 100 mA**

Location of holes to access and release locking prongs. Cover and screen are removable for cleaning. Locking prongs.

UL/ULC/ EN-54 UL & ULC UL & ULC UL/ULC/ EN-54

* Functionality contingent on panel compatibility. ** Must be limited by control panel. Relay Contact Ratings: Resistive or Inductive (60% power factor load). Form-a: 2.0A at 30VAC/DC. Form-C: 0.6A at 110VDC, 2.0A at 30VDC, 1.0A at 125 VAC. (A) = ULC model designation.

1154d1.tif

Page 2 of 4 DN-1154:A 6/4/08

Notes

DN-1154:A 6/4/08 Page 3 of 4

NOTIFIER is a registered trademark of Honeywell International Inc. Noryl is a registered trademark of GE Plastics, a subsidiary of General Electric Company. 2008 by Honeywell International Inc. All rights reserved. Unauthorized use of this document is strictly prohibited.

This document is not intended to be used for installation purposes. We try to keep our product information up-to-date and accurate. We cannot cover all specific applications or anticipate all requirements. All specifications are subject to change without notice.

Made in the U.S. A.

For more information, contact Notifier. Phone: (203) 484-7161, FAX: (203) 484-7118. www.notifier.com

Page 4 of 4 DN-1154:A 6/4/08

Das könnte Ihnen auch gefallen

- Voltage Drop Calculation of HT MotorsDokument7 SeitenVoltage Drop Calculation of HT MotorsGAGAN100% (1)

- Chapter 14 Cable Support SystemsDokument24 SeitenChapter 14 Cable Support SystemsjoorgesilvaNoch keine Bewertungen

- Temperature Transmitter III YTA320 CatalogueDokument9 SeitenTemperature Transmitter III YTA320 Cataloguedon121don121Noch keine Bewertungen

- THe Manual For Cropping The Fixed One JHFH PDFDokument6 SeitenTHe Manual For Cropping The Fixed One JHFH PDFdon121don121Noch keine Bewertungen

- MTL7700 Series Shunt-Diode Safety Barrier (INTRINSICALLY SAFE LOOP)Dokument24 SeitenMTL7700 Series Shunt-Diode Safety Barrier (INTRINSICALLY SAFE LOOP)don121don121Noch keine Bewertungen

- The Flow Guide For PT TT Compensation For Crude Oil ManualDokument32 SeitenThe Flow Guide For PT TT Compensation For Crude Oil Manualdon121don121Noch keine Bewertungen

- Tefal Fuzzy Rice CookerDokument69 SeitenTefal Fuzzy Rice Cookerdon121don121Noch keine Bewertungen

- Field Terminal BoxDokument1 SeiteField Terminal Boxdon121don121Noch keine Bewertungen

- EasyPact EZC - EZC100H3075Dokument2 SeitenEasyPact EZC - EZC100H3075don121don121Noch keine Bewertungen

- Instrument Cables SpecificationDokument12 SeitenInstrument Cables Specificationdon121don121Noch keine Bewertungen

- Universal Temperature Transmitter E&hDokument18 SeitenUniversal Temperature Transmitter E&hdon121don121Noch keine Bewertungen

- 4-20ma Output For Temperature Transmitter Head RequirementDokument10 Seiten4-20ma Output For Temperature Transmitter Head Requirementdon121don121Noch keine Bewertungen

- Flow Measurement FundamentalsThis concise title summarizes the key topic of the document - flow measurement fundamentals - . It starts with "TITLEDokument5 SeitenFlow Measurement FundamentalsThis concise title summarizes the key topic of the document - flow measurement fundamentals - . It starts with "TITLEKHairil AdZharNoch keine Bewertungen

- Quick Time 7 User GuideDokument63 SeitenQuick Time 7 User GuideChristine AmakerNoch keine Bewertungen

- Api 2540Dokument8 SeitenApi 2540biondimi100% (1)

- PT TT Compensation Basics For DP TransmitterDokument3 SeitenPT TT Compensation Basics For DP Transmitterdon121don121Noch keine Bewertungen

- Density Correction Factor For Diesel Vs TemeperatureDokument3 SeitenDensity Correction Factor For Diesel Vs Temeperaturedon121don121Noch keine Bewertungen

- Specifications - Flow Meter For DP Transmitter CorrectionDokument2 SeitenSpecifications - Flow Meter For DP Transmitter Correctiondon121don121Noch keine Bewertungen

- Density Correction Factor For Diesel Vs TemeperatureDokument3 SeitenDensity Correction Factor For Diesel Vs Temeperaturedon121don121Noch keine Bewertungen

- X2500 GeneratorDokument5 SeitenX2500 Generatordon121don121Noch keine Bewertungen

- General Instructions For All Timer Series: Load Current Vibration and ShockDokument1 SeiteGeneral Instructions For All Timer Series: Load Current Vibration and Shockdon121don121Noch keine Bewertungen

- Cable Schedule AppendixDokument8 SeitenCable Schedule Appendixdon121don121Noch keine Bewertungen

- Part Numbering Guide Timers CycleDokument1 SeitePart Numbering Guide Timers Cycledon121don121Noch keine Bewertungen

- Miniature Circuit-Breakers and Earth Leakage Circuit-Breakers (Mcbs/Elcbs)Dokument35 SeitenMiniature Circuit-Breakers and Earth Leakage Circuit-Breakers (Mcbs/Elcbs)occhityaNoch keine Bewertungen

- Relay Super Cycle With TimerDokument8 SeitenRelay Super Cycle With Timerdon121don121Noch keine Bewertungen

- Relay Super Cycle With TimerDokument8 SeitenRelay Super Cycle With Timerdon121don121Noch keine Bewertungen

- Timing Control Enhancement ProgramDokument7 SeitenTiming Control Enhancement Programdon121don121Noch keine Bewertungen

- Timing Diagram Timers CycleDokument1 SeiteTiming Diagram Timers Cycledon121don121Noch keine Bewertungen

- Cycle Timers Number 1Dokument1 SeiteCycle Timers Number 1don121don121Noch keine Bewertungen

- Motor Operated ValveDokument48 SeitenMotor Operated Valvedon121don121Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- VisQ Queue Manager System Guide Version 10.3Dokument27 SeitenVisQ Queue Manager System Guide Version 10.3MSC Nastran Beginner100% (1)

- Kurzweil MicropianoDokument24 SeitenKurzweil Micropianoestereo8Noch keine Bewertungen

- Operations and Service 69UG15: Diesel Generator SetDokument64 SeitenOperations and Service 69UG15: Diesel Generator SetAnonymous NYymdHgyNoch keine Bewertungen

- Task #2 SIA-309 Perancangan Fondasi 2: Retaining WallsDokument1 SeiteTask #2 SIA-309 Perancangan Fondasi 2: Retaining WallsDesti Santi PratiwiNoch keine Bewertungen

- SKFDokument26 SeitenSKFRahul ParikhNoch keine Bewertungen

- RecruitmentDokument73 SeitenRecruitmentArif Ryhan100% (1)

- Spotlight Planet Magazine UpdatedDokument32 SeitenSpotlight Planet Magazine UpdatedOlla John IamBezaleel OluwafemiNoch keine Bewertungen

- Understanding Operating Systems Fifth Edition: Memory Management: Virtual MemoryDokument21 SeitenUnderstanding Operating Systems Fifth Edition: Memory Management: Virtual MemoryRidzuan DolahNoch keine Bewertungen

- AKA DP Close Bus Ring SolutionsDokument2 SeitenAKA DP Close Bus Ring Solutionssun qiNoch keine Bewertungen

- Nmo & DmoDokument29 SeitenNmo & DmoJessica Julien100% (1)

- Secure Email Transaction SystemDokument32 SeitenSecure Email Transaction SystemGautam Sharma100% (1)

- Videojet 3140: Laser Marking SystemDokument2 SeitenVideojet 3140: Laser Marking SystemSudiptoNoch keine Bewertungen

- Hitachi SetFree MiniVRF 0120LRDokument52 SeitenHitachi SetFree MiniVRF 0120LRAhmed AzadNoch keine Bewertungen

- SR.11.10961 - Sour Well Design GuideDokument52 SeitenSR.11.10961 - Sour Well Design GuideMahmoud Ahmed Ali Abdelrazik100% (1)

- Acronyms Used in Offshore ConstructionDokument32 SeitenAcronyms Used in Offshore ConstructionDaniel De Assis ItaborahyNoch keine Bewertungen

- Tugas Dinamika Struktur Shape Function - Kelompok 6Dokument8 SeitenTugas Dinamika Struktur Shape Function - Kelompok 6Mochammad Choirul RizkyNoch keine Bewertungen

- Export Promotion Councils - Final UpdatedDokument14 SeitenExport Promotion Councils - Final UpdatedUtkarsh SaxenaNoch keine Bewertungen

- 220 KV GSS, HeerapuraDokument56 Seiten220 KV GSS, Heerapurapikeshjain33% (3)

- 06b AppendixB2 (1000HPRig) 1582535891879Dokument103 Seiten06b AppendixB2 (1000HPRig) 1582535891879Harsh TiwariNoch keine Bewertungen

- Dse7110 Mkii Dse7120 Mkii Operator ManualDokument100 SeitenDse7110 Mkii Dse7120 Mkii Operator Manualseanfsmyth100% (1)

- wndw3 Print PDFDokument520 Seitenwndw3 Print PDFbryanth9Noch keine Bewertungen

- Jobber JR DetailsDokument2 SeitenJobber JR DetailsUrvish PatelNoch keine Bewertungen

- BS Basics Boundary Scan PDFDokument2 SeitenBS Basics Boundary Scan PDFShankar ArunmozhiNoch keine Bewertungen

- Restaurant Pub VIP Lounge Camp Pune SaleDokument4 SeitenRestaurant Pub VIP Lounge Camp Pune SaleChandrashekhar Naikare0% (1)

- Formalin MsdsDokument10 SeitenFormalin MsdsMank WidhieNoch keine Bewertungen

- FinePrint pdfFactory Pro Trial Version PDF CreationDokument40 SeitenFinePrint pdfFactory Pro Trial Version PDF CreationTUAN NGUYEN VANNoch keine Bewertungen

- SDLC Phases Feasibility Analysis RequirementsDokument4 SeitenSDLC Phases Feasibility Analysis RequirementsBrandon Mitchell0% (1)

- Drilling: Drilling Is A Cutting Process That Uses A Drill Bit To Cut or Enlarge A Hole of Circular Cross-Section inDokument9 SeitenDrilling: Drilling Is A Cutting Process That Uses A Drill Bit To Cut or Enlarge A Hole of Circular Cross-Section inAekanshNoch keine Bewertungen

- ITC 215: Data Structure and Algorithm Module ObjectivesDokument3 SeitenITC 215: Data Structure and Algorithm Module Objectiveskarthikeyan50700HRNoch keine Bewertungen

- RRB Group DDokument35 SeitenRRB Group DRITESH KUMARNoch keine Bewertungen