Beruflich Dokumente

Kultur Dokumente

Katalogeintrag MS BLK-Eng

Hochgeladen von

Lare AnginOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Katalogeintrag MS BLK-Eng

Hochgeladen von

Lare AnginCopyright:

Verfügbare Formate

Knowledge base around Power Quality Medium Voltage Compensation

Power factor correction units (PFC) for medium-high voltage are often used by medium-high voltage drives to the fixed compensation from motors or also as a Power factor correction unit for a group. In a complex plant one central medium-high voltage compensation can raise the cos j of the complete plant over the low-voltage level.

Front view

The compensation mainly consists of: a single capacitor in IP00, a metal enclosed capacitor in IP55 or a complete PFC unit with power factor controller, fuses, contactors and capacitors. It can also be build as a fixed switched step compensation, designed like a Power Factor Correction unit without controller.

A safe thing Protection of capacitors and capacitor banks In electricity networks the purpose of all protection is to protect the equipment against overcurrents and overvoltages and to minimize the effect of these, considering the eco-nomical and technical restrictions and safety regulations.., while preventive protection against permanent damage is the prime concern with motors, transformers, inverters, lines, cables and similar components, the reduction of damage to the environment is the most important criterion for capacitors.

Knowledge base around Power Quality Medium Voltage Compensation

In combination with medium voltage capacitors the melting of the section fuses is not caused by the mains energy as with Iow-voltage capacitors but by the energy stored in the paralleled capacitor elements. Owing to the large number of capacitor elements, the capacitance is not changed by more than about 2 % on melting of a section fuse, Fuses are provided for both poles of each capacitor element. Even if these fuses fail to blow in response to defects, they provide adequate protection against tearing open of the housing on phase-to-earth short-circuits. Properly functioning section fuses may prolong the life of power capacitors and thus ensure uninterrupted Operation. This is only possible, however, as long as a sufficient number of parallel capacitor elements are available. As the capacitors age, however, there comes the time when the fuses of the capacitor elements still intact no longer operate. It is advisable to check the capacitance at intervals of 1 to 2 years. External fuses can also be used for protection although they are not capable of avoiding "progressive" defects with only slightly increased capacitor current and any associated gas development and bursting of the housing. For this reason, MODL recommend to protect each capacitor installation with an unbalance protection

Base unit Extension unit Final field

Capacitors with integrated unbalance protection

Overcurrent and overvoltage protection

An overvoltage protection sufficing for the capacitors is carried out in the upstream protective devices. To protect the windings at a motor fixed compensation, however, an additional overvoltage limiter can be used. In case of an overcurrent situation there is a danger of reverse sparking with very high intensities and ultimate leads to an open arc. To withstand the switching current MODL is using fuse sizes between 1.6 up to 2 times of the rated capacitor current.

Knowledge base around Power Quality Medium Voltage Compensation

Power factor correction with reactors MODL recommends the use of reactor connected capacitors, when the percentage of harmonic load (rectifiers) becomes more than 15% of the total load. Another reason is the avoidance of interferences with the power line. To choose out the right size of capacitors connected with reactors, is made the same way then with normal capacitors, it depends on the need of reactive power of the load. The capacitors forms a harmonic filter together with the reactors. It will be tuned in that way, that the frequency of resonance fR is lower than the 5th harmonics (250Hz). This leads to the effect that the filter becomes reactive for all harmonics (>= 250Hz) which come from rectifiers and therefore no resonance is possible in this range of frequency. Furthermore the harmful harmonics of the 5th which are generated by 6pulse rectifiers will be extracted by the compensation unit.

Effect: There is not only a reduction of the reactive power for the grid, even the harmonic interferences become less. This leads to an enduring improvement of the Power Quality.

Medium Voltage Compensation

Single components

14

Application Design Technical data Type range of capacitors Power capacitors 4RH5

Environment-friendly , all-film technology (Polypropylen- und Aluminium foil) 50 bis 1000 kvar per capacitor, PCB-free, high quality impregnation oil Deliverable for every power line voltages that is used world wide Security through internal fuses and over pressure devices, high switching capability , self healing and low losses High temperature class -25/D, max. ambient temperature at capacitor up to +55 C

High stability of the capacitance, what is very important in a filter together with reactors. The loss of capacitance during life time is almost

insignificant

High load capacity: up to 1.3 times of the nominal current as a buffer for voltage oscillation and for harmonics in the grid Housings made of stainless steel

Reactors

Complete impregnate under vacuum and over-pressure in impregnation resin acc. to temperature class H and temper-hardened in oven Three phased, iron cored with air gap, PolyGapTM core structure Flat copper terminals For indoor use in IP 00, air cooled acc. to IEC 60076

Dimensioned as filter reactor according to the situation at the power line On rubber-metal mountings for anti vibration Thermal sensor on core, at middle axle journal Reactors mainly consists of: steel, aluminium, copper and insulating material. There is no use of forbidden material, like: Mercury, Asbestos, PCB or chlorinated carbon hydrides

Unbalance protection relays to prevent of:

Internal faults - Medium voltage capacitors internally consists of a lot of serial- and parallel-switched capacitors. This leads to the needed voltage resistance and power. - The breakdown from one of this capacitors leads to internal over load. - This over load situation is heating up the capacitor, especially his oil filling. - A ignition or explosion of the hot oil leads to a damage of the hole equipment and the building. External influence - Over voltage, harmonics and high ambient temperatures strain the capacitors.

Medium Voltage Compensation

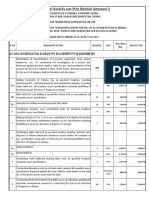

Single components Power capacitors 4RH5 Application Design Technical data

14

EN 60871-1; IEC 60871-1 Ieff = 1,3 x IN UN +10 %

Application range Medium voltage capacitors are used in fixed switched units and in regulated Power Factor Correction Units (PFC). PFCs were capacitors without reactors are build in, can only be used in grids, where the rectifier load is less than 15% of the total load. They can not be used when harmful harmonics are in the grid. Capacitors with protection cover can be used as a fixed switched compensation unit directly beside the consumer.

Technical data Regulations Current load Maximal voltage raise during 12 hours, daily Internal wiring Power loss - at the terminals - inside dielectric Ambient temperature

One-phase 1~ or three-phase 3~

< 0,015 % = 0,15 W/kvar < 0,01 % = 0,1 W/kvar -25 bis +55 short time max. +55 C, C average value during 24 h, max. +45 C average value during 1 year, max. +35 C F -5 to +10 % Upright IP00 or IP54 / IP55 IP55- Design Up to 1000 m NL, above on request Bolts M12, directly at the isolator It depends on location and from the type of isolator up to approx. 20 years, depending on operation conditions Internal Internal Accessories

Configuration Internally a capacitor contains of a lot of single capacitor elements (consist of Polypropylen- and Aluminium foil) witch are build up to one complete capacitor unit. To reach a capacitor cup that can operate with a nominal power line voltage up to 12 kV, such single capacitor elements will be series connected. Every capacitor element does have its own internal section fuse for protection. When an dielectrical breakdown happened this element will be disconnected. The capacitor will have a little loss of capacity then, but a safe operation is still possible. As an additional protection a over pressure device is available. When a required critical value is reached, a signaling contact can be used for a switch off, before a case rupture occurs. In combination with upstream connected and current limiting fuses an adequate protection can be realized. To reduce the voltage within 10 min. down to 75V (what is required) the capacitors does have built-in discharge resistors.

acc. to temperature class D

Indoor humidity class Tolerance of capacity Installing position Degree of protection Outdoor use Altitude of site Electrical connections Tightening torque

Statistical life time

Discharge resistors Fuses Over pressure device

Medium Voltage Compensation

Single Components Type range power capacitors 4RH5

14

Capacitors for indoor or outdoor use. Standard housing is stainless steel with double finish. All capacitors does have porcelain bushings for outdoor use additional an IP 55 protection cover is mounted. Cable entry from the side / bottom up. Capacitors 1~ 50 Hz indoor or outdoor use, IP00 or IP55 7.2 kV 12 kV 200 - 1000 kvar 200 - 1000 kvar

Capacitors 3~ 50 Hz For indoor IP 00 and outdoor applications with internal fuses, over pressure device and (internal) discharge resistors. 3 kV 3.3 kV 5 kV 5.5 kV 6 kV 6.3 kV 6.6 kV 10.5 kV 11 kV 50 50 50 50 50 50 50 50 50 - 800 kvar - 800 kvar - 800 kvar - 800 kvar - 800 kvar - 800 kvar - 800 kvar - 300 kvar - 300 kvar

Capacitors 3~ 60 Hz in IP00 or IP55 2.4 kV 3.45 kV 4.16 kV 50 - 800 kvar 50 - 800 kvar 50 - 800 kvar

Capacitor-banks for 3 ..35 kV, > 1Mvar The capacitors are mounted in a frame and ready wired up. For monitoring the capacitors are connected in a double star or bridge circuit. C.T. for unbalance monitoring relay is included. For indoor or outdoor, IP 00

Medium Voltage Compensation

Single Components

Type range power capacitors 4RH5

Inrush current limiter: The transient switching and inrush currents of a capacitor bank can be limited by a damping reactor, connected in series with the bank. Standards are: 100, 200, 500 or 1000 mH, 65, 100, 160, 200 or 250 A For indoor or outdoor, IP 00, <12 kV as iron coil

Reactors in air coil or iron core construction. For the use in units with reactors or as filters: The filter has two functions, namely to produce capacitive reactive power at basic frequency and to filter out harmonics. Used with reactors 14% there is no suction of the tone modulated (control) signal in the frequency range less than 200Hz. Used with reactors 5,67% or 7%, harmonics will be reduced. We manufacture filter reactors and capacitors according to the customers specification. When the filter is used as tuned filter, each required harmonics has a separate filter circuit. For higher harmonics a wide band filter is used. For indoor or outdoor, IP 00, <12 kV as iron coil, outdoors as air coil Air coil for outdoor use

Coils with iron core up to 12kV for indoor use

Medium Voltage Compensation

Single components Type range unbalance protection & converters

Example of an unbalance relay: For current transformers 1 or 5 A Auxiliary supply: 207- 253V AC 80 132 V DC Consumption: 1 VA Relay for max. 250V / 5A AC, 30V / 3A DC 2 Change-over contact, 4 NO, potential-free Measurement: 0,02 1A bzw. 0,05 5A Transforming factor: 1 - 10000 Operating: 0 +70 C Option: RS 485 Modbus-Interface Dim.: 144x144x58 mm (LxHxW) Protection class: Front IP 54, back side IP 20

A capacitor protection relay is used to protect capacitor banks in low- and medium voltage grids. In case of an overflow of one monitored value in that way that a danger will occur to the capacitor, it must become unconnected from the power line immediately. The instrument indicates all measurement values and adjustments via a big liquid crystal display (LCD). A backlight allows the use even in bad lighting conditions. The set menu can be controlled via four buttons in a easy and intuitive way.

Converters for current measurement in the neutral point are available as accessories, can be mounted directly on the capacitor banks. On request.

Medium Voltage Compensation

Power factor regulator units 4RH5

15

Application Design Technical data Type range of Correction units

Save cost of power, reduce extra losses in transformers and cables, minimize losses in transmission by using Power Factor Correction Units 4RH

Large spectrum of types, different housing variants, natural convection or forced cooling, degree of protection IP40, reactor connected units are forced cooled

Partial filtering of low frequency harmonic currents (by using reactor connected units)

Deliverable for all the power line voltages world wide used, cubicles up to 12 kV

Regulated central compensation, connection ready fr grids with linear or no linear load -without reactors with inrush current limiting reactor -with reactor in 5,67, 7% or 14%

Power from 50 up to 5000 kvar per unit

Modular upgrade is possible depending on the steps with Basic Unit and extension units

In metal enclosed design acc. to EN62271-200 for indoor installation with disturbing arc checked cubicles or in openly construction also able to install outdoors with air reactors

Medium Voltage Compensation

Power factor regulator units 4RH5

Application Design Technical data

15

EN 62271-200 for cubicles Ieff = 1,3 x IN UN +10 %

Application range PFCs inside a cubicle can be used as a single fixed compensation or as a complete regulated Power Factor Correction unit. Capacitors for outdoor installation will be mounted in racks. When build in reactor connected design, air coils will be used. Depending on the harmonics and the frequency of tone modulated signal the unit can be build with or without reactors inside. When the percentage of the non linear load is higher then 15% it is recommended to use a reactor connected PFC.

Technical data Regulations Current load Maximal voltage raise during 12 hours, daily Internal wiring Power loss - at the terminals - inside dielectric - filter reactor

One-phase 1~ or three-phase 3~

< 0,015 % = 0,15 W/kvar < 0,01 % = 0,1 W/kvar between 1,5 und 4W/kvar

Ambient temperature - indoor - outdoor acc. to temperature class D

Configuration Cubicles will be delivered ready for connection in disturbing arc checked cubicles with ventilation slots, normally in a protection category of IP 40. They can be combined to a regulated PFC on demand. A regulator is build in then in the Base unit. The single cubicles consists of: -Vacuum contactor -HV fuses -Power capacitors -Filter circuit reactors (on demand) -Inrush current limiter (on demand) -Straight ball terminal bolt for earthing -Low voltage compartment within Power Factor regulator -Forced ventilation (on demand) -Door contact for safety shutdown For outdoor installation only consists of the single components: Capacitors and air coils. Depending on the size of the capacitor-bank it can be provided a Unbalance protection. Indoor humidity class Outdoor installing Cubicle Altitude of site

-25 bis +35 C, -25 bis +55 C, average value during 24 h, max. +45 C average value 1 year, max. +35 C F IP00- Design IP40 up to 1000 m NL, above on request

Statistical life time

Up to approx. 20 years, depending on operation conditions Internal Internal Accessories

Discharge resistors Fuses Over pressure device Unbalance protection Power Factor Regulator

for converters ../1A or /5A Auxiliary voltage and voltage of operation 110V -or 230V~ Measurement 50-530V

Medium Voltage Compensation

Power factor regulator units 4RH5

MODL Power Factor Correction Unit for medium voltage networks up to 12 kV) For current transformers 1 or 5 A Protection IP40 (IP42), indoor with inrush reactor with reactor connected capacitors 250 ... 2000 kvar / cabinet Mechanical design: - Disturbing arc checked cubicle - Flaps for the disturbing arc decompression in the roof metal - Ventilation slots in the door and in the roof - Reactor connected units have a fan in the roof metal - Door hinge on the left - Connection places to the earthing Electrical construction: - Connection point for a cable feeding from below - Copper busbar for internal connections - Power factor correction units consist of: Basic unit with controller Extension units and a final field - HV fuses - Power capacitors with pressure monitoring device - Power factor controller - Siemens vacuum contactor - Overvoltage protection > 12 kV, if the unit are used for fixed compensation - Inrush current limiter at units without reactor - Filter circuit reactors on swinging metals assembled - Supervision facilities thermostats and temperature switch - door contact for safety shutdown Mode of operation: The compensation system can function automatically or be controlled manually. All operating, control and monitoring functions are effected via the Power Factor Controller fitted in the LV compartment door of the first compensation step. Type as a switchable fixed-compensation This type is different to a unit with power factor controller. The controller is replaced by a time relay with external activation. The time relay guarantees the sufficient discharge before next switch in.

Control cabinets for fixed compensation or as regulated base unit and extension unit. - with reactors 5,67%, 7% or 14% - without reactors, with/without inrush current limiter 3 kV 3.3 kV 5 kV 5.5 kV 6 kV 6.3 kV 6.6 kV 10.5 kV 11 kV 50 50 50 50 50 50 50 50 50 - 800 kvar - 1100 kvar - 1600 kvar - 1800 kvar - 2000 kvar - 2100 kvar - 2200 kvar - 3500 kvar - 3500 kvar

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Power Flow Through A Transmission Line - EEEGUIDEDokument8 SeitenPower Flow Through A Transmission Line - EEEGUIDEdillehNoch keine Bewertungen

- Bili of Qunatity Cum Price Schedule (Annexure-I) : A-I) Soil Investigation Alongwith Soil Resistivity MeasurementDokument5 SeitenBili of Qunatity Cum Price Schedule (Annexure-I) : A-I) Soil Investigation Alongwith Soil Resistivity MeasurementSushant MallickNoch keine Bewertungen

- Report For Four Week Training at Guru Hargobind Thermal Plant (GHTP) Lehra MohabbatDokument23 SeitenReport For Four Week Training at Guru Hargobind Thermal Plant (GHTP) Lehra MohabbatLovepreet SinghNoch keine Bewertungen

- M. H. J. Bollen, Understanding Power Quality Problems.Dokument7 SeitenM. H. J. Bollen, Understanding Power Quality Problems.RaviYadavNoch keine Bewertungen

- Al 811Dokument10 SeitenAl 811yu3zaNoch keine Bewertungen

- Executive Summary: 0.1 Name of The WorkDokument12 SeitenExecutive Summary: 0.1 Name of The WorkDevdoot SahuNoch keine Bewertungen

- Monitoring - of - Partial - Discharges - in - HVDC - Power - Cables-Erik WinkelmannDokument12 SeitenMonitoring - of - Partial - Discharges - in - HVDC - Power - Cables-Erik WinkelmannHafiziAhmadNoch keine Bewertungen

- Subsea High Voltage Power DistributionDokument9 SeitenSubsea High Voltage Power DistributionSeun Sam AdetolaNoch keine Bewertungen

- Insulators & String EfficiencyDokument17 SeitenInsulators & String Efficiencyketan adhwanNoch keine Bewertungen

- Power Plant Protection and Transmission SystemsDokument22 SeitenPower Plant Protection and Transmission SystemsJemersonAguilar67% (3)

- Problems of Planning Hybrid Wind Diesel Power SystemsDokument6 SeitenProblems of Planning Hybrid Wind Diesel Power SystemsmianNoch keine Bewertungen

- Ancillary ServicesDokument21 SeitenAncillary ServicesAndré LuizNoch keine Bewertungen

- Lower voltage drop with busduct systemsDokument1 SeiteLower voltage drop with busduct systemshashimelecNoch keine Bewertungen

- Ahmad Shahsiah CVDokument5 SeitenAhmad Shahsiah CVjlassi MatadorosNoch keine Bewertungen

- Optimised Controller For Renewable Energy SourcesDokument54 SeitenOptimised Controller For Renewable Energy SourcesJuan David Acosta DangondNoch keine Bewertungen

- Fundamentals of Electrical & InstrumentationDokument80 SeitenFundamentals of Electrical & InstrumentationSatya MakhijaNoch keine Bewertungen

- Cigre TB 498Dokument79 SeitenCigre TB 498jchinchayNoch keine Bewertungen

- Session 1998: 21, Rue D'artois, F-75008 Paris © CigréDokument7 SeitenSession 1998: 21, Rue D'artois, F-75008 Paris © Cigrémartin mannoneNoch keine Bewertungen

- Unit 3Dokument87 SeitenUnit 3MR. SUSHIL BARAPATRE0% (1)

- 1MRK505188-BEN B en BuyerAs Guide Line Differential Protection IED RED 670 Pre-Config 1.1Dokument56 Seiten1MRK505188-BEN B en BuyerAs Guide Line Differential Protection IED RED 670 Pre-Config 1.1Anonymous BBX2E87aHNoch keine Bewertungen

- Erc Form Du-M02 - Mer June 2017xlsDokument36 SeitenErc Form Du-M02 - Mer June 2017xlsJess DoodsNoch keine Bewertungen

- Chains Slings and Rigging ProgramDokument34 SeitenChains Slings and Rigging ProgramRuperto Caruanambo MalcaNoch keine Bewertungen

- Subject Code/name: EE 2306-Flexible AC Transmission Systems: Facts 8 Kce/Eee/Qb/Ivyr/FactsDokument26 SeitenSubject Code/name: EE 2306-Flexible AC Transmission Systems: Facts 8 Kce/Eee/Qb/Ivyr/FactssivakumarsarvananNoch keine Bewertungen

- Lecture - 9 - Economic Dispatch of Thermal Units - Part EDokument13 SeitenLecture - 9 - Economic Dispatch of Thermal Units - Part Efahad zubairNoch keine Bewertungen

- NZ Electricity SectorDokument24 SeitenNZ Electricity SectorrajatguptaiitrNoch keine Bewertungen

- Planning Operation Maintenance Power ProjectsDokument2 SeitenPlanning Operation Maintenance Power ProjectskeikodavilaNoch keine Bewertungen

- Yangon Power Improvement Project Final ReportDokument163 SeitenYangon Power Improvement Project Final ReportAustin Than AungNoch keine Bewertungen

- Phase Shifting Transformer Persentation-ABBDokument52 SeitenPhase Shifting Transformer Persentation-ABBSKS_2014Noch keine Bewertungen

- Expt 1Dokument2 SeitenExpt 1Aravind VinasNoch keine Bewertungen

- Lec. 2Dokument15 SeitenLec. 2Ihssan JamallNoch keine Bewertungen