Beruflich Dokumente

Kultur Dokumente

Designing A Hydraulic Ram Pump 2005

Hochgeladen von

Aavash PokhrelOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Designing A Hydraulic Ram Pump 2005

Hochgeladen von

Aavash PokhrelCopyright:

Verfügbare Formate

Designing a Hydraulic Ram Pump

Water For The World

Designing a Hydraulic Ram Pump

Technical Note No. RWS.4.D.5

[ Index | Bottom ]

A hydraulic ram or impulse pump is a device which uses the energy of falling water to lift a lesser amount of water to a higher elevation than the source. See Figure 1. There are only two moving parts, thus there is little to wear out. Hydraulic rams are relatively economical to purchase and install. One can be built with detailed plans and if properly installed, they will give many trouble-free years of service with no pumping costs. For these reasons, the hydraulic ram is an attractive solution where a large gravity flow exists. A ram should be considered when there is a source that can provide at least seven times more water than the ram is to pump and the water is, or can be made, free of trash and sand. There must be a site for the ram at least 0.5m below the water source and water must be needed at a level higher than the source. Factors in Design Before a ram can be selected, several design factors must be known. These are shown in Figure 1 and include: 1. The difference in height between the water source and the pump site (called vertical fall). 2. The difference in height between the pump site and the point of storage or use (lift). 3. The quantity (Q) of flow available from the source. 4. The quantity of water required. 5. The length of pipe from the source to the pump site (called the drive pipe). 6. The length of pipe from the pump to the storage site (called the delivery pipe). Once this information has been obtained, a calculation can be made to see if the amount of water needed can be supplied by a ram. The formula is: D=(S x F x E)/L Where: D = Amount delivered in liters per 24 hours. S = Quantity of water supplied in liters per minute. F = The fall or height of the source above the ram in meters. E = The efficiency of the ram (for commercial models use 0.66, for home built use 0.33 unless otherwise indicated).

http://www.lifewater.org/wfw/rws4/rws4d5.htm (1 of 5) [1/12/2005 12:30:31 PM]

Designing a Hydraulic Ram Pump

L = The lift height of the point of use above the ram in meters. Table 1 solves this formula for rams with efficiencies of 66 percent, a supply of 1 liter per minute, and with the working fall and lift shown in the table. For supplies greater than 1 liter/minute, simply multiply by the number of liters supplied.

Table 1. Ram Performance Data for a Supply of 1 liter/minute Liters Delivered over 24 Hours Lift - Vertical Height to which Water is Raised Above the Ram (m) 5 7.5 10 15 20 30 40 50 60 80 100 125 1.0 144 77 65 33 29 19.5 12.5 1.5 135 96.5 70 54 36 19 15 2.0 220 156 105 79 53 33 25 19.5 12.5 2.5 280 200 125 100 66 40.5 32.5 24 15.5 12 3.0 260 180 130 87 65 51 40 27 17.5 12 3.5 215 150 100 75 60 46 31.5 20 14 4.0 255 173 115 86 69 53 36 23 16 5.0 310 236 155 118 94 71.5 50 36 23 6.0 282 185 140 112 93.5 64.5 47.5 34.5 7.0 216 163 130 109 82 60 48 8.0 187 149 125 94 69 55 9.0 212 168 140 105 84 62 10.0 245 187 156 117 93 69 12.0 295 225 187 140 113 83 14.0 265 218 167 132 97 16.0 250 187 150 110 18.0 280 210 169 124 20.0 237 188 140 Components of Hydraulic Ram Working Fall (m) A hydraulic ram installation consists of a supply, a drive pipe, the ram, a supply line and usually a storage tank. These are shown in Figure 1. Each of these component parts is discussed below: Supply. The intake must be designed to keep trash and sand out of the supply since these can plug up the ram. If the water is not naturally free of these materials, the intake should be screened or a settling basin provided.

http://www.lifewater.org/wfw/rws4/rws4d5.htm (2 of 5) [1/12/2005 12:30:31 PM]

Designing a Hydraulic Ram Pump

When the source is remote from the ram site, the supply line can be designed to conduct the water to a drive pipe as shown in Figure 2. The supply line, if needed, should be at least one pipe diameter larger than the drive pipe. Drive pipe. The drive pipe must be made of a non-flexible material for maximum efficiency. This is usually galvanized iron pipe, although other materials cased in concrete will work. In order to reduce head loss due to friction, the length of the pipe divided by the diameter of the pipe should be within the range of 150-1,000. Table 2 shows the minimum and maximum pipe lengths for various pipe sizes. Table 2. Range of Drive Pipe Lengths for Various Pipe Diameters Drive Pipe Size (mm) 13 20 25 30 40 50 80 100 Length (meters) Minimum Maximum 2 13 3 20 4 25 4.5 30 6 40 7.5 50 12 80 15 100

The drive pipe diameter is usually chosen based on the size of the ram and the manufacturer's recommendations as shown in Table 3. The length is four to six times the vertical fall. Table 3. Drive Pipe Diameters by Hydram Manufacturer's Size Number Hydram Size 1 2 3 3.5 4 5 Pipe Size (mm) 32 38 51 63.5 76 101 Ram. Rams can be constructed using commercially available check valves or by fabricating check valves. They are also available as manufactured units in various sizes and pumping capacities. Rams can be used in tandem to pump water if one ram is not large enough to supply the need. Each ram must have its own drive pipe, but all can pump through a common delivery pipe as shown in Figure 3. 6 127

In installing the ram, it is important that it be level, securely attached to an immovable base, preferably concrete, and that the waste-water be drained away. The pump can-not operate when submerged. Since the ram usually operates on a 24-hour basis the size can be determined for delivery over a 24-hour period. Table 4 shows hydraulic ram capacities for one manufacturer's Hydrams.

http://www.lifewater.org/wfw/rws4/rws4d5.htm (3 of 5) [1/12/2005 12:30:31 PM]

Designing a Hydraulic Ram Pump

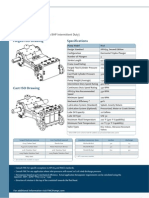

Table 4. Hydram Capacityby Manufacturer's Size Number 1 2 3 3.5 Size of Hydram 4 5X 6X 5Y 6Y

Volume of Drive Water Needed 7-16 12-25 27-55 45-96 68-137 136-270 180-410 136-270 180-410 (liters/min) Maximum Lift (m) 150 150 120 120 120 105 105 105 Delivery Pipe. The delivery pipe can be of any material that can withstand the water pressure. The size of the line can be estimated using Table 5. Table 5. Sizing the Delivery Pipe Delivery Pipe Size (mm) Flow (liters/min) 30 6-36 40 37-60 50 61-90 80 91-234 100 235-360 Storage Tank. This is located at a level to provide water to the point of use. The size is based on the maximum demand per day. Sizing a Hydraulic Ram A small community consists of 10 homes with a total of 60 people. There is a spring l0m lower than the village which drains to a wash which is 15m below the spring. The spring produces 30,000 liters of water per day. There is a location for a ram on the bank of the wash. This site is 5m higher than the wash and 35m from the spring. A public standpost is planned for the village 200m from the ram site. The lift required to the top of the storage tank is 23m. The following are the steps in design. Identify the necessary design factors: 1. Vertical fall is 10m. 2. Lift is 23m to top of storage tank. 3. Quantity of flow available equals 30,000 liters per day divided by 1,440 minutes per day (30,000/1,440) = 20.8 liters per minute. 4. The quantity of water required assuming 40 liters per day per person as maximum use is 60 people x 40 liters per day = 2,400 liters per day.

http://www.lifewater.org/wfw/rws4/rws4d5.htm (4 of 5) [1/12/2005 12:30:31 PM]

Designing a Hydraulic Ram Pump

2,400/1,440 = 1.66 liters per minute (use 2 liters per minute) 5. The length of the drive pipe is 35m. 6. The length of the delivery pipe is 200m. The above data can be used to size the system. Using Table 1, for a fall of 10m and a lift of 80m, 117 liters can be pumped a day for each liter per minute supplied. Since 2,400 liters per day is required, the number of liters per minute needed can be found by dividing 2,400 by 117: 2,400/117 = 20.5 liters per minute supply required. From item 3 above, the supply available is 20.8 liters per minute so the source is sufficient. Table 3 can now be used to select a ram size. The volume of driving water or supply needed is 20.5 liters per minute. From Table 4, a No. 2 Hydram requires from 12 to 25 liters per minute. A No. 2 Hydram can lift water to a maximum height of 150m according to Table 4. This will be adequate since the lift to the top of the storage tank is 23m. Thus, a No. 2 Hydram would be selected. Table 3 shows that for a No. 2 Hydram, the minimum drive pipe diameter is 38mm. Table 2 indicates that the minimum and maximum length for a 40mm pipe (the closest size to 38mm) is 6m-40m. Since the spring is 35m away, the length is all right. Table 5 can be used to select a delivery pipe 30mm in diameter which fits the supply needed, 20.5 liters per minute.

Posted 11/05/97 FLP [ Top | Index | Lifewater Home]

US AID Water for the World Technical Notes are made available online by

PO Box 3131 San Luis Obispo, CA 93403 USA Email us at Info@Lifewater.org

This document is not copyrighted, so you are free to print and distribute it. However, we do request that any such re-distribution be on a noncommercial basis only. Kindly reference US AID, 1982 as the author and this Lifewater web site, http://www.lifewater.org, as the source.

http://www.lifewater.org/wfw/rws4/rws4d5.htm (5 of 5) [1/12/2005 12:30:31 PM]

Water for the World Index

Water For The World

A series of US AID technical notes covering all aspects of rural water supply and sanitation, made available online by Lifewater International.

The Water For The World Technical Notes were published in 1982 by the former Development Information Center of the US Agency for International Development (AID). Although the original Notes are out of print, they still are very useful to anyone working in the field of rural water supply and sanitation. For this reason, Lifewater International has made all 160 of these Technical Notes available online in Adobe Acrobat "Portable Document Format." To view, search and print these documents, download and install the latest version of the free Acrobat ReaderTM. Can you help us with translating these documents? If so, please contact the Lifewater International webmaster. In any citation of these documents, refer to US AID (1982) as the author with this Lifewater International web site as the location where they may be obtained. Kindly direct any inquiries about this this web site to the Lifewater International webmaster, not US AID. The following credits originally appeared on the back page of each Technical Note:

Technical Notes are part of a set of "Water for the World" materials produced under contract to the U.S. Agency for International Development by National Demonstration Water Project, Institute for Rural Water, and National Environmental Health Association. Artwork was done by Redwing Art Service. Technical Notes are intended to provide assistance to a broad range of people with field responsibility for village water supply and sanitation projects in the developing nations. For more detail on the purpose, organization and suggestions for use of Technical Notes, see the introductory Note in the series, titled "Using 'Water for the World' Technical Notes." Other parts of the "Water for the World" series include a comprehensive Program Manual and several Policy Perspectives. Further information on these materials may be obtained from the Development Information Center, Agency for International Development, Washington, D. C., 20523, USA.

Top Level Index

HUMAN RESOURCES (HR) SANITATION (SAN)

[ Top | Bottom ]

http://www.lifewater.org/wfw/wfwindex.htm (1 of 8) [1/12/2005 12:30:42 PM]

Water for the World Index

Community Participation q Operation and Maintenance Training RURAL WATER SUPPLY (RWS) q Surface Water q Ground Water q Water Treatment q Water Distribution q Water Storage

q

Simple Excreta and Washwater Disposal q Combined Excreta and Washwater Disposal q Solid Waste Disposal DISEASE (DIS) q Water Supply, Sanitation and Disease q Specific Diseases

q

How to Use Technical Notes (HR.G)

HUMAN RESOURCES

Overview of Water and Sanitation System Development (HR.1) PDF/HTML Community Participation (HR.2)

q q q

[ Index | Bottom ]

Methods of Initiating Community Participation in Water Supply and Sanitation (HR.2.M) PDF Community Participation in Planning Water Supply and Sanitation Programs (HR.2.P) PDF Community Participation in Implementing Water Supply and Sanitation Programs (HR.2.I) PDF

Operation and Maintenance Training (HR.3)

q q q q

Methods of Operation and Maintenance Training (HR.3.M) PDF Planning Operation and Maintenance Training (HR.3.P) PDF Implementing Operation and Maintenance Training (HR.3.1) PDF Evaluating Operation and Maintenance Training (HR.3.I.2) PDF

RURAL WATER SUPPLY

Overview of Rural Water Supply (RWS.G) PDF/HTML Surface Water (RWS.1)

q q q q

[ Index | Bottom ]

Methods of Developing Sources of Surface Water (RWS.1.M) PDF/HTML Planning How to Use Sources of Surface Water (RWS.1.P.1) PDF Conducting Sanitary Surveys to Determine Acceptable Surface Water (RWS.1.P.2) PDF Selecting a Source of Surface Water (RWS.1.P.3) PDF

http://www.lifewater.org/wfw/wfwindex.htm (2 of 8) [1/12/2005 12:30:42 PM]

Water for the World Index

q q q q q q q q q q q q q q q

Choosing Where to Place Intakes (RWS.1.P.4) PDF Evaluating Rainfall Catchments (RWS.1.P.5) PDF Designing Structures for Springs (RWS.1.D.1) PDF Designing Intakes for Ponds, Lakes and Reservoirs (RWS.1.D.2) PDF Designing Intakes for Streams and Rivers (RWS.1.D.3) PDF Designing Roof Catchments (RWS.1.D.4) PDF Designing Small Dams (RWS.1.D.5) PDF Constructing Structures for Springs (RWS.1.C.1) PDF Constructing Intakes for Ponds, Lakes and Reservoirs (RWS.1.C.2) PDF Constructing Intakes for Streams and Rivers (RWS.1.C.3) PDF Constructing, Operating and Maintaining Roof Catchments (RWS.1.C.4) PDF Constructing Small Dams (RWS.1.C.5) PDF Maintaining Structures for Springs (RWS.1.O.1) PDF Maintaining Intakes (RWS.1.O.2) PDF Maintaining Small Dams (RWS.1.O.5) PDF

[ Index | Bottom ]

Ground Water (RWS.2)

q q q q q q q q q q q q q q q q q q

Methods of Developing Sources of Ground Water (RWS.2.M) PDF Planning How to Use Sources of Ground Water (RWS.2.P.1) PDF Selecting a Method of Well Construction (RWS.2.P.2) PDF Selecting a Well Site (RWS.2.P.3) PDF Designing Dug Wells (RWS.2.D.1) PDF Designing Driven Wells (RWS.2.D.2) PDF Designing Jetted Wells (RWS.2.D.3) PDF Designing Bored or Augered Wells (RWS.2.D.4) PDF Designing Cable Tool Wells (RWS.2.D.5) PDF Constructing Dug Wells (RWS.2.C.1) PDF Constructing Driven Wells (RWS.2.C.2) PDF Constructing Jetted Wells (RWS.2.C.3) PDF Constructing Bored or Augered Wells (RWS.2.C.4) PDF Constructing Cable Tool Wells (RWS.2.C.5) PDF Maintaining Well Logs (RWS.2.C.6) PDF Testing the Yield of Wells (RWS.2.C.7) PDF Finishing Wells (RWS.2.C.8) PDF Disinfecting Wells (RWS.2.C.9) PDF

[ Index | Bottom ]

Water Treatment (RWS.3)

http://www.lifewater.org/wfw/wfwindex.htm (3 of 8) [1/12/2005 12:30:42 PM]

Water for the World Index

q q q q q q q q q q q q q q q q q q

Methods of Water Treatment (RWS.3.M) PDF Determining the Need for Water Treatment (RWS.3.P.1) PDF Taking a Water Sample (RWS.3.P.2) PDF Analyzing a Water Sample (RWS.3.P.3) PDF Planning a Water Treatment System (RWS.3.P.4) PDF Designing Basic Household Water Treatment Systems (RWS.3.D.1) PDF Designing a Small Community Sedimentation Basin (RWS.3.D.2) PDF Designing a Slow Sand Filter (RWS.3.D.3) PDF Designing a Small Community Disinfection Unit (RWS.3.D.4) PDF Water Treatment in Emergencies (RWS.3.D.5) PDF Constructing a Household Sand Filter (RWS.3.C.1) PDF Constructing a Sedimentation Basin (RWS.3.C.2) PDF Constructing a Slow Sand Filter (RWS.3.C.3) PDF Constructing a Disinfection Unit (RWS.3.C.4) PDF Operating and Maintaining Household Treatment Systems (RWS.3.O.1) PDF Operating and Maintaining a Sedimentation Basin (RWS.3.O.2) PDF Operating and Maintaining a Slow Sand Filter (RWS.3.O.3) PDF Operating and Maintaining a Chemical Disinfection Unit (RWS.3.O.4) PDF

[ Index | Bottom ]

Water Distribution (RWS.4)

q q q q q q q q q q q q q q q q q q

Methods of Delivering Water (RWS.4.M) PDF Choosing Between Gravity Flow and Pumps (RWS.4.P.1) PDF Choosing Between Community Distribution Systems and Household Water (RWS.4.P.2) PDF Selecting Pipe Materials (RWS.4.P.3) PDF Selecting a Power Source for Pumps (RWS.4.P.4) PDF Selecting Pumps (RWS.4.P.5) PDF Manufacturing Hand Pumps Locally (RWS.4.P.6) PDF Designing a System of Gravity Flow (RWS.4.D.1) PDF Determining Pumping Requirements (RWS.4.D.2) PDF Designing a Transmission Main (RWS.4.D.3) PDF Designing Community Distribution Systems (RWS.4.D.4) PDF Designing a Hydraulic Ram Pump (RWS.4.D.5) PDF/HTML Installing Pipes (RWS.4.C.1) PDF Installing Mechanical Pumps (RWS.4.C.2) PDF Installing Hand Pumps (RWS.4.C.3) PDF Constructing Community Distribution Systems (RWS.4.C.4) PDF Constructing a Distribution System with Household Connections (RWS.4.C.5) PDF Detecting and Correcting Leaking Pipes (RWS.4.O.1) PDF

http://www.lifewater.org/wfw/wfwindex.htm (4 of 8) [1/12/2005 12:30:42 PM]

Water for the World Index

q q q

Operating and Maintaining Mechanical Pumps (RWS.4.O.2) PDF Operating and Maintaining Hand Pumps (RWS.4.O.3) PDF Operating and Maintaining Household Water Connections (RWS.4.O.5) PDF

[ Index | Bottom ]

Water Storage (RWS.5)

q q q q q q q q q

Methods of Storing Water (RWS.5.M) PDF Determining the Need for Water Storage (RWS.5.P.1) PDF Designing a Household Cistern (RWS.5.D.1) PDF Designing a Ground Level Storage Tank (RWS.5.D.2) PDF Designing an Elevated Storage Tank (RWS.5.D.3) PDF Constructing a Household Cistern (RWS.5.C.1) PDF Constructing a Ground Level Storage Tank (RWS.5.C.2) PDF Constructing an Elevated Storage Tank (RWS.5.C.3) PDF Maintaining Water Storage Tanks (RWS.5.O.1) PDF

SANITATION

Overview of Sanitation (SAN.G) PDF Simple Excreta and Washwater Disposal (SAN.1)

q q q q q q q q q q q q q q

[ Index | Bottom ]

Simple Methods of Excreta Disposal (SAN.1.M.1) PDF Simple Methods of Washwater Disposal (SAN.1.M.2) PDF Planning Simple Excreta and Washwater Disposal Systems (SAN.1.P) PDF Designing Slabs for Privies (SAN.1.D.1) PDF Designing Pits for Privies (SAN.1.D.2) PDF Designing Privy Shelters (SAN.1.D.3) PDF Designing Aqua Privies (SAN.1.D.4) PDF Designing Bucket Latrines (SAN.1.D.5) PDF Designing Compost Toilets (SAN.1.D.6) PDF Designing Sumps, Soakage Pits and Trenches (SAN.1.D.7) PDF Constructing Slabs for Privies (SAN.1.C.1) PDF Constructing Pits for Privies (SAN.1.C.2) PDF Constructing Privy Shelters (SAN.1.C.3) PDF Constructing Aqua Privies (SAN.1.C.4) PDF

http://www.lifewater.org/wfw/wfwindex.htm (5 of 8) [1/12/2005 12:30:42 PM]

Water for the World Index

q q q q q q q

Constructing Bucket Latrines (SAN.1.C.5) PDF Constructing Compost Toilets (SAN.1.C.6) PDF Constructing, Operating & Maintaining Sumps, Soakage Pits & Trenches (SAN.1.C.7) PDF Operating and Maintaining Privies (SAN.1.O.1) PDF Operating and Maintaining Aqua Privies (SAN.1.O.4) PDF Operating and Maintaining Bucket Latrines (SAN.1.O.5) PDF Operating and Maintaining Compost Toilets (SAN.1.O.6) PDF

[ Index | Bottom ]

Combined Excreta and Washwater Disposal (SAN.2)

q q q q q q q q q q q q q q q q q q q q q q q

Methods of Combined Washwater and Excreta Disposal (SAN.2.M) PDF Planning Combined Washwater and Excreta Disposal Systems (SAN.2.P.1) PDF Estimating Sewage or Washwater Flows (SAN.2.P.2) PDF Determining Soil Suitability (SAN.2.P.3) PDF Designing Subsurface Absorption Systems (SAN.2.D.1) PDF Designing Cesspools (SAN.2.D.2) PDF Designing Septic Tanks (SAN.2.D.3) PDF Designing Sewer Systems (SAN.2.D.4) PDF Designing Stabilization Ponds (SAN.2.D.5) PDF Designing a System of Stabilization Ponds (SAN.2.D.6) PDF Designing Mechanically Aerated Lagoons (SAN.2.D.7) PDF Designing Non-Conventional Absorption Disposal Systems (SAN.2.D.8) PDF Constructing, Operating & Maintaining Subsurface Absorption Systems (SAN.2.C.1) PDF Constructing Cesspools (SAN.2.C.2) PDF Constructing Septic Tanks (SAN.2.C.3) PDF Constructing Sewer Systems (SAN.2.C.4) PDF Constructing Stabilization Ponds (SAN.2.C.5) PDF Constructing Mechanically Aerated Lagoons (SAN.2.C.7) PDF Constructing, Operating & Maintaining Non-Conventional Absorption Systems (SAN.2.C.8) PDF Operating and Maintaining Septic Tanks (SAN.2.O.3) PDF Operating and Maintaining Sewer Systems (SAN.2.O.4) PDF Operating and Maintaining Stabilization Ponds (SAN.2.O.5) PDF Operating and Maintaining Mechanically Aerated Lagoons (SAN.2.O.7) PDF

[ Index | Bottom ]

Solid Waste Disposal (SAN.3)

q q q

Methods of Solid Waste Management (SAN. 3. M) PDF Planning Solid Waste Management Systems (SAN.3.P) PDF Designing a Landfill (SAN.3.D.1) PDF

http://www.lifewater.org/wfw/wfwindex.htm (6 of 8) [1/12/2005 12:30:42 PM]

Water for the World Index

q q q q q q q q

Designing a Composting System (SAN.3.D.2) PDF Designing a Solid Waste Collection System (SAN.3.D.3) PDF Designing a Biogas System (SAN.3.D.4) PDF Constructing a Biogas System (SAN.3.C.4) PDF Operating and Maintaining a Landfill (SAN.3.O.1) PDF Operating and Maintaining a Composting System (SAN.3.O.2) PDF Operating a Solid Waste Collection System (SAN.3.O.3) PDF Operating and Maintaining a Biogas System (SAN.3.O.4)PDF

DISEASE

Overview of Diseases (DIS.G) PDF /HTML Water Supply, Sanitation and Disease (DIS.1)

q q q

[ Index | Bottom ]

Means of Disease Transmission (DIS.1.M.1) PDF Methods of Improving Environmental Health Conditions (DIS.1.M.2) PDF Planning Disease Control Programs (DIS.1.P.1) PDF

Specific Diseases (DIS.2)

q q q q q

Methods of Controlling Schistosomiasis (DIS.2.M.1) PDF Methods of Controlling African Trypanosomiasis (DIS.2.M.2) PDF Methods of Controlling South American Trypanosomiasis (DIS.2.M.3) PDF Methods of Controlling Enteric Diseases (DIS.2.M.4) PDF Methods of Controlling Onchocerciasis (DIS.2.M.5) PDF

[ Index | Lifewater Home]

Home | About Lifewater | HELP | Training | Water for the World | Gifts | Links

http://www.lifewater.org/wfw/wfwindex.htm (7 of 8) [1/12/2005 12:30:42 PM]

Water for the World Index

Contact Us

Last modified 08/13/02

http://www.lifewater.org/wfw/wfwindex.htm (8 of 8) [1/12/2005 12:30:42 PM]

http://www.lifewater.org/wfw/rws4/rws4d51.gif

http://www.lifewater.org/wfw/rws4/rws4d51.gif [1/12/2005 12:30:43 PM]

http://www.lifewater.org/wfw/rws4/rws4d52.gif

http://www.lifewater.org/wfw/rws4/rws4d52.gif [1/12/2005 12:30:43 PM]

http://www.lifewater.org/wfw/rws4/rws4d53.gif

http://www.lifewater.org/wfw/rws4/rws4d53.gif [1/12/2005 12:30:43 PM]

Lifewater Home Page

Lifewater International

Christians helping the rural poor obtain safe water

"A child dies every 15 seconds from diarrhoea, caused largely by poor sanitation and water supply. " You can do something about it!

Click here for info on Lifewater's response to the Asian Tsunami Disaster

Please go to our "Gifts" page to donate online. Thank you!

Find out about Lifewater and what you can do Receive the Lifewater Newsletter

Get HELP for your water problems Give a gift of water and give life! Enter the Volunteers' Corner

(Username and password required)

Get training for rural water supply development Read Water for the World Tech Notes for more help

Visit the Lifewater Canada web site

Follow links to water-related web sites and books

Search the Lifewater site for:

Search powered by WebGlimpse Copyright 1996, University of Arizona

Search

Call toll free 888-543-3426 or Email Info@Lifewater.org For staff phone numbers and email adddresses, please see our Contact

Last modified 01/05/05

Us page.

http://www.lifewater.org/index.htm [1/12/2005 12:30:44 PM]

U.S. Agency for International Development

Web Site GO

Tsunami Relief - A 9.0-magnitude earthquake and destructive tsunami has caused massive damage in many countries in South and Southeast Asia. USAID is assisting in the relief and recovery effort.

Click Here to Donate Now Helping Rebuild Iraq - USAID has been helping Iraqis reconstruct their country since the Saddam Hussein regime was overthrown in May 2003. Assistance to Afghanistan - USAID is helping build a safe, stable society that meets the needs of its people and eliminates an environment that breeds terrorism.

q

Afghanistan

GO

USAID provides economic and humanitarian assistance in more than 100 countries to provide a better future for all.

GO

Browse USAID Keyword List

Darfur Humanitarian Crisis - Though the security situation continues to deteriorate and providing humanitarian assistance is difficult, USAID is doing all it can to help. New Global Branding - The USAID Graphic Standards Manual sets the standards for the design of Agency communications. Fiscal Year 2004 Performance and Accountability Report - This report outlines what USAID has accomplished and how well we have carried out our mission. HIV/AIDS - The U.S. government is the world leader in responding to the global pandemic of AIDS and has made the fight against HIV/AIDS a top priority.

q q

01/11/05: New USAID Mission Director for India Sworn In 01/11/05: Remarks by USAID Administrator Andrew S. Natsios - US Relief Efforts to Tsunami-Affected Countries 01/10/05: Transcript and Video - President Bush Thanks USAID Employees and NGO Presidents 12/31/04: Editorial: Responding to Asia's Tragedy, by Administrator Natsios - Published in The Washington Post 12/29/04: Briefing by USAID Administrator Andrew S. Natsios Coordination of Relief Assistance for Victims of the Recent Tsunamis 12/16/04: Sweet Water Canal Restoration Complete 12/13/04: Lloyd O. Pierson Sworn In As Head of USAID's Bureau for Africa 12/08/04: Remarks by Assistant Administrator Adolfo Franco at the Caribbean Central America Action (CCAA) Conference on the Caribbean Basin

http://www.usaid.gov/ (1 of 2) [1/12/2005 12:30:48 PM]

U.S. Agency for International Development

What's New

Privacy Policy : FAQs : Help Desk : FOIA Requests : No FEAR Act : OIG Hotline

Regulations.gov FedForms - Your First Step in Federal Forms Last Updated on: January 12, 2005

http://www.usaid.gov/ (2 of 2) [1/12/2005 12:30:48 PM]

Das könnte Ihnen auch gefallen

- Hookah Bar Business PlanDokument34 SeitenHookah Bar Business PlanAbdelkebir LabyadNoch keine Bewertungen

- Coil Pump Performance Under Variable Operating ConditionsDokument18 SeitenCoil Pump Performance Under Variable Operating ConditionsIime Pertuz MontoyiitaNoch keine Bewertungen

- School Form 10 SF10 Learners Permanent Academic Record For Elementary SchoolDokument10 SeitenSchool Form 10 SF10 Learners Permanent Academic Record For Elementary SchoolRene ManansalaNoch keine Bewertungen

- Manual Geo5 2018 Feb enDokument1.520 SeitenManual Geo5 2018 Feb enCEGUS CATALINNoch keine Bewertungen

- Hydraulic Ram Pump Research Programme Technical ReleaseDokument6 SeitenHydraulic Ram Pump Research Programme Technical ReleaseAirPop24Noch keine Bewertungen

- Coanda Intake ScreenDokument26 SeitenCoanda Intake ScreenAnonymous aigwY0jgzpNoch keine Bewertungen

- Sewage Works Design Standard PDFDokument43 SeitenSewage Works Design Standard PDFmishtinilNoch keine Bewertungen

- Development and Operational Experience With Topless Wood Gasifier Running A 3.75 KW Diesel Engine PumpsetDokument10 SeitenDevelopment and Operational Experience With Topless Wood Gasifier Running A 3.75 KW Diesel Engine PumpsetMag FhearadhaighNoch keine Bewertungen

- Permissible Velocities in Lined ChannelsDokument2 SeitenPermissible Velocities in Lined ChannelsEknath TaleleNoch keine Bewertungen

- Manual of Mainlaying Practice guide for water pipe design and installationDokument127 SeitenManual of Mainlaying Practice guide for water pipe design and installationtongdannyNoch keine Bewertungen

- Coanda Intake Basics: Self-Cleaning Water Intake GuideDokument4 SeitenCoanda Intake Basics: Self-Cleaning Water Intake GuideClemente CurnisNoch keine Bewertungen

- Rotodynamic Vertical Pumps: For Manuals Describing Installation, Operation, and MaintenanceDokument57 SeitenRotodynamic Vertical Pumps: For Manuals Describing Installation, Operation, and MaintenanceShubhrajeet TiwariNoch keine Bewertungen

- Instalasi Turbin Air IIDokument10 SeitenInstalasi Turbin Air IIIfnu SetyadiNoch keine Bewertungen

- Rampump17 130607092419 Phpapp01 PDFDokument50 SeitenRampump17 130607092419 Phpapp01 PDFRaden GilićNoch keine Bewertungen

- Banki Turbine A Construction ManualDokument58 SeitenBanki Turbine A Construction Manualerick_mdsNoch keine Bewertungen

- Design, Manufacture and Test A Hydraulic Ram: ThesisDokument42 SeitenDesign, Manufacture and Test A Hydraulic Ram: ThesisIrfan ShaikhNoch keine Bewertungen

- Development and Performance Evaluation of A Three Rollers Acha (Digitaria Exilis) Dehusking MachineDokument11 SeitenDevelopment and Performance Evaluation of A Three Rollers Acha (Digitaria Exilis) Dehusking MachineAZOJETE100% (1)

- Hydraulic Ram Pump ReportDokument42 SeitenHydraulic Ram Pump ReportliviciuklNoch keine Bewertungen

- Presentation PDFDokument33 SeitenPresentation PDFVetriselvan ArumugamNoch keine Bewertungen

- Precise automated or manual tilting weir gatesDokument3 SeitenPrecise automated or manual tilting weir gatessandaldm100% (1)

- Lecture 4 Hydraulic Design of Drainage StructuresDokument27 SeitenLecture 4 Hydraulic Design of Drainage StructuresSilas Nana-Baah MensahNoch keine Bewertungen

- Belt spec guide to find your part numberDokument2 SeitenBelt spec guide to find your part numberJoão FerreiraNoch keine Bewertungen

- Coanda Hydro Intake ScreenDokument32 SeitenCoanda Hydro Intake ScreenefcarrionNoch keine Bewertungen

- NuFlo EZ-In User Manual - PEDDokument32 SeitenNuFlo EZ-In User Manual - PEDsarkaft100% (1)

- Irrigation MethodsDokument1 SeiteIrrigation Methodssalmanabu25Noch keine Bewertungen

- Spancast Site Visit Report on Precast Concrete ProductsDokument20 SeitenSpancast Site Visit Report on Precast Concrete ProductsAddrien DanielNoch keine Bewertungen

- Bomba OblDokument24 SeitenBomba OblJos RicardoNoch keine Bewertungen

- Slide GateDokument11 SeitenSlide Gate陈淀Noch keine Bewertungen

- Designing Cut-Off Walls Under Concrete DamDokument17 SeitenDesigning Cut-Off Walls Under Concrete DamNazakat HussainNoch keine Bewertungen

- Intruction Manual FSADokument10 SeitenIntruction Manual FSAtrantuan74Noch keine Bewertungen

- 01 ST601 Design of Hydraulic Steel Structures (Miter Gates)Dokument55 Seiten01 ST601 Design of Hydraulic Steel Structures (Miter Gates)JonesNoch keine Bewertungen

- Winches and Reels Tension in Line and Pressure On The Drum and Flanges PDFDokument18 SeitenWinches and Reels Tension in Line and Pressure On The Drum and Flanges PDFjosebernal_mzaNoch keine Bewertungen

- Under Running Single GirderDokument8 SeitenUnder Running Single GirderJorge GtzNoch keine Bewertungen

- Hidrostal Submersible Immersible PDFDokument8 SeitenHidrostal Submersible Immersible PDFariyamanjulaNoch keine Bewertungen

- Base Plate GroutingDokument2 SeitenBase Plate GroutingTamer EmamNoch keine Bewertungen

- V1S3 Traveling Block Manual 2015.4.17Dokument6 SeitenV1S3 Traveling Block Manual 2015.4.17tavingus2Noch keine Bewertungen

- Design, Construction and Maintenance of Relief WellsDokument92 SeitenDesign, Construction and Maintenance of Relief Wellsmote34Noch keine Bewertungen

- Steel Beam SpecificationDokument24 SeitenSteel Beam SpecificationDilshad AhemadNoch keine Bewertungen

- HDPE Stub End Dimension Specification Chart PN 3.2-16Dokument4 SeitenHDPE Stub End Dimension Specification Chart PN 3.2-16Garfang RattanapunNoch keine Bewertungen

- Plunger Pump M18Dokument4 SeitenPlunger Pump M18Pipe LopezNoch keine Bewertungen

- Waterfront Stoplogs GuideDokument1 SeiteWaterfront Stoplogs GuideiculasiNoch keine Bewertungen

- Shear Force For SBRDokument14 SeitenShear Force For SBRnjava1978Noch keine Bewertungen

- Wirth TPK 2200Dokument2 SeitenWirth TPK 2200PABLOHEREDIANoch keine Bewertungen

- GSI SiloDokument32 SeitenGSI Silousman sharifNoch keine Bewertungen

- Army TM 5-818-1 Air Force Afm 88-3, Chap. 7Dokument204 SeitenArmy TM 5-818-1 Air Force Afm 88-3, Chap. 7math0506Noch keine Bewertungen

- Tyrolean Intake Calculation PDFDokument125 SeitenTyrolean Intake Calculation PDFAlban100% (1)

- Code of Practice on Sewerage and Sanitary WorksDokument56 SeitenCode of Practice on Sewerage and Sanitary Worksgridguerilla2555Noch keine Bewertungen

- Irrigation Structures Modules: Canal Drops and RegulatorsDokument26 SeitenIrrigation Structures Modules: Canal Drops and RegulatorsIssa DrdrNoch keine Bewertungen

- Trash Rack Rotary AdiyasaDokument1 SeiteTrash Rack Rotary AdiyasaHengki f Sukresno100% (1)

- Griffin Construction Dewatering Systems GuideDokument36 SeitenGriffin Construction Dewatering Systems Guideakash nairNoch keine Bewertungen

- Designing A Hydraulic Ram Pump: Water For The WorldDokument25 SeitenDesigning A Hydraulic Ram Pump: Water For The Worldsms19100% (2)

- Water For The WorldDokument12 SeitenWater For The WorldzaharniciucsNoch keine Bewertungen

- Hydraulic Ram PumpDokument5 SeitenHydraulic Ram PumpHatem AbdelnabiNoch keine Bewertungen

- PlumbingDokument62 SeitenPlumbingyildyusuf100% (2)

- Guidelines For Sizing: FeaturesDokument8 SeitenGuidelines For Sizing: FeaturesApih Ibrahim100% (1)

- Paddle Powered Water PumpDokument35 SeitenPaddle Powered Water PumpJahanzaib Khan100% (1)

- Ram Pump PDFDokument9 SeitenRam Pump PDFoliververonamanuelNoch keine Bewertungen

- Designing Efficient Sewage Pumping SystemsDokument10 SeitenDesigning Efficient Sewage Pumping SystemsPriyanka Rupasinghe67% (3)

- Sewer Bypass PumpingDokument6 SeitenSewer Bypass PumpingSohaib AhmedNoch keine Bewertungen

- Bs 6700 Pipe SizingDokument20 SeitenBs 6700 Pipe SizingVelan SivasakthiNoch keine Bewertungen

- Basic Pump Station DesignDokument24 SeitenBasic Pump Station Designzaldy1985Noch keine Bewertungen

- GEMI Equations ToolDokument10 SeitenGEMI Equations TooljnmanivannanNoch keine Bewertungen

- Schneider ACB 2500 amp MVS25 N - Get Best Price from Mehta Enterprise AhmedabadDokument7 SeitenSchneider ACB 2500 amp MVS25 N - Get Best Price from Mehta Enterprise AhmedabadahmedcoNoch keine Bewertungen

- Aero T RopolisDokument9 SeitenAero T RopolisZeynep çetinelNoch keine Bewertungen

- CV Experienced Marketing ProfessionalDokument2 SeitenCV Experienced Marketing ProfessionalPankaj JaiswalNoch keine Bewertungen

- Understanding the Causes and Misconceptions of PrejudiceDokument22 SeitenUnderstanding the Causes and Misconceptions of PrejudiceმარიამიNoch keine Bewertungen

- Taxation of XYZ Ltd for 2020Dokument2 SeitenTaxation of XYZ Ltd for 2020zhart1921Noch keine Bewertungen

- MKT201 Term PaperDokument8 SeitenMKT201 Term PaperSumaiyaNoorNoch keine Bewertungen

- Dua' - Study Circle 1Dokument12 SeitenDua' - Study Circle 1Dini Ika NordinNoch keine Bewertungen

- Hamilton EssayDokument4 SeitenHamilton Essayapi-463125709Noch keine Bewertungen

- IFB Microwave Oven Customer Care in HyderabadDokument8 SeitenIFB Microwave Oven Customer Care in HyderabadanilkumarNoch keine Bewertungen

- Qustion 2020-Man QB MCQ - MAN-22509 - VI SEME 2019-20Dokument15 SeitenQustion 2020-Man QB MCQ - MAN-22509 - VI SEME 2019-20Raees JamadarNoch keine Bewertungen

- Cartagena PresentationDokument20 SeitenCartagena PresentationPaula SimóNoch keine Bewertungen

- Anthony VixayoDokument2 SeitenAnthony Vixayoapi-533975078Noch keine Bewertungen

- Investment Decision RulesDokument113 SeitenInvestment Decision RulesHuy PanhaNoch keine Bewertungen

- Pradeep Kumar SinghDokument9 SeitenPradeep Kumar SinghHarsh TiwariNoch keine Bewertungen

- Ombudsman Complaint - TolentinoDokument5 SeitenOmbudsman Complaint - TolentinoReginaldo BucuNoch keine Bewertungen

- Intermediate Algebra For College Students 7th Edition Blitzer Test BankDokument19 SeitenIntermediate Algebra For College Students 7th Edition Blitzer Test Bankdireful.trunnionmnwf5100% (30)

- Microsoft Word - I'm Secretly Married To A Big S - Light DanceDokument4.345 SeitenMicrosoft Word - I'm Secretly Married To A Big S - Light DanceAliah LeaNoch keine Bewertungen

- Spouses Ismael and Teresita Macasaet Vs Spouses Vicente and Rosario MacasaetDokument20 SeitenSpouses Ismael and Teresita Macasaet Vs Spouses Vicente and Rosario MacasaetGladys Laureta GarciaNoch keine Bewertungen

- MG6863 - ENGINEERING ECONOMICS - Question BankDokument19 SeitenMG6863 - ENGINEERING ECONOMICS - Question BankSRMBALAANoch keine Bewertungen

- Business LawDokument4 SeitenBusiness LawMelissa Kayla ManiulitNoch keine Bewertungen

- Baccmass - ChordsDokument7 SeitenBaccmass - ChordsYuan MasudaNoch keine Bewertungen

- Decathlon - Retail Management UpdatedDokument15 SeitenDecathlon - Retail Management UpdatedManu SrivastavaNoch keine Bewertungen

- English The Salem Witchcraft Trials ReportDokument4 SeitenEnglish The Salem Witchcraft Trials ReportThomas TranNoch keine Bewertungen

- Call LetterDokument1 SeiteCall Letterஉனக்கொரு பிரச்சினைனா நான் வரேண்டாNoch keine Bewertungen

- Araneta v. Gatmaitan, 101 Phil. 328Dokument3 SeitenAraneta v. Gatmaitan, 101 Phil. 328Bibi JumpolNoch keine Bewertungen

- Life Member ListDokument487 SeitenLife Member Listpuiritii airNoch keine Bewertungen

- Todd Pace Court DocketDokument12 SeitenTodd Pace Court DocketKUTV2NewsNoch keine Bewertungen

- Service Culture Module 2Dokument2 SeitenService Culture Module 2Cedrick SedaNoch keine Bewertungen