Beruflich Dokumente

Kultur Dokumente

70M Offshore Brochure

Hochgeladen von

Anilton SouzaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

70M Offshore Brochure

Hochgeladen von

Anilton SouzaCopyright:

Verfügbare Formate

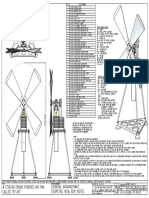

Ultra High Pressure Electrical Offshore Services Pump Unit

70 M P12 / Zone 2, Group IIA, T3 Mounted in a Lifting Frame certified to DNV 2.7.1

WOMA Designed SINGLE 70m UHP specifically for use in the Offshore Oil & Gas industry. Main Drive 30/36Kw, Three phase, surface cooled, electric motor WOMA Pump producing 9.9 L/M @ 2000 Bar. EEx de LLC T 6 Explosion proof Technical specification: Pump Type WOMA 70M P12 Nominal Flow Q = 9.9 litres per minute Operating Pressure P = 2000 Bar / 29,000 psi Single gun operation Flow from 2 Units can be converged for greater production demands Pumping Medium Water NPSH 3-8 Bar Water Temperature Max. 60 Deg. Celsius Requested Drive P = 36 kW,65A Driving Speed N = 729 RPM Pressure regulator as spill valve and in function as 2/2-way valve continuously adjustable, pneumatically operated.

Fully Certified Offshore Lifting Frame (DNV) 2.7.1 Switch BoxStar Delta Explosion Proof Class EEx de IIC T 6

hpwater@woma.com.au www.woma.com.au

Ultra High Pressure Electrical Offshore Services Pump Unit

70 M P12 / Zone 2, Group IIA, T3 Mounted in a Lifting Frame certified to DNV 2.7.1

Consisting of: HP PUMP TYPE WOMA 70M P12 Nominal Flow Rate Operating Pressure Maximum NPSH Pumping Medium Water Temperature Maximum Requested Drive Driving Speed Materials: Pump Head Conversion Set Plungers

Q = 9.9 Litres/ Minute p = 2,000 Bar / 29,000 PSI 3-8 BAR Water 60o Celsius P = 36 kW n = 729 rpm Stainless Steel Stainless Steel Tungsten Carbide

Pressurised water control through: Pressure regulator as spill valve and in function as 2/2-way valve continuously adjustable, pneumatically operated. Check valve, pneumatically operated. Function: Closing of consumer line at pressure less pump work Transmission by: Reduction gear flanged direct to motor (Explosion proof) according to ATEX (1:2,47 type Fender. Drive: Motor Output Speed Frequency Tension Construction Protection Explosion Class System complete with E-Switch Box: Electric 30/36kW 1500/1800 rpm 50/60 cycle 400/460/690 V B3 IP 55 EEx de IIB T4

Switch BoxStar Delta Explosion Proof Class EEx de IIC T 6 equipped with; Operating Hour Counter Emergency Stop Buttons Mains Power Supply Connection 35m of Power Cable Automatic Shutdown in case of; Booster Pressure Minimum (Dry-Run protection) Water Temperature maximum Compressed Air Minimum Header Tank Water Level Minimum

Ultra High Pressure Electrical Offshore Services Pump Unit

70 M P12 / Zone 2, Group IIA, T3 Mounted in a Lifting Frame certified to DNV 2.7.1

Booster Pump Prime Pump runs off main drive to ensure main pump is fed with correct quantity and pressure of water at all times Filter Housing Single Filter with 3 Filter Cartridges 5 micron Header tank made of stainless steel Volume approximately 80 litres. Tank complete with level control and Bypass return to Header. Further equipment: Pneumatic switch box (6 bar air pressure & 3 I per switch at site) Full lift safety valve Pressure gauge 2 Side doors Water SupplyChicago coupling Discharge Connection for VHP hose (DN8, 2100bar) Discharge Connection for safety valveChicago coupling Compressed air connection for external supply Compress air connection for UHP gun Central emergency stop button Standard tool kit Documentation 1 fold Further equipment to comply to Offshore Specs Unit equipped with stainless steel 316 crash frame C/W fork lift pockets

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Three-Phase Electric Motor: General Information FileDokument66 SeitenThree-Phase Electric Motor: General Information FileJacob SánchezNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- JCTN SampleDokument8 SeitenJCTN Samplepalaniraj pNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Physics 151 LectureDokument72 SeitenPhysics 151 LecturechioNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- M1 Ques Slide 1 - 1Dokument4 SeitenM1 Ques Slide 1 - 1knizam1971Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Mill Liner BrochureDokument28 SeitenMill Liner BrochureJoseNoch keine Bewertungen

- Approved List of Manufacturers: CategoryDokument3 SeitenApproved List of Manufacturers: Categorytomj9104Noch keine Bewertungen

- SECTION 15010: Handbook of FundamentalsDokument5 SeitenSECTION 15010: Handbook of FundamentalsAndy WijayaNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- T Mech Clamp CatalogueDokument29 SeitenT Mech Clamp CatalogueKABIR CHOPRANoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Physics XI STBB MOC 2023Dokument3 SeitenPhysics XI STBB MOC 2023Habib U Zaman MemonNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Parafusos Com Gargantachapter 3Dokument7 SeitenParafusos Com Gargantachapter 3Miguel QueirosNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Manning S CoefficientDokument9 SeitenManning S CoefficientvyrgoNoch keine Bewertungen

- PDF 5 Mechanics of DBDokument16 SeitenPDF 5 Mechanics of DBRizette PaloganNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Especificaciones de Rectificadora de CigueñalDokument10 SeitenEspecificaciones de Rectificadora de CigueñalCR OtinianoNoch keine Bewertungen

- r050210104 Fluid MechanicsDokument10 Seitenr050210104 Fluid MechanicsSrinivasa Rao G100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Hydraulic and Compressible Flow TurbomachinesDokument146 SeitenHydraulic and Compressible Flow TurbomachinesPaul Healy100% (3)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Las2 PSDokument1 SeiteLas2 PSlukewendellrNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Asme Sec Viii D1 Nma App y PDFDokument15 SeitenAsme Sec Viii D1 Nma App y PDFADRIANNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Dynamic Oring SealingDokument49 SeitenDynamic Oring SealingRobert ChristoNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Vapor Pressure of A Pure LiquidDokument9 SeitenVapor Pressure of A Pure LiquidLuluaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- GEA PHE Fullywelded Phe en 1Dokument12 SeitenGEA PHE Fullywelded Phe en 1gemagdyNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- JEE Main 2020-22 PYQ Heat and ThermodynamicsDokument208 SeitenJEE Main 2020-22 PYQ Heat and Thermodynamicspankaj baidNoch keine Bewertungen

- GB E4313 - AWS A5.1 E6013 Welding Rods - Carbon Steel ElectrodeDokument2 SeitenGB E4313 - AWS A5.1 E6013 Welding Rods - Carbon Steel ElectrodeArfanAli100% (1)

- Troubleshooting: 4-1. Error ModesDokument8 SeitenTroubleshooting: 4-1. Error ModesluisNoch keine Bewertungen

- CV - Vishal SharmaDokument5 SeitenCV - Vishal SharmaVISHAL SHARMANoch keine Bewertungen

- LR Energy Guidance Notes For The Calculation of Probabilistic Explosion LoadsDokument18 SeitenLR Energy Guidance Notes For The Calculation of Probabilistic Explosion LoadsjmScriNoch keine Bewertungen

- Scalar Wars The Brave New World of Scalar ElectromagneticsDokument76 SeitenScalar Wars The Brave New World of Scalar ElectromagneticsPerfectKey21Noch keine Bewertungen

- Gastester G4125 InstructionsDokument20 SeitenGastester G4125 InstructionsTom ToyeNoch keine Bewertungen

- 1Dokument39 Seiten1aimanzoeyNoch keine Bewertungen

- Wear Resistance of Material Used in Slurry TransportDokument7 SeitenWear Resistance of Material Used in Slurry TransportwoodoobooNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Kyko Fan Stirling JDW CompletDokument3 SeitenKyko Fan Stirling JDW CompletNam Hoang50% (2)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)