Beruflich Dokumente

Kultur Dokumente

Cold-Cracking Control in Low-Alloy Steel Welds

Hochgeladen von

Shijumon KpOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cold-Cracking Control in Low-Alloy Steel Welds

Hochgeladen von

Shijumon KpCopyright:

Verfügbare Formate

McMaster University

DigitalCommons@McMaster

Open Access Dissertations and Theses Open Dissertations and Theses

9-1-1979

Cold-Cracking Control in Low-Alloy Steel Welds

Vivek Pavaskar

This Thesis is brought to you for free and open access by the Open Dissertations and Theses at DigitalCommons@McMaster. It has been accepted for

inclusion in Open Access Dissertations and Theses by an authorized administrator of DigitalCommons@McMaster. For more information, please

contact scom@mcmaster.ca.

Recommended Citation

Pavaskar, Vivek, "Cold-Cracking Control in Low-Alloy Steel Welds" (1979). Open Access Dissertations and Theses. Paper 2753.

http://digitalcommons.mcmaster.ca/opendissertations/2753

McMaster

Handlton; Ontario

r ..

"

S.eptembcr 1979

, .

(

.-

-,

'.

-'

' ..

,,'

"

.'

0"

.-

'- ""

.-

....

,

...

..

/

-. . ..

,

'.

"

,

.\

.. ....

."-

"\ .

~

'.

_,L

r"

I

I

)

a

. .

. ,

#

..

c

IN

'.

"

LOW-ALLOY S'1'E!:L WELDS

-

. .

" .

'.

'.>

, .

..

, ,

, .

" }.

'.

,

,"

. ' .

- .

MSUR Of' DCD+Rnax: (197'9)

~

(MetaUurcJY aDd ICateria1.a SC1eftCe)

. -

AT11'HOR:

SUPERVISOR:

Vivek Pavaskar. B. '1'ech. ( I ~ InSt!tute of

'recbnology. BcGlbay)

Dr. J _ S. JCirkaldy

-.

-,

.'

,

4 \.

"

. t

, ~

ii

....

"

0

.

tIIf

.

(

~

\

/'

/

.:

,.,.

-',

,

...

" .

, '.

....

..

..

..

,.

..

-\

, 's. . I

BAZ microst:ructure" anc1'1-lyckogen level

, \ -

t&J. faet="<; 5!"'. cold s""ceptihlUty RAZ.

Implant v ious hYdroqen leve'1.s over A range of steel. CCIIIpO-

I, , ':. . ...

and he 1n s ..shows how the

,

level influence the cx::itic4l -stress for cold-cracking.

,

_._.--_.. -

, ,

. 'Based on implant test 4 cOrrelation fOrlUula prC'dieting. the

. ,

, stress necessary for cold cracking for given HAZ ,

transfet ,

'"

marten'site in the HAZ -4nd hydrogen -revel, is proposed. Elnpioying this

. ......

. ,

prediction'of 'in the

. .

correlation. together

'HAZ hardness. on

..

.\

tion-cooling relations anc

"

tions, an which can p!cdict the stress necessary for

cracking given implant cooling rate and level,

.p

is constructed.

....

niis, method of predicting the-critical stress'necessary for cold

cracki.ng is an over tht: ex.isting regression formulas fo'l;

. ,-

estindting cold-,racking susceptibility.

, . .

This formula has been to predict cold-crack-

ing susceptibility data as obtained such as rigid

and to to cold-crack-

ing. Development and use of <l:"l inplant machine ""ith-an automatic

and loading facility reported.

I'

n

f

.

iii

)

.\' , .

,..

" .

1.

;-.-'

., "

f

'.

:

'\...

. '

"

- '

- -

-,

.-

-

.

.........

"

...

. ...,

..

...... . ......

'1'be.. abthoc.1a indebted his aaperviaor, Dr. J. S. J:1%'ka1dy,

,

'.

. .

.

I

for de< 'for hia cont.iJluoua

- ... .. 1#

throughout the course of this 'nlanks. are a1.so'due to

"many\ of gradUoite students in the De-partment of Meta11urgy

for their advice and assistance. X wou1d al.so

like to thank the technical staff of the Department of Metallurw and

the machine shop for their assjstan<:e in de-

o "

veloping the Equipment, Thanks are also due to Mrs.

the excellent typing 'of this thesis.

/'"

, , .

suppOrt of the Natural Sciences and Engineering

Research Couneil of Canada is gratefully acknowledged .

./

, .

,

,

-.._-

..

. -.

r

i

1

1

"

iv

'.

G ,/

'.

-.

. ;

PAGE"

OIAP1'ER 1 .IN'l'RODOCTION 1

CHAP'1"ER 2 ASSESSDlC THE OF THE HEAT ,

. .

AFP'EX:"tEO ZONE (HAZ) IN S'l"EEL

'-.

2.1 Weldability Formulas for !,-ssessi{\g

Susceptibility

/

4

2.2 Implant Testin; for

: Susceptibi lit.y

. 15

J

CHAPTER 3 INFLUENCE OF HAZ .;.:::> HYOROGEtl LEVEL ON

, ,

3.1

Test Data

..

19

3.2 Influence of , Harcness on a

CR

20

3. 3 (' f i ed' Corre ticnt"Forr..u Ill, . : or a

CR

ROle in o.

. .

23

25

3.4.1 Concentration and

, .

. '

Str*:;ss I::tensity in tl'\t: of Haximum

i 36

3.4.2 , . 38

CHAPTER 0 . BAS!S 0; tNPG1, PLATE

CR .

Cooling Rate

4.2.1 He<lt-.Tran:ifer wit'h 30"r.",=,H. Fl'Ow

42

46

o

4,_2..1.1 Applic<ltio:'\ 0: 3:) HC<1t F.lm"

\..

..

4.2

r

I

"/

..

\

v

I

J_

-.

.,

.

..

.. '

.0

51

PACZ,';

-

. ',"

... ...... .' .... : .

.'-'-,' ,. -'-

'.;"

2D, Heat Flow

2.SD Heat Flow .

4.2.2 Heat 'transfer With

Heat

( .

4.2.4 Representation of Heat Flow

.... 0

!

,

I

. /

! "

-, .

'.'\ J

,

I

;

/ /

Conditions as a Function of Plate 'l'hiclcness 52

."

4.2.5 Procedure for Preaicting Cooling Rate 53

4.2'.6 Discussion

4.3 Prediction of Heat Affected Zone Microstructure

55

4.3,i , Klcroconstituent -.Composition - COoling

,

Rate 57

4.3.2-Hardness - Composition -'Cooling Rate

Reiations

t

59

;

(--4.3.3 Prediction of HAZ , Martensite and Hardness

, w

59

4.3.4 Discussion 63

CHAPTER 5 DETERMINATION OF PRACTICAL WELDING PROCEDURES ON THE

BASIS OF IMPLANT TEST 82

5.1 General Remarks 82

5.2 Between Implant Test and Otht!T kstraint

Tests 82

'5.3 Determination of Prehea.t to Avoid Cracking 84

5.3.1 Estimation of Reuction Stress Developed in

the Welc 87

.'

5.3.2 of on Resicual Hydrogen

Level 88

5.'.3 Prediction of Prehedt Level to Crucking 91

vi

t

7 CONCLUSIONS

\

!!e!..

92

110

110

110

111

113

113

115

115

120

126

126

-

133

..

.:... ..

, .

';'.:.'

- -'..

6.2.3 The Pressure Systeo for the Implant Test

6.2.1 AutO!Datic Deposition of Electrodes

6.2.2 '!'he Il:lpl4nt Loadinc;' tem

6.3.2 Implant 7est'Details.

6.3.1 Welding

6.4 Prelic1nary ?ests

6.5 DisCI..-ssion

6.3 Standardization of the- Iop1a."1': Testing Procedure

6.1 General Remarks

of th"e Testinc; Machine

, "

._. ':--

.... -: ..

.... ,..

,-,

',.' ,"

.:. .".'

.'

..,p.. :,.

;;"' .. ':"

APPEt'DIX I 1-3

APPENDIX II 137

III 139

144

o

vii

-. l

-

.

LIST 'OPTJU3LES

TABLE

i

PACE

,

Steel weldments

1

2

3

5

6

7

8

9

10

Formulas to Assess Cold-craddng of HAZ in

, ,

Precautions for Various carbon

Equivalents

Index Proposed by Bradstreet

Re1.a.t.ion Between carbon Equivalent and weldability .

.

Low Hydrogen Electrodes

Procedure,for Prevention",of Cold-Cracking

Implant Test' Datd \

Comparison Between Our's and Christensen's Correlation

Influence of Hydrogen Lever on,oCR

Calculated Stress Intensity and HeR ,at

Comparison Between Reported dnd Calculated Cooling

.

I

6-7'::'

18

10

10

.11

i

24

26

" '31

39

J

Times' Between 800C - 500C .. 56

11 Prediction of OCR Basis of Heat Input,

Thickness, Plate and Hydrogen

"

12 Prediction of HAZ and OCR for the Ito-Bcssyo

Data 73-81

13-16 Prchaat Levels Predicted for Various-Steel Compositions,

Plate Thickness, Heat Hydrogen Level With

17

Fillet Weld Configuration

Welding Hcat Input Details

viii

102-109

116

-

. --

"

..

18

.19

t

)

- . .

(bserved

. tiJDeS - _sooC

t

0Mtmic:al CoD:posi.tiCXlS of ...the Steels used for

_ l)apl.ant: Testing

..!..

PACE

--

..

123

.129

...

. ,

. ...

. -

I

,

J

.., .

ix

..

'.

,

..

'.

,

"

:

"

..

PACE

1

2

3

5

6

7

8

9

10

11

12

13

14

Bai.ley' s (14) Nomog%4JD of safe Welding Procedures

for C-Mn Steels

Ito-Bessyo (1'6) System for Determining' safe Weldi.ng

Procedures

!m;)lanting Steel . Specimen by Welding'

SChematic Diagram Showing Implant Te9t

Typical Stress VS Fracture Time Curve fo'r an

"

Implant Test

.

. (23)

of 0ck With HAZ Hardness

, Weld Cracking and HAZ Hardness Plot

C1S

)

'COrrelation Between OCR and Both , Martensite and

Hardness as Parameters

Correlation Between OCR and HAZ INDEX

COmparison Between COrrelated and Observed With

, ,as

Comparison Between Correlated and Observed With

CR

, Martensite and Hardness, as Parameters

Influence of Hydrogen Level on OCR

Variation of Hydrogen Index Wi th HydrC?3en Level

,Stress Intensity and Hydrogen Concentration Combina- ...

12

14

16

16

17

21

22

27

29

30

32

33

'\

tions for Fracture

(4)

as Suggested, Beachem

...

15 Influence of Notch Radius on the Location of the

Hy,drogen Assisted

C35)

Crack1ng ,-

..

x

....

35

37

-

..

.' ... .. :.

;PIGDRE

.

".

,'lr. -

:1

...). .

.'

."

,.

.-

",

PAGE

-

..

.'

,

, .

..

.'

...

..

18

19

20

21

22

23-25

CUWbiua' of St:ress."Intensity and

".' .-

.CoDceDt:raj:ion critical at (Sea

'Block PridictiDg (Sea on the of ..

. - ........

."

Wel.di:D9 Beat anput, Plate Thickness," Plate C'omposi-

.....

tieD.. and Hydrogen Level

Beat Cone.it:i.ons in Welding

vari&t5:-on. .with

:- . .

of B

3D

with

of Coo1i:lg Rate 'with Plate ickness ,

Tr

f .' d Cool' . Cha (42).

ans ODDa:'t:ion an Rate rt

J ":-

" Martensite and Cooling Rate for Three c-Mn

SteelS'

40

49

54

58

61-62

..

. ,

26 . Cqmpa.rison Between predicted and Observed " Martensite

.' (for.Christense:\"s :,)ata(22,23'

.'.

27 Between Predicted A."\d ObserVed HAZ

(fOr Christensen's Data(22,23

..

'64

65

....

28

29

30

". "

31

Cpmparison .Beo.:ee,n 'Predicted A."\d Observed RAZ Hardness

(f

. (lS} .

or . Data)

...

Between'Predicted and Observed OCR (for

. Data)

, Plot of " weld Cracki:\g Predicted 0CR'!for

(15) Data)

. (15t

Plot of " Weld Ito-Bessyo Cracking

..

Parameter P

c

66

68

69

'70

, .

.j

.' .

xi

A

..

. .

.' -

..

,- .,

..

" -

a..

.

.'-

.-

. .-

"

'.

P:tGORE

32 CoIIIpari.saD Between Lower Critical. .

.

Obtained frcm Implant '!'est and from RIC and TBr:::

'.

Tests

'.

83

-

....

.33

'34

350

Critericn or A'V'Oiding Cold-Cracks in Welded

Structures

Procedur; fOr Rec:ommend.ing Preheat.to A'V'Oid Cracking

.

Intensity of Restraint vs Plate Thickness for Welded

85

86

- (43)

Construction

1.

-.

89

36

37-44

45

46

47

Bead .Model for .. Diffusion Analysis

Be.bleen Predicted Preheats and ReCOlllJDended

(B.S. Standard) Preheats

System for AutOmatic Deposi ti6n of MSMAW Electrodes

Implant l.oading System

.-

System for

89

94-107

112

114

114

.. <

48 General View of the Implant Complete

Wi th tic ana Loading Facility 117

I

49

so

51.

S2

53

- .

Details of the weld;ing Arrangement

Detailed View of the Loading System

Weld Bead Sections for Three Heat Inputs

Typical Thermal Cycle Profile in Welding

Implant Specimen Details

.Base Used for Implant Test

118

119

121

122

124

125

55 Section of Implant Specimen Showing the Location

of the Notch 127

56

.

. Typical Variation of Hardness Across the

xii'

128

58

57

FIGtIBE

Diagam for St2e1 No.:

50.

.

.

'.

0

'.

.

.' ....

PAGE

1

-130

.

2

.,-

131

'0

..

"-.-

110': .....

o

.'

'.

.,

.

.'

,.

--

..

..

0

0

-

. .

xiii

,

CHAPTER 1

....

Hydrogen induced cold-crac:king has one of the .major problems'

of this' type can take many fonlS _ although

they have some qene.r'a1 characteristics and are influenced by CO""IDOn

basic factors.

, As the name implies, these cracks form at low temperatures

generally below and often exhibit a delay phenomenon. Even after

the weld has cooled to room temperature, there may be a further lapse of

time ranging from a' few minutes to severa1 hours.

not tolerated in a.structure, and since they are

'0.

..

often' difficult to detect and expensive to repair, it becomes essential

the fabricator to take precautions during welding to prevent their

formation,

J

Even though the general causes of hydrogen cracking and the means

of preventing these cracks are known" recent industrial surveys have

shown that cold-cracking is widely encountered, indicating that

the ability to satisfactorily predict cold-cracking susceptibility has.

not been developed.

Hence, development of a t'el;'able, quick and economic method for

predicting hydrogen craclcing in a real welded.. joint is desirable to 00-

termine when conventional welding techniques can be used wi thout the

likelihood of failure from hydrogen cracking. In addition, needless

expense of preheating and low-hydrogen techniques cou1d be avoided; re-

1

Das könnte Ihnen auch gefallen

- Single & Headered Relief Vent Piping Analysis: Todd Jekel, PH.D., P.E. Industrial Refrigeration ConsortiumDokument32 SeitenSingle & Headered Relief Vent Piping Analysis: Todd Jekel, PH.D., P.E. Industrial Refrigeration ConsortiumShijumon KpNoch keine Bewertungen

- Recommended Torque Values.Dokument1 SeiteRecommended Torque Values.Shijumon KpNoch keine Bewertungen

- 3-5400 GB PDFDokument16 Seiten3-5400 GB PDFShijumon KpNoch keine Bewertungen

- Corrosion and Climatic Effects in Electronics: Risto HienonenDokument420 SeitenCorrosion and Climatic Effects in Electronics: Risto HienonenShijumon KpNoch keine Bewertungen

- 11.5: Vapor Pressure: Evaporation and CondensationDokument5 Seiten11.5: Vapor Pressure: Evaporation and CondensationShijumon KpNoch keine Bewertungen

- Development of Multicomponent Vaporization/condensation Model For A Reactor Safety Analysis Code SIMMER-III Theoretical Modeling and Basic VerificationDokument16 SeitenDevelopment of Multicomponent Vaporization/condensation Model For A Reactor Safety Analysis Code SIMMER-III Theoretical Modeling and Basic VerificationShijumon KpNoch keine Bewertungen

- Cp01195den 0117.Dokument124 SeitenCp01195den 0117.Shijumon KpNoch keine Bewertungen

- Flawless Project Delivery Flaw Close-Out Sheet Yibal Khuff Project (YKP)Dokument2 SeitenFlawless Project Delivery Flaw Close-Out Sheet Yibal Khuff Project (YKP)Shijumon KpNoch keine Bewertungen

- Flange Calculations As Per en 1591.Dokument44 SeitenFlange Calculations As Per en 1591.Shijumon Kp100% (3)

- Torque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....Dokument1 SeiteTorque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....Shijumon Kp100% (2)

- Calculating Tank Wetted Area.Dokument17 SeitenCalculating Tank Wetted Area.Shijumon KpNoch keine Bewertungen

- Flawless Project Delivery Flaw Close-Out Sheet Yibal Khuff Project (YKP)Dokument1 SeiteFlawless Project Delivery Flaw Close-Out Sheet Yibal Khuff Project (YKP)Shijumon KpNoch keine Bewertungen

- ASME PCC - 1, App. ODokument1 SeiteASME PCC - 1, App. OShijumon KpNoch keine Bewertungen

- Specifications For Oil Free Compressors (750 CFM & 250 CFM) 180318.Dokument1 SeiteSpecifications For Oil Free Compressors (750 CFM & 250 CFM) 180318.Shijumon KpNoch keine Bewertungen

- jpcrd628 PDFDokument360 Seitenjpcrd628 PDFShijumon KpNoch keine Bewertungen

- 2010 03Dokument288 Seiten2010 03Shijumon KpNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Homework 1Dokument3 SeitenHomework 1Bukhosi MsimangaNoch keine Bewertungen

- Technical Proposal: Genale Dawa-6 Hydroelectric Power ProjectDokument336 SeitenTechnical Proposal: Genale Dawa-6 Hydroelectric Power ProjectEyob AdNoch keine Bewertungen

- IRGC (2021) - Spotlight - Risk Governance and The Rise of DeepfakesDokument4 SeitenIRGC (2021) - Spotlight - Risk Governance and The Rise of DeepfakessaidNoch keine Bewertungen

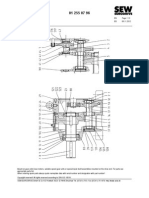

- Parts List 01 255 07 96: Helical Gear Unit R107Dokument3 SeitenParts List 01 255 07 96: Helical Gear Unit R107Parmasamy Subramani50% (2)

- Philips BV Pulsera C ArmsDokument2 SeitenPhilips BV Pulsera C ArmsWaheed MidoNoch keine Bewertungen

- Your Profile 16personalitiesDokument3 SeitenYour Profile 16personalitiesapi-583293897Noch keine Bewertungen

- Project Goals/ ObjectivesDokument51 SeitenProject Goals/ ObjectivesJoyce Abegail De PedroNoch keine Bewertungen

- Lampiran BDokument3 SeitenLampiran BIqbhal WanaharaNoch keine Bewertungen

- Pavilion Design Workshop + Competition: Uni - Xyz/competitionsDokument14 SeitenPavilion Design Workshop + Competition: Uni - Xyz/competitionsNikunj DwivediNoch keine Bewertungen

- 103096-CG9-20AD IIDokument30 Seiten103096-CG9-20AD IICristian Eduardo Chavez GallardoNoch keine Bewertungen

- Ronalyn AramboloDokument3 SeitenRonalyn AramboloRonalyn AramboloNoch keine Bewertungen

- Sika Cemflex 1Dokument3 SeitenSika Cemflex 1rasasiNoch keine Bewertungen

- Atoll 3.3.2 Technical Reference Guide RadioDokument912 SeitenAtoll 3.3.2 Technical Reference Guide Radioratelekoms100% (4)

- Cembrit Patina Design Line - LowresDokument11 SeitenCembrit Patina Design Line - LowresRaul AntonieNoch keine Bewertungen

- Facility Details On DataCenterDokument26 SeitenFacility Details On DataCenterishtiaqkhurshid470Noch keine Bewertungen

- Loupe S Dental Brochure Sur 6351Dokument16 SeitenLoupe S Dental Brochure Sur 6351bernadinadwiNoch keine Bewertungen

- TPCN Monthly List of Subcontractors 06-2017Dokument3 SeitenTPCN Monthly List of Subcontractors 06-2017Teddy WilsonNoch keine Bewertungen

- Lecture - 6 EDokument33 SeitenLecture - 6 ETung HoNoch keine Bewertungen

- Mobile Crane Inspector & CertificationDokument3 SeitenMobile Crane Inspector & CertificationgptothNoch keine Bewertungen

- Draw 224-1Dokument8 SeitenDraw 224-1Alther Dabon33% (3)

- RFCC KBR FeaturesDokument24 SeitenRFCC KBR FeaturesKannanGK100% (1)

- SSMT Solution ManualDokument12 SeitenSSMT Solution ManualPraahas Amin0% (1)

- KEDA Quotation of 2 3 4 Inch Mini Gold DredgerDokument3 SeitenKEDA Quotation of 2 3 4 Inch Mini Gold DredgerShane CapstickNoch keine Bewertungen

- Chip Tuning Remaping Book Engine Fuel Map DesignDokument13 SeitenChip Tuning Remaping Book Engine Fuel Map Designopenjavier5208100% (10)

- Eaturing: To Smaller Recording Performance Speakers: - The GuideDokument76 SeitenEaturing: To Smaller Recording Performance Speakers: - The GuideMatthew WalkerNoch keine Bewertungen

- World Currency White Paper Vol 1. by H.I.M Dr. Lawiy-Zodok Shamuel, D.D.Dokument11 SeitenWorld Currency White Paper Vol 1. by H.I.M Dr. Lawiy-Zodok Shamuel, D.D.:Lawiy-Zodok:Shamu:-El50% (2)

- Computer Network-II Lab ProgramsDokument5 SeitenComputer Network-II Lab ProgramsAnshul ChauhanNoch keine Bewertungen

- Design and Estimation of Dry DockDokument78 SeitenDesign and Estimation of Dry DockPrem Kumar100% (4)

- 4.1 OUM Cloud Approach Presentation-ManagerDokument24 Seiten4.1 OUM Cloud Approach Presentation-ManagerFeras AlswairkyNoch keine Bewertungen