Beruflich Dokumente

Kultur Dokumente

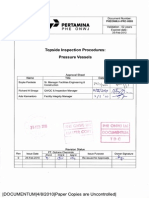

Vessel Inspection Procedure

Hochgeladen von

mahmoud_elnaggar_5Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Vessel Inspection Procedure

Hochgeladen von

mahmoud_elnaggar_5Copyright:

Verfügbare Formate

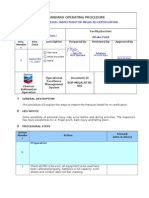

Trust International for Industrial and Petroleum Services- Limited

ONSHORE REGENERATION GAS SUBCOOLER E-2521

REF NO

DATE

S/N

SUBJECT SCOPE

REFERENCES 2

DEFINITIONS

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited

ITEM DESCRIPTION

PREINSPECTION REQUIREMENTS

TYPES OF INSPECTION

INSPECTION PROCEDURE

REPORTING 8

ATTACHMENTS 9

1- SCOPE

This procedure delineates the internal inspection of the onshore regeration gas sub cooler E -2521 during the scheduled shutdown to determine the status of internal surfaces of the vessel, and the need for repair or re rating according to the code requirements. 2- REFERENCES;

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited 2.1 API STD 510

Pressure vessel inspection code : maintenance inspection, re rating , repair and alteration. Inspection of pressure vessels National board inspection code guidance notes and supporting information for rashpetco (Egypt) written schemes of examination managed by the pressure system data base.

2.2 2.3 2-4

API RP 572 ANSI/NB-23 R7126

2-5 vessel drawings and data sheets

3. 3.1 3.2 3.3 3.4 3.5 3.6 3.7

DEFINITIONS: API ANSI ASME MAWP MDMT NB WSOE The American Petroleum Institute The American National Standards institute The American Society for Mechanical Engineers Maximum allowance working pressure minimum design metal temperature ASME national board Written scheme of examination

4.

ITEM DESCRIPTION:

The onshore regeration gas subcooler E-2521, located horizontally at roseta gas field, was fabricated by JOY INDUSTRIES , under manufacturer's number 1101 at 1999 from stainless steel in accordance with ASME code sec. VIII Div. 1,1998 edition, and stamped by "U" stamp. The medium inside the vessel is HS gas shell side / HC gas tube side.

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited SHELL:

The shell is constructed from two courses of "SA-240-316. with dimensions of 660.4 ID * 25.4 mm thick and length of shell is 5870 mm, the corrosion allowance is 0.0 mm.

HAEDS : The heads are constructed from one piece of SA-240-316 formed to be elliptical 2:1 with dimensions of 660.4 ID * 25.4 mm thick, the corrosion allowance is 0.0 mm. NOZZELS : The nozzles are fabricated from SA-213-316, total number of tubes are 321 in one pass, tube outside diameter is 25.4 with 2.1 mm thickness and 6096 mm length. BOLTS : Stud bolts / nuts are constructed from SA -193-B7/SA-194-2H COATING : No cating exists on internal or external surfaces.

NAMEPLATE : The name plate is fabricated from stinless steel material and includes the following information:

Manufacturer

Manufacturer's S/N : Tag number Year built MAWP shell side MDMT shell side : : : :

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited MAWP shell side MDMT shell side MAWP tube side MDMT tube side Test pressure : : : : :

Construction code : Code stamp :

ACCESS : No access is available to inside the vessel, however inspector shall use 8"N3,N4 and other available nozzles to inspect the internal surface of the shell.

5. 5.1

PREINSPECTION REQUIREMENTS: Operation and inspection history of the tank shall be available for review by the inspector. For example: operating conditions, including process upsets that may affect mechanical integrity, inspection reports, and data for each type of inspection conducted (for example, internal, external, thickness measurements), and inspection recommendations for repair.

5.2

For an internal inspection, the tank shall be isolated by blinds or other positive methods from all sources of liquids, gases, and / or vapors. The vessel shall be drained, purged, cleaned, ventilated, and gas tested. Where required , protective equipment shall be worn that will protect the eyes, lungs, and other parts of the body from specific hazards that may exists in the vessel.

5.3

No access is available to inside the vessel , however inspector shall use 8" N3,N4 and other available nozzles to inspect the internal surfaces of the shell using fiberscope

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited and/or the inspection mirror as access permits. 5.4

Nozzles shall be opened as required by inspector, isolation kits ( if required ),shall be available at site during the S/D to enable of the nozzles. Electrical line source terminal of 220 V shall be available near to vessel. Powerful light source shall be available to inspect the inside surface of the vessel.

5.5 5.6

5.7

The vessel shall be prepared for hydraulic pressure testing of both the shell and the tube side at 127 barg using tap water as a test medium and hold for 1 hour. The required pump, calibrated pressure gauges and blind flanges/ spades shall be available for hydraulic pressure testing . the inspector shall witness the hydraulic pressure testing. ( use guidelines for hydraulic pressure testing PT/01) NDT and other inspection equipment shall be available for inspector to conduct the internal inspection (required inspection equipment are attached).

5.8

6.

TYPES OF INSPECTION:

The internal inspection of the tank included, visual inspection, dye penetration and UT wall thickness measurements and supplements with NDT as required per examination specification RPCO-05, issue 1 ( WSOE ), and hydrostatic testing for both the shell and tube side at 127 barg for 1 hour hold.

7. 7.1

INSPECTION PROCEDURE: Check the tank tag number and name plate.

7.2

Obtain the safe entry permit from the appropriate HSE personnel.

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited 7.3

Check that cleaning of the vessel is adequate and the internal surface of the shell, heads, and nozzles are clearly visible.

7.4

Check that inspection and NDT equipment that shall be used during the inspection are available and valid. Check that the light source that shall be used is operating and powerful and check for the availability of electrical line source terminal that be used to operate the NDT equipment.

7.5

7.6 If the vessel is not properly prepared for internal inspection, the inspector shall decline to make the inspection until the tank is ready for that inspection. inspection.

7.7

Examine the internal surfaces of shell and heads carefully, as access permits, for possible cracks, general corrosion , pitting , and other signs of deterioration. If there is a suspect indication, use Dye penetrates according to approved NDT procedures; to verify the indication. Ultrasonic testing may be used for determining the depth of indication. Pit depth shall be measured by depth gauge or venire caliber

7.8

If evidence of distortion is found, it may be necessary to make a detailed check of the actual contours or principal dimensions of the vessel and to compare those contours and dimensions with the original design details.

7.9

Examine welded joints and the adjacent heat-affected zones for service-induced cracks or other defects.

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited 7.10

Carry out PT on 10% of all seam and girth welds on the shell, plus all "T" weld inspections, to distance of 300 mm from inspection of weld looking for signs of cracking and other weld defects ( including transverse cracking where appropriate ). Carry out PT on nozzles.

7.11

7.12 Examine the surfaces of. Nozzles and other openings for distortion, crack, and other defects, using a mirror as necessary, paying particular attention to the welding used to attach the parts and their reinforcements.

7.13

Examine accessible flange faces for distortion and determine the condition of gasketseating surfaces.

7.14 Examine the tubing and tube sheets externally for possible cracks and other signs of deterioration.

7.15

Examine the earthing conditions, and describe the status in the final inspection report.

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited 7.16

Measure the wall thichness of the shell at 500 mm intervals ( as access permits ) from the datum points ( shell-to-front head weld seam ) till the shell-to-rear head weld seam. The readings will be taken in four directions (3,6,9,12 o'clock ). Readings also will be taken on heads and nozzles and shall be included in the report. Clearly mark all defects found with a permanent marker on place. Sketch the size and location of defects and document the findings on the final inspection report. Witness the hydraulic pressure test at 127 barg for both shell and tube side using tap water as a test medium and hold for 1 hour . ( use guidelines for hydraulic pressure testing ( PT/01) Sate areas not accessible and reasons why.

7.17

81.7

81.7

8.

REPORTING: 8.1 All findings shall be reported in the attached final inspection report form.

9. 9.1 9.2 9.3 9.4

ATTACHEMENTS: Sketch for onshore registration gas subcooler E-2521 List of required inspection equipment. Inspection check list. final inspection report.

9.1

LIST OF REQUIRED INSPECTION EQUIPMENT

S/N

DESCRIPTION

QTY REQ.

RECOMMENDED TYPE

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited Ultrasonic thickness meter. 1 Inspection mirror with telescopic hand, the mirror size shall fit into 2" pipe at least. 1 ANY

Any

Pocket size flash light 3 1 Any

Measuring tape 5 m. 4 Flexible fiberscope with light source and forward & side tip. Dye penetration material kit ( penetrant-remover-developer ) Ultrasonic instrument for crack detection with cables and 0, 45, 60, 70 degree angle probes, with IIW-V2 block. 1 Any

Olympus or equivalent From only one family product e.g. Ely , or magnaflux etc.

KRAUTKRAMER OR EQUIVALENT

Still photos digital camera. 8 1 Sony or equivalent

Depth gauge or vernier caliber. 9 Magnifier lens 2, 5, or 8X 10 1 Any 1 Any

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited Permanent markers (Yellow/red color).

11 12

Any

9.2

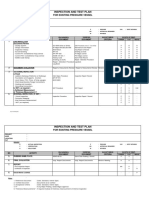

INSPECTION CHECK LIST

S/N 1

ITEM Shell internal / external surface Head internal / external surface Shell-to-shell circumferential weld seam Shell-to shell longitudinal weld seam Shell-to-head circumferential weld seam N1 16" -900# tube inlet N1 16" -900# tube outet N3 8"-900# shell inlet N4 8"-900# shell oulet N1A 2"-900#P1 connection N2A2"-900#P1 connection N3A2"-900#P1 connection N4A2"-900#P1 connection

CODITION

ACCEPTANCE

REMARKS

5 6 7 8 9 10 11 12 13

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited 14 15 16 17 18 19 20 N1B2"-900#T1 connection N2B2"-900#T1 connection N3B2"-900#T1 connection N4B2"-900#T1 connection Earthing External bolts & nuts Opened flange faces and gaskets State areas not accessible and reasons why

21

9.4

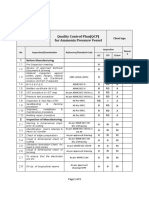

FINAL INSPECTION REPORT

PRESSURE VESSEL EXAMINATION REPORT

PART 1: VESSEL DESCRIPTION Pressure System Name Vessel serial number Tag number Installation Area Examination Specification Number

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited Data of examination Data of last examination

Vessel Drawing Number

Data of manufacture

Manufacturer

Design Code

PART 2: VESSEL DATA Shell Contents Max/min design pressure (bar) Max/min design temperature (C degree) Material Thickness (mm) Corrosion allowance (mm) Material (lining) Insulation PART 3: EXETENT AND METHOD OF EXAMINATION Examination and/or tests carried out, plus no of attached sheets. Tube side

Parts not examined with reasons

PART 4: CONDITION OF VESSEL (SUMMARY) EXTELNAL

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited Element Access ladders/platforms Man ways Heads Shell Nozzles Protective coatings insulation Condition

Comments

Bolted attachments Welded attachments Supports/ skirt/ mounts Ear thing Nameplate Internal Element Access ladders/platforms Man ways Heads Shell Nozzles Protective coatings Condition Comments

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited Tubes Tube plates Welded attachments / supports Bolted attachments / trays Strainers /filters/demisters

Definition of vessel Condition C-Nothing to report B-Less significant Fault A2-significant and fault Surface rust, light scale or corrosion not exceeding 0.5mm and within the corrosion allowance-damage judged not to be dangerous Corrosion greater than 0.5mm possible cracking adjacent to welds-more significant damage than B but no immediate of failure A1-Imminent Danger

Vessel in excellent condition no signs of damage or corrosionnothing to report

Heavy corrosion and/or deep pitting or cracking of any description; vessel operating above SOLsignificant damage with risk of imminent danger

PART5: Anomalies and defects

PART6: Statement by Inspector

I declare that the above equipment has been inspected according to the examination described in part 3 and that this document is a true report of the inspection carried out

Inspectors name

signature

data

PART 7: Statement by competent person

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Trust International for Industrial and Petroleum Services- Limited

The vessel is suitable for its design specified in part 2 subject to the relief system remaining in order: YES/NO The written scheme of examination require amending as result of this examination : yes / no Description of amendments required The above equipment may be used within the duty specified in part 2, subject to the following conditions Next thorough examination due before

Name

signature

002 03 4256162 : : 2626524 30 200 - nd Al Saraya Towers, Ali Bin Abi-Talib Square, Alpansi Tower, 2 Floor, Smouha, Alexandria, Egypt Tel: 002 03 4265252 - Fax: 002 03 4265152 - www.trusteg.com - Email: trust@trusteg.com

Das könnte Ihnen auch gefallen

- Vessel Inspection ProcedureDokument16 SeitenVessel Inspection Procedurekptl6185Noch keine Bewertungen

- Sop-miqa-Attk-001 - Pressure Vessel Inspection For Migas Re-Certification (2007)Dokument10 SeitenSop-miqa-Attk-001 - Pressure Vessel Inspection For Migas Re-Certification (2007)Iksan Adityo MulyoNoch keine Bewertungen

- Vessel Inspection PDFDokument18 SeitenVessel Inspection PDFAhmed Imtiaz Rao100% (1)

- Inspection ProcedureDokument4 SeitenInspection ProcedureAozoraLazora100% (1)

- API 510 Pressure Vessel InspectorDokument1 SeiteAPI 510 Pressure Vessel InspectorNurul Amirah PrinceszaNoch keine Bewertungen

- Pressure Vessel Dimension Inspection PDFDokument17 SeitenPressure Vessel Dimension Inspection PDFEqubal KhanNoch keine Bewertungen

- JOSOP 607 - Repair Procedure For Flowlines, Pipelines, Vessels, Tanks, Separators and Other EquipmentDokument7 SeitenJOSOP 607 - Repair Procedure For Flowlines, Pipelines, Vessels, Tanks, Separators and Other EquipmentOrdu Henry Onyebuchukwu100% (1)

- Hydro Test ProcedureDokument9 SeitenHydro Test ProcedureAdeel QaiserNoch keine Bewertungen

- Pressure Vessel Inspection Procedure Rev.2Dokument24 SeitenPressure Vessel Inspection Procedure Rev.2Ariq Fauzan100% (7)

- ITP-PRESSURE VESSEL ExistingDokument2 SeitenITP-PRESSURE VESSEL ExistingArisNoch keine Bewertungen

- Shrikant B. Moje CVDokument6 SeitenShrikant B. Moje CVPaul PhiliphsNoch keine Bewertungen

- OES-INS-P057 Piping Inspection ProcedureDokument9 SeitenOES-INS-P057 Piping Inspection ProcedureMatheus Ribeiro100% (2)

- Pressure Vessel InspectionDokument44 SeitenPressure Vessel Inspectionأحمد صبحى100% (4)

- Vessel Pressure TestingDokument3 SeitenVessel Pressure TestingYetkin ErdoğanNoch keine Bewertungen

- Sample Report Tank Structural Profile SurveyDokument36 SeitenSample Report Tank Structural Profile SurveyOwais MalikNoch keine Bewertungen

- Boilers and Unfired Pressure VesselsDokument67 SeitenBoilers and Unfired Pressure Vesselsviansh1974Noch keine Bewertungen

- Pressure Vessel Repair ProcedureDokument7 SeitenPressure Vessel Repair ProcedureAndy UgohNoch keine Bewertungen

- 10080-1-SS-PP-018 - PMI Procedure PDFDokument23 Seiten10080-1-SS-PP-018 - PMI Procedure PDFDrM Design2Noch keine Bewertungen

- Base Line SurveyDokument10 SeitenBase Line Surveycisar0007Noch keine Bewertungen

- ITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CDokument2 SeitenITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CAmel Rayhan Aira100% (5)

- Pressure Testing of Pressure VesselDokument3 SeitenPressure Testing of Pressure VesselAriq FauzanNoch keine Bewertungen

- Process Piping Inspection Procedure Rev.2 PDFDokument34 SeitenProcess Piping Inspection Procedure Rev.2 PDFLevi Porter100% (6)

- Mechanical Boiler Inspection ReportDokument1 SeiteMechanical Boiler Inspection ReportAfzal pathanNoch keine Bewertungen

- Inspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A CommentsDokument1 SeiteInspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A CommentsmukeshayoorNoch keine Bewertungen

- Ab-512 Ou Pressure Equipment Integrity Management Requirements ImrDokument33 SeitenAb-512 Ou Pressure Equipment Integrity Management Requirements ImrMohamed Al-Amir Al-KhayatNoch keine Bewertungen

- Procedure For Vacuum Box TestingDokument3 SeitenProcedure For Vacuum Box TestingZakirUllahNoch keine Bewertungen

- 00 Saip 74 - CuiDokument8 Seiten00 Saip 74 - CuiAbdelrahman HosnyNoch keine Bewertungen

- Sec-Visual Inspection Report For Boiler Pressure Parts Lower Panels (Unit - #6)Dokument5 SeitenSec-Visual Inspection Report For Boiler Pressure Parts Lower Panels (Unit - #6)حمودي معز100% (2)

- Piping Inspection: TPI ServicesDokument3 SeitenPiping Inspection: TPI ServicesAnkit KumarNoch keine Bewertungen

- TML ProcedureDokument19 SeitenTML Procedurejeswin100% (1)

- Vessel Cleaning ProcedureDokument5 SeitenVessel Cleaning ProcedureZool HilmiNoch keine Bewertungen

- 10.400.413 Unfired Pressure Vessel Inspection ProcedureDokument17 Seiten10.400.413 Unfired Pressure Vessel Inspection ProcedureedwinsazzzNoch keine Bewertungen

- Inspection and Welding Repairs of Pressure VesselsDokument8 SeitenInspection and Welding Repairs of Pressure VesselsAlper Çakıroğlu100% (1)

- Maintaining and Repairing Heat Exchanger TubesDokument14 SeitenMaintaining and Repairing Heat Exchanger TubesMicheal Brooks100% (1)

- API 510 Petrosync Course PDFDokument301 SeitenAPI 510 Petrosync Course PDFAkramKassis100% (1)

- PRP CML Placement TestingDokument30 SeitenPRP CML Placement TestingMohamed Al-Amir Al-KhayatNoch keine Bewertungen

- Heat Exchanger InspectionDokument43 SeitenHeat Exchanger Inspectionabdul aziz100% (6)

- Quality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingDokument3 SeitenQuality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingFaisal Awad100% (1)

- Piping External Visual Inspection ProcedureDokument3 SeitenPiping External Visual Inspection Procedurecamasa2011100% (1)

- Sample ReportDokument8 SeitenSample ReportRonel John CustodioNoch keine Bewertungen

- Pressure Relieving Device Inspection ProcedureDokument2 SeitenPressure Relieving Device Inspection Procedurecamasa2011Noch keine Bewertungen

- Pressure Vessel InspectionsDokument29 SeitenPressure Vessel InspectionsStephanie Webb100% (2)

- Tank Calibration:, Surveys & InspectionsDokument2 SeitenTank Calibration:, Surveys & InspectionsIETqatarNoch keine Bewertungen

- Risk Based Inspection of Pressure Vessels, PipingDokument20 SeitenRisk Based Inspection of Pressure Vessels, PipingBen0% (1)

- Air Leak TestingDokument5 SeitenAir Leak Testingkusdiyanta100% (2)

- Repair Welding Temper BeadDokument9 SeitenRepair Welding Temper BeadwilliamjdtNoch keine Bewertungen

- Repair Techniques For in Service and Out of Service Buried PipelinesDokument26 SeitenRepair Techniques For in Service and Out of Service Buried PipelinesAnonymous wKvJXBJ2i100% (1)

- ITP-Pressure Vessel Repair, Modification, AlterationDokument5 SeitenITP-Pressure Vessel Repair, Modification, Alterationyosafateden67% (3)

- Astm 890Dokument3 SeitenAstm 890bsnegi111Noch keine Bewertungen

- Pheonwj I PRC 0005 0Dokument54 SeitenPheonwj I PRC 0005 0Iksan Adityo Mulyo100% (1)

- Saep 1146Dokument8 SeitenSaep 1146Ronanki RaviNoch keine Bewertungen

- VBTDokument5 SeitenVBTMohdHuzairiRusliNoch keine Bewertungen

- QYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementDokument6 SeitenQYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementAbdul Khaleem KhanNoch keine Bewertungen

- Helium Leak TestDokument8 SeitenHelium Leak TestHiren Panchal50% (2)

- Maintenance and Repair of Pressure VesselsDokument81 SeitenMaintenance and Repair of Pressure Vesselsjishnunelliparambil100% (3)

- SGS IND Storage Tank A4 EN 14 PDFDokument8 SeitenSGS IND Storage Tank A4 EN 14 PDFAjejejeNoch keine Bewertungen

- NRL Pipeline Hydrotest Format PDFDokument1 SeiteNRL Pipeline Hydrotest Format PDFJaved Mohammed100% (1)

- Maintenanc and Repair of Pressure VesselsDokument93 SeitenMaintenanc and Repair of Pressure VesselsVimin Prakash100% (12)

- Vessel Inspection ProcedureDokument17 SeitenVessel Inspection ProcedureVimal RajNoch keine Bewertungen

- Hydrostatic Testing ProcedureDokument7 SeitenHydrostatic Testing Proceduremomin100% (2)

- Female Data Entry Engineer CV/Resume SampleDokument2 SeitenFemale Data Entry Engineer CV/Resume Samplemahmoud_elnaggar_5Noch keine Bewertungen

- Female Data Entry Engineer CV/Resume SampleDokument2 SeitenFemale Data Entry Engineer CV/Resume Samplemahmoud_elnaggar_5Noch keine Bewertungen

- Female Data Entry Engineer CV/Resume SampleDokument3 SeitenFemale Data Entry Engineer CV/Resume Samplemahmoud_elnaggar_5Noch keine Bewertungen

- Female Data Entry Engineer CV/Resume SampleDokument2 SeitenFemale Data Entry Engineer CV/Resume Samplemahmoud_elnaggar_5Noch keine Bewertungen

- Female Data Entry Engineer CV/Resume SampleDokument2 SeitenFemale Data Entry Engineer CV/Resume Samplemahmoud_elnaggar_5Noch keine Bewertungen

- Female Data Entry Engineer CV/Resume SampleDokument2 SeitenFemale Data Entry Engineer CV/Resume Samplemahmoud_elnaggar_5Noch keine Bewertungen

- Female Data Entry Engineer CV/Resume SampleDokument2 SeitenFemale Data Entry Engineer CV/Resume Samplemahmoud_elnaggar_5100% (1)

- Female Data Entry Engineer CV/Resume SampleDokument2 SeitenFemale Data Entry Engineer CV/Resume Samplemahmoud_elnaggar_5Noch keine Bewertungen

- Female Data Entry Engineer CV/Resume SampleDokument3 SeitenFemale Data Entry Engineer CV/Resume Samplemahmoud_elnaggar_5Noch keine Bewertungen

- Female Data Entry Engineer CV/Resume SampleDokument2 SeitenFemale Data Entry Engineer CV/Resume Samplemahmoud_elnaggar_5100% (1)

- Female Data Entry Engineer CV/Resume SampleDokument2 SeitenFemale Data Entry Engineer CV/Resume Samplemahmoud_elnaggar_5Noch keine Bewertungen

- Female Data Entry Engineer CV/Resume SampleDokument3 SeitenFemale Data Entry Engineer CV/Resume Samplemahmoud_elnaggar_5Noch keine Bewertungen

- Piping IsometricDokument4 SeitenPiping Isometricmahmoud_elnaggar_5Noch keine Bewertungen

- Piping IsometricDokument7 SeitenPiping Isometricmahmoud_elnaggar_5Noch keine Bewertungen

- Female Data Entry Engineer CV/Resume SampleDokument4 SeitenFemale Data Entry Engineer CV/Resume Samplemahmoud_elnaggar_5Noch keine Bewertungen

- Guidelines Use of The Word AnzacDokument28 SeitenGuidelines Use of The Word AnzacMichael SmithNoch keine Bewertungen

- Labor CasesDokument47 SeitenLabor CasesAnna Marie DayanghirangNoch keine Bewertungen

- Digital Documentation Class 10 NotesDokument8 SeitenDigital Documentation Class 10 NotesRuby Khatoon86% (7)

- Epenisa 2Dokument9 SeitenEpenisa 2api-316852165100% (1)

- Portfolio Report Zarin Tasnim Tazin 1920143 8Dokument6 SeitenPortfolio Report Zarin Tasnim Tazin 1920143 8Fahad AlfiNoch keine Bewertungen

- Application of ARIMAX ModelDokument5 SeitenApplication of ARIMAX ModelAgus Setiansyah Idris ShalehNoch keine Bewertungen

- Accounting II SyllabusDokument4 SeitenAccounting II SyllabusRyan Busch100% (2)

- Lemon AidDokument17 SeitenLemon AidJade Anne Mercado BalmesNoch keine Bewertungen

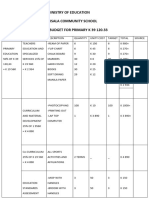

- Ministry of Education Musala SCHDokument5 SeitenMinistry of Education Musala SCHlaonimosesNoch keine Bewertungen

- RCC Design of Toe-Slab: Input DataDokument2 SeitenRCC Design of Toe-Slab: Input DataAnkitaNoch keine Bewertungen

- Ver Notewin 10Dokument5 SeitenVer Notewin 10Aditya SinghNoch keine Bewertungen

- Research Proposal IntroductionDokument8 SeitenResearch Proposal IntroductionIsaac OmwengaNoch keine Bewertungen

- Historical DocumentsDokument82 SeitenHistorical Documentsmanavjha29Noch keine Bewertungen

- Bug Head - Fromjapanese To EnglishDokument20 SeitenBug Head - Fromjapanese To EnglishAnonymous lkkKgdNoch keine Bewertungen

- Unit 13 - Business Hotels and Sales ConferencesDokument24 SeitenUnit 13 - Business Hotels and Sales ConferencesMiguel Angel Escoto CanoNoch keine Bewertungen

- Assessment 21GES1475Dokument4 SeitenAssessment 21GES1475kavindupunsara02Noch keine Bewertungen

- A CMOS Current-Mode Operational Amplifier: Thomas KaulbergDokument4 SeitenA CMOS Current-Mode Operational Amplifier: Thomas KaulbergAbesamis RanmaNoch keine Bewertungen

- Admissibility of Whatsapp Messages in Court For Family MattersDokument3 SeitenAdmissibility of Whatsapp Messages in Court For Family Mattersnajihah adeliNoch keine Bewertungen

- Project Management: Chapter-2Dokument26 SeitenProject Management: Chapter-2Juned BhavayaNoch keine Bewertungen

- Mercury 150HPDokument5 SeitenMercury 150HP이영석0% (1)

- The "Solid Mount": Installation InstructionsDokument1 SeiteThe "Solid Mount": Installation InstructionsCraig MathenyNoch keine Bewertungen

- Data Book: Automotive TechnicalDokument1 SeiteData Book: Automotive TechnicalDima DovgheiNoch keine Bewertungen

- VISCOROL Series - Magnetic Level Indicators: DescriptionDokument4 SeitenVISCOROL Series - Magnetic Level Indicators: DescriptionRaduNoch keine Bewertungen

- QG To AIS 2017 PDFDokument135 SeitenQG To AIS 2017 PDFMangoStarr Aibelle VegasNoch keine Bewertungen

- Computer System Architecture: Pamantasan NG CabuyaoDokument12 SeitenComputer System Architecture: Pamantasan NG CabuyaoBien MedinaNoch keine Bewertungen

- Careem STRATEGIC MANAGEMENT FINAL TERM REPORTDokument40 SeitenCareem STRATEGIC MANAGEMENT FINAL TERM REPORTFahim QaiserNoch keine Bewertungen

- SMK Techno ProjectDokument36 SeitenSMK Techno Projectpraburaj619Noch keine Bewertungen

- Brochure 2017Dokument44 SeitenBrochure 2017bibiana8593Noch keine Bewertungen

- Bismillah SpeechDokument2 SeitenBismillah SpeechanggiNoch keine Bewertungen

- Flow Chart For SiFUS Strata Title ApplicationDokument5 SeitenFlow Chart For SiFUS Strata Title ApplicationPhang Han XiangNoch keine Bewertungen