Beruflich Dokumente

Kultur Dokumente

EPA Method 3102

Hochgeladen von

Roberto SabaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EPA Method 3102

Hochgeladen von

Roberto SabaCopyright:

Verfügbare Formate

METHOD #: 310.

2 TITLE:

Approved for NPDES (Editorial Revision 1974) Alkalinity (Colorimetric, Automated, Methyl Orange) Alkalinity Autoanalyzer 00410

ANALYTE: INSTRUMENTATION: STORET No.

1.0

Scope and Application 1.1 This automated method is applicable to drinking, surface, and saline waters, domestic and industrial wastes. The applicable range is 10 to 200 mg/L as CaCO3. This method is not an approved NPDES method as cited in the Federal Register December 1, 1976 for samples containing turbidity or color.

1.2

2.0

Summary of Method 2.1 Methyl orange is used as the indicator in this method because its pH range is in the same range as the equivalence point for total alkalinity, and it has a distinct color change that can be easily measured. The methyl orange is dissolved in a weak buffer at a pH of 3.1, just below the equivalence point, so that any addition of alkalinity causes a loss of color directly proportional to the amount of alkalinity.

3.0

Sample Handling and Preservation 3.1 Sample should be refrigerated at 4C and run as soon as practical. Do not open sample bottle before analysis.

4.0

Interferences 4.1 Sample turbidity and color may interfere with this method. Turbidity must be removed by filtration prior to analysis. If sample is filtered, this method is not approved for NPDES monitoring. Sample color that absorbs in the photometric range used will also interfere. Apparatus 5.1 Technicon Auto Analyzer consisting of: 5.1.1 Sampler I. 5.1.2 Manifold. 5.1.3 Proportioning pump. 5.1.4 Colorimeter equipped with 15 mm tubular flow cell and 550 nmfilters. 5.1.5 Recorder equipped with range expander.

5.0

6.0

Reagents 6.1 6.2 6.3 6.4 Methyl Orange: Dissolve 0.125 g of methyl orange in 1 liter ofdistilled water. pH 3.1 Buffer: Dissolve 5.1047 g of potassium acid phthalate in distilled water and add 87.6 mL 0.1 N HCl and dilute to 1 liter. Stable for one week. Methyl Orange-Buffered Indicator: Add 1 liter of pH 3.1 buffer (6.2) to 200 mL methyl orange solution (6.1) and mix well. Stable for 24 hours. Stock Solution: Dissolve 1.060 g of anhydrous sodium carbonate (oven-dried at 250C for 4 hours) in distilled water and dilute to 1000 mL. 1.0 mL = 1.00 mg CaCO3. 6.4.1 Prepare a series of standards by diluting suitable volumes of stock solution to 100.0 mL with distilled water. The following dilutions are suggested: mL of Stock Solution 1.0 2.0 4.0 6.0 8.0 10.0 18.0 20.0

Conc., mg/L as CaCO3 10 20 40 60 80 100 180 200

7.0

Procedure 7.1 7.2 No advance sample preparation is required. Set up manifold as shown in Figure 1. Allow both colorimeter and recorder to warm up for 30 minutes. Run a baseline with all reagents, feeding distilled water through the sample line. Adjust dark current and operative opening on colorimeter to obtain stable baseline. Place distilled water wash tubes in alternate openings on sampler and set sample timing at 2.0 minutes. Place working standards in sampler in order of decreasing concentration. Complete filling of sampler tray with unknown samples. Switch sample line from distilled water to sampler and begin analysis.

7.3 7.4 7.5 8.0

Calculation 8.1 Prepare standard curve by plotting peak heights of processed standards against known concentrations. Compute concentration of samples by comparing sample peak heights with standard curve.

9.0

Precision and Accuracy 9.1 In a single laboratory (EMSL), using surface water samples at concentrations of 15, 57, 154, and 193 mg/L as CaCO 3 the standard deviation was 0.5.

9.2

In a single laboratory (EMSL), using surface water samples at concentrations of 31 and 149 mg/L as CaCO3 recoveries were 100% and 99%, respectively. Bibliography

1. 2.

Technicon Auto Analyzer Methodology, Bulletin 1261, Technicon Controls, Inc., Chauncey, N.Y. (1961). Standard Methods for the Examination of Water and Wastewater, 14th Edition, p 278, Method 403 (1975).

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

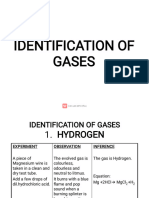

- Organic Chem. NotesDokument117 SeitenOrganic Chem. NoteselcarlsansNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Contents DrugDokument6 SeitenContents Drugwestcoastaromatics0% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- PropeneDokument2 SeitenPropenemow007100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- PWO Water/oil Cooler: Lightweight, Compact and Efficient For Industrial and Marine ApplicationsDokument12 SeitenPWO Water/oil Cooler: Lightweight, Compact and Efficient For Industrial and Marine ApplicationsRomulus Situ MorankNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- CLIA TechniqueDokument43 SeitenCLIA Techniquemagendi indra muktiNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Cased Hole Modullar Dynamic TesterDokument23 SeitenCased Hole Modullar Dynamic TesterDhiaa LaMiNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Sandvikprocesssystems Kumarswamypaper 120525032106 Phpapp02Dokument12 SeitenSandvikprocesssystems Kumarswamypaper 120525032106 Phpapp02naufalNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Neo SealDokument2 SeitenNeo Sealpravi3434Noch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Beggs - Brill Method PDFDokument12 SeitenBeggs - Brill Method PDFTiago Mendes TavaresNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- DS - P - 39!07!13 - 1A-TETPOR AIR Datasheet-Pharma (Low Res)Dokument4 SeitenDS - P - 39!07!13 - 1A-TETPOR AIR Datasheet-Pharma (Low Res)Vijay Pawar Innovative TechnologiesNoch keine Bewertungen

- Light Weight ConcreteDokument20 SeitenLight Weight ConcreteOm TundalwarNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Fox Fluid Mechanics 8th Solved Problem 3.17Dokument1 SeiteFox Fluid Mechanics 8th Solved Problem 3.17Patricia RodriguesNoch keine Bewertungen

- 1 How Plants Grow and Chapt1 of Book3 PhotosynDokument15 Seiten1 How Plants Grow and Chapt1 of Book3 Photosynrashmi_harryNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Biology Grade 11 Midterm ReviewDokument35 SeitenBiology Grade 11 Midterm Review02-11TH2- Trần Ngọc Ngân AnhNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Notes For Chemistry PracticalsDokument32 SeitenNotes For Chemistry Practicalsj0ntj2ivjyNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Well Completion Exam 1 Study GuideDokument19 SeitenWell Completion Exam 1 Study GuideKreitzCondalorNoch keine Bewertungen

- Advances in Sensing and Biosensing of Bisphenols: A ReviewDokument27 SeitenAdvances in Sensing and Biosensing of Bisphenols: A ReviewericNoch keine Bewertungen

- Lecture 7 Gamma Ray LogDokument39 SeitenLecture 7 Gamma Ray LogNaser Khan100% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Programme of The M.Sc. (Other Than Mathematics, Statistics & Geography) (Part I) ExaminationDokument4 SeitenProgramme of The M.Sc. (Other Than Mathematics, Statistics & Geography) (Part I) ExaminationRajkumar PomajiNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Metallographic Preparation of Cast Iron: Application NotesDokument6 SeitenMetallographic Preparation of Cast Iron: Application NotesmarianaNoch keine Bewertungen

- Bezaprint Black BDC - TdsDokument2 SeitenBezaprint Black BDC - TdsMahdiNoch keine Bewertungen

- Mineral Water Plant Gayatri DeviDokument24 SeitenMineral Water Plant Gayatri DeviRishabh GuptaNoch keine Bewertungen

- HWA GUAN Material Spec PDFDokument12 SeitenHWA GUAN Material Spec PDFkhai ruleNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Cheat Sheet Modelling 1718Dokument2 SeitenCheat Sheet Modelling 1718Siti MaisarahNoch keine Bewertungen

- Solutions - AIATS Medical-2020 (XII Studying) - Test-5 - (Code-A & B) - 22-12-2019 PDFDokument30 SeitenSolutions - AIATS Medical-2020 (XII Studying) - Test-5 - (Code-A & B) - 22-12-2019 PDFShashank KashyapNoch keine Bewertungen

- Daftar Alat, Biaya Pengujian Dan Operator: TMT 3 September 2016 Jenispengujian Biaya Per Sampel (Rupiah) Operator Ket.Dokument6 SeitenDaftar Alat, Biaya Pengujian Dan Operator: TMT 3 September 2016 Jenispengujian Biaya Per Sampel (Rupiah) Operator Ket.Charis Achmad TajuddinNoch keine Bewertungen

- Chapter 11 Lecture Notes: The Structure of DNADokument9 SeitenChapter 11 Lecture Notes: The Structure of DNAKrishna VenkataNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Ministry of Commerce & Industry: RillingDokument3 SeitenMinistry of Commerce & Industry: RillingMick DelantorNoch keine Bewertungen

- High Temperature Physicochemical Properties of High Alumina Blast Furnace SlagDokument200 SeitenHigh Temperature Physicochemical Properties of High Alumina Blast Furnace SlagBernardo Loureiro PattoNoch keine Bewertungen

- Indian Institute of Welding - ANB Refresher Course - Module 07Dokument55 SeitenIndian Institute of Welding - ANB Refresher Course - Module 07dayalram0% (1)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)