Beruflich Dokumente

Kultur Dokumente

Mirilla Vaposcope Sightglasses DBL 818475 01 VK14-VK16 en

Hochgeladen von

Alberto Jara N.Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mirilla Vaposcope Sightglasses DBL 818475 01 VK14-VK16 en

Hochgeladen von

Alberto Jara N.Copyright:

Verfügbare Formate

GESTRA

Issue Date: 8/05

GESTRA Steam Systems

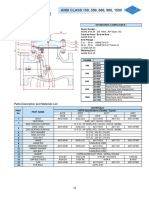

Vaposcope Sightglasses VK 14, DN 15, DN 20, DN 25, DN 40, DN 50, PN 16 VK 16, DN 15, DN 20, DN 25, DN 40, DN 50, PN 40

Product Range A VK 14 VK 16

Description

The GESTRA Vaposcope is a sight flow indicator specially designed for monitoring flow conditions in pipelines. If installed upstream of steam traps the Vaposcope can be used for checking the traps for steam loss or for banking-up of condensate.

Function

Fortsetzung

The regulator of the steam trap is probably failing or the cleaning valves are open. Fig. 3

Design

VK 14 Straight-through type body with sightglasses made from borosilicate glass to DIN 7080 for fluids pH 9 at either end. The equipment has no moving parts. VK 16 Straight-through type body with sightglasses made from borosilicate glass to DIN 7080 for fluids pH 10 at either end. The equipment is fitted with a mica disk and has no moving parts. VK 14

Function

Steam and condensate flow in a pipe in separate phases towards the steam trap. The regulator of a properly working steam trap is adjusted in such a way that only condensate but not steam is discharged. The condensate in the sightglass VK flows under the deflector which remains immersed, or at least touches the condensate surface. Due to this siphon effect condensate is continuously moved to the steam trap where it is evacuated. Fig. 1 Complete flooding of the Vaposcope VK indicates banking-up of condensate. This may be done on purpose or because the steam trap is either undersized or failing to work correctly. Fig. 2 If the water level in the sightglass VK is being considerably depressed during normal operation, it is a sure sign that the steam trap is passing live steam.

End Connections

VK 14: Flanges EN, PN 16. VK 16: Flanges EN, PN 16 ASME B16.34, Class 150 RF ASME B16.34, Class 300 RF Screwed sockets (for BSP and NPT threads) Socket-weld ends

Pressure/Temperature Ratings VK 14

p-T series Material Size (DN) Connection pH value Max. allowable pressure PMA Max. allowable temperature TMA

1

PN 16

according to EN 1092-2 EN-JL1040 (EN-GJL-250) / GG-25 (0.6025) 15, 20, 25, 40, 50 Flanged to DIN, PN 16 9

VK 16

[bar g] [C]

16.0 10 to 50

14.4 100

12.8 200

11.2 250

9.6 280 1)

) If mica disks are retrofitted the temperature is increased to 300 C.

Pressure/Temperature Ratings VK 16

p-T series Material Size (DN) Connection pH value Max. allowable pressure PMA Max. allowable temperature TMA [bar g] [C]

PN 40

according to EN 1092-1, material group 3E0 1.0460 (P250GH) / 1.0460 (C 22.8) 15, 20, 25, 40, 50 Flanged to DIN, PN 40, ASME Class 300 10 40.0 20 37.3 100 30.2 200 28.4 250 25.8 300

Fig. 2 Fig. 1

Pressure/Temperature Ratings VK 16

p-T series Material Size (DN) Connection pH value Max. allowable pressure PMA Max. allowable temperature TMA [bar g] [C]

Class 150

ASME B16.34 material group 1.1 1.0460 (P250GH) / 1.0460 (C 22.8) 15, 20, 25, 40, 50 Flanged to ASME Class 150 10 19.7 20 17.7 100 14.0 200 12.1 250 10.2 300

Fig. 3

Vaposcope Sightglasses VK 14, DN 15, DN 20, DN 25, DN 40, DN 50, PN 16 VK 16, DN 15, DN 20, DN 25, DN 40, DN 50, PN 40

Installation

Upstream of the steam trap, with the deflector pointing downwards and in accordance with the direction indicated by the flow arrow. For installation in vertical and horizontal pipes.

Materials

Materials VK 14 Body Union nuts1) Flange2) Body screws3) Sightglass Sightglass gasket

1

EN EN-JL 1040 (EN-GJL-250) 1.1181 (C35E) P250GH (1.0460) 5.6

DIN GG-25 (0.6025) CK 35 (1.1181) C 22.8 (1.0460) 5.6 MAXOS Borosilicate glass, DIN 7080 Graphite / CrNi

ASTM4) A 126 Class B A 194-2H A 105

Steam / condensate

Siphon

Deflector

) For sightglass fixing with DN 15-25, to ISO 8434-1, form N, series S. 2 ) Flange for sightglass fixing with DN 40, 50 3 ) Hexagon-head cap screw M 16 x 40, EN 24017 for sightglass fixing 4 ) ASTM equivalent stated for guidance only. Take different chemical and physical properties to DIN into account.

Steam / condensate

Materials VK 16 Body Insert Flange2) Body screws3) Sightglass Sightglass gasket

2 3 4

EN 1.0460 (P250GH) 1.0619 (GP240GH) 1.0460 (P250GH) 5.6

DIN 1.0460 (C 22.8) 1.0619 (GS C-25) 1.0460 (C 22.8) 5.6 MAXOS Borosilicate glass, DIN 7080 Graphite / CrNi

ASTM4) A 105 A 216 WCB A 105

Deflector Siphon

) Flange for sightglass fixing with DN 40, 50 ) Hexagon-head cap screw M 16 x 40, EN 24017 for sightglass fixing ) ASTM equivalent stated for guidance only. Take different chemical and physical properties to DIN into account.

When ordering please state:

Service pressure, service temperature, pH value of the fluid The following test certificates can be issued on request, at extra cost: in accordance with EN 10204/2.2 and 3.1B. All inspection requirements have to be stated with the order. After supply of the equipment certificates can no longer be established. Charges and extent of the above mentioned certificates as well as the different tests confirmed therein are listed in our price list Test and Inspection Charges for Standard Equipment. For other tests and inspections than those listed above, please consult us.

Dimensions

PED (Pressure Equipment Directive)

The equipment complies with the requirements of the Pressure Equipment Directive PED 97/23/EC. Applicable with fluids of group 2. With CE marking (apart from equipment excluded from the scope of the Directive according to section 3.3).

VK 14, DN 15, 20, 25

Dimensions and weights VK 14 Size DN [mm] [inch] Length A [mm] [kg] Approx. weight

VK 16, DN 15 DN 50

Flanged to DIN 15 130 3.0 20 150 3.7 25 1 160 4.3 40 1 200 14.0 50 2 230 16.0

ATEX (Atmosphre Explosible)

The equipment does not have its own potential source of ignition and is therefore excluded from the scope of the ATEX Directive 94/9/EC. Applicable in Ex zones 0, 1, 2, 20, 21 and 22 (1999/92/EC). Without Ex marking.

Dimensions and weights VK 16 Size DN [mm] [inch] Length B Approx. weight [mm] [kg]

Flanged to DIN 15 150 4.0 20 150 5 25 1 160 5.5 40 1 200 13.0 50 2 230 15.5

Screwed sockets / Socket-weld ends 15 95 2.9 20 95 3.1 25 1 95 3.0 40 1 130 8.5 50 2 210 9.0

Supply in accordance with our general terms of business.

GESTRA AG

P. O. Box 10 54 60, D-28054 Bremen Mnchener Str. 77, D-28215 Bremen Telephone +49 (0) 421 35 03 - 0, Fax +49 (0) 421 35 03 - 393 E-Mail gestra.ag@flowserve.com, Internet www.gestra.de

818475-01/805c 2005 GESTRA AG Bremen Printed in Germany

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- SPE 76-002 (2006) Flange MaterialsDokument6 SeitenSPE 76-002 (2006) Flange Materials김창배Noch keine Bewertungen

- 4CC-6CC-8CC Spare Parts ListDokument17 Seiten4CC-6CC-8CC Spare Parts ListJohan SmitNoch keine Bewertungen

- Resilient Seat Gate Valve Non Rising Stem 11A EngDokument5 SeitenResilient Seat Gate Valve Non Rising Stem 11A EngdoostareganNoch keine Bewertungen

- Flanged Orifice Plate PDFDokument2 SeitenFlanged Orifice Plate PDFAlaa RamadanNoch keine Bewertungen

- 600-50S-0002 Rev5 (Recovered)Dokument189 Seiten600-50S-0002 Rev5 (Recovered)Anonymous l4Vcl2bBNoch keine Bewertungen

- Literature For Blow-Off ValveDokument16 SeitenLiterature For Blow-Off Valvevon18100% (1)

- Assembly - FlayerDokument8 SeitenAssembly - FlayerIbrahim MesfinNoch keine Bewertungen

- Genuine Service Parts For Commercial VehiclesDokument44 SeitenGenuine Service Parts For Commercial Vehiclesjuan apazaNoch keine Bewertungen

- Cable Lugs Bonding WireDokument3 SeitenCable Lugs Bonding WireJwalaNoch keine Bewertungen

- ME2309 CAD CAM Lab Manual PDFDokument39 SeitenME2309 CAD CAM Lab Manual PDFAnonymous bj8F8c100% (1)

- Vaas Automation PVT LTD: 90 Series Installation, Operating & Maintenance ManualDokument5 SeitenVaas Automation PVT LTD: 90 Series Installation, Operating & Maintenance ManualDanielle JohnsonNoch keine Bewertungen

- 04-SAMSS-005 2018 Check Valves - Flanged, Lug, and Butt-WeldingDokument10 Seiten04-SAMSS-005 2018 Check Valves - Flanged, Lug, and Butt-WeldingWHWENNoch keine Bewertungen

- Catalog Ava Fa CouplingDokument1 SeiteCatalog Ava Fa Couplingazlen494Noch keine Bewertungen

- DA EVK-Basic EN 050121Dokument5 SeitenDA EVK-Basic EN 050121Fernando RuedaNoch keine Bewertungen

- 01 Surface Spooled (Stack-Up) WellheadsDokument111 Seiten01 Surface Spooled (Stack-Up) WellheadsYoucef LiasNoch keine Bewertungen

- Pipes 2006Dokument28 SeitenPipes 2006droessaert_stijnNoch keine Bewertungen

- AxialFans BifurcatedDokument25 SeitenAxialFans Bifurcatedblindjaxx100% (1)

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDokument12 SeitenSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNoch keine Bewertungen

- Cast Steel Swing Check Valve: ANSI CLASS 150, 300, 600, 900, 1500Dokument3 SeitenCast Steel Swing Check Valve: ANSI CLASS 150, 300, 600, 900, 1500Andri AjaNoch keine Bewertungen

- MSS SP-25 (2008)Dokument27 SeitenMSS SP-25 (2008)adprimNoch keine Bewertungen

- GS Ep PVV 146Dokument8 SeitenGS Ep PVV 146SangaranNoch keine Bewertungen

- Flanges Temperature and Pressure Ratings For Group 1.1 MaterialsDokument4 SeitenFlanges Temperature and Pressure Ratings For Group 1.1 MaterialspipestressNoch keine Bewertungen

- 816 Soval - Compuerta OS&Y RW UL-FM FLXFL 14 A 24Dokument1 Seite816 Soval - Compuerta OS&Y RW UL-FM FLXFL 14 A 24alexis morales espinozaNoch keine Bewertungen

- FFXMQ-P-Ducted-Engineering-Data4 FXMQ P Ducted Engineering DataDokument42 SeitenFFXMQ-P-Ducted-Engineering-Data4 FXMQ P Ducted Engineering Datalongtt100% (1)

- Chapter 12 PDFDokument52 SeitenChapter 12 PDFdi abiNoch keine Bewertungen

- Thermoplastic Support Catalog 1st Edition PDFDokument38 SeitenThermoplastic Support Catalog 1st Edition PDFlaguna028Noch keine Bewertungen

- Catalogo ValvulaDokument1 SeiteCatalogo Valvulajcojedar2009Noch keine Bewertungen

- parker接头样本Dokument135 Seitenparker接头样本words2zhigang_612545Noch keine Bewertungen

- Valve StandardDokument27 SeitenValve Standardsgupta_615796Noch keine Bewertungen

- Is 7332 1 1991 PDFDokument15 SeitenIs 7332 1 1991 PDFslamienkaNoch keine Bewertungen