Beruflich Dokumente

Kultur Dokumente

Alufer N en

Hochgeladen von

Stephen MalobaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Alufer N en

Hochgeladen von

Stephen MalobaCopyright:

Verfügbare Formate

Ref.

: Technische fiches/1

Technical data sheet

TF Alufer N.EN 14/07/11-5

1/3 www.zinga.eu

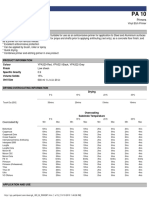

ALUFER N

ZM-RE-PRO-04-A (01/08/06)

Alufer N is a moisture curing one pack polyurethane. Micaceous iron oxides create the special lamellar structure which create a very tight paint film excellent water and corrosion resistance. Alufer N can be applied as an intermediate and/or topcoat on Zinga. Alufer N can be used for immersion in water, sea water and several chemicals.

Physical data and technical information

Wet product - micaceous iron oxides - aluminium silicates - magnesium silicates moisture curing aromatic polyisocyanate prepolymers. 1,52 Kg/dm ( 0,05 Kg/dm) at 20C - 79% by weight ( 2%) - 66% by volume ( 2%) 105 KU ( 5 KU) at 20C 300 g/L (= 198 g/Kg)

Components Binder Density Solid content Viscosity VOC Dry film

Colour Gloss Packing

Grey Mat

1L 4L 20 L Conservation

available (per box of 6 L) available available

Storage

2 years in the original, unopened package stored in a dry environment at temperatures between 20C and +40C.

Ref.: Technische fiches/1

Technical data sheet

TF Alufer N.EN 14/07/11-5

2/3 www.zinga.eu

Application data

Surface preparation

When the waiting time between the successive coats is abnormally prolonged or in extremely polluted areas, the primed surface can become contaminated. All contamination that hampers the adhesion of the paint should be removed by appropriate means. Surfaces contaminated with oil and grease should be washed down with solvent, alkaline solutions or emulsifier. Salt deposits or other water-soluble contaminations should be removed with water and brush, water under high pressure or steam. Possible white zinc rust on zinc dust primers should be removed with water and rigid nylon brush. Coverage and consumption - for 80 m DFT: 7,5 m/L - for 100 m DFT: 6,0 m/L - for 150 m DFT: 4,0 m/L depends upon the roughness profile of the substrate and the application method

Theoretical coverage Practical coverage

Environmental conditions during application minimum 0C maximum 35C minimum 30% maximum 98% minimum 3C above the dew point

Ambient temperature Relative humidity Surface temperature

Drying process and overcoating for 80 m DFT at relative humidity of 75%: - 10C: dustdry: 2,5 hours tackfree: 4 hours dry: 6 hours - 20C: dustdry: 1 hours tackfree: 2,5 hours dry: 4 hours - 30C: dustdry: 40 minutes tackfree: 1,5 hours dry: 3 hours for 80 m DFT at relative humidity of 75%: 10C: minimum: 24 hours maximum: 3 months 20C: minimum: 6 hours maximum: 1 month 30C: minimum: 4 hours maximum: 1 week Remark: At longer intervals a good cleaning is necessary to avoid intermediate coat contamination which could disturb the adherence of the next coat.

Drying time

Overcoating

Ref.: Technische fiches/1

Technical data sheet

TF Alufer N.EN 14/07/11-5

3/3 www.zinga.eu

Instructions for use

Application by brush and roller 5 to 10% with Zingasolv

Dilution

Application by conventional spray-gun 10 to 20% with Thinner 41 3 to 5 bar 1,2 to 1,5 mm

Dilution Pressure at the nozzle Nozzle opening

Application by airless spraying 5 to 15% with Thinner 41 100 to 300 bar 0,017 to 0,024 inch

Dilution Pressure at the nozzle Nozzle opening Remarks

Stripe coat Dry layer thickness Cleaning

It is always recommended to treat corners, sharp edges, bolts and nuts before applying a uniform coat. Recommended: 60 to 100 m Maximum: 120 to 160 m With Zingasolv

For more specific and detailed recommendations concerning the application of Alufer N, please contact the Zingametall representative. For detailed information about the health and safety hazards and precautions for use, please refer to the Alufer N safety data sheet.

Waiver

The information on this sheet is merely indicative and is given to the best of our knowledge based on practical experience and testing. The conditions or methods of handling, storage, use or disposal of the product cannot be controlled by us and are therefore outside our responsibility. For these and other reasons we retain no liability in case of loss, damage or costs that are caused by or that are linked in any way to the handling, storage, use or disposal of the product. Any claim concerning deficiencies must be made within 3 months upon reception of the goods quoting the relevant batch number. We retain the right to change the formula if properties of the raw material are changed. This data sheet replaces all former specimens.

Das könnte Ihnen auch gefallen

- Heat Resisting Silicone Aluminium PaintDokument3 SeitenHeat Resisting Silicone Aluminium Paintrumi_2kNoch keine Bewertungen

- PC 1787 - Apcotherm HR 600 PDFDokument3 SeitenPC 1787 - Apcotherm HR 600 PDF41464147Noch keine Bewertungen

- Zinga Technical Data SheetDokument6 SeitenZinga Technical Data SheetVikas TanejaNoch keine Bewertungen

- PC 4050 - Apcofine 910Dokument3 SeitenPC 4050 - Apcofine 910rohitNoch keine Bewertungen

- Apcodur CF 699: Product DescriptionDokument4 SeitenApcodur CF 699: Product DescriptionShravana PrasadNoch keine Bewertungen

- Barrier 90 - English (Uk) - Issued.06.12.2007Dokument3 SeitenBarrier 90 - English (Uk) - Issued.06.12.2007Mohamed FaragNoch keine Bewertungen

- PC 0189 - Heat Resisting Silicone Aluminium Paint - Apcotherm 540Dokument3 SeitenPC 0189 - Heat Resisting Silicone Aluminium Paint - Apcotherm 540onshore purchase100% (1)

- TDS - CHEMFLAKE CV - English (Uk) - Issued.13.04.200Dokument4 SeitenTDS - CHEMFLAKE CV - English (Uk) - Issued.13.04.200wey5316Noch keine Bewertungen

- Tds - Alkydprimer - Issued.31.08.2005Dokument4 SeitenTds - Alkydprimer - Issued.31.08.2005wey5316Noch keine Bewertungen

- 2020.10.04-AL JAZEERA-Red Oxide Primer (JI-71001)Dokument3 Seiten2020.10.04-AL JAZEERA-Red Oxide Primer (JI-71001)Jafffar MahasnehNoch keine Bewertungen

- TDS - Solvalitt Midtherm - English (Uk) - Issued.26.11.2010Dokument4 SeitenTDS - Solvalitt Midtherm - English (Uk) - Issued.26.11.2010Fauzan BenraxidNoch keine Bewertungen

- TDS - Barrier 90 - English (Uk) - Issued.05.10.2011Dokument4 SeitenTDS - Barrier 90 - English (Uk) - Issued.05.10.2011ansarALLAAHNoch keine Bewertungen

- Mascoat - Thermal Insulation Coating 02-MI-DTI Spec Sheet 0113Dokument2 SeitenMascoat - Thermal Insulation Coating 02-MI-DTI Spec Sheet 0113Ying Kei ChanNoch keine Bewertungen

- TDS Zingatarfree en 2Dokument4 SeitenTDS Zingatarfree en 2Veronica CNoch keine Bewertungen

- Sellador Elastico Autonivelante Alto Desempeno Sikaflex 2c SLDokument2 SeitenSellador Elastico Autonivelante Alto Desempeno Sikaflex 2c SLEleazar MendezNoch keine Bewertungen

- Pa 10Dokument3 SeitenPa 10LymeParkNoch keine Bewertungen

- Jazeera Acrythane 60Dokument3 SeitenJazeera Acrythane 60salam nazarNoch keine Bewertungen

- Solvalitt Jotun (Azad Ras Tanura)Dokument3 SeitenSolvalitt Jotun (Azad Ras Tanura)AzadAhmadNoch keine Bewertungen

- Technical Data Sheet Jazeera Marine Primer JM-31001: Description: Recommended Use: CharacteristicsDokument3 SeitenTechnical Data Sheet Jazeera Marine Primer JM-31001: Description: Recommended Use: CharacteristicsMark DingalNoch keine Bewertungen

- Oasis QD Special PrimerDokument2 SeitenOasis QD Special PrimerMaurice DavisNoch keine Bewertungen

- Qerpodu01 Pctransfer Oxzeich 8file 890-000-000-000-014Dokument2 SeitenQerpodu01 Pctransfer Oxzeich 8file 890-000-000-000-014dantopanNoch keine Bewertungen

- Solvalitt TDSDokument4 SeitenSolvalitt TDSphillipskincaidNoch keine Bewertungen

- Vinyguard Silvergrey 88 - English (Uk) - Issued.06.12.Dokument3 SeitenVinyguard Silvergrey 88 - English (Uk) - Issued.06.12.Mohamed FaragNoch keine Bewertungen

- Baltoflake - English (Uk) - Issued.25.03.2010Dokument4 SeitenBaltoflake - English (Uk) - Issued.25.03.2010Mohamed FaragNoch keine Bewertungen

- TDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Dokument5 SeitenTDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Khaled GamalNoch keine Bewertungen

- Sikaflex®-11 FC: Product Data SheetDokument3 SeitenSikaflex®-11 FC: Product Data SheetHaradhon DattaNoch keine Bewertungen

- Jotun Resist 5WFDokument4 SeitenJotun Resist 5WFSergio SmithNoch keine Bewertungen

- Tds - Antifouling Seaforce 90 - English (Uk) - IssueDokument3 SeitenTds - Antifouling Seaforce 90 - English (Uk) - Issuewey5316Noch keine Bewertungen

- JotunBitum Ballastic BlackDokument3 SeitenJotunBitum Ballastic BlackMekhmanNoch keine Bewertungen

- Technical Data:: Oasis Epoxy TL 8758Dokument2 SeitenTechnical Data:: Oasis Epoxy TL 8758Maurice DavisNoch keine Bewertungen

- Penguard Express ZPDokument5 SeitenPenguard Express ZPMustafa Al-YasseriNoch keine Bewertungen

- PC 7051 - Apcomin Industrial EnamelDokument3 SeitenPC 7051 - Apcomin Industrial EnamelHithayathulla KhanNoch keine Bewertungen

- Jotazinc PDFDokument4 SeitenJotazinc PDFAnonymous YtgIj2A9nWNoch keine Bewertungen

- ALUFLEX - English (Uk) - Issued.28.11.2005Dokument3 SeitenALUFLEX - English (Uk) - Issued.28.11.2005wey5316Noch keine Bewertungen

- Asian Apcodur Epoxy Mio PaintDokument3 SeitenAsian Apcodur Epoxy Mio PaintPrinceRaghavNoch keine Bewertungen

- Jazeera Damp MasticDokument3 SeitenJazeera Damp MasticAhmad BougeisNoch keine Bewertungen

- Penguard ZP AO - English (Uk) - Issued.06.12.2007Dokument3 SeitenPenguard ZP AO - English (Uk) - Issued.06.12.2007Mohamed FaragNoch keine Bewertungen

- Lux A Prime 1501Dokument2 SeitenLux A Prime 1501paulloh64100% (1)

- 7-LINE® - 7-824 SERIES: Product Data SheetDokument6 Seiten7-LINE® - 7-824 SERIES: Product Data SheetJose Manuel Guizado SolisNoch keine Bewertungen

- Jotun-Penguard Primer - Tech DataDokument4 SeitenJotun-Penguard Primer - Tech Dataanwarali1975Noch keine Bewertungen

- Penguard Primer PDFDokument4 SeitenPenguard Primer PDFheri_prasetyadi7715Noch keine Bewertungen

- U-SEAL 500: One-Part Elastic Polyurethane Adhesive/sealantDokument5 SeitenU-SEAL 500: One-Part Elastic Polyurethane Adhesive/sealantCamilo Hernán Torres ZamoraNoch keine Bewertungen

- Sigmaguard 720Dokument4 SeitenSigmaguard 720Danny DurhamNoch keine Bewertungen

- Instructions For Use: Blotting / Transfer ManifoldsDokument3 SeitenInstructions For Use: Blotting / Transfer ManifoldsIsah MohammedNoch keine Bewertungen

- Apcothane 676 AlDokument3 SeitenApcothane 676 AlJOSEPH GRAHAMSENGGNoch keine Bewertungen

- Aluflex - English (Uk) - Issued.06.12.2007Dokument3 SeitenAluflex - English (Uk) - Issued.06.12.2007Mohamed FaragNoch keine Bewertungen

- TDS - Baltoflake S2000 - English (Uk) - Issued.26.11.2010Dokument4 SeitenTDS - Baltoflake S2000 - English (Uk) - Issued.26.11.2010rezza182Noch keine Bewertungen

- Tankguard ARDokument4 SeitenTankguard ARSherif Abdelhameed100% (1)

- TDS - Muki Z 2008 - English (Uk) - Issued.26.11.2010Dokument4 SeitenTDS - Muki Z 2008 - English (Uk) - Issued.26.11.2010Keith ChooNoch keine Bewertungen

- Barrier ZepDokument3 SeitenBarrier ZepJairo Gómez SánchezNoch keine Bewertungen

- Araldite 2011Dokument2 SeitenAraldite 2011nrd9771Noch keine Bewertungen

- Sigma Cover 510Dokument4 SeitenSigma Cover 510supriadi90315100% (1)

- 81970Dokument2 Seiten81970khalid764Noch keine Bewertungen

- Tds - Antifouling Seaforce 60 - English (Uk) - IssueDokument3 SeitenTds - Antifouling Seaforce 60 - English (Uk) - Issuewey5316Noch keine Bewertungen

- Chemflake Special - English (Uk) - Issued.08.01.2010Dokument5 SeitenChemflake Special - English (Uk) - Issued.08.01.2010Mohamed FaragNoch keine Bewertungen

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Issue #9 Printing and Graphics Science Group NewsletterVon EverandIssue #9 Printing and Graphics Science Group NewsletterNoch keine Bewertungen

- Solid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityVon EverandSolid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityBewertung: 5 von 5 Sternen5/5 (2)

- ASME Sec VIII Div 1 Ed 2010 471 PDFDokument9 SeitenASME Sec VIII Div 1 Ed 2010 471 PDFStephen Maloba100% (1)

- Penguard HB: Technical DataDokument4 SeitenPenguard HB: Technical DataStephen MalobaNoch keine Bewertungen

- 04 - Sappco Upvc Pipes and FittingsDokument40 Seiten04 - Sappco Upvc Pipes and FittingsStephen MalobaNoch keine Bewertungen

- Angus Fire CorporateDokument12 SeitenAngus Fire CorporateStephen MalobaNoch keine Bewertungen

- 6411-1 RHMB85Dokument2 Seiten6411-1 RHMB85Stephen MalobaNoch keine Bewertungen

- 6410-1 RHMB65Dokument2 Seiten6410-1 RHMB65Stephen MalobaNoch keine Bewertungen

- Penguard HB: Technical DataDokument4 SeitenPenguard HB: Technical DataStephen MalobaNoch keine Bewertungen

- 70 QuotesDokument9 Seiten70 QuotesStephen MalobaNoch keine Bewertungen

- Marine Thinner 23 09 2014Dokument1 SeiteMarine Thinner 23 09 2014Руслан ЛобыревNoch keine Bewertungen

- C2L1 - The Artist & The ArtisanDokument16 SeitenC2L1 - The Artist & The ArtisanShiori EulinNoch keine Bewertungen

- Elementis Specialties Product Overview AmericasDokument6 SeitenElementis Specialties Product Overview AmericasSandra RojasNoch keine Bewertungen

- Paul Sip - Egg TemperaDokument13 SeitenPaul Sip - Egg TemperaBeck YepsenaNoch keine Bewertungen

- Creating Classical Oil Portrait:Cesar SantosDokument3 SeitenCreating Classical Oil Portrait:Cesar Santosc cNoch keine Bewertungen

- Astm D 4060-10Dokument5 SeitenAstm D 4060-10Stephanie MartinezNoch keine Bewertungen

- Temacoat GPL-S PrimerDokument4 SeitenTemacoat GPL-S Primermp87_ingNoch keine Bewertungen

- CN - Surfactants Anionic - SURFACTANTS Coatings and Emulsion PolymerizationDokument16 SeitenCN - Surfactants Anionic - SURFACTANTS Coatings and Emulsion PolymerizationSalah100% (1)

- Operations Manual: Painting and Decorating Education OM001Dokument11 SeitenOperations Manual: Painting and Decorating Education OM001AdisorNoch keine Bewertungen

- Pu Exterior Paint - NovotaDokument2 SeitenPu Exterior Paint - NovotasamirNoch keine Bewertungen

- Penguard HB - English (Uk) - Issued.06.12.2007Dokument4 SeitenPenguard HB - English (Uk) - Issued.06.12.2007Mohamed FaragNoch keine Bewertungen

- Pds Hempadur Speed-Dry ZP 500 En-GbDokument3 SeitenPds Hempadur Speed-Dry ZP 500 En-GbDHANOOPNoch keine Bewertungen

- Information Contained in This Document Is Subject To Use and Disclosure Restrictions Under The AgreementDokument19 SeitenInformation Contained in This Document Is Subject To Use and Disclosure Restrictions Under The AgreementGürkan ArslanNoch keine Bewertungen

- Hempel Paint Remover TDSDokument3 SeitenHempel Paint Remover TDSrichard nagassarNoch keine Bewertungen

- Administrative Building PorlaDokument244 SeitenAdministrative Building PorlaSandeep_AjmireNoch keine Bewertungen

- TDS DC 56Dokument2 SeitenTDS DC 56manox007Noch keine Bewertungen

- SQT Technical Data For MArbleDokument19 SeitenSQT Technical Data For MArbleHamayet RaselNoch keine Bewertungen

- PCB Layout and ArtworkDokument59 SeitenPCB Layout and ArtworkPhil GainNoch keine Bewertungen

- Surface Preparation & Painting Procedure: List of ContentDokument20 SeitenSurface Preparation & Painting Procedure: List of Contentsherviny50% (4)

- Home Decor 193 1 PDFDokument17 SeitenHome Decor 193 1 PDFashutoshkumar5549Noch keine Bewertungen

- Estimate-Main Plant-Sppl-Ap-23.10.2022Dokument10 SeitenEstimate-Main Plant-Sppl-Ap-23.10.2022swapnilNoch keine Bewertungen

- Nirmal Bang Paint Sector Update 010920Dokument88 SeitenNirmal Bang Paint Sector Update 010920Anish AnandNoch keine Bewertungen

- SIGMALINE™ 2500: Product Data SheetDokument5 SeitenSIGMALINE™ 2500: Product Data SheetEduardoNoch keine Bewertungen

- Paint: Guide To Preparing Hot-Dip Galvanized Steel ForDokument12 SeitenPaint: Guide To Preparing Hot-Dip Galvanized Steel ForEidrish ShaikhNoch keine Bewertungen

- D-5381 Kosmetika XRFDokument2 SeitenD-5381 Kosmetika XRFTako JankhoteliNoch keine Bewertungen

- Approved Painting Scheme - ObraDokument21 SeitenApproved Painting Scheme - ObraCaspian Datta100% (3)

- Improve Your Paintings Luminous Watercolor Mixing Ewing Craftsy v1Dokument10 SeitenImprove Your Paintings Luminous Watercolor Mixing Ewing Craftsy v1Raisona AlamNoch keine Bewertungen

- Building Technology 1 - Building Materials: Midterm ProjectDokument68 SeitenBuilding Technology 1 - Building Materials: Midterm ProjectAngeLyn CaguimbalNoch keine Bewertungen

- Jotafloor TC EDokument6 SeitenJotafloor TC ERidwanSalminNoch keine Bewertungen

- Off White: Smartcare Damp Block 2KDokument2 SeitenOff White: Smartcare Damp Block 2KSankar Nath ChakrabortyNoch keine Bewertungen