Beruflich Dokumente

Kultur Dokumente

Starting System

Hochgeladen von

Argenis BriceñoOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Starting System

Hochgeladen von

Argenis BriceñoCopyright:

Verfügbare Formate

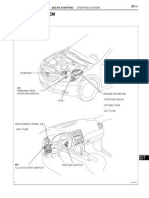

STARTING SYSTEM

IN-VEHICLE INSPECTION .......................... ST 2

STARTER ................................................ ST 2

STARTER RELAY .................................... ST 3

NEUTRAL START SWITCH ..................... ST 3

STARTING SYSTEM CIRCUIT .................... ST 4

STARTER ..................................................... ST 5

COMPONENTS ...................................... ST 5

UNIT CHECK OF STARTER .................... ST 7

DISASSEMBLY ....................................... ST 8

INSPECTION .......................................... ST12

ASSEMBLY ............................................. ST19

SPECIFICATIONS ....................................... ST23

SSTs ............................................................ ST23

TIGHTENING TORQUE ............................... ST23

ST

JST00001-00000

TO INDEX

IN-VEHICLE INSPECTION

STARTER

1. Place the shift lever to the neutral position. Apply the park-

ing brake lever.

2. Remove the EFI fuse provided inside the relay box so that

the engine may not start.

3. Set the ignition switch to the ST position. Check to see if

the engine cranks.

4. If the engine will not crank, check the battery for damage

or charging state. Also, check the harness for continuity.

5. On the A/T vehicles, check the starter relay and neutral

start switch.

6. If the engine still will not crank even after the checks

above have been performed, remove the starter motor

and perform the unit check.

ST2

WARNING:

When removing the starter, firstly disconnect the nega-

tive terminal of the battery. Then, disconnect the posi-

tive terminals (+B, ST) at the starter side. Since the

battery voltage is always applied to the starter +B ter-

minal, failure to observe this removing sequence may

lead to battery short, which is extremely dangerous.

CAUTION:

If the starter terminals or connections between the bat-

tery terminals and the wires are loose, the connections

may generate heat. Thus, loose terminals or connec-

tions are potentially-hazard. Be certain to securely

tighten the terminals or wires.

When installing the starter, install the starter in the

clutch housing positively and be sure to tighten the at-

taching bolts to the specified torque. Improper installa-

tion can cause premature wear of the teeth of the pin-

ion gear or ring gear and also can cause breakage of

the clutch housing.

[Reference]

Starter Installing Torque: 25.9 - 48.1 Nm

Terminal B

Terminal ST

Terminal C

JST00002-00000

JST00003-00002

STARTER RELAY

1. Remove the lid of the relay box inside the engine compart-

ment and pull out the starter relay.

2. Inspection of relay continuity

(1) Check that there is continuity between the terminals

and .

Specified Value: 109 - 113

(2) Check that there is continuity between the terminals

and when a voltage of 12 V is applied between the

terminals and .

NOTE:

If the trouble has not been solved by repairing the

relay, check wire harness.

3. Install the starter relay to the relay box.

ST3

4 2

3 1

JST00004-00000

JST00005-00004

JST00006-00000

NEUTRAL START SWITCH

As for the neutral start switch check, refer to the Section EF.

JST00080-00000

STARTING SYSTEM CIRCUIT

ST4

Engine

ECU

68 STA

Ignition switch

ST

Battery

A

M

6

0

A

B ST

B ST

P.C H.C

P.C H.C

C

C

0.8 kW

1.0 kW

Engine

ECU

68 STA

11 A/T

Starter relay

Neutral start switch

Ignition switch

ST

Battery

A

M

6

0

A

B ST

B ST

P.C H.C

P.C H.C

C

C

0.8 kW

1.0 kW

JST00007-00006

JST00000-00007

M/T

A/T

STARTER

COMPONENTS

ST5

B

B

]

]

]

]

]

]

]

]

]

JST00008-00008

RATED OUTPUT: 0.8 kW

Magnetic switch

Bearing

Drive housing Assy

Plate washer

Pinion drive lever

Snap ring

Pinion stop collar

Starter clutch

Armature

] Yoke Assy

] Brush

] Brush spring

] Brush holder

] Insulator

] Bearing

] Commutator end frame

] Through bolt

] Dust protector

ST6

]

]

]

]

]

,

,

,

,

,

,

,

]

]

]

]

JST00000-00009

RATED OUTPUT: 1.0 kW

Magnetic switch

Bearing

Drive housing Assy

Snap ring

Pinion stop collar

Starter clutch

Snap ring

Washer

Pinion drive lever

] Bearing

] Center bearing

] Internal gear

] Washer

] Planetary carrier shaft

] Bearing

] Washer

] Planetary gear

] Plate

] Yoke Assy

, Brush

, Armature

, Brush holder

, Brush spring

, Bearing

, Through bolt

, Commutator end frame

UNIT CHECK OF STARTER

CAUTION:

Each of the following tests must be performed within

three to five seconds. If you fail to observe this caution

and the starter should be energized for more than this

duration, the coil may be burnt out.

If the magnet switch should be tested as a unit, there is

the possibility that the switch section is damaged.

Hence, be sure to test it in the assembled state.

NOTE:

Since the magnet switch can not be overhauled, re-

place it if it is malfunctioning.

Pull-in test

1. Disconnect the lead wire from the terminal C of the mag-

netic switch.

2. Connect the negative () terminal of the battery to the

starter body as well as to the terminal C of the magnetic

switch.

3. Connect the positive (+) terminal to the terminal ST.

Ensure that the pinion is pushed outward.

If the drive pinion fails to move out, replace the magnetic

switch.

NOTE:

The cause for the pinion to fail to pull in is open wire in

the P.C. of the magnet switch or improper sliding of the

plunger. Hence, replace the magnet switch.

Hold-in test

After the check has been performed following the same pro-

cedure as the pull-in test, disconnect the negative terminal of

the magnetic switch terminal.

Ensure that the drive pinion is held in a pushed-out state.

If the drive pinion fails to be held, replace the magnetic

switch.

NOTE:

The cause for the pinion to fail to be held is open wire

in the P.C. of the magnet switch. Hence, replace the

magnet switch.

ST7

JST00009-00010

JST00010-00011

JST00011-00012

JST00012-00013

JST00013-00014

Inspection of plunger return

After the check has been performed following the same pro-

cedure as the hold-in test, disconnect the ground terminal of

the starter body. Ensure that the drive pinion is drawn into the

drive housing.

If the drive pinion fails to be drawn, replace the magnetic

switch.

NOTE:

The cause for the pinion to fail to return is that either

H.C. or P.C. of the magnet switch is grounded or short-

ed. Hence, replace the magnet switch.

ST8

No-load performance test

Connect the battery and an ammeter to the starter as shown

in the right figure. Ensure that the starter rotates smoothly with

the pinion moving out.

Measure the current the starter is drawing.

Specified Current:

0.8 kW TYPE 50 A/11.5 V

1.0 kW TYPE 90 A/11.5 V

NOTE:

Prior to the test, be sure to connect the lead wire to the

magnetic switch.

DISASSEMBLY

STARTER (0.8 kW)

1. Disconnect the lead wire from the magnetic switch.

2. Remove the attaching nut of the magnetic switch from the

drive housing.

3. Remove the magnetic switch from the drive housing.

JST00014-00015

JST00015-00016

JST00016-00017

JST00017-00018

4. Remove the commutator end frame cover by removing the

two screws.

5. Remove the insulator from the brush holder.

6. Remove the brush spring and brush from the brush holder.

7. Remove the brush holder from the yoke.

8. Remove the yoke from the armature.

9. Remove the pinion drive lever and the armature from the

drive housing.

10. With the SST put over the shaft, lightly tap the SST so as to

remove the pinion stop collar from the snap ring.

SST: 09238-87701-000

ST9

JST00018-00019

JST00019-00020

JST00020-00021

JST00021-00022

JST00022-00023

11. Detach the snap ring by prying it off with snap ring pliers.

12. Remove the starter clutch from the shaft.

ST10

STARTER (1.0 kW)

1. Disconnect the lead wire from the magnetic switch.

2. Remove the attaching nut of the magnetic switch from the

drive housing.

3. Remove the magnetic switch from the drive housing.

4. Separate the drive housing and yoke by removing the two

through bolts.

5. Separate the commutator end frame and yoke by remov-

ing the two screws.

JST00023-00024

JST00024-00025

JST00025-00026

JST00026-00027

JST00027-00028

6. Separate the yoke and center bearing.

7. Pull out the armature from the yoke.

8. Remove the brushes from the brush holder by lifting the

brush springs by means of nose pliers or the like.

NOTE:

Care must be exercised not to scratch the commutator

during the removal.

9. Remove the plate from the center bearing.

10. Remove the planetary gears.

11. With the SST put over the shaft, lightly tap the SST so as to

remove the pinion stop collar from the snap ring.

SST: 09238-87701-000

12. Remove the snap ring from the shaft. Remove the starter

clutch from the shaft.

ST11

JST00028-00029

JST00029-00030

JST00030-00031

JST00031-00032

JST00032-00033

13. Remove the snap ring. Pull out the shaft from the center

bearing.

ST12

14. Pull out the internal gear from the center bearing.

NOTE:

When the internal gear is removed, align the recess

provided at the circumference of the center bearing

with the recess provided at the circumference of the in-

ternal gear.

INSPECTION

Armature

1. Check of armature insulation

Ensure that no continuity exists between the commutator

and the armature coil, using an ohmmeter.

If continuity exists, replace the armature.

2. Check of commutator continuity

Check continuity between respective adjacent segments

of the commutator, using an ohmmeter.

If no continuity exists between any adjacent segments, re-

place the armature.

Check of commutator

1. Check each contact surface of the commutator segments

with the brushes for burning.

If the surfaces are dirty or burnt, correct the commutator

surfaces, using abrasive paper (No. 400) or a lathe.

JST00033-00034

JST00034-00035

JST00035-00036

JST00036-00037

JST00037-00038

2. Check of commutator for circle runout

Support the armature at its both ends on a V-block.

Check the commutator for circle runout, using a dial

gauge.

Standard Circle Runout:

0.8 kW TYPE: 0.05 mm

1.0 kW TYPE: 0.02 mm

Limit:

0.8 kW TYPE: 0.40 mm

1.0 kW TYPE: 0.05 mm

If the circle runout exceeds the allowable limit, turn down

the commutator on a lathe.

At this point, care must be exercised to ensure that the

commutator diameters are not less than the minimum re-

quired diameter of 27 mm.

3. Measurement of commutator diameter

Measure the commutator diameter by means of a microm-

eter or vernier calipers.

Standard Diameter: 28 mm

Minimum Diameter: 27 mm

If the commutator diameter is less than the minimum diam-

eter, replace the armature.

4. Check of commutator undercut depth

If the depth of the insulator groove between commutator

segments is less than 0.2 mm, it is necessary to undercut

the insulator so that the groove depth may become 0.45 -

0.75 mm.

Check of field coil

1. Field coil continuity test

Perform field coil continuity test at a point between the

lead wires (brush), using an ohmmeter.

If no continuity exists, replace the yoke.

0.8 kW TYPE: 4 lead wires are available

1.0 kW TYPE: 2 lead wires are available

2. Field coil short test

1.0 kW TYPE

Perform field coil short test at a point between the brush

and the yoke proper, using an ohmmeter.

If continuity exists, replace the yoke.

ST13

Dial gauge

V-block

JST00038-00039

JST00039-00040

JST00040-00041

JST00041-00042

JST00042-00043

0.8 kW TYPE

Ensure that continuity exists between the yoke and the

brush at the field coil side.

If no continuity exists, replace the yoke.

ST14

Check of brushes

1. Measurement of brush length

Measure the brush length, using vernier calipers.

Standard Length:

0.8 kW TYPE: 10 mm

1.0 kW TYPE: 14 mm

Minimum Length:

0.8 kW TYPE: 7.8 mm

1.0 kW TYPE: 11.1 mm

If the length is less than the minimum requirement, replace

the brush.

NOTE:

It is possible to replace the brush holder or yoke with

the brush.

2. Procedure for brush replacement

(1) Cut the brush lead wire at the terminal side.

(2) Remove welding traces with a file or the like to correct

the brush terminal to the specified dimensions.

Specified Dimensions:

Thickness: 1.3 - 1.5 mm

Width: 5 mm

NOTE:

Be sure to remove the section of the brush terminal as

indicated in the right figure. Since the section to be re-

moved is narrow, be very careful not to damage the

field coil.

(3) Stick the plate section of a replacement brush onto the

welding side of the lead wire. Make pressure connec-

tion over the overlaid section by pinching it with pliers.

NOTE:

Be sure to take out the brush lead wire in the correct

direction.

JST00043-00044

JST00044-00045

JST00045-00046

JST00046-00047

JST00047-00048

(4) Solder the pressure connection. Correct the section,

using a file or the like, so that the section conforms to

the dimensions, as indicated in the right figure.

NOTE:

When performing the soldering, heat the section to be

soldered thoroughly. Be very careful not to allow any

solder to flow into the positive side lead wire.

Be sure to allow solder in a sufficient amount to flow

into the inside of the plate.

Ensure that no solder oozes to the field side.

Check of brush holder (Only for 1.0 kW TYPE)

1. Check of brush holder for insulation

Measure the insulation between the positive and negative

terminal of the brush holder.

Insulation Resistance: 0.1 M or more

If the insulation resistance is less than the specification,

replace the brush holder.

Check of starter clutch

1. Inspection of pinion gear and spline teeth

Check the teeth of the pinion gear and spline for wear or

damage.

If any damage exists, replace the clutch. Also, inspect the

flywheel ring gear for wear or damage.

2. Check of starter clutch

While holding the clutch, turn the pinion clockwise. Ensure

that the pinion turns smoothly.

Turn the pinion counterclockwise. Ensure that the pinion is

locked.

If the check results are unsatisfactory, replace the starter

clutch.

Check of magnetic switch

1. Plunger check

Push in the plunger with your fingers and release your fin-

gers. Ensure that the plunger returns quickly to the original

position. If the plunger exhibits poor returning or fails to re-

turn, replace the magnetic switch.

ST15

Brush holder

JST00048-00049

JST00049-00050

JST00050-00051

JST00051-00052

JST00052-00053

2. Pull-in coil open circuit test

Using an ohmmeter, ensure that continuity exists between

the terminal ST and the terminal C.

If no continuity exists, replace the magnetic switch.

ST16

3. Hold-in coil open circuit test

Ensure that continuity exists between the terminal ST and

the magnetic switch body.

If no continuity exists, replace the magnetic switch.

Replacement of drive housing bearing

1. Remove the bearing, using the following SST with a press

or the like.

SST: 09221-87301-000

NOTE:

When pulling out the bearing, be sure to remove it from

the inside.

JST00053-00054

JST00054-00055

JST00080-00080

2. Install the bearing, using the following SST with a press or

the like.

SST: 09221-87301-000

NOTE:

When installing the bearing, be sure to install it from

the outside.

Check of center bearing (Only for 1.0 kW TYPE)

1. Measure the outer diameter of the center bearing sliding

section of the planetary carrier shaft.

Specified Value: 15 mm

JST00081-00081

JST00082-00082

2. Measure the inner diameter of the center bearing so as to

determine the clearance.

Specified Value: 0.03 mm

Allowable Limit: 0.10 mm

If the clearance exceeds the allowable limit, replace the

bearing or he planetary carrier shaft.

3. Bearing replacement

(1) Remove the bearing, using a suitable tool in combina-

tion with a press or the like.

NOTE:

When pulling out the bearing, be sure to remove it from

the inside.

(2) Install the bearing, using a suitable tool in combination

with a press or the like.

NOTE:

When installing the bearing, be sure to install it from

the outside.

NOTE:

The bearing should be driven into position in such a

way that the bearing is recessed within 0.5 mm from

the edge of the center bearing.

Check of end frame bearing

1.0 kW TYPE

1. Measure the outer diameter of the end frame sliding sec-

tion of the armature shaft.

Specified Value: 7 mm

ST17

JST00083-00083

JST00084-00084

JST00085-00085

JST00086-00086

JST000887-00087

2. Measure the inner diameter of the end frame bearing so

as to determine the clearance.

Specified Value: 0.03 mm

Allowable Limit: 0.10 mm

If the clearance exceeds the allowable limit, replace the

bearing or the armature.

ST18

3. Bearing replacement

(1) Remove the bearing, using a tap as shown in the right

figure.

NOTE:

Be certain to clamp the end frame in a vise with a cloth

interposed so that no scratch may be made on the end

frame.

(2) Install a new bearing, using a suitable tool in combina-

tion with a press or the like.

0.8 kW TYPE

1. Bearing replacement

(1) Remove the bearing, using the following SST with a

press or the like.

SST: 09221-87301-000

NOTE:

When pulling out the bearing, be sure to remove it from

the inside.

(2) Install the bearing, using the following SST with a

press or the like.

SST: 09221-87301-000

NOTE:

When installing the bearing, be sure to install it from

the outside.

JST00088-00088

JST00089-00089

JST00090-00090

JST00091-00091

JST00092-00092

ASSEMBLY

NOTE:

Use high-temperature grease to lubricate the bearings

and sliding parts when assembling the starter.

STARTER (0.8 kW)

1. Install the starter clutch on the armature shaft.

2. Pass the pinion stop collar on the armature shaft.

3. Fit the new snap ring onto the armature shaft.

4. With the starter clutch pushed up, lightly tap the shaft with

a plastic hammer so as to fit the pinion stop collar onto the

snap ring.

5. Install the pinion drive lever and armature in the drive

housing.

NOTE:

Apply high-temperature grease to the sliding sections

of the armature shaft and drive lever.

6. Install the yoke in the drive housing.

7. Install the brush holder over the armature shaft.

8. Install the brush and brush spring in the brush holder.

ST19

JST00058-00059

JST00059-00060

JST00060-00061

JST00061-00062

JST00062-00063

9. Install the insulator on the brush holder.

10. Attach the commutator end frame to the yoke assembly.

ST20

11. While hooking the magnetic switch over the pinion drive

lever, install the magnetic switch onto the drive housing.

Secure the magnetic switch with the two nuts.

12. Connect the lead wire to the magnetic switch.

STARTER (1.0 kW)

1. Place the internal gear into the center bearing.

NOTE:

When the internal gear is placed, align the recess pro-

vided at the circumference of the center bearing with

the recess provided at the circumference of the internal

gear.

2. Place the planetary carrier shaft into the center bearing

with the washers.

Clamp it with the snap ring.

JST00063-00064

JST00064-00065

JST00065-00066

JST00066-00067

JST00067-00068

3. Pass the pinion stop collar through the center bearing

shaft.

Then, attach the new snap ring to the shaft groove.

4. With the starter clutch pushed up, lightly tap the shaft with

a plastic hammer so as to fit the pinion stop collar onto the

snap ring.

5. Install the planetary gear to the planet carrier.

NOTE:

Apply high-temperature grease to the gear sections of

the planetary gears.

6. Install the plate to the center bearing.

NOTE:

During the installation, be sure to align the recess pro-

vided at the circumference of the plate with the recess

provided at the circumference of the center bearing.

7. Place the armature in the yoke.

8. Place the brush in the brush holder.

9. Connect the center bearing with the yoke.

NOTE:

During connection, be sure to align the recess sections

at the connecting section.

ST21

Snap ring

Pinion stop collar

JST00068-00069

JST00069-00070

JST00070-00071

JST00071-00072

JST00072-00073

10. Install the commutator end frame to the yoke.

ST22

11. Install the pinion drive lever and armature in the drive

housing.

NOTE:

Apply high-temperature grease to the sliding sections

of the armature shaft and drive lever.

Align the protrusion of the center bearing with the re-

cess of the drive housing.

12. Tighten the through bolt.

JST00073-00074

JST00074-00075

13. While hooking the magnetic switch over the pinion drive

lever, install the magnetic switch onto the drive housing.

Secure the magnetic switch with the two nuts.

NOTE:

Be sure to install the rubber boot in the spring section

securely.

JST00075-00076

14. Connect the lead wire to the magnetic switch.

JST00076-00077

SPECIFICATIONS

SSTs

TIGHTENING TORQUE

ST23

Starter type Planetary type (Cold spec.)

12 V - 1.0 kW

Less than 90 A

14.0 mm

11.1 mm

28 mm

27 mm

0.45 - 0.75 mm

0.2 mm

0.02 mm

0.05 mm

Conventional

12 V - 0.8 kW

Less than 50 A

10.0 mm

7.8 mm

28 mm

27 mm

0.45 - 0.75 mm

0.2 mm

0.05 mm

0.4 mm

Rated voltage and output power

No-load characteristic at 11.5 V

Brush length

Specified value

Allowable limit

Specified value

Allowable limit

Specified value

Allowable limit

Specified value

Outer diameter

Commutator Undercut depth

Maximum circle runout

Allowable limit

Shape Part number

09238-87701-000

09221-87301-000 Remover & Replacer

Remover & Replacer

Part name

Tightening components

Nm kgf-m

25.9 - 48.1 2.6 - 4.9 Starter Engine

Tightening torque

JST00077-00000

JST00078-00078

JST00079-00000

TO INDEX TO NEXT SECTION

Das könnte Ihnen auch gefallen

- Daihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 Starting System PDFDokument23 SeitenDaihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 Starting System PDFMozes SimataaNoch keine Bewertungen

- Engine Electrical SystemDokument14 SeitenEngine Electrical SystemMatthew Robert QuinnNoch keine Bewertungen

- K25 8Dokument17 SeitenK25 8mushfiq66Noch keine Bewertungen

- Toyota Supra - Ignition Systems - 2JZ-GTEDokument13 SeitenToyota Supra - Ignition Systems - 2JZ-GTETomislav RupčićNoch keine Bewertungen

- Series 1204: Orange Research IncDokument3 SeitenSeries 1204: Orange Research IncWilson VelásquezNoch keine Bewertungen

- 2AZ FE StartingDokument16 Seiten2AZ FE StartingLuks FernandezNoch keine Bewertungen

- Cab TiltDokument39 SeitenCab TiltFrederikus100% (1)

- Toyota Camry 2006-2011 2AZ-FE ChargingDokument21 SeitenToyota Camry 2006-2011 2AZ-FE ChargingMichael MatthewsNoch keine Bewertungen

- Accelerator Control System: SectionDokument7 SeitenAccelerator Control System: SectionmohhizbarNoch keine Bewertungen

- Acc PDFDokument8 SeitenAcc PDFCarlos Eduardo ZelidonNoch keine Bewertungen

- STC Series: Three-Phase Synchronous GeneratorsDokument9 SeitenSTC Series: Three-Phase Synchronous GeneratorsReezka PutraNoch keine Bewertungen

- ST PDFDokument23 SeitenST PDFzeroNoch keine Bewertungen

- AlternatorDokument19 SeitenAlternatorcpgmotorsNoch keine Bewertungen

- Lucas K1F MagnetoDokument10 SeitenLucas K1F MagnetoThunderbird3100% (1)

- Bolens Lawn Tractor RepairDokument46 SeitenBolens Lawn Tractor Repairdakehi1188342157% (7)

- SI F920A ShimanoDokument7 SeitenSI F920A ShimanoolligesNoch keine Bewertungen

- Alternador ComprobaciónDokument8 SeitenAlternador ComprobaciónvictorhernandezregaNoch keine Bewertungen

- Generator Starter ClutchDokument9 SeitenGenerator Starter ClutchMar PopNoch keine Bewertungen

- Charging System: PrecautionDokument17 SeitenCharging System: PrecautionlogammicNoch keine Bewertungen

- Timing Belt: Service and Repair Timing Belt Removal and InstallationDokument3 SeitenTiming Belt: Service and Repair Timing Belt Removal and InstallationJosé Carlos da silvaNoch keine Bewertungen

- Magpower Clutch Model CDokument4 SeitenMagpower Clutch Model CJuan CaceresNoch keine Bewertungen

- Chrysler 300 2005 6 Cylinders G 3.5L FI SOHC HO 32969104Dokument312 SeitenChrysler 300 2005 6 Cylinders G 3.5L FI SOHC HO 32969104Kevin JunkNoch keine Bewertungen

- ChassisElectrical PDFDokument111 SeitenChassisElectrical PDFDhany SiregarNoch keine Bewertungen

- Accelerator Control System: SectionDokument6 SeitenAccelerator Control System: SectionRafaelCazalesFuentesNoch keine Bewertungen

- SKI Elec Tronic Reverse (Line-Up) - Supplement mmr2017-121 enDokument9 SeitenSKI Elec Tronic Reverse (Line-Up) - Supplement mmr2017-121 enErne Lange OlsenNoch keine Bewertungen

- Galant CH 2 Engine Electrical PDFDokument14 SeitenGalant CH 2 Engine Electrical PDFjustcheerfulNoch keine Bewertungen

- Instruction Manual G-550: Vertex Standard Co., Ltd. Vertex StandardDokument12 SeitenInstruction Manual G-550: Vertex Standard Co., Ltd. Vertex Standardsdelpi5146Noch keine Bewertungen

- Accelerator Control, Fuel & Exhaust Systems: Draining Water Fuel Filter CheckDokument22 SeitenAccelerator Control, Fuel & Exhaust Systems: Draining Water Fuel Filter CheckDwight GeorgeNoch keine Bewertungen

- 13 - Starting TOYOTA PDFDokument19 Seiten13 - Starting TOYOTA PDFAngello Esquerre RojasNoch keine Bewertungen

- Toyota Truck RAV4 2WD L4-2.0L (1AZ-FE) 2002: Timing Chain: Service and RepairDokument15 SeitenToyota Truck RAV4 2WD L4-2.0L (1AZ-FE) 2002: Timing Chain: Service and RepairyosnielNoch keine Bewertungen

- ChargingDokument17 SeitenChargingSJElliNoch keine Bewertungen

- Ford Think Service Manual - Section 3 PowertrainDokument16 SeitenFord Think Service Manual - Section 3 PowertrainDennis Jason AntiNoch keine Bewertungen

- Alternator - Remove and InstallDokument2 SeitenAlternator - Remove and InstallHugo CiprianiNoch keine Bewertungen

- Accelerator Control System: SectionDokument8 SeitenAccelerator Control System: SectionmanuelmanriqueNoch keine Bewertungen

- AA06058 Modificacion de La Caja de Resistencia Camion 129 y 130Dokument7 SeitenAA06058 Modificacion de La Caja de Resistencia Camion 129 y 130Jose A. Basanta H.Noch keine Bewertungen

- Altronic V Service Manual (FORM AV SM)Dokument15 SeitenAltronic V Service Manual (FORM AV SM)francis_mouille_iiNoch keine Bewertungen

- Alternator and RegulatorDokument6 SeitenAlternator and Regulatorsonny1234Noch keine Bewertungen

- Generator: Removal of Generator (4A-Fe)Dokument20 SeitenGenerator: Removal of Generator (4A-Fe)henysNoch keine Bewertungen

- LV Air Circuit Breakers M-PACT - M-PRODokument32 SeitenLV Air Circuit Breakers M-PACT - M-PRO322399mk7086Noch keine Bewertungen

- Eclipse 90-99 ElectricalDokument540 SeitenEclipse 90-99 ElectricalManuel VizaNoch keine Bewertungen

- Accelerator Control System: SectionDokument8 SeitenAccelerator Control System: SectionOmar RodriguezNoch keine Bewertungen

- Barton Flotrac 308 User ManualDokument16 SeitenBarton Flotrac 308 User ManualJose Fernando Davila VigoNoch keine Bewertungen

- Yamaha Dynamic Spark Tester Special Tool Ym-34487 90890-06754 PDFDokument5 SeitenYamaha Dynamic Spark Tester Special Tool Ym-34487 90890-06754 PDFDr DNoch keine Bewertungen

- Erth SwitchDokument20 SeitenErth SwitchPutraKurniawanNoch keine Bewertungen

- Starting SystemDokument2 SeitenStarting SystemSebastian SirventNoch keine Bewertungen

- Delco-Remy Electrolock: TYPES 427 & 428Dokument1 SeiteDelco-Remy Electrolock: TYPES 427 & 428Regan AndrewNoch keine Bewertungen

- Sistema de Carga de Kawasaki Er650Dokument10 SeitenSistema de Carga de Kawasaki Er650Willian Jose Navarro ZepedaNoch keine Bewertungen

- Toyota Celica GT L4 1.8L 1ZZ FEDokument21 SeitenToyota Celica GT L4 1.8L 1ZZ FEWolfgang WilliamsNoch keine Bewertungen

- Mxu 500-18-21Dokument48 SeitenMxu 500-18-21alexander ortizNoch keine Bewertungen

- Toyota Camry CE Sedan L4-2.2L DOHC (5S-FE) MFI 2001: Timing Belt: Service and RepairDokument17 SeitenToyota Camry CE Sedan L4-2.2L DOHC (5S-FE) MFI 2001: Timing Belt: Service and RepairWenceslao Francisco Mejía EspinozaNoch keine Bewertungen

- Speed Sensor - AdjustDokument6 SeitenSpeed Sensor - AdjustЕвгений АбрамовNoch keine Bewertungen

- Group 00E: Harness Connector INSPECTION - . - . - . - . - . - . - . - . - . - How To Diagnose. - . - . - . - . - . .Dokument16 SeitenGroup 00E: Harness Connector INSPECTION - . - . - . - . - . - . - . - . - . - How To Diagnose. - . - . - . - . - . .Art Del R SalongaNoch keine Bewertungen

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Von EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Bewertung: 3 von 5 Sternen3/5 (4)

- Motorcycle, Solo (Harley-Davidson Model WLA)Von EverandMotorcycle, Solo (Harley-Davidson Model WLA)Noch keine Bewertungen

- Electromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationVon EverandElectromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationBewertung: 4 von 5 Sternen4/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- 110 Waveform Generator Projects for the Home ConstructorVon Everand110 Waveform Generator Projects for the Home ConstructorBewertung: 4 von 5 Sternen4/5 (1)

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationVon EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNoch keine Bewertungen

- SOLAR BOOST™ 3024i: Installation and Operation ManualDokument19 SeitenSOLAR BOOST™ 3024i: Installation and Operation ManualArgenis BriceñoNoch keine Bewertungen

- Linear Voltage RegulatorDokument12 SeitenLinear Voltage Regulatorilg1Noch keine Bewertungen

- LG Eay62851201 Eax64908101, LGP4755-13PDokument72 SeitenLG Eay62851201 Eax64908101, LGP4755-13PArgenis BriceñoNoch keine Bewertungen

- LG 50pj250r-Ta Chassis Pp01aDokument34 SeitenLG 50pj250r-Ta Chassis Pp01aNICHOLASNoch keine Bewertungen

- LP-1 Logic Probe PDFDokument8 SeitenLP-1 Logic Probe PDFArgenis BriceñoNoch keine Bewertungen

- LG 19LG30 Ua PDFDokument25 SeitenLG 19LG30 Ua PDFArgenis BriceñoNoch keine Bewertungen

- Kannand 406 User - ManualDokument60 SeitenKannand 406 User - ManualArgenis BriceñoNoch keine Bewertungen

- Ggs 6Dokument17 SeitenGgs 6Argenis BriceñoNoch keine Bewertungen

- Service Manual: Bassbreaker™ 15Dokument22 SeitenService Manual: Bassbreaker™ 15John govanNoch keine Bewertungen

- Rational Algebraic Expressions: ObjectivesDokument11 SeitenRational Algebraic Expressions: ObjectivesSonny ArgolidaNoch keine Bewertungen

- English To MetricDokument2 SeitenEnglish To MetricJohn Reynard PacsonNoch keine Bewertungen

- St. John of Buug Foundation IncDokument12 SeitenSt. John of Buug Foundation Inctammy a. romuloNoch keine Bewertungen

- Design-of-Experiments Study To Examine The Effect of Polarity On Stud WeldingDokument8 SeitenDesign-of-Experiments Study To Examine The Effect of Polarity On Stud WeldingtazzorroNoch keine Bewertungen

- Test Class MethodsDokument7 SeitenTest Class Methodsvarun.chintatiNoch keine Bewertungen

- 7 Maths em 2020-21Dokument326 Seiten7 Maths em 2020-21ThNoch keine Bewertungen

- CSBS Syllabus Book 01 11 2021 1Dokument117 SeitenCSBS Syllabus Book 01 11 2021 1PRITHVI P. K SEC 2020Noch keine Bewertungen

- 05 Traps PDFDokument17 Seiten05 Traps PDFDevinaacsNoch keine Bewertungen

- Excel Sales Report TemplateDokument3 SeitenExcel Sales Report TemplateMark11311100% (1)

- KB1250F1Dokument2 SeitenKB1250F1Peter PeterNoch keine Bewertungen

- Laboratory Assignments On Experiment 1: Measurement of Self-Inductance by Maxwell's BridgeDokument2 SeitenLaboratory Assignments On Experiment 1: Measurement of Self-Inductance by Maxwell's BridgesparshNoch keine Bewertungen

- LISTENING THE INVENTION THAT CHANGED THE WORLD (I) - Revisin Del IntentoDokument2 SeitenLISTENING THE INVENTION THAT CHANGED THE WORLD (I) - Revisin Del IntentoÁngela67% (3)

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDokument18 SeitenSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudNoch keine Bewertungen

- In The: CavityDokument9 SeitenIn The: Cavitybrowar444Noch keine Bewertungen

- Presupposition: A Short PresentationDokument13 SeitenPresupposition: A Short PresentationShaimaa SuleimanNoch keine Bewertungen

- Elemental Analysis of Crude OilsDokument8 SeitenElemental Analysis of Crude OilsMirzan Alexandra Torres LaraNoch keine Bewertungen

- Lab 1Dokument4 SeitenLab 1zakariaNoch keine Bewertungen

- Vulgare Mill.) Terhadap Bakteri Staphylococcus Aureus ATCC 25923Dokument8 SeitenVulgare Mill.) Terhadap Bakteri Staphylococcus Aureus ATCC 25923MUHAMMAD RIZKY HUSULUDINNoch keine Bewertungen

- Che 243 Fluid Dynamics: Problem Set #4 Solutions: SolutionDokument9 SeitenChe 243 Fluid Dynamics: Problem Set #4 Solutions: SolutionKyungtae Park100% (2)

- W 9540Dokument6 SeitenW 9540imharveNoch keine Bewertungen

- Basics of Circuit Analysis: RC RLCDokument18 SeitenBasics of Circuit Analysis: RC RLCdavissblaineNoch keine Bewertungen

- CCNA 4 - Chapter 2 QuzDokument1 SeiteCCNA 4 - Chapter 2 Quzchobiipiggy26Noch keine Bewertungen

- Notes 240105 063345 933Dokument6 SeitenNotes 240105 063345 933Rachel MaharaniNoch keine Bewertungen

- Pilot Optd. Pr. Relief Valve Modular Construction: MPPR 06Dokument3 SeitenPilot Optd. Pr. Relief Valve Modular Construction: MPPR 06Dillibabu RNoch keine Bewertungen

- Traffic Accidents - Balai Polis Trafik Jalan Tun H.SDokument3 SeitenTraffic Accidents - Balai Polis Trafik Jalan Tun H.SsimoniaNoch keine Bewertungen

- Rational and Irrational NumbersDokument16 SeitenRational and Irrational NumbersSumit JoshiNoch keine Bewertungen

- VPLS Practice GuideDokument7 SeitenVPLS Practice Guidedelgado08Noch keine Bewertungen

- Modern Aldol Reactions, Part1Dokument344 SeitenModern Aldol Reactions, Part1KybernetikumNoch keine Bewertungen

- SIMULATION of EMERGENCY ROOMS USING FLEXSIMDokument10 SeitenSIMULATION of EMERGENCY ROOMS USING FLEXSIMBrandon VarnadoreNoch keine Bewertungen