Beruflich Dokumente

Kultur Dokumente

Sme

Hochgeladen von

nitin jainOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sme

Hochgeladen von

nitin jainCopyright:

Verfügbare Formate

SME SECTOR PERSPECTVIE INDIA 1.

. RELEVANCE OF THE SMEs Growth of all segments of manufacturing and services enterprises be they micro, small, medium or large is critical for economic development and creation of jobs. India has nearly three million small and medium enterprises, which constitute more than 80 percent of the total number of industrial enterprises in the country. They contribute nearly 35 percent in direct export and 45 percent in the overall export from the country. SMEs are one of the biggest employments providing sectors (over 30 million jobs). The concept of cluster development emerged about 15 years ago and offers a new insight into the potential of SMEs in enhancing their access to new technology. A cluster is a geographic concentration of firms and their various service providers and is defined by: (a) a product / product range, and (b) a place (name of a city, town, and village) with forward linkages (selling agents, direct customers) and backwards linkages (raw materials, suppliers, machinery suppliers) linked to production activities. It is estimated that there are 600 modern SME clusters and 2,000 rural and artisan based clusters in India. To make their products globally competitive, Indian SMEs need to upgrade their technology. The problems faced by the SMEs, particularly in accessing technology and maintaining competitiveness, are formidable. In recent years, the Government of India (GOI) has launched a number of initiatives to help small industries. Many of the SMEs are reeling under the current phase of economic slowdown, which is threatening their survival. In fact, many of these units are looking towards innovative and out of the box ways to improvise their operations. 2. SCOPE OF ENERGY CONSERVATION Numerous sectors specific studies have confirmed that energy intensity in industry can be reduced with the widespread adoption of commercially available technologies to improve energy efficiency, producing significant aggregate impacts and global benefits from reduced emissions of greenhouse gases. It is consistent with several GOI sector priorities and national plans specifically, the National Mission for Enhanced Energy Efficiency in Industry under the National Action Plan for Climate Change released by GOI on June 30, 2008 has emphasized the need for improving energy efficiency in the manufacturing sector. Despite recent Indian reductions in overall energy intensity, the SME sector has fallen behind larger Indian industry benchmarks in terms of productivity, technology upgrading, and energy efficiency. In this context, the Bureau of Energy Efficiency is laying adequate emphasis on the SME sector as presented in the Working Group on Power for 11th Five Year Plan (2007-2012) sub Group 5. SMEs are facing high and rising energy costs, unlike certain other sectors of the economy such as agriculture, that benefit from subsidized energy prices. As SMEs are also exposed to global competition, price and cost pressures are areas of high and increasing importance. SMEs, especially those for whom energy costs represent a large portion of total production costs, can reap especially high direct economic benefits from improving efficiency of energy conversion and reduction of energy losses, yet numerous barriers and market failures have prevented widespread adoption. Key impediments include the following: Lack of awareness and capacity on the part of SMEs to take up energy conservation and to perceive effective programs.

Lack of scientific approach, measured data on the energy performance status. This is also related to the skill of key personal employed by them and reticence to improve the reporting system due the tax oriented approach followed by the SMEs. Low credibility of the service providers such as energy auditors / ESCOs, and dearth of champions and strategic partners. Limited access to affordable financing / incentives to induce SMEs to come one board. Low priority energy efficiency is one of several priorities and usually ranks low in sectors where incidence of energy cost is less than 10 percent of the manufacturing cost. Lack of coordination among the Government and private sector agencies involved in energy efficiency related activities.

3. PAST INTERVENTIONS Energy efficiency in SMEs is not a new program in India. In the past, several governments induced interventions have addressed this area. Often these programs have not succeeded in achieving large scale replication. A few bilateral / multilateral programs under the aegis of United Nations Industrial Development Organization (UNIDO), Swedish Development Cooperation Agency (SIDA), Indo German Energy Program, and USAID were seeded during the past few years. Several national agencies like the National Productivity Council (NPC), The Energy Research Institute, Petroleum Conservation Research Association (PCRA), National Small Scale Industries Corporation, Winrock International, National Institute for Secondary Steel Technologies, etc. have been working at the grassroots level. A recently completed World Bank Global Technical Assistance Project, Developing Financial Intermediation Mechanisms in China, India and Brazil (the 3 CEE Project) led to the launching of five pilot lending schemes for energy efficiency at SMEs by Indian banks. Financing institutions / banks such as the State Bank of India (SIA), Small Industries Bank of India, Indian Renewable Energy Development Agency, and the ICICI bank, among others, have been funding and supporting energy efficiency projects in SME units. The ministry of Micro, Small, and Medium Enterprises, Government of India, has to count on BEE, PCRA and SIDBI for massive efforts needed in this area. 4. GAP AREAS Implementation of energy conservation measures in SMEs has been at a far slower rate than expected despite substantive efforts in the past 20 years. Imperfect information about energy efficiency among small and medium enterprises still persists, preventing increased adoption of efficient technologies. A central barrier, which will be the primary target area of the proposed project, is the current gap in understanding between the energy auditors / EE practitioners who prepare technical proposals for the SME clients and the local banks who evaluate loan proposals, not technical studies. This is mainly due to lack of facilitation efforts in connecting reliable energy audits to loan applications. Several clusters do not have access to the local service providers. Often there is doubt about their credentials. Thus, the 3CEE Report has pointed out that end users and bankers often find that certain claims of energy savings are overstated. The technical credibility gap is an area to be addressed by energy professionals and supporting organizations such as BEE and PCRA. There also appears to be a need to systematically support development of a large number of EE investment proposals under a programmatic approach to aggregate demand for EE investments in SME industrial clusters and to create a sustainable mechanism for identifying, preparing, and financing these proposals at the local level. ESCOs / energy service providers would perhaps be more readily accepted by end users if they were able to finance the energy efficiency projects and realize their contribution related to the energy savings. So far, the issue of financing ESCOs has not been taken seriously even by

major stakeholders like the State Bank of India, who have in the business of energy efficiency financing for the past 7 8 years. Quoting from the proceedings of the ECO III sponsored Workshop Accelerating Implementation of Energy Efficiency Projects in SMEs held on June 11, 2008, Project Management Cell, UNDP GEF Project for Steel Re rolling Mills Sector, traced the tardy progress in respect to the energy efficiency scheme operating from 2001 to June 2007 for their massive program with US$14 million budget equally shared between GOI (through the Ministry of Steel) and Global Environmental Facilities (GEF). The Program has several features, such as the removal of barriers to energy efficiency financing through capacity building, implementing ESCO projects and monitoring and evaluation programs in the Steel re rolling sector. The industry showed lukewarm interest in implementing capital intensive measures, such as the replacement of inefficient re rolling mill furnaces. The reasons cited were mismatches between the solutions attempted and the user industry specificities. In fact, several programs fail to trigger market response and active participation due to lack of foresight about current attitudes regarding solutions to EE. Often, the role to be played by the energy solution provider for developing trust among the key actors is not given adequate attention at the program design stage. Energy efficiency programs also need substantive efforts for periodic review and midterm corrections to ensure results. Often frequent changes in the Program implementing agencies also adversely affect the outcome. In many instances, the Banks have announced special schemes to finance energy efficiency in SMEs but they generally suffered from inadequate preparedness to market and facilitate SME customers interest and involvement. For that reason, nationalized banks Union Bank of India, Canara Bank, Bank of India, and Bank of Baroda had launched schemes similar to the State Bank of Indias initiative. These schemes did not evoke enough response as per the 3 CEE Project Report. This can be attributed to the lack of adequate preparedness of these banks to ensure a good response from users. According to the 3CEE Report, the following impediments are often faced by the banks and SMEs while implementing energy efficiency projects: 1) Lack of available capital, especially for smaller enterprises 2) Inadequate information on appropriate equipment and technology 3) Under emphasis on EE investment financing by domestic financial institutions

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Proforma For Call For Book ChaptersDokument2 SeitenProforma For Call For Book Chaptersnitin jainNoch keine Bewertungen

- Beaches Hill Stations & DesertsDokument14 SeitenBeaches Hill Stations & Desertsnitin jainNoch keine Bewertungen

- Classical Dance Forms in India - 1Dokument39 SeitenClassical Dance Forms in India - 1nitin jainNoch keine Bewertungen

- Soya SausDokument1 SeiteSoya Sausnitin jainNoch keine Bewertungen

- Navratri 1Dokument1 SeiteNavratri 1nitin jainNoch keine Bewertungen

- B Day PoemDokument8 SeitenB Day Poemnitin jainNoch keine Bewertungen

- Notes - Industrial MarketingDokument11 SeitenNotes - Industrial Marketingnitin jainNoch keine Bewertungen

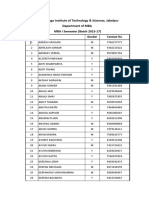

- MBA 2015-17 CounsellingDokument43 SeitenMBA 2015-17 Counsellingnitin jainNoch keine Bewertungen

- India's E-Commerce Industry Likely To Touch $38 Billion Mark in 2016 - AssochamDokument3 SeitenIndia's E-Commerce Industry Likely To Touch $38 Billion Mark in 2016 - Assochamnitin jainNoch keine Bewertungen

- III Sem SpecilazationDokument16 SeitenIII Sem Specilazationnitin jainNoch keine Bewertungen

- Proposal For The Program Under "Aawhan"'-A Step Towards Corporate ResponsibilityDokument1 SeiteProposal For The Program Under "Aawhan"'-A Step Towards Corporate Responsibilitynitin jainNoch keine Bewertungen

- Sno. Names Events: M.B.A 1St Sem Section "B"Dokument2 SeitenSno. Names Events: M.B.A 1St Sem Section "B"nitin jainNoch keine Bewertungen

- List Evebts All12Dokument2 SeitenList Evebts All12nitin jainNoch keine Bewertungen

- Ecommerce ADDON SYLLABUSDokument2 SeitenEcommerce ADDON SYLLABUSnitin jainNoch keine Bewertungen

- AD-ON Course in - Tally ERP 09Dokument1 SeiteAD-ON Course in - Tally ERP 09nitin jainNoch keine Bewertungen

- What Is Green MarketingDokument3 SeitenWhat Is Green Marketingnitin jainNoch keine Bewertungen

- VAD - 202 Certificate in Green MarketingDokument2 SeitenVAD - 202 Certificate in Green Marketingnitin jainNoch keine Bewertungen

- E-Commerce GRADUATION 2018Dokument33 SeitenE-Commerce GRADUATION 2018nitin jainNoch keine Bewertungen

- Certificate Program in Advanced MS Excel: A Comprehensive Online Program Designed For ProfessionalsDokument4 SeitenCertificate Program in Advanced MS Excel: A Comprehensive Online Program Designed For Professionalsnitin jainNoch keine Bewertungen

- Gyan Ganga Group of Institutions, Jabalpur: Department of Mba Additional Course - StatusDokument1 SeiteGyan Ganga Group of Institutions, Jabalpur: Department of Mba Additional Course - Statusnitin jainNoch keine Bewertungen

- Time Table With Skill Development ClassesDokument1 SeiteTime Table With Skill Development Classesnitin jainNoch keine Bewertungen

- Symbiosis Digital MarketingDokument6 SeitenSymbiosis Digital Marketingnitin jainNoch keine Bewertungen

- Gyan Ganga Institute of Technology & Sciences, Jabalpur Assignment QuestionDokument1 SeiteGyan Ganga Institute of Technology & Sciences, Jabalpur Assignment Questionnitin jainNoch keine Bewertungen

- Sales & Retail ManagementDokument2 SeitenSales & Retail Managementnitin jainNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ii. Market Research: 1. Analysis of The Demand For The Air Conditioner Distribution in VietnamDokument6 SeitenIi. Market Research: 1. Analysis of The Demand For The Air Conditioner Distribution in VietnamĐinh Thị Vân AnhNoch keine Bewertungen

- Catálogo Global ATTSU EN - 2022 - Interactiu - Baix - OptDokument140 SeitenCatálogo Global ATTSU EN - 2022 - Interactiu - Baix - OptAbbas Al MisbahNoch keine Bewertungen

- Performance Evaluation of An Oil Fired Boiler A Case Study in Dairy Industry.Dokument8 SeitenPerformance Evaluation of An Oil Fired Boiler A Case Study in Dairy Industry.atul100% (8)

- Heat Transfer and Flow Characteristics of Spiral Fin-And-tube Heat Exchangers A Review - PongsoiDokument15 SeitenHeat Transfer and Flow Characteristics of Spiral Fin-And-tube Heat Exchangers A Review - PongsoiMeshal Al-mutairi100% (1)

- FINI Cat MicroPlus enDokument24 SeitenFINI Cat MicroPlus enGuilherme RochaNoch keine Bewertungen

- ENERGY AUDIT, CONSERVATION AND POWER FACTOR Improvement - Study NotesDokument6 SeitenENERGY AUDIT, CONSERVATION AND POWER FACTOR Improvement - Study NotesRaghu Raman100% (1)

- Ratio Analysis (Pankaj)Dokument72 SeitenRatio Analysis (Pankaj)Vikash Gupta100% (1)

- ZAX9200iTerry EsDokument12 SeitenZAX9200iTerry EsRavi KumarNoch keine Bewertungen

- Energy Recovery Atlas CopcoDokument3 SeitenEnergy Recovery Atlas CopcoSergio LinNoch keine Bewertungen

- Hetero NKP EhsDokument63 SeitenHetero NKP Ehsshraddha yawaleNoch keine Bewertungen

- Menreg 41 PDFDokument6 SeitenMenreg 41 PDFBaher SalehNoch keine Bewertungen

- K 46 Compact Spinning Machine Brochure 2530-V3 75220 Original English 75220Dokument28 SeitenK 46 Compact Spinning Machine Brochure 2530-V3 75220 Original English 75220Pradeep JainNoch keine Bewertungen

- Housekeeping Management by Matt A. CasadoDokument282 SeitenHousekeeping Management by Matt A. Casadogianghong317Noch keine Bewertungen

- Subsidies Offered by GovtDokument32 SeitenSubsidies Offered by GovtAnoop NautiyalNoch keine Bewertungen

- Climate TechDokument306 SeitenClimate TechsmilyNoch keine Bewertungen

- Rieter C 81 Card Brochure 3586 v1 98697 enDokument28 SeitenRieter C 81 Card Brochure 3586 v1 98697 enAyan MukherjeeNoch keine Bewertungen

- Case Study - WalDokument26 SeitenCase Study - WalBhoomika TejnaniNoch keine Bewertungen

- Energy Audit Handbook 2nd EditionDokument32 SeitenEnergy Audit Handbook 2nd EditionmohammadtaheriNoch keine Bewertungen

- Case AnalysisDokument4 SeitenCase AnalysisJustine Kaye Porcadilla100% (2)

- Manner of FinancingDokument14 SeitenManner of FinancingJenny Rhose MallariNoch keine Bewertungen

- Digital Transformation Case StudyDokument3 SeitenDigital Transformation Case StudyDeep KhandhediaNoch keine Bewertungen

- Climate Change - ActivityDokument2 SeitenClimate Change - ActivityAndrea MoniqueNoch keine Bewertungen

- Test - T NG H P Unit 6Dokument3 SeitenTest - T NG H P Unit 6Hoàng Phi NgaNoch keine Bewertungen

- Đề thi vào 10 (2021)Dokument5 SeitenĐề thi vào 10 (2021)Thu Giang Nguyễn100% (2)

- (Rapra Review Reports) S.M. Halliwell-Polymers in Building and Construction-Smithers Rapra Press (2003)Dokument150 Seiten(Rapra Review Reports) S.M. Halliwell-Polymers in Building and Construction-Smithers Rapra Press (2003)Leandro RosendoNoch keine Bewertungen

- Final Report - A17 - Group 3-SunhouseDokument38 SeitenFinal Report - A17 - Group 3-SunhouseNhư Nguyễn Ngọc QuỳnhNoch keine Bewertungen

- Annual Report MRFDokument152 SeitenAnnual Report MRFGaurav GuptaNoch keine Bewertungen

- Course Description - DFC - Energy Efficiency & Energy Management in Buildings & IndustryDokument3 SeitenCourse Description - DFC - Energy Efficiency & Energy Management in Buildings & IndustryJaret FajriantoNoch keine Bewertungen

- GFCDokument3 SeitenGFCWahaj AzizNoch keine Bewertungen

- Energy and Water Conservation in Housekeeping DepartmentDokument4 SeitenEnergy and Water Conservation in Housekeeping Departmentmadhu anvekarNoch keine Bewertungen