Beruflich Dokumente

Kultur Dokumente

Performance of Waste Tyre Rubber On Model Flexible Pavement

Hochgeladen von

Nimmy FredrickOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Performance of Waste Tyre Rubber On Model Flexible Pavement

Hochgeladen von

Nimmy FredrickCopyright:

Verfügbare Formate

VOL. 4, NO.

6, AUGUST 2009

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2009 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

PERFORMANCE OF WASTE TYRE RUBBER ON MODEL FLEXIBLE PAVEMENT

D. S. V. Prasad1 and G. V. R. Prasada Raju2

2

BVC Engineering College, Odalarevu, India Department of Civil Engineering, JNT University, Kakinada, India E-Mail: dsvp9@yahoo.com

ABSTRACT This paper investigates the performance of flexible pavement on expansive soil subgrade using gravel/flyash as subbase course with waste tyre rubber as a reinforcing material. It was observed that from the laboratory test results of direct shear and CBR, the gravel subbase shows better performance as compared to flyash subbase with different percentages of waste tyre rubber as reinforcing material. Cyclic load tests are also carried out in the laboratory by placing a circular metal plate on the model flexible pavements. It was observed that the maximum load carrying capacity associated with less value of rebound deflection is obtained for gravel reinforced subbase compared to flyash reinforced subbase.

Keywords: waste tyre rubber, flyash, expansive soil, gravel, cyclic tests.

1. INTRODUCTION Reinforced earth technique has been gaining popularity in the field of civil engineering due to its highly versatile and flexible nature. In the recent years, this technique has been suggested for a variety of geotechnical applications ranging from retaining structures and earth embankments, foundation beds for heavy structures on soft grounds, viaduct bridges and other applications (Henry Vidal, 1968; Hausmannn, 1990; Rao, 1996). Reinforcement of soil with synthetic fibers is potentially an effective technique for increasing soil strength. Scrap tyres are a high-profile waste material for which several beneficial uses have been proposed and put into practice (Ahmed, 1993). The use of tyre shreds or mixer of tyre shreds and sand (i.e. rubber-sand) as light weight fills (Bernal et al; 1997) could significantly minimize the waste tyre disposal problem that currently exists. Shredded waste tyres have many beneficial engineering properties as a light weight fill material and when it is used in road base or subbase, shredded tyre will improve drainage below the pavement and therefore should extend the life of the road way (Dresher et al; 1991). Shredded tyres also posses vibration and damping properties, a benefit in situations where vibratory compaction is hazardous to the surroundings and it is easily compacted and consolidated (Geisler et al.; 1991). The use of waste tyre shreds as back fill material to increase the permeability which resists under compaction and high gravity loads in a soil mass that could result in a decrease of directional strength (Heimdahl,1999). In the present work an attempt is made to use reinforcement material like waste tyre rubber in gravel and flyash subbases in model flexible pavement system laid on expansive soil subgrade and study the relative performance between the reinforced and unreinforced subbase of flexible pavement system. Direct shear and CBR tests are conducted in the laboratory for both gravel and flyash materials with different percentages of waste tyre rubber strips to obtain optimum percentage of reinforcement material. The investigation is further

extended by constructing model flexible pavements in laboratory with different subbases reinforced with optimum percentage of waste tyre rubber and cyclic plate load tests are conducted on the pavement system at saturated state. 2. MATERIALS AND METHODS 2.1 Materials used The following materials were used in this study: Soil Expansive soil collected from Godilanka near Amalapuram is used for this investigation as a subgrade material. The soil properties are WL = 66%, WP = 32%, WS =12%, I.S. Classification = CH (Clay of high compressibility), OMC=23%, MDD = 15.69 kN/m3, Differential Free Swell = 150 %, Soaked CBR = 2 %. Flyash The flyash collected from Vijayawada thermal power station, Vijayawada is used as a subbase course in this work. The properties of flyash are MDD = 13.24 kN/m3, OMC = 24%, WL = 28 %, Soaked CBR = 4 %. Gravel This soil collected from Dwarapudi, near Rajahmundry is used as subbase course. The soil properties are WL = 38%, Wp = 19%, OMC = 12%, MDD = 18.5kN/m3, Soaked CBR = 8. Road metal Road metal, which satisfies MOST specifications, is used for the base course. The size of aggregate 20 mm. Waste tyre rubber Waste tyre rubber chips passing through 4.75 mm sieve were used in this study, as an alternative reinforcement material (Figure-1).

89

VOL. 4, NO. 6, AUGUST 2009

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2009 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com cm compacted thickness amount to a total thickness of 20 cm subgrade. On the prepared subgrade gravel / flyash subbase, mixed with optimum percentage of waste tyre rubber, of compacted thickness 5 cm is laid in 2 layers by compact to OMC and MDD. On the prepared subbase 2 layers of WBM - III each of 2.5 cm compacted thickness is laid to a total thickness of 5 cm. A sand bed of 2cm thick is placed before placement of subgrade soil in the tank and sand drains were provided by means of 3 vertical sand columns of 4 cm diameter from bottom to top of the subgrade soil for saturation. Figure-1. Waste tyre rubber chips. 2.2 Laboratory experimentation Direct shear tests The direct shear tests were conducted in the laboratory as per IS Code (IS: 2720 (Part-13)-1986). The required percentage of waste tyre rubber by dry unit weight of soil was mixed uniformly with the soil. The water content corresponding to OMC of untreated soil was added to the soil in small increments and mixed by hand until uniform mixing of the strips was ensured. The soil was compacted to maximum dry density (MDD) of untreated soil. California Bearing Ratio (CBR) tests Different samples were prepared in the similar lines for CBR test using gravel and flyash materials reinforced with waste tyre rubber strips. The CBR tests were conducted in the laboratory for all the samples as per I.S.Code (IS: 2720 (Part-16)-1979). Preparation of model flexible pavement The model flexible pavements are prepared in a circular steel tank of 60 cm diameter with a depth of 30 cm (Figure-2). Out of which 20 cm depth is for lying subgrade, 5 cm is for subbase and 5 cm for base course. In the circular tank the pulverized expansive soil mixed with water at OMC is laid in 10 layers such that each layer of 2

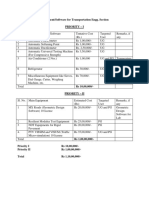

Figure-2. Details of model flexible pavements In this investigation four model flexible pavements were prepared in laboratory with different alternatives as given in Table-1. Expansive soil is used as a subgrade soil for all the tests. For all the four alternative stretches, WBM-III is used as base course was laid uniformly.

Table-1. Details of model flexible pavements. S. No. 1. 2. 3. 4 Subgrade Expansive soil Expansive soil Expansive soil Expansive soil Subbase Gravel Gravel + Waste tyre rubber strips Flyash Flyash + Waste tyre rubber strips Base course WBM III WBM III WBM III WBM III

Cyclic load testing Cyclic Plate load tests were carried out at complete saturated condition on the model flexible pavement system in a circular steel tank of diameter 60 cm as shown in Figure-2. The soil was allowed to absorb water by providing a thin sand layer (10 mm thick) at the bottom and also through vertical sand drains. Two inlet valves are welded on opposite sides of the tank through which water was supplied. The loading was done through a circular metal plate of 10 cm diameter laid on flexible

pavement system. The steel tank was placed on the pedestal of the compression testing machine. A five ton capacity proving ring was connected to the loading frame and the extension rod welded to the circular plate was brought in contact with proving ring. Two dial gauges of least count 0.01 mm were placed on the metal flats welded to the vertical rod to measure the vertical displacements of the loading plate. The load is applied in increments corresponding to tyre pressures of 500, 560, 630, 700 and 1000 kPa and each pressure increment was applied

90

VOL. 4, NO. 6, AUGUST 2009

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2009 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com cyclically until there was insignificant increase in the settlement of the plate between successive cycles. The testing was further continued till the occurrences of failure to record the ultimate loads. Heave measurements The model flexible pavement system was saturated completely by pouring water above the base course. Heave readings were taken with the help of dial gauges at regular intervals for the expansive soil subgrade pavements. These readings were measured until there was no significant change between consecutive readings observed. 3. TEST RESULTS 3.1 Laboratory test results Direct shear tests and CBR tests are conducted by using different percentages of waste tyre rubber mixed with gravel and flyash materials for finding the optimum percentage of waste tyre rubber. Cyclic load tests are conducted for gravel and flyash subbases, reinforced with optimum percentage of waste tyre rubber. Direct shear test results It is observed from the Figures 3 and 4 that cohesion and angle of internal friction values for gravel materials are increased from 11.77 to 26.48 kN/m2 and 360 to 430, respectively with 5.0 % of waste tyre rubber chips and thereafter decreased. For flyash the cohesion and angle of internal friction values are increased from 7.85 to 18.64 kN/m2 and 330 to 390, respectively with 6.0% of waste tyre rubber chips and thereafter decreases. From the test results, the optimum percentage of waste tyre rubber for gravel and flyash are equal to 5 % and 6%, respectively. Test results showed that gravel material reinforced with waste tyre rubber has shown better performance when compared to flyash reinforced material. California bearing ratio (CBR) test results From the Figure-4, the soaked CBR values are increased from 8.0 to 13.32 and 4.0 to 8.73 for 5.0 % and 6.0 % of waste tyre rubber, respectively for gravel and flyash subbase materials and hence the optimum percentage of waste tyre rubber for gravel and flyash are equal to 5% and 6%, respectively.

30

5 4 2 1 0.5 0 0 0.5 1 3 5 2 3 4 6 7

44

5

42

4

6 7 6 3 2 1 4 3 2 1 0 0.5 0 0.5 5 7

Angle of Internal Friction(Degrees)

40 38 36 34 32 30 0 1 2 3

Gravel

Flyash

% of Waste Tyre Rubber

Figure-4. Variation of angle of internal friction values for gravel and flyash materials reinforced with different percentages of waste tyre rubber chips.

14 12 10 8 6 4 2 0 0

5 2 3 4 5

6 7 6

soaked CBR(%)

0.51 0.51

Gravel

Flyash

1 2 3 4 5 6 7 8

% of Waste Tyre Rubber

Figure-5. Variation of soaked CBR values for gravel and flyash materials reinforced with different percentages of waste tyre rubber chips. Cyclic load test results Pressure-deformation behaviour on gravel/flyash subbases reinforced with waste tyre rubber From the test results as shown in Figures 6 and 7 it is observed that load carrying capacity has substantially increased for waste tyre rubber reinforced model flexible pavement. At all the deformation levels gravel reinforced subbase shows better performance as compared to flyash reinforced subbase.

Total Deformation(mm)

0 0 10 20 30 40 50

300

Pressure(kPa) 600 900

1200

1500

Cohesion((kN/m2)

25 20 15 10 5 0 0 1 2 3 4

Gravel

Flyash

5 6 7 8

Untreated Gravel Flyash

Gravel w ith WTR Flyash w ith WTR

% of Waste Tyre Rubber

Figure-3. Variation of cohesion values for gravel and flyash materials reinforced with different percentages of waste tyre rubber chips.

Figure-6. Pressures-total deformation values for gravel /flyash subbase of flexible pavement system laid on expansive soil subgrade.

91

VOL. 4, NO. 6, AUGUST 2009

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2009 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Pressure(kPa) 300 600 900

Elastic Deformation(mm

0 0 3 6 9 12 15 18

1200

1500

Untreated Gravel Flyash

Gravel with WTR Flyash with WTR

Figure-7. Pressures-elastic deformation values for gravel /flyash subbase of flexible pavement system laid on expansive soil subgrade. 3.2 Heave studies The in-situ heave-time plots, as shown in fig.8 for model flexible pavements with gravel/flyash subbases mixed with optimum percentage of waste tyre rubber are presented. It is observed from the figure that there is no significant control of heave for gravel/flyash subbases reinforced with waste tyre rubber. This behaviour is evident from the fact that there is no heave control mechanism with the reinforcement in the pavement system. In fact, it is intended to incorporate reinforcement in the flexible pavement system to strengthen it with little emphasis on heave control.

10 8 6 4 2 0 0 25

Gravel Flyash

different percentage of waste tyre rubber, the optimum percentages of waste tyre rubber are equal to 5% and 6% of dry unit weight of soil, respectively. The load carrying capacity of the laboratory model flexible pavement system has significantly increased for both gravel and flyash subbases reinforced with optimum percentage waste tyre rubber laid on expansive soil subgrade. No significant control of heave is observed for the laboratory model flexible pavements for both the gravel and flyash reinforced with waste tyre rubber tried in this investigation, laid on expansive soil subgrade. At all the deformation levels, gravel reinforced with waste tyre rubber in model flexible pavement has shown better performance, compared to flyash subbase reinforced with waste tyre rubber. REFERENCES Ahmed I. 1993. Laboratory study on properties of rubber soils. Report No. fhwa/in/jhrp-93/4. Purdue University, West Lafayette, Indianapolis. Bernal A., Salgado, R. and Lovell C.W. 1997. Tire Shreds and Rubber-sand as Light Weight Backfill material. Accepted for publication as a technical paper in the Journal of Geotechnical and Geoenvironmental Engineering. Dresher A., Newcomb, D. and Bouhaja M. 1992. Development of Design Guideline for use of Shredded Tires as a lightweight Fill in Road Subgrade and Retaining Walls. Department of Civil and Mineral Engineering, University of Minnesota. August. Geisler E., Cody W., Niemi M.K. 1989. Tires for Subgrade Support. Presented at the Annual Conference on Forest Engineering Meeting, Coeur DAlene, ID. August 27-30. Hausmann M.R. 1990. A text book on Engineering Principles of Ground Modification. McGraw Hill Publication Co., New York. Heimdahl T.C. and Drescher A. 1999. Elastic Anisotropy of Tire Shreds. Journal of Geotechnical and Geoenvironmental Engineering. 125(5): 383-389. Henry Vidal. 1969. The Principle of Reinforced Earth. Highway Research Record. 282: 1-16. IS: 2720 (Part-13). 1986. Method of test for Soils: Part 13, Direct Shear Test Indian Standards. IS: 2720 (Part 16). 1979. Method of test for Soils: Part 16, Laboratory Determination of CBR Indian Standards. Rao G.V. 1996. Geosynthetics in the Indian Environment. Indian Geotechnical Journal. 34(2): 13-18.

Heave(mm)

50

75

100

125

Time(Hours)

Gravel w ith WTR Flyash w ith WTR

Figure-8. Heave-time plot for model flexible pavements laid on expansive soil subgrade with gravel/flyash subbase. 3.3 Comparison between gravel and flyash subbases reinforced with waste tyre rubber From the above studies gravel reinforced model pavement has shown better performance compared to the flyash reinforced model pavement. The improvement in the load carrying capacity could be attributed to improved load dispersion through reinforced subbase on to the subgrade. This in-turn, results in lesser intensity of stresses getting transfer to subgrade, this loading to lesser sub grade stress. Further, it is also observed that heave of the expansive soil subgrade considerably decreases the load carrying capacity of the stretch. 4. CONCLUSIONS From the result of direct shear tests and CBR tests for gravel and flyash materials reinforced with

92

Das könnte Ihnen auch gefallen

- Design of Flexible PavementDokument53 SeitenDesign of Flexible Pavementmohamed hassan adenNoch keine Bewertungen

- AASHTO Flexible Design MethodDokument27 SeitenAASHTO Flexible Design Methodsmile_1611Noch keine Bewertungen

- Roadside Revegetation: An Integrated Approach To Establishing Native PlantsDokument425 SeitenRoadside Revegetation: An Integrated Approach To Establishing Native PlantsFree Rain Garden ManualsNoch keine Bewertungen

- Unit 2 (TECHNIQUE IN PLANNING AND PRE-CONSTRUCTION OF ROADWORK )Dokument22 SeitenUnit 2 (TECHNIQUE IN PLANNING AND PRE-CONSTRUCTION OF ROADWORK )Zara Nabilah100% (1)

- 00 Introduction To Highway Engineering PDFDokument14 Seiten00 Introduction To Highway Engineering PDFJustinOliver0% (1)

- Design Methods For Reinforced Roads With GeogridDokument8 SeitenDesign Methods For Reinforced Roads With Geogridvidyaranya_bNoch keine Bewertungen

- Ensayo CBR (D4429-09a)Dokument7 SeitenEnsayo CBR (D4429-09a)joake spasNoch keine Bewertungen

- Road Safety Audit Report - MMDokument61 SeitenRoad Safety Audit Report - MMNimmy Fredrick100% (1)

- Summer TrainingDokument38 SeitenSummer TrainingBilal Ahmed Barbhuiya50% (2)

- Ground Improvement Case Histories: Compaction, Grouting and GeosyntheticsVon EverandGround Improvement Case Histories: Compaction, Grouting and GeosyntheticsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Geo-Cell Reinforced BaseDokument8 SeitenGeo-Cell Reinforced Baseharishreddy1985Noch keine Bewertungen

- Concrete Pipe Design Manual (ACPA)Dokument561 SeitenConcrete Pipe Design Manual (ACPA)Amanda Cervantes100% (2)

- Aasho Road TestDokument12 SeitenAasho Road TestRogero Mar CNoch keine Bewertungen

- Key Words: Model Tests, Footing, Bearing Capacity, Granular Fill, Clays, Finite Elements, GeotextilesDokument14 SeitenKey Words: Model Tests, Footing, Bearing Capacity, Granular Fill, Clays, Finite Elements, Geotextilesد.م أحمد رشديNoch keine Bewertungen

- Soil Improvement-Sand DrainDokument4 SeitenSoil Improvement-Sand DrainP.Sang-Geo100% (1)

- Journal 10 PDFDokument6 SeitenJournal 10 PDFRuzengulalebih ZEta's-ListikNoch keine Bewertungen

- FullPaper ECEE2010 OhridDokument8 SeitenFullPaper ECEE2010 OhridTheivagularatnam MathanrajNoch keine Bewertungen

- Partial Replacement of Cement With Corn Cob AshDokument11 SeitenPartial Replacement of Cement With Corn Cob AshTIZA MICHAEL B.Engr., BBS, MBA, Aff. M. ASCE, ASS.M. UACSE, M. IAENG. M.ITE.Noch keine Bewertungen

- 517Dokument4 Seiten517Nabeel AL-HakeemNoch keine Bewertungen

- (Corea) Pullout Behavior of Cell (Copiado)Dokument5 Seiten(Corea) Pullout Behavior of Cell (Copiado)Benjamin GonzalezNoch keine Bewertungen

- (Corea) Pullout Behavior of Cell (Copiado)Dokument5 Seiten(Corea) Pullout Behavior of Cell (Copiado)Benjamin GonzalezNoch keine Bewertungen

- Investigationof Performanceof AsphaltDokument6 SeitenInvestigationof Performanceof AsphaltJonathan GaniNoch keine Bewertungen

- Geocell Rut TestDokument8 SeitenGeocell Rut Testmspark futuristicNoch keine Bewertungen

- 1banasal 1652013Dokument78 Seiten1banasal 1652013rajubansalNoch keine Bewertungen

- An Investigation16Dokument19 SeitenAn Investigation16badisnoveNoch keine Bewertungen

- Detail Phase 1Dokument15 SeitenDetail Phase 1shobhitha shobhitha mNoch keine Bewertungen

- An Experimental Investigation On Rubberized ConcreteDokument7 SeitenAn Experimental Investigation On Rubberized ConcreteIJIRSTNoch keine Bewertungen

- Laterite Soil Shear Strength Characteristics From The Use of The Standard Proctor and Compression MachineDokument13 SeitenLaterite Soil Shear Strength Characteristics From The Use of The Standard Proctor and Compression MachineAZOJETENoch keine Bewertungen

- Study On Geotechnical Properties of Stabilized Expansive Soil-Quarry Dust MixesDokument7 SeitenStudy On Geotechnical Properties of Stabilized Expansive Soil-Quarry Dust MixesRVNLPKG6B VBL-GTLMNoch keine Bewertungen

- Soil Stabilization, 2004, Building Roads On Sabkha Soils With Geosynthetic SystemsDokument12 SeitenSoil Stabilization, 2004, Building Roads On Sabkha Soils With Geosynthetic Systemsmircearadulescu55Noch keine Bewertungen

- Msand Research PaperDokument10 SeitenMsand Research PaperPandianKalaimaniNoch keine Bewertungen

- 02e7e528a157227809000000 PDFDokument8 Seiten02e7e528a157227809000000 PDFhathamphanNoch keine Bewertungen

- Economic Construction of Bituminous Road by Utilization of Waste Tyre Rubber - CRMBDokument6 SeitenEconomic Construction of Bituminous Road by Utilization of Waste Tyre Rubber - CRMBIJSTENoch keine Bewertungen

- Effectiveness of Sand Column As A Ground Improvement TechniqueDokument5 SeitenEffectiveness of Sand Column As A Ground Improvement TechniqueMuhammad IrfanNoch keine Bewertungen

- Reinforced Light Weight Geo MaterialsDokument9 SeitenReinforced Light Weight Geo Materialsharishreddy1985Noch keine Bewertungen

- Study On Mechanical Properties of Concrete by Incorporating Waste Foundry SandDokument24 SeitenStudy On Mechanical Properties of Concrete by Incorporating Waste Foundry SandAshokVarmaNoch keine Bewertungen

- Study On Mechanical Properties of Concrete by Incorporating Waste Foundry SandDokument24 SeitenStudy On Mechanical Properties of Concrete by Incorporating Waste Foundry SandAshokVarmaNoch keine Bewertungen

- Improving Properties of Granular Soil Using Waste MaterialsDokument67 SeitenImproving Properties of Granular Soil Using Waste MaterialsArmaan GuptaNoch keine Bewertungen

- Application of Woven Waste Tires Gabion Wall As SLDokument8 SeitenApplication of Woven Waste Tires Gabion Wall As SLXzk MallaboNoch keine Bewertungen

- Ghazavi2004 Granular RubberDokument16 SeitenGhazavi2004 Granular RubbershireenNoch keine Bewertungen

- Paige-Green 2006 DDokument17 SeitenPaige-Green 2006 DWeber SouzaNoch keine Bewertungen

- Modelling A Highway Embankment On Peat Foundations Using Transparent Soil 2016 Procedia EngineeringDokument8 SeitenModelling A Highway Embankment On Peat Foundations Using Transparent Soil 2016 Procedia EngineeringazriNoch keine Bewertungen

- Flexible PavementDokument18 SeitenFlexible PavementarjunhrNoch keine Bewertungen

- Properties of Crumb Rubber Concrete Paving Blocks With SBR LatexDokument7 SeitenProperties of Crumb Rubber Concrete Paving Blocks With SBR LatexTung-Chai LingNoch keine Bewertungen

- Bearing Capacity Improvement of Soil Usi PDFDokument13 SeitenBearing Capacity Improvement of Soil Usi PDFPoornima PoorniNoch keine Bewertungen

- Performance Evaluation of Cement Stabilised Road Base Using Falling Weight DeflectometerDokument8 SeitenPerformance Evaluation of Cement Stabilised Road Base Using Falling Weight DeflectometerJames KhooNoch keine Bewertungen

- Fine Grained Sand Reinforced With Granulated Tire ChipsDokument4 SeitenFine Grained Sand Reinforced With Granulated Tire ChipsEditor IJRITCCNoch keine Bewertungen

- Laboratory Investigation of Bearing Capacity Behavior of Strip Footing On Geogrid-Reinforced Sand SlopeDokument20 SeitenLaboratory Investigation of Bearing Capacity Behavior of Strip Footing On Geogrid-Reinforced Sand Slopejavad khosraviNoch keine Bewertungen

- Asd PDFDokument22 SeitenAsd PDFFelipe SaavedraNoch keine Bewertungen

- Lime Sand Column PDFDokument10 SeitenLime Sand Column PDFvino2424100% (1)

- Efficiency of Pile Groups in Clay Under Different Loading RatesDokument6 SeitenEfficiency of Pile Groups in Clay Under Different Loading RatessenhuNoch keine Bewertungen

- Projet FRCDokument20 SeitenProjet FRCHARSH KUMARNoch keine Bewertungen

- Determination of Optimum Cement Content For Stabilization of Soft Soil and Durability Analysis of Soil Stabilized With CementDokument5 SeitenDetermination of Optimum Cement Content For Stabilization of Soft Soil and Durability Analysis of Soil Stabilized With CementHhowtobe YounesNoch keine Bewertungen

- Constitutive Modelling of A Reinforced Soil Using Hierarchical ModelDokument25 SeitenConstitutive Modelling of A Reinforced Soil Using Hierarchical ModelmohanNoch keine Bewertungen

- Ijciet: ©iaemeDokument6 SeitenIjciet: ©iaemeIAEME PublicationNoch keine Bewertungen

- Experimental Study About Soil Improvement With Glass FibersDokument5 SeitenExperimental Study About Soil Improvement With Glass FibersInnovative Research PublicationsNoch keine Bewertungen

- Draught Requirements of Enamel Coated Animal Drawn Mouldboard PloughDokument7 SeitenDraught Requirements of Enamel Coated Animal Drawn Mouldboard PloughSHOLANKE EZEKIEL SHOWUNMINoch keine Bewertungen

- Inverted Flexible Pavement Response and Performance: Erol Tutumluer and Richard BarksdaleDokument9 SeitenInverted Flexible Pavement Response and Performance: Erol Tutumluer and Richard BarksdaleYUBER JHON ITO CHAI�ANoch keine Bewertungen

- Compressiblility Behaviour of Fibrous Peat Reinforced With Cement Columns (2009)Dokument11 SeitenCompressiblility Behaviour of Fibrous Peat Reinforced With Cement Columns (2009)Lan LohNoch keine Bewertungen

- InternshipDokument16 SeitenInternshipSureshNoch keine Bewertungen

- Materials 07 03337 PDFDokument16 SeitenMaterials 07 03337 PDFKingJsNoch keine Bewertungen

- Behaviour of Mine Waste As Reinforced SoilDokument8 SeitenBehaviour of Mine Waste As Reinforced SoilesatjournalsNoch keine Bewertungen

- Improvement of Sub Base Soil Using Sand-Cement StabilizationDokument6 SeitenImprovement of Sub Base Soil Using Sand-Cement StabilizationPramudyo BayuNoch keine Bewertungen

- Granulated Waste Tyres in Concrete Paving BlockDokument7 SeitenGranulated Waste Tyres in Concrete Paving BlockAravind kumarNoch keine Bewertungen

- Rethalia PDFDokument17 SeitenRethalia PDFRajashekar.PNoch keine Bewertungen

- Applied Sciences: Ffects of Soil Conditioning On Characteristics of ADokument16 SeitenApplied Sciences: Ffects of Soil Conditioning On Characteristics of AMoezselmi.12 SelmiNoch keine Bewertungen

- Stabilization of Soil by Using Plastic Wastes: AbstractDokument6 SeitenStabilization of Soil by Using Plastic Wastes: AbstractUmange Ranasinghe100% (1)

- Performance of Different Geosynthetic Reinforcement Materials in Sand FoundationsDokument9 SeitenPerformance of Different Geosynthetic Reinforcement Materials in Sand FoundationsMariaPaulaMenesesNoch keine Bewertungen

- Priority 1-2 TransportationDokument1 SeitePriority 1-2 TransportationNimmy FredrickNoch keine Bewertungen

- Innovative Infrastructure Solutions: - Manuscript DraftDokument60 SeitenInnovative Infrastructure Solutions: - Manuscript DraftNimmy FredrickNoch keine Bewertungen

- SCS 2019 2571 R1 Reviewer PDFDokument62 SeitenSCS 2019 2571 R1 Reviewer PDFNimmy FredrickNoch keine Bewertungen

- RILEM TC WMR - TG5 Environmental Assessment of WMR Asphalt: Please Send To and December 2019Dokument1 SeiteRILEM TC WMR - TG5 Environmental Assessment of WMR Asphalt: Please Send To and December 2019Nimmy FredrickNoch keine Bewertungen

- SocialDistancing - DraftFINAL 3.5.2020 PDFDokument11 SeitenSocialDistancing - DraftFINAL 3.5.2020 PDFNimmy FredrickNoch keine Bewertungen

- SSRN Id3611806 PDFDokument42 SeitenSSRN Id3611806 PDFNimmy FredrickNoch keine Bewertungen

- AV Article Mobility of Services 25march20Dokument2 SeitenAV Article Mobility of Services 25march20Nimmy FredrickNoch keine Bewertungen

- DST-SERB - Scientific Social Responsibility Initiative Can Boost Mentoring in ScienceDokument3 SeitenDST-SERB - Scientific Social Responsibility Initiative Can Boost Mentoring in ScienceNimmy FredrickNoch keine Bewertungen

- Traffic Growth Rate Estimation Using Transport Demand Elasticity Method: A Case Study For National Highway-63 IntroductionDokument7 SeitenTraffic Growth Rate Estimation Using Transport Demand Elasticity Method: A Case Study For National Highway-63 IntroductionNimmy FredrickNoch keine Bewertungen

- Roads and Road TransportDokument34 SeitenRoads and Road TransportNimmy Fredrick100% (1)

- Dr. Praveen KumarDokument46 SeitenDr. Praveen KumarNimmy FredrickNoch keine Bewertungen

- Transportation Engg SylabusDokument10 SeitenTransportation Engg SylabusNimmy FredrickNoch keine Bewertungen

- Indo US ResearchDokument1 SeiteIndo US ResearchNimmy FredrickNoch keine Bewertungen

- Proposal On Dessie To Hayk Pavement DistressDokument107 SeitenProposal On Dessie To Hayk Pavement DistressOmer AliyeNoch keine Bewertungen

- Subgrade Rutting Flexible PavementDokument5 SeitenSubgrade Rutting Flexible PavementPalak ShivhareNoch keine Bewertungen

- Chapter 3Dokument41 SeitenChapter 3Muhammad Farhan GulNoch keine Bewertungen

- Astm D4602-93 PDFDokument4 SeitenAstm D4602-93 PDFAnonymous rWoXWzqNoch keine Bewertungen

- RPP04 V5S11 BFC31802 Sem120192020Dokument4 SeitenRPP04 V5S11 BFC31802 Sem120192020abood buriahiNoch keine Bewertungen

- Geotechnical EngineeringDokument26 SeitenGeotechnical EngineeringGanesh crNoch keine Bewertungen

- Analysis and Execution of Road Work PDFDokument85 SeitenAnalysis and Execution of Road Work PDFDakshina MurthyNoch keine Bewertungen

- 15cv833-Pavement DesignDokument90 Seiten15cv833-Pavement DesignMEHRAN KAPRANoch keine Bewertungen

- Comparative Study Between Flexible and Rigid PavementDokument8 SeitenComparative Study Between Flexible and Rigid Pavementmist ce19Noch keine Bewertungen

- Correlation of Tensile Strength of Split Cylinder Test and Double Punch Test of A Rubberized Asphalt Concrete Used in Flexible Pavement DesignDokument9 SeitenCorrelation of Tensile Strength of Split Cylinder Test and Double Punch Test of A Rubberized Asphalt Concrete Used in Flexible Pavement DesignSheraz UllahNoch keine Bewertungen

- 8th Semester CivilDokument10 Seiten8th Semester CivilsaadkhalisNoch keine Bewertungen

- Chapter 1 - Introduction To Highway EngineeringDokument39 SeitenChapter 1 - Introduction To Highway EngineeringShera RoseNoch keine Bewertungen

- CE308 Transportation Engineering - I PDFDokument2 SeitenCE308 Transportation Engineering - I PDFangel graceNoch keine Bewertungen

- CH-2, Stress & StrainDokument74 SeitenCH-2, Stress & StrainEba GetachewNoch keine Bewertungen

- Operational Maintenance Strategies For Roads and Highways: Dr. S. S. SeehraDokument10 SeitenOperational Maintenance Strategies For Roads and Highways: Dr. S. S. SeehraPerkresht PawarNoch keine Bewertungen

- IJRPR2138Dokument8 SeitenIJRPR2138Hamunyela LikiusNoch keine Bewertungen

- Highway Research Record No. 33 (2005-06)Dokument199 SeitenHighway Research Record No. 33 (2005-06)shanil3001100% (1)

- CE6504 SCAD MSM by WWW - Learnengineering.inDokument132 SeitenCE6504 SCAD MSM by WWW - Learnengineering.inhdfcNoch keine Bewertungen

- Palestine Polytechnic UniversityDokument40 SeitenPalestine Polytechnic UniversityAhmad Abu GhzalaNoch keine Bewertungen

- SEC 900 Quality Control For RoadDokument24 SeitenSEC 900 Quality Control For RoadpkNoch keine Bewertungen

- Impact of Side Friction On Speed-Flow RelationshipsDokument27 SeitenImpact of Side Friction On Speed-Flow RelationshipsMarijan Jakovljevic75% (4)

- Brownfield Road Design Guidelines-QueenslandDokument111 SeitenBrownfield Road Design Guidelines-QueenslandSankar Cdm100% (1)