Beruflich Dokumente

Kultur Dokumente

Tugas 1 Menara Bahan Isian Lengkap - Komang

Hochgeladen von

Komang SadiaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tugas 1 Menara Bahan Isian Lengkap - Komang

Hochgeladen von

Komang SadiaCopyright:

Verfügbare Formate

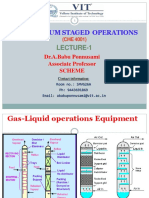

MENARA BAHAN ISIAN (PACKED TOWER)

Penjelasan umum : Menara paking adalah menara yang diisi dengan bahan pengisi, gambar di atas. Di dalam menara ini, cairan akan mengalir ke bawah (Liquid can be distributed over the packing material by one of three devices: weirs, tubes, or spray nozzles) melalui permukaan bawah pengisi, sedangkan gas akan mengalir ke atas secara arus berlawanan, melalui ruang kosong yang ada diantara bahan pengisi. Digunakan untuk sistem gas-cairan dimana salah satu dari resistansi fasa yang ada mengontrol atau kedua fasa sama-sama berpengaruh. The overall pressure drops across packed towers are usually between 5 and 25 cm (2 and 10 in.) of water. Thus, packed towers are generally considered as medium-energy scrubbers. Bahan isian (packed) Merupakan komponen packed tower yang paling mahal Adapun fungsi bahan pengisi ialah untuk memperluas bidang kontak antara kedua fase (uap cair). Bahan pengisi yang banyak digunakan antara lain cincin rasching, cincin lessing, cincin partisi, sadel bell, sadel intalox dan cicin pall. These strangely shaped pieces are supposed to impart good vapor-liquid contact when a particular type is placed together in numbers, without causing excessive pressure-drop across a packed section. This is important because a high pressure drop would mean that more energy is required to drive the vapor up the distillation column. Berbahan dasar : stoneware, porcelain, or metal, but presently, a large majority are made of high-density thermoplastics (polyethylene and polypropylene).

Contoh aplikasi : Odor removal in organic chemical, meat packing, rendering, fish and general food processing plants Gaseous absorption in steel plants and in fertilizer and other chemical process industries used to absorb inorganic gases into liquid Packed towers are mainly used to remove gaseous pollutants

Packed column are the best options when:

Costs: packed column tends are less expensive than plate column for small column diameter (<0.6 m). Corrosive chemicals handling: cheap ceramic packing material, or other chemicals resistant packing element can be easily used.

Packed towers are most suited to applications where a high gas-removal efficiency is required and the exhaust gas is relatively free from particles. These include removing HCl, NH4, and SO2 gases from a variety of process streams

Packings versus Trays A tray column that is facing throughput problems may be de-bottlenecked by replacing a section of trays with packings. This is because: packings provide extra inter-facial area for liquid-vapor contact efficiency of separation is increased for the same column height packed columns are shorter than trayed columns Packed columns are called continuous-contact columns while trayed columns are called staged-contact columns because of the manner in which vapor and liquid are contacted.

NB : The countercurrent-flow packed tower does not operate effectively if there are large variations in the liquid or gas flow rates. If either the liquid-injection rate or the gas flow rate through the packing bed is too high, a condition called flooding may occur. Flooding is a condition where the liquid is "held" in the pockets, or void spaces, between the packing and does not drain down through the packing. Flooding can be reduced by reducing the gas velocity through the bed or by reducing the liquid-injection rate.

Das könnte Ihnen auch gefallen

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshVon EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNoch keine Bewertungen

- Mass Transfer EquipmentsDokument32 SeitenMass Transfer EquipmentsAjaykumarNoch keine Bewertungen

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168Von EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168Noch keine Bewertungen

- Fluid Flow Through Packed and Fluidized Bed: Momentum Transfer CHE1005Dokument69 SeitenFluid Flow Through Packed and Fluidized Bed: Momentum Transfer CHE1005blub blueNoch keine Bewertungen

- 6.equipments For Gas Liquid Operations PDFDokument27 Seiten6.equipments For Gas Liquid Operations PDFMohit SathwaraNoch keine Bewertungen

- Discussion For Gas AbsorptionDokument6 SeitenDiscussion For Gas AbsorptionhaanaNoch keine Bewertungen

- What Is Meant by Vapor and Liquid LoadingDokument5 SeitenWhat Is Meant by Vapor and Liquid LoadingSushant PaiNoch keine Bewertungen

- Absorber DesignDokument26 SeitenAbsorber DesignNauman Arif Waince100% (4)

- Absorption in Plate and Packed TowersDokument5 SeitenAbsorption in Plate and Packed TowersDewi SarahNoch keine Bewertungen

- Chemical AbsorptionDokument6 SeitenChemical AbsorptionmubashirfareedNoch keine Bewertungen

- What Is The Distillation Column?: Batch ColumnsDokument9 SeitenWhat Is The Distillation Column?: Batch ColumnsAbdo MohsenNoch keine Bewertungen

- Designing of AbsorbersDokument11 SeitenDesigning of AbsorbersKhaqan AminNoch keine Bewertungen

- Absorption Flue GasDokument62 SeitenAbsorption Flue GasReza RhiNoch keine Bewertungen

- 8,9-Equipment For Vapor-Liquid SeparationsDokument39 Seiten8,9-Equipment For Vapor-Liquid SeparationsFawadNoch keine Bewertungen

- Chapter 6 Design of EquipmentsDokument18 SeitenChapter 6 Design of Equipmentsgshdavid100% (1)

- Flow in Packed BedsDokument54 SeitenFlow in Packed BedsleasturbaNoch keine Bewertungen

- Mass Transfer PartDokument11 SeitenMass Transfer Partoctoviancletus100% (1)

- Equipments Regarding AbsorptionDokument7 SeitenEquipments Regarding AbsorptionGerry Lou QuilesNoch keine Bewertungen

- Absorption (FGD)Dokument62 SeitenAbsorption (FGD)Chaidir FajariNoch keine Bewertungen

- Lecture 14-15 - Gas-Liquid Contact EquipmentDokument11 SeitenLecture 14-15 - Gas-Liquid Contact EquipmentMihir Kumar MechNoch keine Bewertungen

- TraysDokument19 SeitenTraysShaukat AliNoch keine Bewertungen

- Distillation ColumnsDokument12 SeitenDistillation ColumnsJade RanteNoch keine Bewertungen

- Stripping Coloumn PDFDokument18 SeitenStripping Coloumn PDFEmir DjafarNoch keine Bewertungen

- Equipment For Gas-Liquid OperationsDokument22 SeitenEquipment For Gas-Liquid OperationsBrandeice Barrett75% (4)

- Types of Trays The Packing MaterialDokument5 SeitenTypes of Trays The Packing MaterialalyNoch keine Bewertungen

- PackingDokument20 SeitenPackingOpayan SarkarNoch keine Bewertungen

- Absorber Design:: Theoretical BackgroundDokument15 SeitenAbsorber Design:: Theoretical BackgroundAndreea IoanaNoch keine Bewertungen

- TraysDokument9 SeitenTraysElladaNoch keine Bewertungen

- Packed Towers: 12.1 Device TypeDokument10 SeitenPacked Towers: 12.1 Device TypeSagar BhavsarNoch keine Bewertungen

- Equipment For Gas Absorption: Instructor: Zafar ShakoorDokument34 SeitenEquipment For Gas Absorption: Instructor: Zafar ShakoorMALIK ZARYABBABARNoch keine Bewertungen

- Absorption EquipmentsDokument33 SeitenAbsorption EquipmentsMohana Murali33% (3)

- Packed Bed Is A Hollow TubeDokument3 SeitenPacked Bed Is A Hollow TubeKubra ĖdrisNoch keine Bewertungen

- Peralatan Absorpsi (Dela)Dokument14 SeitenPeralatan Absorpsi (Dela)dela ayu FitriaNoch keine Bewertungen

- FALLSEM2021-22 CHE4001 ETH VL2021220100382 Reference Material I 17-Aug-2021 Lecture-1 (Tray Vs Packed Column)Dokument62 SeitenFALLSEM2021-22 CHE4001 ETH VL2021220100382 Reference Material I 17-Aug-2021 Lecture-1 (Tray Vs Packed Column)sanyukta sinhaNoch keine Bewertungen

- Packed BedDokument3 SeitenPacked BedNaveen KumarNoch keine Bewertungen

- Data AnalysisDokument15 SeitenData AnalysisMaira Jean Ruth SilvozaNoch keine Bewertungen

- Stripping (Chemistry) : From Wikipedia, The Free EncyclopediaDokument3 SeitenStripping (Chemistry) : From Wikipedia, The Free EncyclopediaEzequiel Guillermo Trejo NavasNoch keine Bewertungen

- Absorption ColumnsDokument55 SeitenAbsorption Columnsina23aj0% (1)

- Packed Columns Vs Plate ColumnsDokument8 SeitenPacked Columns Vs Plate ColumnsSiri Nal100% (1)

- Types of Packing Used in AbsorptionDokument2 SeitenTypes of Packing Used in AbsorptionMuhammad Salman67% (3)

- Column Internals ExplainedDokument9 SeitenColumn Internals ExplainedFranklin Santiago Suclla PodestaNoch keine Bewertungen

- Basic Distillation Concept 1705563192Dokument10 SeitenBasic Distillation Concept 1705563192rajesh_sgNoch keine Bewertungen

- Department of Chemical Engineering: COMSATS Institute of Information Technology Lahore CampusDokument6 SeitenDepartment of Chemical Engineering: COMSATS Institute of Information Technology Lahore CampusNaeem AshrafNoch keine Bewertungen

- Mass Transfer Equipments (Tray Towers)Dokument26 SeitenMass Transfer Equipments (Tray Towers)AjaykumarNoch keine Bewertungen

- Gas-Liquid Operations Equipment: Mr. Chintan K. Modi Asst. Professor Chemical Engineering Department SrictDokument76 SeitenGas-Liquid Operations Equipment: Mr. Chintan K. Modi Asst. Professor Chemical Engineering Department SrictSoma BerwariNoch keine Bewertungen

- EXP 3 Packed Absorption Column Raschig RingDokument14 SeitenEXP 3 Packed Absorption Column Raschig RingHaiqal AzizNoch keine Bewertungen

- Process Column & Internals Part II (Packed Column) Rev-1Dokument51 SeitenProcess Column & Internals Part II (Packed Column) Rev-1sinner123Noch keine Bewertungen

- 8 - Packed Tower Design-1Dokument65 Seiten8 - Packed Tower Design-1M.H vafaeiNoch keine Bewertungen

- Types Packing of Distillation Column by Huda ShahDokument7 SeitenTypes Packing of Distillation Column by Huda ShahHuda ShahNoch keine Bewertungen

- Choosing Column InternalsDokument7 SeitenChoosing Column Internalspetrolhead1Noch keine Bewertungen

- 2 Gas AbsorptionDokument28 Seiten2 Gas AbsorptionGökçe ErdoğanNoch keine Bewertungen

- 0.115 F Where,: Flood PDokument2 Seiten0.115 F Where,: Flood PSujan BasyalNoch keine Bewertungen

- Stripping (Chemistry)Dokument3 SeitenStripping (Chemistry)sujithsaneNoch keine Bewertungen

- ChE307-2 Gas Absorption ColumnDokument10 SeitenChE307-2 Gas Absorption ColumnJudgement AslemiNoch keine Bewertungen

- Random Column Packing: Government Polytechnic Jalna Packings Used in Destillation ColoumDokument9 SeitenRandom Column Packing: Government Polytechnic Jalna Packings Used in Destillation ColoumMs. YMPNoch keine Bewertungen

- Shroff S. R. Rotary Institute of Chemical Technology TOPIC: Equipment Used For AdsorptionDokument10 SeitenShroff S. R. Rotary Institute of Chemical Technology TOPIC: Equipment Used For AdsorptionChintan ModiNoch keine Bewertungen

- Filtration & Separation JournalDokument7 SeitenFiltration & Separation Journaldevang asherNoch keine Bewertungen

- INTRA Process EquipmentDokument24 SeitenINTRA Process EquipmentMón Quà Vô GiáNoch keine Bewertungen

- Packed TowersDokument44 SeitenPacked Towersnawazkhan98482Noch keine Bewertungen

- Absorption ColumnsDokument55 SeitenAbsorption ColumnsHuzefa CalcuttawalaNoch keine Bewertungen

- Visual Design Elements and PrinciplesDokument9 SeitenVisual Design Elements and PrinciplesgamerootNoch keine Bewertungen

- Phy P1Dokument105 SeitenPhy P1Godfrey Muchai100% (1)

- 1 s2.0 S2352484722007922 MainDokument21 Seiten1 s2.0 S2352484722007922 MainEspinoza Payano Blas RussNoch keine Bewertungen

- Full Lab Report #8Dokument13 SeitenFull Lab Report #8Joe Morrison100% (2)

- Institute of Aeronautical EngineeringDokument4 SeitenInstitute of Aeronautical EngineeringACE PROFILESNoch keine Bewertungen

- Radar ReceiversDokument15 SeitenRadar Receiversmas3565560100% (2)

- Algebra Age ProblemsDokument5 SeitenAlgebra Age ProblemswarlockeNoch keine Bewertungen

- Autopano Giga 2.6 User ManualDokument80 SeitenAutopano Giga 2.6 User ManualMiBayatiNoch keine Bewertungen

- Hot Rolled Bulb Flats PDFDokument4 SeitenHot Rolled Bulb Flats PDFLaurentiu GavrilaNoch keine Bewertungen

- Rubik's Revenge (4x4x4)Dokument5 SeitenRubik's Revenge (4x4x4)Febbi Abdul MuktiNoch keine Bewertungen

- Sony MDS-JB920QS Service ManualDokument72 SeitenSony MDS-JB920QS Service ManualSinisa SlavinicNoch keine Bewertungen

- IB Physics Answers ThemeADokument15 SeitenIB Physics Answers ThemeANicole El-hazhaliNoch keine Bewertungen

- Epoxidation of Vegetable Oils - A ReviewDokument8 SeitenEpoxidation of Vegetable Oils - A ReviewNorberto SchischoffNoch keine Bewertungen

- Sleeperwall 1Dokument6 SeitenSleeperwall 1John SmithNoch keine Bewertungen

- Enter Your Response (As An Integer) Using The Virtual Keyboard in The Box Provided BelowDokument102 SeitenEnter Your Response (As An Integer) Using The Virtual Keyboard in The Box Provided BelowCharlie GoyalNoch keine Bewertungen

- 121 B.P.S. XII - Physics Chapter Notes 2014 15 PDFDokument87 Seiten121 B.P.S. XII - Physics Chapter Notes 2014 15 PDFkumarnpccNoch keine Bewertungen

- Industrial Training PresentationDokument16 SeitenIndustrial Training PresentationChia Yi MengNoch keine Bewertungen

- Adaptive Control by LandauDokument6 SeitenAdaptive Control by LandauSabit RashidNoch keine Bewertungen

- Classical Theory of DetonationDokument20 SeitenClassical Theory of Detonationalexander.lhoistNoch keine Bewertungen

- 2 Torsion of ThinWalled StructuresDokument12 Seiten2 Torsion of ThinWalled StructuresJ.p. ZhuNoch keine Bewertungen

- Special Types of Matrices: By: Engr. Glenda Alega - de MesaDokument22 SeitenSpecial Types of Matrices: By: Engr. Glenda Alega - de Mesasairin parkNoch keine Bewertungen

- A Companion To Fourier Analysis For Physics Students: Gol Mohammad NafisiDokument25 SeitenA Companion To Fourier Analysis For Physics Students: Gol Mohammad NafisiIridian ÁvilaNoch keine Bewertungen

- 02 VF10 Appliance Information enDokument2 Seiten02 VF10 Appliance Information enGabriel ZorattiNoch keine Bewertungen

- Permanent WayDokument7 SeitenPermanent Wayaishwarya mundraNoch keine Bewertungen

- Reading: Test 1Dokument10 SeitenReading: Test 131郭譿斳VeraNoch keine Bewertungen

- 2021 PHYS F3 T1 Exam1 NohighlightDokument17 Seiten2021 PHYS F3 T1 Exam1 NohighlightElsaaaNoch keine Bewertungen

- Equilibrium of Rigid Bodies Structural AnalysisDokument20 SeitenEquilibrium of Rigid Bodies Structural AnalysisJohn Lemmor G. CandelariaNoch keine Bewertungen

- Final School TranscriptDokument3 SeitenFinal School TranscriptSteven TeguhNoch keine Bewertungen

- A Model For Traffic SimulationDokument5 SeitenA Model For Traffic Simulationraci78Noch keine Bewertungen

- VV2230 - FERA - DR John Newnham - 22 Nov 06Dokument15 SeitenVV2230 - FERA - DR John Newnham - 22 Nov 06breeeeezzzzzeNoch keine Bewertungen

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindVon EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNoch keine Bewertungen

- The Fabric of Civilization: How Textiles Made the WorldVon EverandThe Fabric of Civilization: How Textiles Made the WorldBewertung: 4.5 von 5 Sternen4.5/5 (58)

- Highest Duty: My Search for What Really MattersVon EverandHighest Duty: My Search for What Really MattersNoch keine Bewertungen

- Hero Found: The Greatest POW Escape of the Vietnam WarVon EverandHero Found: The Greatest POW Escape of the Vietnam WarBewertung: 4 von 5 Sternen4/5 (19)

- Sully: The Untold Story Behind the Miracle on the HudsonVon EverandSully: The Untold Story Behind the Miracle on the HudsonBewertung: 4 von 5 Sternen4/5 (103)

- The End of Craving: Recovering the Lost Wisdom of Eating WellVon EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellBewertung: 4.5 von 5 Sternen4.5/5 (81)

- System Error: Where Big Tech Went Wrong and How We Can RebootVon EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootNoch keine Bewertungen

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- Reality+: Virtual Worlds and the Problems of PhilosophyVon EverandReality+: Virtual Worlds and the Problems of PhilosophyBewertung: 4 von 5 Sternen4/5 (24)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestVon EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestBewertung: 4 von 5 Sternen4/5 (28)

- Pale Blue Dot: A Vision of the Human Future in SpaceVon EverandPale Blue Dot: A Vision of the Human Future in SpaceBewertung: 4.5 von 5 Sternen4.5/5 (588)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyVon EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNoch keine Bewertungen

- Packing for Mars: The Curious Science of Life in the VoidVon EverandPacking for Mars: The Curious Science of Life in the VoidBewertung: 4 von 5 Sternen4/5 (1395)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaVon EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNoch keine Bewertungen

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (54)

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (242)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterVon EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNoch keine Bewertungen

- The Future of Geography: How the Competition in Space Will Change Our WorldVon EverandThe Future of Geography: How the Competition in Space Will Change Our WorldBewertung: 4 von 5 Sternen4/5 (5)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (122)

- The Weather Machine: A Journey Inside the ForecastVon EverandThe Weather Machine: A Journey Inside the ForecastBewertung: 3.5 von 5 Sternen3.5/5 (31)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterVon EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterBewertung: 5 von 5 Sternen5/5 (3)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansVon EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNoch keine Bewertungen

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureVon EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureBewertung: 5 von 5 Sternen5/5 (125)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationVon EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationBewertung: 4.5 von 5 Sternen4.5/5 (46)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseVon EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseBewertung: 3.5 von 5 Sternen3.5/5 (12)