Beruflich Dokumente

Kultur Dokumente

API6D Ball Valves Inspection and Test Procedures

Hochgeladen von

Chi ChaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

API6D Ball Valves Inspection and Test Procedures

Hochgeladen von

Chi ChaCopyright:

Verfügbare Formate

Technical Standard

API6D Ball & Plug Valve Inspection & Test Procedure

Page 1

Scope This standard provides specific inspection items to be performed on all ball & plug valves. The valves shall be provided with a serial numbering system and will be documented for traceability purposes. Valve Range Type : Body: Material : Pressure rating: Bore dia.: Floating & trunnion ball & lubricated plug Split body 2p & 3p and top entry Cast & forged, carbon steel, stainless steel, alloy steel & duplex steel ASME Class 150, 300, 600, 900,1500 NPS 1 to 24 full bore NPS 3 to 24 reduced bore

1.1

1.2

Applicable Code and Standard Valve Design : API6D, ASME B16.34, API607, API608 Face to Face Dimension : ANSI B16.10 End Flange Dimension : ASME B16.5 Inspection and Test : API6D Non Destructive Examination (NDE) : ASME B16.34 (If required on purchase order) Radiographic Examination (RT) Liquid Penetrant Examination (PT) Magnetic Particle Examination (MT) Ultrasonic Examination (UT)

Inspection Items Inspection items are as follows: Material test; Visual inspection; Dimensional check; Assembly/performance test; Pressure test; (1) Hydrostatic Shell Test (2) High Pressure Valve Closure Test (3) Low Pressure Valve Closure Test Final Inspection, NDE (If required)

Page 2

Material Test GSL/QTY-JH-03 The materials of body, body cap, ball and stem shall be confirmed to meet the respective material specifications on the basis of respective mill certificates. Visual inspection Check visually that: GSL/QTY-JH-06

4 4-1 4-2 4-3 4-4 4-5 4-6 4-7 5 5-1 5-2 5-3

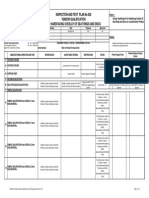

Casting surfaces both the exterior and interior are free from holes, burrs, scale, cracks, etc.in accordance with MSS SP55. Machined faces and all surfaces are free from flaws or unevenness on finished surfaces. The fluid passage is finished appropriately and free from foreign debris. Angles and corners the dimensions of which are not specified in the drawings and standards are chamfered and rounded appropriately. The nominal pressure, nominal diameter, and other necessary information should be properly indicated on the body surface and lable. The flow direction shall be properly indicated when restricted. Bore should be unobstructed when valve is in full open position. Dimensional Check GSL/QTY-JH-05 Dimensions shall be checked in accordance with the drawings and specified values. The dimensional tolerance of flanges shall be as specified in ASME BI6.5, buttweld end to ANSI B16.25. The tolerance of the face-to-face dimension shall be in accordance with API6D (Table 1). Table 1 Face-to-face dimensional tolerance (unit : mm)

!

6 6-1 6-2

!!

Assembly/Torque Test GSL/QPS8.2-02 The valve operating torque shall be determined prior to pressure test, without load and in dry condition. The operating torque shall be within the manufacturers specified range. Both the directions of the hole in the ball and the two faces of the stem or the flow direction indication at the stem top shall coincide with each other.

Pressure Test Testing Requirements Item Hydrostatic Shell Test High Pressure Closure Test (Hydrostatic) Low Pressure Closure Test (Gas) Ball or Plug Valve Yes Yes Yes

GSL/QPS8.2-01

7-1

Hydrostatic Shell Test With the valve kept half open fill the body with water and apply test pressure shown in Table 2. Make sure that the connections are tight then use leak detector spray on all body joins & body surfaces to ensure zero leakage and all parts are free from leakage. At this time, the test duration shall be as shown in Table 3. For stainless steel and the duplex stainless steel valves, the chloride content of test water shall not exceed 30 ppm by mass. Table 2 Shell test API6D/ASME B16.34unit MPa Material of 150lb 300lb 600lb Shell WCB/ A105N 3.14 7.58 15.4 LCB/ LF2 2.84 7.26 14.51 CF8,CF8M/ 2.94 7.65 15 316/ 304 LC3/ LF3 3.14 7.85 15.59

900lb 23.14 21.77 22.46 23.34

1500lb 38.44 36.09 37.27 38.83

Table 3Test duration for shell test and closure test(API6D) [unit min] Testing High Pressure Valve Low Pressure Valve Size Item Hydrostatic Shell Test Closure Test Closure Test (Gas) (NPS) Hydrostatic) 1/2 ~ 4 2 2 2 6 ~ 10 5 5 5 12 ~ 18 15 5 5 20 30 5 5

Page 4

7-2

High Pressure Valve Seat Test Hydrostatic) With the valve closed fullytest in both directions, one driection at a time at pressure given in Table 4.1. Use leak detector spray on entire seal area to ensure zero leakage. The test duration shall be as shown in Table 3. Note. For stainless steel and the duplex stainless steel valves, the chloride content of test water shall not exceed 30 ppm by mass. Table 4.1 All valves (API6D/ASME B16.34) [unit Mpa]

Pressure NPS 1/2 ~ 24 2.26 5.79 11.46 17.16 28.54 62.1 150lb 300lb 600lb 900lb 1500lb 2500lb

7-3

Low Pressure Valve Seat Test (Gas): With the valve closed fully test in both directions, one direction at a time at pressure of 0.6MPag. Use leak detector spray on entire seal area to ensure zero leakage. The test duration shall be as shown in Table 3. Acceptance Criteria for Closure Test (ISO5208) Seat Leakage Rate Soft Seated 0 Leakage (A) Metal Seated 01mm 3/ SDN (D)

7-4

7-5

After Pressure Testing The test water is to be entirely evacuated from valve bore. For carbon steel valves, the interior of the valve is to be sprayed or coated with rust preventative oil to prevent rust and corrosion during transit and storage. Final Inspection GSL/QPS8.2-04 Paint Check 1) The paint check shall be made after the above mentioned tests have been completed. 2) Check that finished coat is free from peeling, unevenness, blistering, etc. 3) Specification and coluor shall be in accordance with customers specifications. Unless otherwise specified, it shall be marking and tagging are correct. Ensure sure that all in accordance with the GSL standards. Body finish of casting/ forging to be physically inspected in accordance with MSS-SP55 Non Destructive Examination (Supplementary Examination.) GSL/QP7.5-02 Supplementary types of non destructive examination are required only if specified in the purchase order and only to the extent specified. Magnetic Particle, Radiographic, Liquid Penetrant and Ultrasonic Examination of steel castings or forgings shall be in accordance with specifications in client purchase order.

8 8-1

8-2 8-3 9

Page 5

Das könnte Ihnen auch gefallen

- Valve Maintenance1Dokument11 SeitenValve Maintenance1mister pogiNoch keine Bewertungen

- Material Inspection ReportDokument5 SeitenMaterial Inspection ReportAndreas SchlagerNoch keine Bewertungen

- Pressure Gauge Technical InformationsDokument4 SeitenPressure Gauge Technical Informationssahayaraaj100% (1)

- B31.1 Weld Insp.Dokument3 SeitenB31.1 Weld Insp.Ivan AlanizNoch keine Bewertungen

- Texsteam-Ñ Bomba QuímicaDokument8 SeitenTexsteam-Ñ Bomba QuímicarivomarNoch keine Bewertungen

- Nuflo Mc-III Exp DatasheetDokument4 SeitenNuflo Mc-III Exp DatasheetJerrydawangNoch keine Bewertungen

- WIKA Calibration Certificate for Process CalibratorDokument3 SeitenWIKA Calibration Certificate for Process CalibratorBalaji BobadeNoch keine Bewertungen

- Company Introduction - Shinwoo ValveDokument26 SeitenCompany Introduction - Shinwoo ValveLe Cam NhanNoch keine Bewertungen

- Vc-Api 650 PDFDokument6 SeitenVc-Api 650 PDFShinta ShowiantariNoch keine Bewertungen

- Installation and Operations Maintenance Manual Ball Valve: Valvtechnologies, IncDokument20 SeitenInstallation and Operations Maintenance Manual Ball Valve: Valvtechnologies, IncJUANITOPYTNoch keine Bewertungen

- Inspection and Test Plan No 826 Vendor Qualification For Hardfacing Overlay of Seat Rings and DiscsDokument3 SeitenInspection and Test Plan No 826 Vendor Qualification For Hardfacing Overlay of Seat Rings and DiscsGohilakrishnan ThiagarajanNoch keine Bewertungen

- Safety Alert Space HeatersDokument2 SeitenSafety Alert Space HeatersRamadan KareemNoch keine Bewertungen

- Installation, Operation and Maintenance Manual (GRS)Dokument8 SeitenInstallation, Operation and Maintenance Manual (GRS)igorsfaceNoch keine Bewertungen

- Identification of Risk and Providing GuiDokument5 SeitenIdentification of Risk and Providing GuiJay PanitanNoch keine Bewertungen

- API E-165 Standard Test Method For Liquid Penetrant Examination PDFDokument20 SeitenAPI E-165 Standard Test Method For Liquid Penetrant Examination PDFDaniel GamioNoch keine Bewertungen

- Phased Array UT Weld Inspection and Crack DetectionDokument3 SeitenPhased Array UT Weld Inspection and Crack DetectionGistek MarcoNoch keine Bewertungen

- Hydro Test ProcedureDokument2 SeitenHydro Test ProcedureDhanushka B HerathNoch keine Bewertungen

- Proc SopDokument90 SeitenProc SopJohn Dolan100% (1)

- SPECIAL DESIGN CRYOGENIC BALL VALVESDokument10 SeitenSPECIAL DESIGN CRYOGENIC BALL VALVESshenkoviNoch keine Bewertungen

- Fire Policy 1Dokument2 SeitenFire Policy 1caleb99Noch keine Bewertungen

- TubestarDokument29 SeitenTubestarPernando Saga100% (1)

- HOSE TEST METHODS GUIDEDokument5 SeitenHOSE TEST METHODS GUIDEtriagusmanNoch keine Bewertungen

- Installing and Operating a Thermal Relief ValveDokument12 SeitenInstalling and Operating a Thermal Relief ValveHiren Panchal100% (1)

- Hydro test report for 750mm dismantling jointDokument2 SeitenHydro test report for 750mm dismantling jointAnonymous a8oga83Noch keine Bewertungen

- Hydrostatic Test ProcedureDokument7 SeitenHydrostatic Test Procedurelaleye_olumideNoch keine Bewertungen

- HT and XT Running and Handling SeminarDokument38 SeitenHT and XT Running and Handling SeminarNhoj AicragNoch keine Bewertungen

- RA Elevator ManualDokument8 SeitenRA Elevator ManualBahman MatouriNoch keine Bewertungen

- NDT For Corrosion InspectionDokument80 SeitenNDT For Corrosion InspectionAnil Kumar TNoch keine Bewertungen

- API's 9th Internal Audit FormDokument32 SeitenAPI's 9th Internal Audit Formislam atifNoch keine Bewertungen

- Hydo Test ProcedureDokument2 SeitenHydo Test ProcedureAbdulMajidYousoffNoch keine Bewertungen

- Lrut 4Dokument20 SeitenLrut 4AbinashBeheraNoch keine Bewertungen

- Drillstring Hardbanding: Arcraft Plasma IndiaDokument10 SeitenDrillstring Hardbanding: Arcraft Plasma Indiapavi32Noch keine Bewertungen

- Iraq Gates Contracting Company: Kaz 12.2 Rehabilitation ProjectDokument8 SeitenIraq Gates Contracting Company: Kaz 12.2 Rehabilitation ProjectAhmedNoch keine Bewertungen

- Boiler Hydrostatic TestingDokument2 SeitenBoiler Hydrostatic Testingbonginkosi mathunjwaNoch keine Bewertungen

- S.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5Dokument7 SeitenS.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5கோகுல் இராNoch keine Bewertungen

- 01 - Transfer Pumps & TexsteamDokument26 Seiten01 - Transfer Pumps & TexsteamMarsyaNoch keine Bewertungen

- Crosby Pressure Relief Valve EngineeringDokument93 SeitenCrosby Pressure Relief Valve EngineeringHuy IpNoch keine Bewertungen

- Fender Accessories (Panels, Chains, Brackets) Catalogue en V1.3Dokument10 SeitenFender Accessories (Panels, Chains, Brackets) Catalogue en V1.3loicdertyNoch keine Bewertungen

- API Repair ProcedureDokument1 SeiteAPI Repair ProcedurejacquesmayolNoch keine Bewertungen

- Installation, Operation & Maintenance Manual: Virgo Engineers LimitedDokument47 SeitenInstallation, Operation & Maintenance Manual: Virgo Engineers LimitedSreenivasNoch keine Bewertungen

- Tests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water LevelDokument6 SeitenTests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water Levelahmed121Noch keine Bewertungen

- LEEA Correspondence Courses: Assignment 1.3Dokument3 SeitenLEEA Correspondence Courses: Assignment 1.3alexedamalaNoch keine Bewertungen

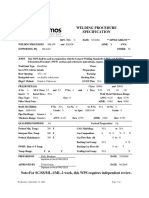

- Welding Procedure SpecificationDokument2 SeitenWelding Procedure SpecificationWaranya Musika100% (1)

- Gate & Globe PDFDokument0 SeitenGate & Globe PDFZoebairNoch keine Bewertungen

- Inspection Capabilities - 2016Dokument4 SeitenInspection Capabilities - 2016muhamadrafie1975Noch keine Bewertungen

- GV-040 Cameron Model Gate ValvesDokument1 SeiteGV-040 Cameron Model Gate ValvesSuresh BalrajNoch keine Bewertungen

- CDA/UNS Grade C954 Aluminium Bronze Material Data SheetDokument1 SeiteCDA/UNS Grade C954 Aluminium Bronze Material Data SheetchandraNoch keine Bewertungen

- GRE INS-009, Flange Bolting ProcedureDokument6 SeitenGRE INS-009, Flange Bolting Proceduresyed jafar100% (1)

- Work Instruction FOR: Charpy Impact TestDokument4 SeitenWork Instruction FOR: Charpy Impact TestmahendraNoch keine Bewertungen

- Tanktrader Bitutainer SpecDokument9 SeitenTanktrader Bitutainer SpecNauman AliNoch keine Bewertungen

- Material & Processes For NDT Part 2Dokument11 SeitenMaterial & Processes For NDT Part 2Anonymous gFcnQ4goNoch keine Bewertungen

- 2012 Ol1 1.7 UDokument14 Seiten2012 Ol1 1.7 UalexedamalaNoch keine Bewertungen

- Red Tee STDDokument3 SeitenRed Tee STDGlishna Peushan WidanapathiranaNoch keine Bewertungen

- Well Services BrochureDokument2 SeitenWell Services BrochureAiddie GhazlanNoch keine Bewertungen

- Manifold Burst Pressure TestDokument3 SeitenManifold Burst Pressure TestrajeshNoch keine Bewertungen

- Safety 2Dokument15 SeitenSafety 2hyde2520015754Noch keine Bewertungen

- Inspection and Maintenance of Drillpipe Ebook PDFDokument39 SeitenInspection and Maintenance of Drillpipe Ebook PDFAntónio OliveiraNoch keine Bewertungen

- Sop Iii-300 R00Dokument13 SeitenSop Iii-300 R00Bepdj100% (1)

- Why Is "Cold Cutting" Superior To Plasma Cutting?Dokument9 SeitenWhy Is "Cold Cutting" Superior To Plasma Cutting?ahmedNoch keine Bewertungen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- Review 2Dokument22 SeitenReview 2EDENNoch keine Bewertungen

- Tds Anticor Cba 63Dokument2 SeitenTds Anticor Cba 63حازم أيمنNoch keine Bewertungen

- Chamfer VC-2CDokument2 SeitenChamfer VC-2CLê Duy HướngNoch keine Bewertungen

- Department of EducationDokument7 SeitenDepartment of EducationJay BustamanteNoch keine Bewertungen

- Materials Used For Manufacturing Furniture in PakistanDokument9 SeitenMaterials Used For Manufacturing Furniture in Pakistaninayahjunaid89Noch keine Bewertungen

- The Welding Journal 1958 4Dokument226 SeitenThe Welding Journal 1958 4Alexey100% (2)

- Abschreckmedien EDokument24 SeitenAbschreckmedien EhsemargNoch keine Bewertungen

- Fakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaDokument5 SeitenFakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaHairul Effendy Ab MaulodNoch keine Bewertungen

- Layout ToolsDokument20 SeitenLayout ToolsmarlitoNoch keine Bewertungen

- WSF1600 6500a Varilex Unitec 2008Dokument2 SeitenWSF1600 6500a Varilex Unitec 2008Luis Manuel Montoya RiveraNoch keine Bewertungen

- MTT20 CAT777G-Appendix-4 PDFDokument59 SeitenMTT20 CAT777G-Appendix-4 PDFJose Manuel Carcamo SaezNoch keine Bewertungen

- B Container SecurityDokument5 SeitenB Container SecurityJobaerNoch keine Bewertungen

- TLE SMAW For DemoDokument3 SeitenTLE SMAW For DemoRobin Rafael PescaderoNoch keine Bewertungen

- Modelo Certificación Submittal F1554-55 PDFDokument2 SeitenModelo Certificación Submittal F1554-55 PDFedwinsazzzNoch keine Bewertungen

- Assignment On Sheet-Forming ProcessesDokument4 SeitenAssignment On Sheet-Forming ProcessesMohammed ArishNoch keine Bewertungen

- Iso 15618-2-2001Dokument30 SeitenIso 15618-2-2001abdulkadir aliNoch keine Bewertungen

- New dwg notes additional instrument connectionsDokument1 SeiteNew dwg notes additional instrument connectionsPraful Kumar JhaNoch keine Bewertungen

- Report RobotDokument10 SeitenReport RobotAimy SufeaNoch keine Bewertungen

- WBPCB hazardous waste importers listDokument4 SeitenWBPCB hazardous waste importers listFarmBoxer India ChinaGardentecNoch keine Bewertungen

- C-1540 TEREX 1000 Rev - 02aDokument46 SeitenC-1540 TEREX 1000 Rev - 02aSoubhik BagchiNoch keine Bewertungen

- RotaBall FlexBall IOMDokument2 SeitenRotaBall FlexBall IOMjorgeNoch keine Bewertungen

- ISSF The Ferritic Solution EnglishDokument68 SeitenISSF The Ferritic Solution EnglishdhurushaNoch keine Bewertungen

- Report Beach CleanerDokument35 SeitenReport Beach CleanerRaja Mane0% (1)

- Paper-5: Mno 8H Xe MN 4ho HioDokument2 SeitenPaper-5: Mno 8H Xe MN 4ho HiosubhaseduNoch keine Bewertungen

- En 10204 GuideDokument1 SeiteEn 10204 Guideduong trung100% (2)

- Katalog GS PT. GLAXO SEMESTADokument8 SeitenKatalog GS PT. GLAXO SEMESTAdimas prayogoNoch keine Bewertungen

- Shell Moulding Production ProcessDokument21 SeitenShell Moulding Production ProcessUzair AzziNoch keine Bewertungen

- GANESH Precision GT-1340 Geared-Head Engine Lathe: 13" Swing Over Bedways, 40" Center DistanceDokument3 SeitenGANESH Precision GT-1340 Geared-Head Engine Lathe: 13" Swing Over Bedways, 40" Center DistancemattnificentNoch keine Bewertungen

- Liquid Penetrant ExaminationDokument5 SeitenLiquid Penetrant ExaminationKevin ThomasNoch keine Bewertungen

- Evapo-Rust™: Non-Harmful Rust RemoverDokument2 SeitenEvapo-Rust™: Non-Harmful Rust RemoverYoutube For EducationNoch keine Bewertungen