Beruflich Dokumente

Kultur Dokumente

Sist Diferenc 1764 797

Hochgeladen von

Gio Dosjotazeta FullboostOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sist Diferenc 1764 797

Hochgeladen von

Gio Dosjotazeta FullboostCopyright:

Verfügbare Formate

CAPACITACIN FINNING CHILE

ABRIL 2003

797B (JSM) OFF-HIGHWAY TRUCK

DIFERENCIAL

-2-

CAPACITACIN FINNING CHILE

ABRIL 2003

INSTRUCTOR NOTES

-3-

CAPACITACIN FINNING CHILE

ABRIL 2003

Describa los componentes enumerados

1*....................................................

2*....................................................

3*....................................................

4*...................................................

5*...................................................

6*...................................................

Rear Axle

797B rear axle

1. Differential

2. Banjo housing

3. Final drives

4. Rear brakes

5. Rear wheels

Shown is the 797B rear axle arrangement. The differential (1) is installed

into the rear of the banjo housing (2). On all other truck models, the

differential is installed from the front. Power flows from the transmission

to the differential. The differential divides the power to the right and left

axle shafts. Torque is transmitted equally from the differential through

the two axle shafts to the final drives (3). The differential adjusts the

speed of the axle shafts for vehicle cornering, therefore, the power

delivered to the axle shafts is unequal during cornering.

6. Rear spindle

The rear brakes (4) are located inside the rear wheels (5). The hub of the

brakes are connected to and rotate with the rear wheels. The anchor

housing of the brakes is bolted to and held stationary by the rear

spindles (6).

-4-

CAPACITACIN FINNING CHILE

ABRIL 2003

797B WHEEL STATION

SPINDLE

ANCHOR

REAR BRAKE

797B wheel station

HUB

REAR WHEEL

FINAL DRIVE

Shown is a sectional view of the 797B wheel station. Torque is

transmitted equally from the differential through the two axle shafts to the

final drives.

The rear brakes are located inside the rear wheels. The hub of the brakes

are connected to and rotate with the rear wheels. The anchor housing of

the brakes is bolted to and held stationary by the rear spindles.

-5-

CAPACITACIN FINNING CHILE

ABRIL 2003

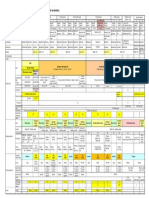

797B REAR AXLE LUBRICATION

BRAKE/COOLING

ECM

FINAL DRIVE

DIVERTER VALVE

RELIEF/ DIVERTER

VALVE AND SOLENOID

DRIVE

PUMP

FINAL DRIVE

FILTER

MOTOR

DIFF.

FILTER

TEMP.

SENSOR

BANJO

SUCTION

SCREEN

RELIEF

VALVE

PUMP

FINAL DRIVE

OIL LEVEL

797B rear axle

lubrication system

DIFF. HOT

OIL LEVEL

DIFF. COLD

OIL LEVEL

Shown is the rear axle lubrication system. A rear axle lubrication drive

pump provides oil flow to the rear axle lubrication drive motor. A

relief/diverter valve and solenoid controls the pressure in the rear axle

lubrication pump drive circuit. The setting of the relief valve is

13780 kPa (2000 psi).

The rear axle lubrication drive motor rotates a three-section pump that

provides lubrication to the differential and final drives. The two front

sections of the pump pull oil from the rear axle housing (banjo housing)

through a suction screen. The rear section of the pump pulls oil from the

carrier housing through a suction screen located below the differential.

Rear axle lubrication

controlled by

brake/cooling ECM

The amount of oil that flows to the differential and final drives is

controlled by the brake/cooling ECM. The brake/cooling ECM controls a

solenoid on the rear axle lubrication drive pump and a solenoid on the

final drive diverter valve. The solenoids are energized to control the oil

flow depending on the rear axle oil temperature.

-6-

CAPACITACIN FINNING CHILE

ABRIL 2003

Describa los componentes enumerados

1*....................................................

2*....................................................

3*....................................................

Differential and final

drives oil system

1. Rear axle lubrication

drive motor

2. Suction screen

Shown is the front of the 797B rear axle. The bevel gear/differential is

pressure lubricated. The final drive components are lubricated in a

conventional splash manner; however, oil circulation through the wheel

bearings and final drive is provided by the rear axle pump. A rear axle

lubrication drive pump provides oil flow to the rear axle lubrication drive

motor (1). The rear axle lubrication drive motor rotates a three-section

pump that provides pressure lubrication to the differential and oil

circulation through the final drives. The two front sections of the pump

pull oil from the rear axle housing through a suction screen (2). The rear

section of the pump pulls oil from the carrier housing through a suction

screen located below the differential (see Visual No. 34).

Brake/Cooling ECM

controls rear axle

lubrication system

The amount of oil that flows to the differential and final drives is

controlled by the Brake/Cooling ECM. The Brake/Cooling ECM controls

two solenoids that direct oil flow to or away from the final drive and

differential depending on the rear axle oil temperature.

3. Rear axle oil

temperature sensor

A rear axle oil temperature sensor (3) is located at the front of the rear

axle housing (see Visuals No. 30 and 33).

CAPACITACIN FINNING CHILE

ABRIL 2003

-7Describa los componentes enumerados

1*....................................................

2

2*....................................................

3*....................................................

4*...................................................

797B differential

1. Scavenge screen

pan

2. Lubrication oil

distribution and

relief valve manifold

Shown is the 797B differential. Oil is scavenged from the differential

through a screen located in the pan (1) below the differential. Lubrication

and cooling oil flows from the pump to the differential bearings through a

distribution and relief valve manifold (2) and several steel tubes. If the

differential lubrication oil pressure exceeds 689 kPa (100 psi), a relief

valve in the manifold will open. Relief oil flows to the differential sump.

3. TCS axle speed

sensors

The Traction Control System (TCS) axle speed sensors (3) are located on

the differential. There is a sensor located on both sides of the differential.

The sensors can be accessed for service through a cover on the rear axle

housing (see Visual No. 109). The sensors provide input signals to the

Brake/Cooling ECM. The Brake/Cooling ECM uses these sensors to

determine if one of the rear wheels are spinning. If one of the rear wheels

is spinning, the Brake/Cooling ECM sends a signal to engage the brake on

the spinning wheel. Engaging the brake on the spinning wheel generates

a higher level of torque across the differential and therefore an increase in

torque to the wheel with better traction results.

4. Removal and

installation rollers

The differential is removed and installed by resting the two rollers (4) on

tubes in the axle housing. The differential can then slide in or out of the

rear axle housing.

CAPACITACIN FINNING CHILE

ABRIL 2003

-8Describa los componentes enumerados

1*....................................................

2*....................................................

3*....................................................

1

3

1. Rear axle lubrication

drive pump

2. Brake actuation

pump

3. Brake cooling drive

pump

4. Rear axle lube drive

pump relief/diverter

valve and solenoid

Rear axle drive pump

pressure tap

Rear axle lube drive

pump solenoid

ENERGIZED

- Pump turned OFF

Rear axle lube drive

pump solenoid

DE-ENERGIZED

- Pump turned ON

4*...................................................

The rear axle lubrication drive pump (1) is located at the lower rear

section of the pump drive. The rear axle lubrication drive pump is

connected to the brake actuation pump (2) and the brake cooling drive

pump (3). The rear axle lubrication drive pump pulls oil from the small

top hydraulic tank (see Visual No. 86). Oil flows from the rear axle

lubrication drive pump to the rear axle lubrication drive motor located on

the rear axle housing. The pump is driven by the engine, therefore the

differential and final drive components can be cooled and lubricated even

when the truck is stopped. A relief/diverter valve and solenoid (4)

controls the pressure in the rear axle lubrication drive pump circuit. The

setting of the relief valve is 13780 kPa (2000 psi). Rear axle drive pump

pressure can be measured at a pressure tap (not shown) located on the

drive pump.

Banjo oil temperatures less than -4C (25F) produces a condition where

it becomes impractical to pump high viscosity 50 or 60 weight oil. Under

this condition the solenoid on the Rear Axle (RAX) lube drive pump is

energized. This allows the RAX lube pumps to be turned off; however,

there is some pressure drop across the diverter valve which allows a small

amount of rotation of the lube pumps, and therefore, some slight

movement of oil throughout the system When the banjo oil temp reaches

-4C (25F) and the vehicle is moving, the solenoid on the RAX lube

drive pump diverter valve is de-energized and the RAX lube pump begins

to pump charge oil to the rear axle components.

CAPACITACIN FINNING CHILE

ABRIL 2003

-9Describa los componentes enumerados

1*....................................................

2

2*....................................................

3*....................................................

4*...................................................

1. Rear axle oil pump

2. Rear axle drive

motor

3. Axle housing suction

screen cover

4. Rear axle oil

temperature sensor

Shown is a closer view of the rear axle oil pump (1) and the drive

motor (2). The two front sections of the pump pull oil from the axle

housing reservoir through the suction screen behind the cover (3) and

provide charge supply oil to the final drives and the differential. The rear

section of the pump scavenges oil from the differential through a suction

screen (see Visual No. 34) and returns it to the axle housing reservoir.

A rear axle oil temperature sensor (4) is located at the front of the rear

axle housing. The sensor provides input signals to the Brake/Cooling

ECM. The Brake/Cooling ECM sends the signals to the VIMS, which

informs the operator of the rear axle oil temperature. A warning

Category 2 will be logged above 118C (244F). A warning Category 3

will be logged above 126C (259F).

- Differential cold

mode speed limiting

The rear axle oil temperature sensor also provides the input signal

required for the differential cold mode speed limiting function. The

differential cold mode limits the truck top speed until the oil temperature

is high enough to ensure proper lubrication. Shifting is limited to FIFTH

GEAR when the differential oil temperature is below -4C (25F).

Shifting is limited to SIXTH GEAR when the differential oil temperature

is greater than -4C (25F) and below 24C (75F).

- Solenoid activation

The rear axle oil temperature sensor signal is also used by the

Brake/Cooling ECM as the input that tells the ECM when to energize or

de-energize the rear axle drive pump diverter solenoid (see the previous

Visual) and the final drive diverter valve solenoid (see Visual No. 38).

CAPACITACIN FINNING CHILE

ABRIL 2003

-10Describa los componentes enumerados

1*....................................................

2*....................................................

3*....................................................

4*...................................................

5*...................................................

6*...................................................

6

7*...................................................

1. Differential carrier

suction screen

The rear section of the rear axle cooling pump pulls oil from the

differential carrier sump through the suction screen (1). Oil flows from

the rear pump section to the axle housing.

2. Carrier oil level sight

glass

Two compartments must be filled with oil to fill the rear axle housing; the

carrier housing and the axle housing (see Visual No. 26 STMG-1). The

carrier oil level is checked with a sight glass at location (2). The carrier

housing is drained by removing a magnetic plug from the hole (3).

3. Carrier housing drain

plug hole

4. Axle housing fill and

TCS axle sensor

service hole

5. Housing oil level

sight glass

6. Axle housing drain

plug hole

7. TOS sensors

The axle housing can be filled through one of the two access holes (4).

The TCS axle speed sensors are serviced through these two holes. The

axle housing oil level is checked with a sight glass at location (5). The

axle housing is drained by removing a magnetic plug from the hole (6).

The two Transmission Output Speed (TOS) sensors (7) are located near

the differential bevel gear. The TOS sensors are serviced by removing the

large access cover.

CAPACITACIN FINNING CHILE

ABRIL 2003

-11Describa los componentes enumerados

1*....................................................

6

8

2*....................................................

5

3*....................................................

7

2

4*...................................................

5*...................................................

6*...................................................

3

7*...................................................

8*...................................................

1. Differential carrier

housing suction

tube

2. Differential scavenge

pump outlet

3. Rear axle housing

suction tube

4. Differential bearing

lube supply tube to

filter

5. Differential filter

6. Differential bearing

lube supply port to

differential

7. Final drive bearing

lube supply tube to

diverter valve

8. Final drive filter

Shown is the right inside of the axle housing. The rear section of the rear

axle cooling pump pulls oil from the carrier housing through the tube (1)

and a suction screen located below the differential (see previous Visual).

Scavenged oil from the differential flows to the banjo housing through the

tube (2).

The two front sections of the rear axle cooling pump pull oil from the rear

axle housing through the tube (3) and a suction screen (see Visual

No. 33).

Oil flows from the center pump section through the tube (4), the

differential filter (5), and the port (6) to the differential bearings.

Oil flows from the front pump section through the tube (7), the final drive

diverter valve (see Visuals No. 38 and 40), and the final drive filter (8) to

the final drive bearings.

CAPACITACIN FINNING CHILE

ABRIL 2003

-12Describa los componentes enumerados

1*....................................................

5

2*....................................................

3*....................................................

2

4*...................................................

3

1

5*...................................................

1. Final drive lube

supply tube to

diverter valve

2. Tube to differential

for warming oil

3. Final drive lube

supply tube to filter

4. Final drive filter

5. Left and right final

drive lube supply

tubes

Shown is the top left inside of the axle housing. Oil flows from the front

section of the rear axle cooling pump through the tube (1) to the final

drive diverter valve (see Visuals No. 38 and 40). The diverter valve is

controlled by the Brake/Cooling ECM. When the rear axle oil

temperature is below 60C (140F), the Brake/Cooling ECM energizes a

solenoid on the diverter valve. When the solenoid is energized, oil flows

through the tube (2) and sprays on the differential. The differential warms

the oil through the mechanical action of oil churning by the pinion and

ring gears.

When the rear axle oil temperature is above 60C (140F), the

Brake/Cooling ECM de-energizes the solenoid on the diverter valve.

When the solenoid is de-energized, oil flows from the diverter valve

through the tube (3), the final drive filter (4), and the two tubes (5) to the

final drives and wheel bearings on both sides of the truck.

CAPACITACIN FINNING CHILE

ABRIL 2003

-13Describa los componentes enumerados

1*....................................................

....................................................

....................................................

2*....................................................

....................................................

....................................................

1. Right final drive and

wheel bearing lube

tube

2. Oil baffle

Shown is the right inside of the axle housing. Oil flows through the

tube (1) to the right final drive and wheel bearings. An oil baffle (2) is

installed on both sides of the rear axle. The oil baffle promotes

circulation of oil around the wall of the axle housing, which increases

heat transfer. The oil baffle also prevents overfilling of the final drives

during short side slope and cornering events.

CAPACITACIN FINNING CHILE

ABRIL 2003

-14Describa los componentes enumerados

1*....................................................

2*....................................................

4

3*....................................................

4*...................................................

1. Differential oil filter

Oil flows from the center section of the rear axle cooling pump through

the differential oil filter (1) to the differential bearings.

2. Final drive diverter

valve

Oil flows from the front section of the rear axle cooling pump through the

final drive diverter valve (2) and the final drive oil filter (3) to the final

drives and wheel bearings on both sides of the truck. The diverter valve

is controlled by the Brake/Cooling ECM. When the rear axle oil

temperature is below 60C (140F), the Brake/Cooling ECM energizes

the solenoid (4) on the diverter valve. When the solenoid is energized, oil

sprays on the differential and the differential warms the oil. In relation to

the final drives this fulfills two functions:

3. Final drive oil filter

4. Final drive diverter

valve solenoid

First, the final drives are not overfilled with cold oil.

Second, the elevated level of oil in the bevel gear group reservoir

allows the bevel gear and pinion to churn the oil, causing rapid

mechanical heating of the oil. The goal is to get the oil in the system

up to 60C (140F) as quick as possible so that normal filtering of the

oil and oil circulation through the final drives can occur.

When the rear axle oil temperature is above 60C (140F), the

Brake/Cooling ECM de-energizes the solenoid on the diverter valve.

When the solenoid is de-energized, oil flows through the filter to the final

drives and wheel bearings on both sides of the truck.

CAPACITACIN FINNING CHILE

ABRIL 2003

-15Describa los componentes enumerados

1*....................................................

2*....................................................

2

3*....................................................

Differential oil filter

1. Filter bypass switch

Shown is the differential oil filter. An oil filter bypass switch (1) is

located on the filter housing. The bypass switch provides an input signal

to the Brake/Cooling ECM. The Brake/Cooling ECM sends the signal to

the VIMS, which informs the operator if the filter is restricted. If the

filter is restricted and oil temperature is above 60C (140F), a warning

Category 1 will be logged after 20 seconds. A warning Category 3 will

be logged after 30 minutes.

Differential oil filter

has in-line bypass

Proper oil flow to the bevel gear bearings must be maintained at all times.

Loss of flow or diminished flow will result in rapid bearing burn-up under

high speed vehicle operating conditions. The oil filter for the bevel gear

group is an in-line bypass type. If the filter bypasses, either due to cold

oil or a plugged filter element, the bevel gear group will receive unfiltered

oil. In the case where the filter plugs due to contaminant build up, dirty

oil is better than no oil since the bevel gear group would progress to

catastrophic failure rapidly without oil.

2. Differential oil

pressure sensor

A differential oil pressure sensor (2) is also located on the filter housing.

The pressure sensor also provides an input signal to the Brake/Cooling

ECM. If the differential oil pressure is less than 117 kPa (17 psi) when

the engine speed is above 1250 rpm and the oil temperature is above

60C (140F), a warning Category 3 (DIFF LUBE PRES LO) will be

logged. The minimum pressure allowed changes when engine speeds and

oil temperatures are greater. Differential oil pressure can be measured at

the tap (3).

3. Differential oil

pressure tap

CAPACITACIN FINNING CHILE

ABRIL 2003

-16Describa los componentes enumerados

1*....................................................

1

3

2*....................................................

3*....................................................

Final drive oil filter

1. Filter bypass switch

Shown is the final drive oil filter. An oil filter bypass switch (1) is located

on the filter housing. The bypass switch provides an input signal to the

Brake/Cooling ECM. The Brake/Cooling ECM sends the signal to the

VIMS, which informs the operator if the filter is restricted. If the filter is

restricted and oil temperature is above 60C (140F), a warning

Category 1 will be logged after 20 seconds.

Final drive oil filter

bypasses to sump

When the filter element plugs the unfiltered oil is bypassed back to the

axle housing (sump) rather than being bypassed in-line which could allow

contaminated oil to flow through the wheel bearings. The final drives can

operate for an extended period of time with the filter in the bypass

condition because the primary lubrication of the final drives is by splash

lube.

2. Final drive oil

pressure switch

A final drive oil pressure switch (2) is also located on the filter housing.

The oil pressure switch also provides input signals to the brake/cooling

ECM. The brake/cooling ECM sends the signals to the VIMS, which

informs the operator of the final drive oil pressure. If the final drive oil

pressure is less than 160 kPa (23 psi) when the engine speed is above

1300 rpm and the diverter solenoid is de-energized, a warning Category 1

(FNL LUB PRES LO) will be logged.

3. Final drive oil

pressure tap

Final drive oil pressure can be measured at the tap (3).

-17-

CAPACITACIN FINNING CHILE

ABRIL 2003

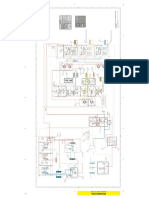

FINAL DRIVE

REACTION

HUB

SECOND REDUCTION

RING GEAR

WHEEL

INNER

THRUST WASHER

FINAL DRIVE

ADAPTER HOUSING

SECOND REDUCTION

CARRIER

SECOND REDUCTION

PLANETARY GEAR

SECOND REDUCTION

SUN GEAR

SPINDLE

AXLE SHAFT

OUTER

THRUST WASHER

FIRST REDUCTION

SUN GEAR

FIRST REDUCTION

CARRIER

FIRST REDUCTION

RING GEAR

FIRST REDUCTION

PLANETARY GEAR

Final Drive

Double reduction

planetary gear final

drive

Shown is a sectional view of the double reduction planetary final drive.

Power is mechanically transmitted from the differential through the axle

shaft to the sun gear of the first reduction planetary. The final drive is a

carrier drive planetary arrangement; therefore, the first and second

reduction ring gears are splined together and grounded to the spindle

through the reaction hub so they don't rotate.

The power input to the first reduction sun gear from the axle shaft causes

rotation of the first reduction planetary gears and carrier and the power is

output at reduced speed and increased torque through the first reduction

carrier. The first reduction carrier is directly connected to the second

reduction sun gear with splines so the power output from the first

reduction planetary is input to the second reduction sun gear. The power

input to the second reduction sun gear causes rotation of the second

reduction planet gears and carrier.

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Farm Machinery & Equipment - W4Dokument37 SeitenFarm Machinery & Equipment - W4bhaskarNoch keine Bewertungen

- Spur 1Dokument1 SeiteSpur 1Wayan E P KsamawatiNoch keine Bewertungen

- Dreadnought Type 2 in 1 Brake EjectorDokument10 SeitenDreadnought Type 2 in 1 Brake EjectorVikk SuriyaNoch keine Bewertungen

- Rajednra 2022 Price List PDFDokument28 SeitenRajednra 2022 Price List PDFMurali YNoch keine Bewertungen

- Air Brakes ManualDokument95 SeitenAir Brakes ManualGeorge Tsakataras100% (1)

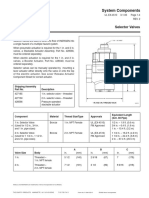

- Ansul: System ComponentsDokument1 SeiteAnsul: System ComponentsingjfhpNoch keine Bewertungen

- Pump A10VO DFR PrincipleDokument25 SeitenPump A10VO DFR Principlemaintenance 2kpb100% (1)

- Mir d245s & d45ks Rev.2Dokument1 SeiteMir d245s & d45ks Rev.2open hartigNoch keine Bewertungen

- Mechanical Engineering: Technical EnglishDokument13 SeitenMechanical Engineering: Technical EnglishLuisVazPatoNoch keine Bewertungen

- BR Shoe RoadDokument1 SeiteBR Shoe RoadBalto CrisNoch keine Bewertungen

- Thuy Luc Drd100-200Dokument27 SeitenThuy Luc Drd100-200ANH LÊNoch keine Bewertungen

- 5 Classification of Brakes 160217042825Dokument39 Seiten5 Classification of Brakes 160217042825manipsg100% (1)

- Valve Definitions: N2 - CL150 RFFE, CS, Trim 8Dokument5 SeitenValve Definitions: N2 - CL150 RFFE, CS, Trim 8Chirag ShahNoch keine Bewertungen

- 01 Technical MapDokument1 Seite01 Technical MapRian JordanNoch keine Bewertungen

- Sce MaticDokument2 SeitenSce Matictyok sajaNoch keine Bewertungen

- 03.hyd System Part1Dokument69 Seiten03.hyd System Part1Samidi100% (5)

- KladivarDokument107 SeitenKladivaranta77Noch keine Bewertungen

- Hydraulic SymbolsDokument7 SeitenHydraulic SymbolsSENANAYAKE S.H.RNoch keine Bewertungen

- Tipos Sellos Bombas FZXDokument2 SeitenTipos Sellos Bombas FZXFernando Pulgar BarillasNoch keine Bewertungen

- PUMPSDokument25 SeitenPUMPScharmaine fosNoch keine Bewertungen

- LKH-35 Centrifugal Pump: Spare Parts ListDokument4 SeitenLKH-35 Centrifugal Pump: Spare Parts ListJavier Conesa OutedaNoch keine Bewertungen

- Type2 - (IEC 60947-4-1)Dokument21 SeitenType2 - (IEC 60947-4-1)011253Noch keine Bewertungen

- Toyota U140F Transmission Repair Manual RM772UDokument163 SeitenToyota U140F Transmission Repair Manual RM772UOktavia IndrianiNoch keine Bewertungen

- Electrical CircuitsDokument12 SeitenElectrical CircuitsSrinath Gadeela100% (3)

- Al4 Automatic TransmissionDokument56 SeitenAl4 Automatic TransmissionDamien Jorgensen100% (2)

- Hydraulic Brake Systems GuideDokument28 SeitenHydraulic Brake Systems GuideMilion dugumaNoch keine Bewertungen

- Maintenance Manual Electric CB en 英语Dokument94 SeitenMaintenance Manual Electric CB en 英语Carlos Bernabe Gonzalez100% (3)

- Construction Features and Operating Principles of Oil Centrifugal PurifierDokument4 SeitenConstruction Features and Operating Principles of Oil Centrifugal PurifierŇel DanNoch keine Bewertungen

- Price ListDokument8 SeitenPrice ListGughhNoch keine Bewertungen

- SR - No. Part No. Description Brand ModelDokument5 SeitenSR - No. Part No. Description Brand Modelramsey222Noch keine Bewertungen