Beruflich Dokumente

Kultur Dokumente

Rigging JSA Rigger

Hochgeladen von

aQiLGunawanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rigging JSA Rigger

Hochgeladen von

aQiLGunawanCopyright:

Verfügbare Formate

Document Number HG-Rig-011 Issued by, Rigging Department Approved by, Director

HaGun Institute

RIGGING RESPONSIBILITY PROCEDURE

1 RIGGING PRACTICES

1.1 SECTION CONTENTS

This section provides basic rigging information for the safe use of slings. Rigging requires careful evaluation because of the wide variety of safety factors which must be considered in each case. These factors include, but are not limited to: size and type of sling, the method of fastening, sheaves, sprockets, and drums, condition of equipment or material, size and shape of load, type of attachment, the lifting environment, weather and atmospheric conditions. Some serious hazards result from overloading, improper hitching or slinging which allow the load to drop or slip; obstructing free movement of loaded sling; and using equipment for a purpose not intended or designed.

1.2 GENERAL REQUIREMENTS FOR RIGGING

1.2.1 SAFE USE OF SLINGS 1.2.1.1 Safe Operating Practice:

Slings that are damaged or defective should not be used. Slings should not be shortened with knots or bolts or other makeshift devices. Sling legs should not be kinked. Slings should not be loaded in excess of their rated capacities. Slings used in a basket hitch should have the loads balanced to prevent slippage. Slings should be securely attached to their loads. Slings should be padded or protected from the sharp edges of their loads. Suspended loads should be kept clear of all obstructions. All personnel should be kept clear of loads about to be lifted and of suspended loads. Hands or fingers should not be placed between the sling and its load while the sling is being tightened around the load. Shock loading is prohibited. A sling should not be pulled from under a load when the load is resting on the sling. Slings should be stored where they will not be damaged by extreme heat, corrosion, being run over, or being kinked.

1.2.2 TYPES OF SLINGS

Slings are available in alloy steel chain, wire rope with fiber core or steel rope core, metal mesh, natural or synthetic fiber rope, or synthetic wedding. Slings should be used in accordance with manufacturers recommendations and regulatory requirements.

Revised: 0 Page 1 of 12 Date: 28 September 2012

Document Number HG-Rig-011 Issued by, Rigging Department Approved by, Director

HaGun Institute

RIGGING RESPONSIBILITY PROCEDURE

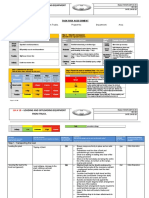

1.2.3 RATED CAPACITY OF SLINGS

Care must be exercised when using tables and charts for slings. The units of measurements need to be noted in each case. Rated capacity may need to be reduced because of the configuration of attachment to load. Rated capacity may need to be reduced because of non-vertical load angel. Rated capacity may need to be reduced because of high or low operating temperatures. Rated capacity may need to be reduced because of end connection and splices. Rated capacity, where there is more than one leg, applies only where the load is distributed evenly between legs. Typical Rigging Arrangements (see following pages) Figure 1 Wire Ropes and Wire Rope Slings Table of Rated Capacities in Tons (2,000 lbs.) Figure 2 Other Wire Rope and Wire Rope Slings Table of Rated Capacities in Tons (2,000 lbs.) Figure 3 Manila Ropes and Manila Rope Slings Table of Rated Capacities in Lbs. Figure 4 Manila Rope and Tackle Table of Rated Capacities in Lbs. Figure 5 Wire Rope Connections Figure 6 Stresses of Lines on Inclined Planes Figure 7 Weights of Materials for Approximating Rigging Loads.

Revised: 0 Page 2 of 12 Date: 28 September 2012

Document Number HG-Rig-011 Issued by, Rigging Department Approved by, Director

HaGun Institute

RIGGING RESPONSIBILITY PROCEDURE

Figure 1 Wire

Rope Slings Table of Rated Capacities in Tons (2000 lbs.)

Revised: 0 Page 3 of 12 Date: 28 September 2012

Document Number HG-Rig-011 Issued by, Rigging Department Approved by, Director

HaGun Institute

RIGGING RESPONSIBILITY PROCEDURE

Figure 2 Other

Wire Rope and Wire Rope Slings Table of Rated Capacities in Tons (2000 lbs.)

Revised: 0 Page 4 of 12 Date: 28 September 2012

Document Number HG-Rig-011 Issued by, Rigging Department Approved by, Director

HaGun Institute

RIGGING RESPONSIBILITY PROCEDURE

Figure 3

Manila Ropes and Manila Rope Slings Table of Rated Capacities in lbs.

Revised: 0 Page 5 of 12 Date: 28 September 2012

Document Number HG-Rig-011 Issued by, Rigging Department Approved by, Director

HaGun Institute

RIGGING RESPONSIBILITY PROCEDURE

Figure 4 Manila

Rope and Tackle Table of Rated capacities in Lbs.

1. 2. 3. 4.

Tables are based on the use of new manila rope and tackle that is in good condition. If sisal rope is used, values in tables should be reduced by one third. Tackle values allow for one snatch block, snatching lead line to engine spool. When using more than one snatch block, add one extra part for each additional snatch block in addition to the number of parts shown for the weight to lift.

Revised: 0 Page 6 of 12 Date: 28 September 2012

Document Number HG-Rig-011 Issued by, Rigging Department Approved by, Director

HaGun Institute

RIGGING RESPONSIBILITY PROCEDURE

Figure 5

Wire Rope Connections

The rated capacity of slings must be reduced according to the percent efficiency of the end connections.

Revised: 0 Page 7 of 12 Date: 28 September 2012

Document Number HG-Rig-011 Issued by, Rigging Department Approved by, Director

HaGun Institute

RIGGING RESPONSIBILITY PROCEDURE

Figure 6

Stress of Lines on inclined Planes

Revised: 0 Page 8 of 12 Date: 28 September 2012

Document Number HG-Rig-011 Issued by, Rigging Department Approved by, Director

HaGun Institute

RIGGING RESPONSIBILITY PROCEDURE

WEIGHT OF STEEL PLATE THICKNESS IN INCHES 3/8 1/2 5/8 3/4 7/8 1 POUNDS PER SQ. FOOT 15.3 20.4 25.5 30.6 35.7 40.8 SQ. FEET PER TON 131 98 79 65 56 49 THICKNESS IN INCHES 1 - 1/8 1 - 1/4 1 - 3/8 1 - 1/2 1 - 3/4 2 POUNDS PER SQ. FOOT 45.9 51.0 56.1 61.2 71.4 81.6 SQ. FEET PER TON 44 39 35.7 32 28 24

MATERIAL

APPROXIMATE WEIGHT PER CU. FOOT, IN POUNDS

Aluminium _____________________________________________________________ 166 Asphalt ________________________________________________________________ 81 Brass ________________________________________________________________ 524 Brick (common) (3 Tons Per Thousand) _____________________________________ 120 Bronze _______________________________________________________________ 534 Concrete (4050 Lbs. Per Cu. Yg.) __________________________________________ 150 Copper _______________________________________________________________ 537 Crushed Rock _______________________________________ (2565 Lbs. Per Cu. Yd.) 95 Dry Earth, Loose _____________________________________ (2052 Lbs. Per Cu. Yd.) 76 Iron Casting __________________________________________________________ 450 Lead _________________________________________________________________ 708 Lumber, Fir, Spruce (2666 Lbs. Per 1000 Bd. Ft.) _______________________________ 32 Lumber, Oak (5166 Lbs. Per 1000 Bd. Ft) _____________________________________ 62 Portland Cement (376 Lbs. Per Barrel) _______________________________________ 94 Steel _________________________________________________________________ 490 Water _______________________________________________________________ 62.5

Table 1.1 Weights of Materials for Approximating Rigging Loads

Revised: 0 Page 9 of 12 Date: 28 September 2012

Document Number HG-Rig-011 Issued by, Rigging Department Approved by, Director

HaGun Institute

RIGGING RESPONSIBILITY PROCEDURE

1.2.4 HAND SIGNALS

Common Used Hand Signals Figure 7 Crane Swinging Beam Hand Signals

Figure 7 Crane Swinging Beam Hand Signals (pt. 1/3)

Revised: 0 Page 10 of 12 Date: 28 September 2012

Document Number HG-Rig-011 Issued by, Rigging Department Approved by, Director

HaGun Institute

RIGGING RESPONSIBILITY PROCEDURE

Figure 7 Crane Swinging Beam Hand Signals (pt. 2/3)

Revised: 0 Page 11 of 12 Date: 28 September 2012

Document Number HG-Rig-011 Issued by, Rigging Department Approved by, Director

HaGun Institute

RIGGING RESPONSIBILITY PROCEDURE

Figure 7 Crane Swinging Beam Hand Signals (pt. 3/3)

Revised: 0 Page 12 of 12 Date: 28 September 2012

Das könnte Ihnen auch gefallen

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Dokument3 SeitenKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNoch keine Bewertungen

- Genie E Series Slab Scissor Lift Operation PDFDokument11 SeitenGenie E Series Slab Scissor Lift Operation PDFRajesh gpNoch keine Bewertungen

- Rock Breaker Self ChecklistDokument1 SeiteRock Breaker Self ChecklistNair R RakeshNoch keine Bewertungen

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Dokument4 SeitenThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNoch keine Bewertungen

- Job Safety Analysis WorksheetDokument7 SeitenJob Safety Analysis WorksheetMohamedSaidNoch keine Bewertungen

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDokument2 SeitenJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNoch keine Bewertungen

- Jsa Loading and Unloading of Pile PipesDokument4 SeitenJsa Loading and Unloading of Pile PipesOsiobe Ewomazino100% (1)

- 09 JSA For Excavation and Blinding at Pump House 1 & 3Dokument4 Seiten09 JSA For Excavation and Blinding at Pump House 1 & 3Hilbrecht De Pedro100% (1)

- Jsa Fan Coil Unites MaintenanceDokument5 SeitenJsa Fan Coil Unites MaintenanceASLAM MULANINoch keine Bewertungen

- Job Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedDokument2 SeitenJob Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedZulfokar FahdawiNoch keine Bewertungen

- JSA-Hydraulic Press Testing For PilesDokument6 SeitenJSA-Hydraulic Press Testing For PilesUMUTNoch keine Bewertungen

- Basic Safety Instructions For All Employees Visiting or Working in The Construction of The HgpepDokument42 SeitenBasic Safety Instructions For All Employees Visiting or Working in The Construction of The Hgpepmalik jahanNoch keine Bewertungen

- Instructions For Using The Risk Assessment FormDokument9 SeitenInstructions For Using The Risk Assessment FormMalik Khuram ShazadNoch keine Bewertungen

- Updated JSA For SAPMTofficeDokument30 SeitenUpdated JSA For SAPMTofficeShaikh Abu bakarNoch keine Bewertungen

- Job Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureDokument2 SeitenJob Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureM Waqas HabibNoch keine Bewertungen

- Jsa For Dismantel of StructureDokument2 SeitenJsa For Dismantel of StructureBaiju SinghNoch keine Bewertungen

- Building De-Dusting JSADokument3 SeitenBuilding De-Dusting JSAJayesh J PillaiNoch keine Bewertungen

- 02JHA On Welding and Gas CuttingDokument8 Seiten02JHA On Welding and Gas CuttingPiyush SinghNoch keine Bewertungen

- JSA - LOAD TEST PILE No. 1Dokument6 SeitenJSA - LOAD TEST PILE No. 1Sanjeet SinghNoch keine Bewertungen

- Job Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Dokument5 SeitenJob Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Madhan KannanNoch keine Bewertungen

- Wire Rope Cutting ChartDokument8 SeitenWire Rope Cutting ChartAkash SharmaNoch keine Bewertungen

- Jsa Insulation WorkDokument20 SeitenJsa Insulation WorkazerNoch keine Bewertungen

- 4.cutting Grinding WeldingDokument5 Seiten4.cutting Grinding WeldingMohammad Fazal KhanNoch keine Bewertungen

- JSA For Erection Modification QSTECDokument7 SeitenJSA For Erection Modification QSTECMohamed NouzerNoch keine Bewertungen

- JSA For The Conveyor BeltDokument1 SeiteJSA For The Conveyor BeltSaklain MustakNoch keine Bewertungen

- Jsa Ducting Rev 00Dokument1 SeiteJsa Ducting Rev 00SRR HSE Department, Sandvik Project,Noch keine Bewertungen

- JSA For Scaffolding Erection Removal Around AT-911Dokument1 SeiteJSA For Scaffolding Erection Removal Around AT-911Equipment Materials100% (1)

- 9 Use of Hand Roller Compactor SafetyDokument2 Seiten9 Use of Hand Roller Compactor SafetyarchieNoch keine Bewertungen

- JOB SAFETY ANALYSIS - Idler Frame StencilingDokument1 SeiteJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNoch keine Bewertungen

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDokument6 SeitenPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNoch keine Bewertungen

- Work Method Statement: Confined SpaceDokument3 SeitenWork Method Statement: Confined SpaceKarthik babu0% (1)

- Covering Holes Tailgate Safety TalkDokument1 SeiteCovering Holes Tailgate Safety TalkBalaji RajasekaranNoch keine Bewertungen

- JSA Erection & Dismantling of ScaffoldingDokument3 SeitenJSA Erection & Dismantling of ScaffoldingMc Evans MagallanesNoch keine Bewertungen

- ARK JSA Manual ExcavationDokument8 SeitenARK JSA Manual ExcavationMohammed Ali QaziNoch keine Bewertungen

- JSA Format Erection of Column 903-C-02,03Dokument5 SeitenJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- Lifting Operations Risk Assessment Crane Risk AssessmentDokument13 SeitenLifting Operations Risk Assessment Crane Risk Assessment9853318441Noch keine Bewertungen

- Daily JSADokument4 SeitenDaily JSAumn_mlkNoch keine Bewertungen

- Job Safety Analysis Erection SiloDokument3 SeitenJob Safety Analysis Erection SiloDanangNoch keine Bewertungen

- Risk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)Dokument3 SeitenRisk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)AmeerHamzaWarraichNoch keine Bewertungen

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADokument2 SeitenJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- 15.tube Bundle Puller.Dokument3 Seiten15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- Nasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetDokument2 SeitenNasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetRaza Muhammad SoomroNoch keine Bewertungen

- Job Hazard Analysis - Granite Surface PlateDokument2 SeitenJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNoch keine Bewertungen

- Job Safety Analysis: How To Use This FormDokument4 SeitenJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- Lifting Hoisting Hazard HuntDokument1 SeiteLifting Hoisting Hazard Hunt曹庆园100% (1)

- SOP SOP0007 Hitachi Electric Jack HammerDokument3 SeitenSOP SOP0007 Hitachi Electric Jack HammerWidya BungaNoch keine Bewertungen

- Job Safety Analysis - Cone ErectionDokument7 SeitenJob Safety Analysis - Cone ErectionMohammed MinhajNoch keine Bewertungen

- Akk Jha Installation of Diesel TankDokument3 SeitenAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- JSA-03 Shed DismantlingDokument3 SeitenJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- RiggingDokument2 SeitenRiggingpruncu.alianmNoch keine Bewertungen

- Job Safety Analysis WorksheetDokument4 SeitenJob Safety Analysis WorksheetSAHIL SHARMANoch keine Bewertungen

- 14.lifting Operations & Lifting EquipmentDokument28 Seiten14.lifting Operations & Lifting EquipmentbabadapbadapNoch keine Bewertungen

- Jsa PaintDokument2 SeitenJsa PaintKhalid NaseemNoch keine Bewertungen

- Hira - Mobile CraneDokument4 SeitenHira - Mobile CraneSantosh SinghNoch keine Bewertungen

- JS A Excavation Work For Electrical CableDokument3 SeitenJS A Excavation Work For Electrical CableMohammed MinhajNoch keine Bewertungen

- Job Safety Analysis - Overhead Power LinesDokument2 SeitenJob Safety Analysis - Overhead Power Linesrenee100% (2)

- Confine Space at Water TankDokument7 SeitenConfine Space at Water TanknaraNoch keine Bewertungen

- Loading-Unloading-Low-Loader Risk AssmntDokument10 SeitenLoading-Unloading-Low-Loader Risk AssmntStansilous Tatenda NyagomoNoch keine Bewertungen

- Lashing SystemDokument3 SeitenLashing SystemAekJay100% (1)

- 2.1 DRH Literary Translation-An IntroductionDokument21 Seiten2.1 DRH Literary Translation-An IntroductionHassane DarirNoch keine Bewertungen

- Dept & Sem: Subject Name: Course Code: Unit: Prepared byDokument75 SeitenDept & Sem: Subject Name: Course Code: Unit: Prepared by474 likithkumarreddy1Noch keine Bewertungen

- Trading Journal TDA Branded.v3.5 - W - Total - Transaction - Cost - BlankDokument49 SeitenTrading Journal TDA Branded.v3.5 - W - Total - Transaction - Cost - BlankChristyann LojaNoch keine Bewertungen

- PronounsDokument6 SeitenPronounsHải Dương LêNoch keine Bewertungen

- New Microsoft Office Word DocumentDokument5 SeitenNew Microsoft Office Word DocumentSukanya SinghNoch keine Bewertungen

- P66 M10 CAT B Forms and Docs 04 10Dokument68 SeitenP66 M10 CAT B Forms and Docs 04 10VinayNoch keine Bewertungen

- Case Study To Find Tank Bulging, Radial Growth and Tank Settlement Using API 650Dokument15 SeitenCase Study To Find Tank Bulging, Radial Growth and Tank Settlement Using API 650Jafer SayedNoch keine Bewertungen

- Rs2-Seamanship (Inc Anchoring, Mooring, Berthing, Pilot Ladder)Dokument19 SeitenRs2-Seamanship (Inc Anchoring, Mooring, Berthing, Pilot Ladder)Mdpn. Salvador67% (3)

- Business Plan: Muzammil Deshmukh, MMS From Kohinoor College, MumbaiDokument6 SeitenBusiness Plan: Muzammil Deshmukh, MMS From Kohinoor College, MumbaiMuzammil DeshmukhNoch keine Bewertungen

- Chestionar 2Dokument5 SeitenChestionar 2Alex AndruNoch keine Bewertungen

- Reference by John BatchelorDokument1 SeiteReference by John Batchelorapi-276994844Noch keine Bewertungen

- Advanced Physiotherapeutic SyllabusDokument1 SeiteAdvanced Physiotherapeutic SyllabusAnup SharmaNoch keine Bewertungen

- Ariba Collaborative Sourcing ProfessionalDokument2 SeitenAriba Collaborative Sourcing Professionalericofx530Noch keine Bewertungen

- Ankle Injury EvaluationDokument7 SeitenAnkle Injury EvaluationManiDeep ReddyNoch keine Bewertungen

- Shaqlawa Technical College: IT DepartmentDokument20 SeitenShaqlawa Technical College: IT Departmentbilind_mustafaNoch keine Bewertungen

- Empanelled Hospitals List Updated - 06-12-2022 - 1670482933145Dokument19 SeitenEmpanelled Hospitals List Updated - 06-12-2022 - 1670482933145mechmaster4uNoch keine Bewertungen

- English For General SciencesDokument47 SeitenEnglish For General Sciencesfauzan ramadhanNoch keine Bewertungen

- GA Power Capsule For SBI Clerk Mains 2024 (Part-2)Dokument82 SeitenGA Power Capsule For SBI Clerk Mains 2024 (Part-2)aa1904bbNoch keine Bewertungen

- 16 Personalities ResultsDokument9 Seiten16 Personalities Resultsapi-605848036Noch keine Bewertungen

- Channel & Lomolino 2000 Ranges and ExtinctionDokument3 SeitenChannel & Lomolino 2000 Ranges and ExtinctionKellyta RodriguezNoch keine Bewertungen

- Atom SDDokument5 SeitenAtom SDatomsa shiferaNoch keine Bewertungen

- 1 Prof Chauvins Instructions For Bingham CH 4Dokument35 Seiten1 Prof Chauvins Instructions For Bingham CH 4Danielle Baldwin100% (2)

- SRS Document Battle Royale Origins - V2Dokument36 SeitenSRS Document Battle Royale Origins - V2Talha SajjadNoch keine Bewertungen

- Work Site Inspection Checklist 1Dokument13 SeitenWork Site Inspection Checklist 1syed hassanNoch keine Bewertungen

- Wins Salvacion Es 2021Dokument16 SeitenWins Salvacion Es 2021MURILLO, FRANK JOMARI C.Noch keine Bewertungen

- Chapter 13Dokument15 SeitenChapter 13anormal08Noch keine Bewertungen

- Four Hour Body Experiment Tracker TemplateDokument4 SeitenFour Hour Body Experiment Tracker Templatechanellekristyweaver100% (1)

- PR Earth Users Guide EMILY1Dokument2 SeitenPR Earth Users Guide EMILY1Azim AbdoolNoch keine Bewertungen

- VLT 6000 HVAC Introduction To HVAC: MG.60.C7.02 - VLT Is A Registered Danfoss TrademarkDokument27 SeitenVLT 6000 HVAC Introduction To HVAC: MG.60.C7.02 - VLT Is A Registered Danfoss TrademarkSamir SabicNoch keine Bewertungen

- Modified Airdrop System Poster - CompressedDokument1 SeiteModified Airdrop System Poster - CompressedThiam HokNoch keine Bewertungen