Beruflich Dokumente

Kultur Dokumente

Indax Grating

Hochgeladen von

MuTe JameeLa BimbimShopCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Indax Grating

Hochgeladen von

MuTe JameeLa BimbimShopCopyright:

Verfügbare Formate

Industrial Access Systems

Grid Grating and Components

A division of Korvest Ltd

GRATING

GRATING

Table of Contents

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Introduction Surface Finish Grating Components Indax Grating Identification Codes Panel Width & Load Bearing Bars Guide to Selection of Grating Types Safe Loads & Deflections Manufacturing Tolerances Grating Terminology Indax Grating Installation Details Indax Grating Fastening Details Stair Tread Types Tread Dimensions Installation

1 1 2-4 5 6 7 8 - 12 14 15 - 17 19 - 20 21 22 - 23 24 25

GRATING

1. Introduction

Indax supply a wide range of steel grid grating products, stair treads, expanded mesh, roof walkways and fibreglass reinforced products including fibreglass grating and handrail components and associated products. We also supply fabricated handrail panels and handrail components including stanchions, bends and self closing gates. A product with a wide range of applications, Indax Grating can be used in industry as walkway flooring or as screens, drain covers and stairways. Indax supplies grid grating fabricated to customers specifications, including cut outs, banding and kick plates. Alternatively we can supply full sheets, in black or galvanised finishes.

2. Surface Finish

Indax Grating is available in a choice of two finishes: 1. Hot Dip Galvanised Indax has its own in-house galvanising plant thus enabling quicker turnaround times. The hot dip galvanising process produces a durable, abrasion resistant coating of metallic zinc and zinc-iron alloy layers metallurgically bonded to the steel base, at a bath temperature of 450C. All galvanising conforms to Australian/New Zealand Standard AS/NZS 4680:2006 Hot-dip galvanized (zinc) coatings on fabricated ferrous articles. 2. Untreated (ungalvanised) Untreated (ungalvanised) full sheets or panels can be supplied to customers who wish to fabricate their own panels to their own specifications.

Industrial Access Systems

GRATING

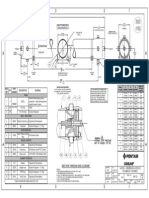

3. Grating Components

Wid

th

Le

ng

th

Banding

Thickness of Web Thickness of Flange

Pitch of Cross Bar Cross Bar Pitch of Load Bearing Bar

Load Bearing Bar

Pitch of Load Bearing Bar

The centre distance between two adjacent load bearing bars is called the pitch of the load bearing bar. The standard pitch is 30mm (Series 1), 40mm (Series 2) & 60mm (Series 3).

Pitch of Cross Bar

The centre distance between two adjacent cross bars is called the pitch of the cross bar. The standard is 100mm. 50mm is available on request.

Twisted Cross Bar

Industrial Access Systems

GRATING

3. Grating Components

(continued)

Load Bearing Bar Shapes

Indax Grating grid grating is manufactured in three different load bearing bar section shapes - I bar, flat bar and serrated bar. I Bar This is usually supplied when a load bearing bar thickness of 5 mm is specified. The load bearing bar has a section shape in the form of an I where the flange has a thickness of 5 mm and the web 3 mm. The advantage of an I bar section over a rectangular section is that for the same strength, the I bar is lighter.

Flat Bar

The load bearing bar has a rectangular section shape and is available in a broad range of heights.

I Bar grating

I Bar section

Flat load bearing bar section shapes

Flat Bar grating

Industrial Access Systems

GRATING

3. Grating Components

(continued)

25

32

5 5

Serrated load bearing bar sections Serrated load bearing bar grating

Serrated Flat Load Bearing Bar

This load bearing bar has a rectangular section with a serrated pattern rolled into the top surface. The serrations provide an excellent nonslip surface and, because they are rolled in, there are no sharp edges.

GRATING

4. Indax Grating Identification Codes

KGA, KGB, KGC etc signify the series. This example shows the KGA series. KGA = Series 1 (30mm load bearing bar pitch with 100mm cross bar pitch). KGB = Series 1 (30mm load bearing bar pitch with 50mm cross bar pitch). KGC = Series 2 (40mm load bearing bar pitch with 100mm cross bar pitch). KGD = Series 2 (40mm load bearing bar pitch with 50mm cross bar pitch). KGE = Series 3 (60mm load bearing bar pitch with 100mm cross bar pitch). KGF = Series 3 (60mm load bearing bar pitch with 50mm cross bar pitch). Size of load bearing bar (height & thickness). In this example the height of the load bearing bar is 32 mm and thickness is 3 mm. Load bearing bar pitch (spacing). Series One = 30mm, Series Two = 40mm & Series Three = 60mm

KGA 323 30 100 FB G

Designates the surface treatment. G = Galvanised U = Untreated Designates the shape of load bearing bars. FB = Flat Bar IB = I Bar SEFB = Serrated Edge Flat Bar Designates the cross bar pitch or spacing. For example 100 indicates a pitch of 100mm.

Industrial Access Systems

GRATING

5. Panel Width and Load Bearing Bars

Relationship Between Panel Width and the Number and Size of Load Bearing Bars

Note: The panel widths shown in this table are based on a load bearing bar thickness of 5 mm. For a load bearing bar thickness of 3 mm, the panel widths shown must be reduced by 2 mm.

Industrial Access Systems

GRATING

6. Guide to Selection of Grating Type

Maximum Recommended Spans (mm) for Various Grid Sizes and Loads.

Light and Medium Duty

Heavy Duty

Industrial Access Systems

GRATING

7. Safe Loads and Deflections

Industrial Access Systems

GRATING

7. Safe Loads and Deflections

(continued)

Industrial Access Systems

GRATING

7. Safe Loads and Deflections

(continued)

10

Industrial Access Systems

GRATING

7. Safe Loads and Deflections

(continued)

Industrial Access Systems

11

GRATING

7. Safe Loads and Deflections

(continued)

12

Industrial Access Systems

GRATING

Industrial Access Systems

13

GRATING

8. Manufacturing Tolerances

Load bearing bar lean

width

1/200 of width

load bearing bar

1/200 of width

Longitudinal bow

Transverse bow

Cross bar spacing and alignment

Overall dimensions and squareness

14

Industrial Access Systems

GRATING

9. Grating Terminology

Load Bearing Bar

A load carrying bar spanning across support members.

Cross Bar

Round or square twisted bar welded at 90 degrees to the load bearing bars.

Edge Bar (Banding Bar)

A trimming bar, usually of the same height as the load bar and welded to the load bar. Often an edge bar is used to trim around cutouts. Banding bars are welded with a 3 mm fillet weld (min) to; every 5th load bearing bar - series 1 grating every 4th load bearing bar - series 2 grating every 3rd load bearing bar - series 3 grating

Length of Panel (Span)

Overall dimension of the panel as measured parallel to the load bearing bars.

Width of Panel

Overall dimension of the panel as measured in a direction perpendicular to the load bearing bars. The width of the panel will always be to the nearest load bearing bar unless otherwise stipulated on the order.

Industrial Access Systems

15

GRATING

9. Grating Terminology

(continued)

Nosing

A component attached to the front or leading edge of the stair tread. Its purpose is to minimise slippage.

Kick Plate

A heavy plate or bar which (when specified) is welded to the ends or sides of the assembly and around cutouts. Its purpose is to stop feet from slipping off the edge.

Serrations

Notches or corrugations formed into the top edge of the load bearing bars. Their purpose is to minimise slippage.

16

Industrial Access Systems

GRATING

9. Grating Terminology

(continued)

Cut Outs

Sections of the grating removed to allow other components to pass through eg. pipes, structural elements, handrails etc.

Gross Area

The area calculated using the overall width and the overall length.

Industrial Access Systems

17

GRATING

10. Indax Grating Installation Details

10.0

10.0

10.0

10.0

10.0

10.0

minimum clearance is equal to support angle thickness

15.0

support angle

Industrial Access Systems

19

GRATING

10. Indax Grating Installation Details

(continued)

10.0

load bearing bar

10.0

load bearing bar

20

Industrial Access Systems

GRATING

11. Indax Grating Fastening Details

When attaching gratings to supporting steelwork, the most positive fixing method, and by far the most economical, is to employ on-site welding. Where panels are required to be removable or where surface treatment of the grating (eg. galvanising) may be damaged, it is recommended that Indax Grating fixing clips are employed. Indax Grating fixing clips are supplied as standard with a zinc-plated finish. Where there is no lateral restraint provided by the support structure, a minimum of four clips per panel must be used to restrain floor panels. Where larger panels are to be fixed, it is advisable to use extra clips at mid span or on any available intermediate supports.

Welding Recommended for all permanently installed gratings, and for gratings that are to be removed only at infrequent intervals.

Saddle Clip - Type B This can be secured quickly and safely by a single person, working from the floor surface.

Note: In order to reduce the risk of accidents occurring, Indax recommend that, where panels are used on site as a means of providing temporary access during erection, they should be lightly tack-welded to the supporting steelwork. Due to constant traffic, unfixed panels have a tendency to slowly drift away from their supports with the eventual result that the panels may tip over under the weight of a person. When a group of panels are in their correct position they should be fixed immediately using one of the recommended methods.

Industrial Access Systems

21

GRATING

12. Stair Tread Types

Although Indax Grating stair treads can be fabricated to suit specific individual size requirements, cost savings can be taken advantage of by selecting standard lengths and widths. The majority of Indax Grating standard treads are fabricated using KGA255/30/IB (25 x 5 I section load bearing bar) and KGA325/30/IB (32 x 5 I section load bearing bar).

KGT1

Welded fixing Banded ends No nosing

KGT2

Bolted fixing Holed end plates No nosing

KGT3

Welded fixing Banded ends Floor plate nosing

22

Industrial Access Systems

GRATING

12. Stair Tread Types

(continued)

KGT4

Bolted fixing Holed end plates Floor plate nosing

KGT5

Welded fixing Banded ends Abrasive nosing

KGT6

Bolted fixing Holed end plates Abrasive nosing

Industrial Access Systems

23

GRATING

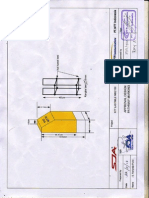

13. Tread Dimensions

load bearing bar

cross bar

nosing length

width

24

Industrial Access Systems

pitch 30 mm

GRATING

14. Installation

Bolting Type

Bolted installation

Welding Type

Welded installation

Industrial Access Systems

25

Industrial Access Systems

GRATING

Grid Grating and Components

South Australia - Head Office

574 Prospect Road, Kilburn, SA 5084 PO Box 306, Enfield Plaza, SA 5085 Phone: 08 8360 4545 Fax: 08 8360 4595 Email: indax@korvest.com.au Website: korvest.com.au

Queensland

5/125 Kerry Rd Archerfield Queensland, 4108 Phone: 07 3320 7800 Fax: 07 3216 6861 Email: qld.sales@indax.com.au

Western Australia

12 Vale Street Malaga Western Australia, 6090 Phone: 08 9249 7966 Fax: 08 9249 7855 Email: indax@korvest.com.au

A division of Korvest Ltd

Sept 10

Das könnte Ihnen auch gefallen

- S 306Dokument15 SeitenS 306MuTe JameeLa BimbimShopNoch keine Bewertungen

- A Guidebook To Particle Size AnalysisDokument32 SeitenA Guidebook To Particle Size Analysisghandri1986Noch keine Bewertungen

- Dayton Snap Tie Prod DataDokument1 SeiteDayton Snap Tie Prod DataMuTe JameeLa BimbimShopNoch keine Bewertungen

- Tozen Flexible JointDokument1 SeiteTozen Flexible JointMuTe JameeLa BimbimShopNoch keine Bewertungen

- Data SheetsDokument8 SeitenData SheetsMuTe JameeLa BimbimShopNoch keine Bewertungen

- HSE AnalysistoolDokument5.459 SeitenHSE AnalysistoolwskrebNoch keine Bewertungen

- Multiport Specs 4inDokument1 SeiteMultiport Specs 4inMuTe JameeLa BimbimShopNoch keine Bewertungen

- Tozen Flexible JointDokument1 SeiteTozen Flexible JointMuTe JameeLa BimbimShopNoch keine Bewertungen

- DWG REF QTY Number Description Material Shell: Order SectionDokument2 SeitenDWG REF QTY Number Description Material Shell: Order SectionRamanNegiNoch keine Bewertungen

- 5 Pipe FittingsDokument100 Seiten5 Pipe FittingsHaroon GhaniNoch keine Bewertungen

- Snappy OutletDokument3 SeitenSnappy OutletMuTe JameeLa BimbimShopNoch keine Bewertungen

- ISO14001 (English)Dokument1 SeiteISO14001 (English)MuTe JameeLa BimbimShopNoch keine Bewertungen

- Idrabel Tank CleaningDokument8 SeitenIdrabel Tank CleaningMuTe JameeLa BimbimShopNoch keine Bewertungen

- Thomas ConveyorDokument4 SeitenThomas ConveyorMuTe JameeLa BimbimShopNoch keine Bewertungen

- Hazardous (Classified) LocationsDokument6 SeitenHazardous (Classified) LocationsMuTe JameeLa BimbimShopNoch keine Bewertungen

- Annex General ConditionDokument17 SeitenAnnex General ConditionMuTe JameeLa BimbimShopNoch keine Bewertungen

- Further ReadingDokument2 SeitenFurther ReadingMuTe JameeLa BimbimShopNoch keine Bewertungen

- Software DeveloperDokument1 SeiteSoftware DeveloperMuTe JameeLa BimbimShopNoch keine Bewertungen

- C Series: Air PumpDokument1 SeiteC Series: Air PumpMuTe JameeLa BimbimShopNoch keine Bewertungen

- Remote Controlled Tank Cleaning Tractor C/W Onboard PumpDokument1 SeiteRemote Controlled Tank Cleaning Tractor C/W Onboard PumpMuTe JameeLa BimbimShopNoch keine Bewertungen

- Company ProfileDokument14 SeitenCompany ProfileMuTe JameeLa BimbimShopNoch keine Bewertungen

- Snappy OutletDokument3 SeitenSnappy OutletMuTe JameeLa BimbimShopNoch keine Bewertungen

- Revisi Approval PatokDokument2 SeitenRevisi Approval PatokMuTe JameeLa BimbimShopNoch keine Bewertungen

- Higher Algebra - Hall & KnightDokument593 SeitenHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- C Series: Air PumpDokument1 SeiteC Series: Air PumpMuTe JameeLa BimbimShopNoch keine Bewertungen

- Estimasi Biaya Services dan Spare Part MotorDokument1 SeiteEstimasi Biaya Services dan Spare Part MotorMuTe JameeLa BimbimShopNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Limo GaugeDokument3 SeitenLimo Gaugeajaysharma19686191Noch keine Bewertungen

- 22 Cryometrix Ultra Low Temp Freezers - End UserDokument11 Seiten22 Cryometrix Ultra Low Temp Freezers - End Userapi-220622714Noch keine Bewertungen

- Univan Hs PrimerDokument1 SeiteUnivan Hs PrimerWorapat Puttakasem0% (1)

- Mazas de Ruedas Larrique RulemanesDokument23 SeitenMazas de Ruedas Larrique RulemanesPaisaje SilenciosoNoch keine Bewertungen

- Farnsworth House SummaryDokument6 SeitenFarnsworth House SummaryAshtonNoch keine Bewertungen

- Concrete Mix Design Workshop-Group 3.1Dokument18 SeitenConcrete Mix Design Workshop-Group 3.1Chuckie EntocNoch keine Bewertungen

- Solution Manual Heat and Mass Transfer A Practical Approach 2nd Edition Cengel CHDokument62 SeitenSolution Manual Heat and Mass Transfer A Practical Approach 2nd Edition Cengel CHJohn A. CenizaNoch keine Bewertungen

- Wadgaon SiDokument42 SeitenWadgaon SisagarrakeshNoch keine Bewertungen

- Non-Ferrous Alloys and Structure-Properties RelationshipsDokument12 SeitenNon-Ferrous Alloys and Structure-Properties RelationshipstareasgratisNoch keine Bewertungen

- Composite Beam Bimetallic StripDokument4 SeitenComposite Beam Bimetallic StripBunkun15Noch keine Bewertungen

- ClimalifeDokument5 SeitenClimalifeVicente AlarconNoch keine Bewertungen

- Nitokit Surface SealantDokument4 SeitenNitokit Surface SealanttalatzahoorNoch keine Bewertungen

- Waste Paper Ash as Cement Replacement in ConcreteDokument84 SeitenWaste Paper Ash as Cement Replacement in ConcreteBikila M. Kejela100% (5)

- Ce2202 - Mechanics of FluidsDokument3 SeitenCe2202 - Mechanics of FluidsPrashant GaradNoch keine Bewertungen

- Study On The Corrosive Nature of Soil Towards The Buried-StructuresDokument5 SeitenStudy On The Corrosive Nature of Soil Towards The Buried-Structurespatrick6364Noch keine Bewertungen

- 1 - Final Attic Stock MonitoringDokument1 Seite1 - Final Attic Stock MonitoringJQ INTERNATIONAL CONSTRUCTION COMPANYNoch keine Bewertungen

- 2014 - 11 - Chemical Composition of Ductile Iron PDFDokument24 Seiten2014 - 11 - Chemical Composition of Ductile Iron PDFfelipeNoch keine Bewertungen

- Science GR 345 1st Quarter MG Bow 1Dokument10 SeitenScience GR 345 1st Quarter MG Bow 1api-359551623Noch keine Bewertungen

- Nabertherm TR 60 Operating Instructions Manual 88Dokument88 SeitenNabertherm TR 60 Operating Instructions Manual 88richard100% (1)

- Method of Statement For Sealing Off The Unused Existing Slab OpeningDokument3 SeitenMethod of Statement For Sealing Off The Unused Existing Slab OpeningAzumiNoch keine Bewertungen

- Aluminium GMAW GuideDokument32 SeitenAluminium GMAW GuideDaniel Salinas100% (2)

- Laplace Transform Problems in Heat Transfer and Mass TransferDokument7 SeitenLaplace Transform Problems in Heat Transfer and Mass TransferMuhammad Irfan MalikNoch keine Bewertungen

- Designing High-Lift Airfoils Using Inverse Potential FlowDokument25 SeitenDesigning High-Lift Airfoils Using Inverse Potential Flowmarco_cj_orgNoch keine Bewertungen

- Anvil Pipe Hanger Catalog 2009Dokument236 SeitenAnvil Pipe Hanger Catalog 2009Roger DawkinsNoch keine Bewertungen

- Prevent Heat Exchanger Corrosion with PoluAl XT CoatingDokument2 SeitenPrevent Heat Exchanger Corrosion with PoluAl XT CoatingOlaf MartingNoch keine Bewertungen

- GTU BE Semester VII Refrigeration and Air Conditioning ExamDokument2 SeitenGTU BE Semester VII Refrigeration and Air Conditioning ExamYash PamnaniNoch keine Bewertungen

- Piping Materials SpecificationDokument53 SeitenPiping Materials SpecificationclintNoch keine Bewertungen

- QL - Sound Absorbent (Eng)Dokument2 SeitenQL - Sound Absorbent (Eng)PT MarineNoch keine Bewertungen

- X854Dokument10 SeitenX854RimNoch keine Bewertungen

- Powered Vegetable Cutting Machine RDokument36 SeitenPowered Vegetable Cutting Machine RMubarak ShaikNoch keine Bewertungen