Beruflich Dokumente

Kultur Dokumente

PVCvs

Hochgeladen von

9236162548Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PVCvs

Hochgeladen von

9236162548Copyright:

Verfügbare Formate

Back to the Future, Cast Iron vs. P.V.C.

By Joseph P. Guzzo

Recently there has been some movement to eliminate the code requirement for the use of cast iron and copper pipe and fittings for storm and sanitary drainage and venting for non- residential purposes, and to allow the unrestricted use of P.V.C. and A.B.S. pipe and fittings in all buildings. The proposal was prompted by two members of the administration for the Plumbing Board. They organized a special public hearing on October 18, 2006 at Malden City Hall. Many people either directly or indirectly associated with the plumbing industry attended this hearing to listen and to voice their opinion on this very debatable subject. Most of the people I heard that spoke in opposition to this proposal focused on the dangers of P.V.C. and A.B.S. in relation to fire and smoke. Industry leaders, manufacturers reps., and a Professor from M.I.T. spoke in length about fire safety. Without getting into very technical terms and to keep it simple, basically what they said was by allowing the unrestricted use of P.V.C. in all buildings would be like adding fuel to the fire. So explains the argument that much of the contents of commercial space is made up of some sort of plastic. Although just about everything built must meet some sort of fire rating standard, not to mention the space itself must meet strict fire safety codes. One Plumbing Inspector spoke in favor saying that F.O.G. (fats, oil, and grease) eats cast iron pipe and fittings. My declaration took a very different angle, the lost art of plumbing. First of all I am not completely opposed to P.V.C. etc, it has many good uses. In fact P.V.C has proven to perform better than cast iron and copper in some applications, most of which are already allowed in the code, like photo labs, bar sinks, and beauty salons. The interesting part of this is that even though P.V.C. may perform better it is still only an option. You do not have to use P.V.C. in any of those locations. Only section 10.13 Special Wastes (acid) requires the use of very specific pipe and fittings, most are made of some sort of plastic. From the very beginning P.V.C. was marketed as a time saver, a quicker easier way to get the job done. That was and still is the mind set, even with the general public. Many plumbers feared it would be too easy and would encourage homeowners and unlicensed contractors to perform their own plumbing. Since that time there has been a virtual explosion of do it yourselfers. It is impossible to avoid and very difficult to control. This saturation of handymen and you can do anything attitude cannot be totally blamed on P.V.C. But in the plumbing industry it certainly is part of it. After all how many homeowners have ever attempted to pack and pour a four inch joint. For plumbers, P.V.C. is considered much faster to install than cast iron. And thats not completely a bad thing. But with haste workmanship sometimes suffers. That is what I see more with P.V.C. than anything, poor workmanship on almost a daily basis. Fittings glued in crooked, leaks, fitting that pull apart right in your hands, no hangers, nail holes, plumbers that have never bought a can of cleaner in their career, you name it I have seen it. Is the workmanship any better with cast iron and copper pipe? Not always. But it seems that type of work is at a higher level. Yes it takes more time to put cast iron and copper together, in my opinion thats a good thing. If I could describe it in a word I would just say its more professional. I cannot envision P.V.C. in a restaurant, a hospital or an

industrial building, it just doesnt belong there and doubt any architect or engineer would spec it, which only adds to the debate. You would think that the Plumbing Board would have much more important issues to deal with right now, rather than wasting time on this two person fishing expedition. One of which is continuing education for all plumbers. You remember the law that was passed two years ago? It must be buried under all those P.V.C. fire reports. Or how about getting the code revisions back to a legitimate code committee where they belong. All the major professional national plumbing codes use committees, and extensive input for their revision process, unlike 248 C.M.R. that uses one person sitting at his computer making so called grammatical changes. Have you ever tried to read these so called grammatical changes? I keep repeating that (grammatical changes) because thats what they claim they are anytime I ask. Well unless you can read and understand the hermitian matrix, you probably couldnt. You could try like I did, but you most likely will give up when you run out of migraine pills. Thats if you could even get hold of the top secret novel. I happened to find one on the sidewalk in front of my house. Because of this I allege they have been making much more than grammatical changes, hoping no one would notice. You see the P.V.C. change may have been noticed. I broke into plumbing when I was twelve years old, going to work with my Dad during summers. One of my first jobs was melting and pouring lead in the basement of a twelve unit apartment building in Charlestown. Six plumbers slinging 4 extra heavy cast iron pipe around like twigs. Ready for a Pour, the orders barked. Ill never forget it, and can still smell it. They taught me how to properly pack and caulk a joint. I learned how to clean fittings and solder. And when the rough plumbing was complete, for me anyway it looked better than any finished plumbing job. When I took my test, I had to pack a four inch joint, and solder a 1 1/2 copper male adapter with the socket faced down so the solder would pull in. All while a very stern State Examiner closely watched. I still have all of my caulking and packing irons. My Dad still has his lead wiped joint when he took his test in the 50s. My Son is now a Journeyman Plumber, and soon will be taking his masters exam in front of a computer screen. I can picture it now as my Grandchildren are explained the families plumbing history. Great Granddads lead joint, Granddads old irons, and for Dad, among all the high tech mechanical tools, a can of glue and cleaner and a hack saw. Call me old fashioned or sentimental, believe me I have been called much worse. Just dont call me out of touch. I own and operate just about all of todays modern gadgets. And I have used all of todays high tech plumbing and heating products in my own home. Including P.E.X, C.S.S.T., and yes I used P.VC. Like I said it has its residential applications. I just think theres something to be said about longevity. Change for the better is good. But change just for the sake of change, or to diminish even the state of mind of a professional trade is bad, very bad.

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 350 360 370 SpecDokument4 Seiten350 360 370 SpecJerNoch keine Bewertungen

- Aditya Tetra Firdaussyah: Personal InformationDokument3 SeitenAditya Tetra Firdaussyah: Personal InformationAditya Tetra FirdaussyahNoch keine Bewertungen

- Catawissa BrochureDokument12 SeitenCatawissa Brochurepacho916Noch keine Bewertungen

- Declaration of Originality PDFDokument1 SeiteDeclaration of Originality PDFSaurabh K AgarwalNoch keine Bewertungen

- Username Passw - Not A Member? Please: Top of Form 8552297aa84734 9 - 2 1Dokument13 SeitenUsername Passw - Not A Member? Please: Top of Form 8552297aa84734 9 - 2 1Priya Singh100% (1)

- Huin - 2004 - Managing Deployment of ERP Systems in SMEs Using Multi-AgentsDokument7 SeitenHuin - 2004 - Managing Deployment of ERP Systems in SMEs Using Multi-AgentsStan SmithNoch keine Bewertungen

- Iloilo City Regulation Ordinance 2005-071Dokument5 SeitenIloilo City Regulation Ordinance 2005-071Iloilo City CouncilNoch keine Bewertungen

- Synopsis Format-Practice SchoolDokument4 SeitenSynopsis Format-Practice SchoolArjun GoyalNoch keine Bewertungen

- JT Series Miter Gearbox: Jacton Electromechanical Co.,LtdDokument32 SeitenJT Series Miter Gearbox: Jacton Electromechanical Co.,LtdWarren LeeNoch keine Bewertungen

- ANSULDokument90 SeitenANSULLUIS FERNANDO HERNANDEZ L�PEZNoch keine Bewertungen

- BS 2S 98Dokument8 SeitenBS 2S 98Lokesh NarasimhaiahNoch keine Bewertungen

- Best Practices For Global MES RolloutsDokument8 SeitenBest Practices For Global MES RolloutsCognizantNoch keine Bewertungen

- 2 OL LXC Ksplice OverviewDokument28 Seiten2 OL LXC Ksplice OverviewMatian DalNoch keine Bewertungen

- Steel Fibers For Fiber-Reinforced ConcreteDokument4 SeitenSteel Fibers For Fiber-Reinforced ConcreteIvan TapiaNoch keine Bewertungen

- CSR Chapter 1,2,3Dokument76 SeitenCSR Chapter 1,2,3Amritpal SinghNoch keine Bewertungen

- Integrating Lean Thinking Into ISO 9001 - A First GuidelineDokument25 SeitenIntegrating Lean Thinking Into ISO 9001 - A First GuidelineakanddevNoch keine Bewertungen

- Steel SolutionsDokument4 SeitenSteel Solutionsgodzillafood100% (1)

- AKA Company ProfileDokument25 SeitenAKA Company ProfileFahim ChapraNoch keine Bewertungen

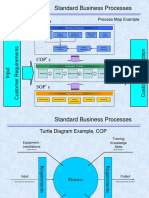

- Process Maps and Turtle Diagrams ExampleDokument2 SeitenProcess Maps and Turtle Diagrams ExampleJohn Oo100% (1)

- Supply Chain TechnologyDokument26 SeitenSupply Chain TechnologyjosetaqueoNoch keine Bewertungen

- Epso Planning enDokument1 SeiteEpso Planning enyiotaliapiNoch keine Bewertungen

- Shemaroo Entertainment LTD Launches Miniplex First of Its Kind Movie Premiere Service On Airtel Digital TV (Company Update)Dokument3 SeitenShemaroo Entertainment LTD Launches Miniplex First of Its Kind Movie Premiere Service On Airtel Digital TV (Company Update)Shyam SunderNoch keine Bewertungen

- Agro Process Flowchart CG and Seed - May 17 - FinalDokument26 SeitenAgro Process Flowchart CG and Seed - May 17 - FinalMarkandeya SatyanarayanaNoch keine Bewertungen

- NIKKI Precision Locknut Catalog 2019Dokument32 SeitenNIKKI Precision Locknut Catalog 2019George babuNoch keine Bewertungen

- 3 Nelson - Up, Up, and Away! - AnswersDokument3 Seiten3 Nelson - Up, Up, and Away! - Answersdmccloy28Noch keine Bewertungen

- ASSHTO Example Strut and TieDokument62 SeitenASSHTO Example Strut and TieSothea Born100% (4)

- 2 A Norma A 185 - 02Dokument5 Seiten2 A Norma A 185 - 02Kenvi AlarconNoch keine Bewertungen

- Dresser Blackhawk Hot Tap-Line Stop ProductsDokument20 SeitenDresser Blackhawk Hot Tap-Line Stop Productskjpatel2Noch keine Bewertungen

- Beumer Overland Belt Conveyor enDokument16 SeitenBeumer Overland Belt Conveyor enIgor San Martín PeñalozaNoch keine Bewertungen

- Steel Techology - Slag Removal and Manipulator Tools NewsletterDokument92 SeitenSteel Techology - Slag Removal and Manipulator Tools NewsletterlouisgatewayNoch keine Bewertungen