Beruflich Dokumente

Kultur Dokumente

Sample Reviewer 2

Hochgeladen von

Emmanuel Linguaje Managbanag IICopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sample Reviewer 2

Hochgeladen von

Emmanuel Linguaje Managbanag IICopyright:

Verfügbare Formate

I.

GENERAL REQUIREMENTS

ADDITION is an extension or increase in floor area or height of a building or structure.

ALLOWABLE STRESS DESIGN is a method of proportioning structural elements such that computed stresses produced in the elements by the allowable stress load combinations do not exceed specified allowable stress (also called working stress design).

ALTER or ALTERATION is any change, addition or modification in construction or occupancy.

APPROVED as to materials and type of construction, refers to approval by the building official as the result of investigation and tests conducted by the building official, or by reason of accepted principles or tests by recognized authorities, technical or scientific organizations.

BUILDING is any structure used or intended for supporting or sheltering any use or occupancy.

BUILDING, EXISTING, is a building erected prior to the adoption of this code, or one for which a legal building permit has been issued.

BUILDING OFFICIAL is the officer or other designated authority charged with the administration and enforcement of this code, or the building officials duly authorized representative.

LOAD AND RESISTANCE FACTOR DESIGN (LRFD) METHOD is a method of proportioning structural elements using load and resistance factors such that no applicable limit state is reached when the structure is subjected to all appropriate load combinations. The term LRFD is used in the design of steel and wood structures.

STRENGTH DESIGN METHOD is a method of proportioning structural elements such that the computed forces produced in the elements by the factored load combinations do not exceed the factored element strength. The term strength design is used in the design of concrete and masonry structures.

STRUCTURE is that which is built or constructed, an edifice or building of any kind, or any piece of work artificially built up or composed of parts joined together in some definite manner.

STRUCTURAL ENGINEER is a registered Civil Engineer with special qualification in the practice of Structural Engineering as recognized by the Board of Civil Engineering of the Professional Regulation Commission of the Philippine Institute of Civil Engineers through the Association of Structural Engineers of the Philippines.

II. GRADING AND EARTHWORK

APPROVAL shall mean that the proposed work or completed work conforms to this section in the opinion of the building official.

AS GRADED is the extent of surface conditions on completion of grading.

BEDROCK is in-place solid rock.

BENCH is a relatively level step excavated into earth material on which fill is to be placed.

BORROW is earth material acquired from an off-site location for use on grading on a site.

CIVIL ENGINEER is a professional engineer licensed to practice in the field of civil engineering.

CIVIL ENGINEERING is the application of the knowledge of the forces of nature, principles of mechanics and the properties of materials to the evaluation, design and construction of civil works.

COMPACTION is the densification of a fill by mechanical means.

EARTH MATERIAL is any rock, natural soil or fill or any combination thereof.

ENGINEERING GEOLOGIST is a licensed geologist experienced and knowledgeable in engineering geology.

ENGINEERING GEOLOGY is the application of geologic knowledge and principles in the investigation and evaluation of naturally occurring rock and soil for use in the design of civil works.

EROSION is the wearing away of the ground surface as a result of the movement of wind, water or ice.

EXCAVATION is the mechanical removal of earth material.

FILL is a deposit of earth material placed by artificial means.

GEOTECHNICAL ENGINEER is an engineer experienced and knowledgeable in the practice of geotechnical engineering.

GEOTECHNICAL ENGINEERING is the application of the principles of soil and rock mechanics in the investigation, evaluation and design of civil works involving the use of earth materials and the inspection or testing of the construction thereof.

GRADE is the vertical location of the ground surface.

GRADE, EXISTING, is the grade prior to grading.

GRADE, FINISH, is the final grade of the site that conforms to the approved plan.

GRADE, ROUGH, is the stage at which the grade approximately conforms to the approved plan.

GRADING is any excavating or filling or combination thereof.

KEY is a designed compacted fill placed in a trench excavated in earth material beneath the toe of a proposed fill slope.

PROFESSIONAL INSPECTION is the inspection required by this code be performed by the civil engineer, geotechnical engineer or engineering geologist. Such inspections include that performed by persons supervised by such engineers or geologists and shall be sufficient to form an opinion relating to conduct of the work.

SITE is any lot or parcel of land or contiguous combination thereof, under the same ownership, where grading is performed or permitted.

SLOPE is an inclined ground surface the inclination of which is expressed as a ratio of vertical distance to horizontal distance.

SOIL is naturally occurring superficial deposits overlying bedrock.

SOILS ENGINEER. See Geotechnical Engineer

SOILS ENGINEERING. See Geotechnical Engineering

TERRACE is a relatively level step constructed in the face of a graded slope surface for drainage and maintenance purposes.

III. GENERAL

ACCESS FLOOR SYSTEM is an assembly consisting of panels mounted on pedestals to provide an under-floor space for the installations of mechanical, electrical, communications or similar systems to serve as an air-supply or return-air plenum.

AGRICULTURAL BUILDING is a structure designed to house farm implements, hay, grain, poultry, livestock or other horticultural products. The structure shall not be a place of human habitation or a place of employment where agricultural products are processed, treated or packaged, nor shall it be a place used by the public.

ALLOWABLE STRESS DESIGN METHOD is a method of proportioning structural elements such that computed stresses produced in the elements by the allowable stress load combinations do not exceed specified allowable stress (also called working stress design).

ASSEMBLY BUILDING is a building or portion of a building for the gathering together of 50 or more persons for such purposes as deliberation, education, instruction, worship, entertainment, amusement, drinking or dining, or awaiting transportation.

AWNING is a shelter supported entirely from the exterior wall of a building.

BALCONY, EXTERIOR, is an exterior floor system projecting from a structure and supported by that structure, with no additional independent supports.

DEAD LOADS consist of the weight of all materials and fixed equipment incorporated into the building or other structure.

DECK is an exterior floor system supported on at least two opposing sides by an adjoining structure and/or posts, piers, or other independent supports.

ESSENTIAL FACILITIES are buildings and other structures that are intended to remain operational in the event of extreme environmental loading from wind or earthquakes.

GARAGE is a building or portion thereof in which motor vehicle containing flammable or combustible liquids or gas in its tank is stored, repaired or kept.

GARAGE, PRIVATE, is a building or portion of a building, not more than 90 sq. m. in area, in which only motor vehicles used by the tenants of the building on the premises are kept or stored.

LIMIT STATE is a condition in which a structure or component is judged either to be no longer useful for its intended function (serviceability limit state) or to be unsafe (strength limit state).

LIVE LOADS are forces or other actions that result from the weight of all building materials, occupants, and their possessions, environmental effects, differential movements, and restrained dimensional changes. Permanent loads are those loads in which variations over time are rare or of small magnitude. All other loads are variable loads.

MARQUEE is a permanent roofed structure attached to and supported by the building and projecting over public property.

OCCUPANCY is the purpose for that a building, or part thereof, is used or intended to be used.

WALLS BEARING WALL is any wall meeting either of the following classifications:

1. Any metal or wood stud wall that supports more than 0.5 KN per linear meter of superimposed load. 2. Any masonry or concrete wall that supports more than 1.0 KN per linear meter superimposed loads, or any such wall supporting its own weight for more than one story.

EXTERIOR WALL is any wall or element of a wall, or any member or group of members, that defines the exterior boundaries or courts of a building and that has a slope of 60 degrees or greater with the horizontal plane.

NONBEARING WALL is any wall that is not a bearing wall

PARAPET WALL is the part of any wall entirely above the roof line.

RETAINING WALL is a wall designed to resist the later displacement of soil or other materials.

IV. WIND LOAD

BASIC WIND SPEED, V is a 3-second gust speed at 10 meters above the ground in Exposure C and associated with an annual probability of 0.02 of being equaled or exceeded (50-year mean recurrence interval).

BUILDING, ENCLOSED, is a building that does not comply with the requirements for open or partially enclosed buildings.

BUILDING, OPEN, is a structure having all walls at least 80% open.

BUILDING, PARTIALLY ENCLOSED is a building that complies with both of the following conditions:

1. The total area of openings in a wall that receives positive external pressure exceeds the sum of the areas of the openings in the balance of the building envelope (walls and roof) by more than 10% and 2. The total area of openings in a wall that receives positive external pressure exceeds 0.5 sq. m. or 1% of the area of that wall, whichever is smaller, and the percentage of openings in the balance of the building envelope does not exceed 20%.

BUILDING, LOW RISE, is an enclosed or partially enclosed building which complies with the following conditions: 1. Mean roof height, h, less than or equal to 18 meters. 2. Mean roof height, h, does not exceed least horizontal dimension.

COMPONENTS AND CLADDING are elements that do not qualify as part of the main wind-force resisting system.

DESIGN FORCE, F, is the equivalent static force to be used in the determination of wind loads for open buildings and other structures.

DESIGN PRESSURE, p, is the equivalent static pressure to be used in the determination of wind loads for buildings.

EFFECTIVE WIND AREA is the area used to determine GCp. For cladding fasteners, the effective wind area shall not be greater than the area that is tributary to an individual fastener.

FLEXIBLE BUILDINGS AND OTHER STRUCTURES are slender buildings and other structures that have a fundamental natural frequency less than 1 Hz. Included are buildings and other structures that have a height, h, exceeding four times the least horizontal dimension.

IMPORTANCE FACTOR, I, is a factor that accounts for the degree of hazard to human life and damage to property.

MAIN WIND-FORCE RESISTING SYSTEM is an assemblage of structural elements assigned to provide support and stability for the overall structure. The system generally receives wind loading from more than one surface.

RECOGNIZED LETERATURE are published research findings and technical papers that are approved by the authority having jurisdiction.

V. EARTHQUAKE

BASE is the level at which the earthquake motions are considered to be imparted to the structure or the level at which the structure as a dynamic vibrator is supported.

BASE SHEAR, V, is the total design lateral force or shear at the base of the structure.

BEARING WALL SYSTEM is a structural system without a complete vertical load-carrying space frame.

BOUNDARY ELEMENT is an element at the edges or openings or at perimeters of shear walls or diaphragms.

BRACED FRAME is an essentially vertical truss system of the concentric or eccentric type that is provided to resist lateral forces.

BUILDING FRAME SYSTEM is an essentially complete space frame that provides support for gravity loads.

CANTILEVERED COLUMN ELEMENT is a column element provided to transfer lateral-force-resisting system that cantilevers from a fixed base and has minimal moment capacity at the top, with lateral forces applied essentially at the top.

COLLECTOR is a member or element provide to transfer lateral forces from a portion of a structure top vertical elements of the lateral-force-resisting system.

COMPONENT is a part or element of an architectural, electrical, mechanical or structural system.

COMPONENT, EQUIPMENT, is a mechanical or electrical component or element that is part of a mechanical and/or electrical system.

COMPONENT, FLEXIBLE, is a component, including its attachments, having a fundamental period greater than 0.06 second.

COMPONENT, RIGID, is a component, including its attachments, having a fundamental period less than or equal to 0.06 second.

CONCENTRICALLY BRACED FRAME is a braced frame in which the members are subjected primarily to axial forces.

DESIGN BASIS GROUND MOTION is that ground motion that has a 10% chance of being exceeded in 50 years as by a site-specific hazard analysis or may be determined by a hazard map. A suite of ground

motion time histories with dynamic properties representative of site characteristics shall be used to represent this ground motion. The dynamic effects of the Design Basis Ground Motion may be represented by the Design Response Spectrum.

DESIGN RESPONSE SPECTRUM is an elastic response spectrum of 5% equivalent viscous damping used to represent the dynamic effects of the Design Basis Ground Motion for the design of structures. This response spectrum may be either a site-specific spectrum based on geologic, tectonic, seismological and soil characteristics associated with a specific site or may be a spectrum.

DESIGN SEISMIC FORCE is the minimum total strength design base shear, factored and distributed.

DIAPHRAGM is a horizontal or nearly horizontal system acting to transmit lateral forces to the verticalresisting elements. The term diaphragm includes horizontal bracing systems.

DIAPHRAGM OR SHEAR WALL CHORD is the boundary element of a diaphragm or shear wall that is assumed to take axial stresses analogous to the flanges of a beam.

DIAPHRAGM STRUT (drag strut, tie, collector) is the element of a diaphragm parallel to the applied load that collects and transfers diaphragm parallel to the applied load that collects and transfers diaphragm shear to the vertical-resisting elements or distributes loads within the diaphragm. Such members may take axial tension or compression.

DRIFT. See story drift

DUAL SYSTEM is a combination of moment-resisting frames and shear walls or braced frames.

ECCENTRICALLY BRACED FRAME (EBF) is a steel-braced frame.

ELASTIC RESPONSE PARAMETERS are forces and deformations determined from an elastic dynamic analysis using an unreduced ground motion representation.

ESSENTIAL FACILITIES are those structures that are necessary for emergency operations subsequent to a natural disaster.

FLEXIBLE ELEMENT or system is one whose deformation under lateral load is significantly larger than adjoining parts of the system.

HORIZONTAL BRACING SYSTEM is a horizontal truss system that serves the same function as a diaphragm.

INTERMEDIATE MOMENT-RESISTING FRAME (IMRF) is a concrete frame.

LATERAL-FORCE-RESISTING SYSTEM is that part of the structural system.

MOMENT-RESISTING SYSTEM is a frame in which members and joints are capable of resisting forces primarily by flexure.

MOMENT-RESISTING WALL FRAME (MRWF) is a masonry wall frame especially detailed to provide ductile behavior.

ORDINARY BRACED FRAME (OBF) is a steel-braced frame or concrete-braced frame.

ORDINARY MOMENT-RESISTING FRAME (OMRF) is a moment-resisting frame not meeting special detailing requirements for ductile behavior.

ORTHOGONAL EFFECTS are the earthquake load effects on structural elements common to the lateralforce-resisting systems along two orthogonal axes.

OVERSTRENGTH is a characteristic of structures where the actual strength is larger than the design strength. The degree of over strength is material-and-system-dependent.

P EFFECT is the secondary effect on shears, axial forces and moments of frame members induced by the vertical loads acting on the laterally displaced building system.

SHEAR WALL is a wall designed to resist lateral forces parallel to the plane of the wall (sometimes referred to as vertical diaphragm or structural wall).

SHEAR WALL-FRAME INTYERACTIVE SYSTEM uses combinations of shear walls and frames designed to resist lateral forces in proportion to their relative rigidities considering interaction between shear walls and frames on all levels.

SOFT STORY is one in which the lateral stiffness is less than 70% of the stiffness of the story above.

SPACE FRAME is a three-dimensional structural system, without bearing walls, composed of members interconnected so as to function as a complete self-contained unit with or without the aid of horizontal diaphragms or floor-bracing systems.

SPECIAL CONCENTRICALLY BRACED FRAME (SCBF) is a steel-braced frame.

SPECIAL MOMENT-RESISTING FRAME (SMRF) is a moment-resisting frame specially detailed to provide ductile behavior.

SPECIAL TRUSS MOMENT FRAME (STMF) is a moment-resisting frame specially detailed to provide ductile behavior.

STORY is the space between levels.

STORY DRIFT is the lateral displacement of one level relative to the level above or below.

STORY DRIFT RATIO is the story drift divided by the story height.

STORY SHEAR, V, is the summation of design lateral forces above the story under consideration.

STRENGTH is the capacity of an element or a member to resist factored load.

STRUCTURE is an assemblage of framing members designed to support gravity loads and resist lateral forces. Structures may be categorized as building structures or nonbuilding structures.

SUBDIAPHRAGM is a portion of a larger wood diaphragm designed to anchor and transfer local forces to primary diaphragm struts and the main diaphragm.

VERTICAL LOAD-CARRYING FRAME is a space frame designed to carry vertical gravity loads.

WALL ANCHORAGE SYSTEM is the system of elements anchoring the wall to the diaphragm and those elements within the diaphragm required to develop the anchorage forces, including sub diaphragms and continuous ties.

WEAK STORY is one in which the story strength is less than 80% of the story above.

VI. CONCRETE

ADMIXTURE is material other than water, aggregate, or hydraulic cement used as an ingredient of concrete and added to concrete before or during its mixing to modify its properties.

AGGREGATE is granular material, such as sand, gravel, crushed stone and iron blast-furnace slag, and when used with a cementing medium forms a hydraulic cement concrete or mortar.

AGGREGATE, LIGHTWEIGHT, is aggregate with a dry, loose weight of 1120 kg/cu.m. or less.

AIR-DRY WEIGHT is the unit weight of a lightweight concrete specimen cured for seven days with neither loss nor gain of moisture at 15deg.C to 27deg.C and dried for 21 days in 50 +- 7 percent relative humidity at 23deg.C +- 1.1deg.C.

ANCHORAGE DEVICE in post-tensioning is a device used to anchor tendons to concrete member; in pretensioning, a device used to anchor tendons during hardening of concrete.

ANCHORAGE ZONE in post-tensioned members is the portion of the member through which the concentrated prestressing force is transferred to the concrete and distributed more uniformly across the section. Its extent is equal to the largest dimension of the cross section. For intermediate anchorage devices, the anchorage zone includes the disturbed regions ahead of and behind the anchorage devices.

BASIC MONOSTRAND ANCHORAGE DEVICE is an anchorage device used with any single 16mm or smaller diameter bar that satisfies the anchorage device requirements of the Post-Tensioning Institutes Specification for Unbonded Single Strand Tendons.

BASIC MULTISTRAND ANCHORAGE DEVICE is an anchorage device used with multiple strands, bars or wires, or single bars larger than 16mm diameter that satisfies the bearing stress and minimum plate stiffness requirements of AASHTO Bridge Specifications.

BONDED TENDON is a prestressing tendon that is bonded to concrete either directly or through grouting.

CEMENTITIOUS MATERIALS are materials, which have cementing value when used in concrete either by themselves, such as Portland cement, blended hydraulic cements and expansive cement, or such materials in combination with fly ash, raw or other calcined natural pozzolans, silica fume, or ground granulated blast-furnace slag.

COLUMN is a member with a ratio of height-to-least-lateral dimension of 3 or greater used primarily to support axial compressive load.

COMPOSITE CONCRETE FLEXURAL MEMBERS are concrete flexural members of precast and castin-place concrete elements, or both, constructed in separate placements but so interconnected that all elements respond to loads as a unit.

COMPRESSION-CONTROLLED SECTION is a cross section in which the net tensile strain in the extreme tension steel at nominal strength is less than or equal to the compression-controlled strain limit.

COMPRESSION-CONTROLLED STRAIN LIMIT is the net tensile strain at balanced strain conditions.

CONCRETE is a mixture of Portland cement or any other hydraulic cement, fine aggregate, coarse aggregate and water, with or without admixtures.

CONCRETE, SPECIFIED COMPRESSIVE STRENGTH OF (fc) is the compressive strength of concrete used in design and expressed in megapascals (Mpa).

CONCRETE, STRUCTURAL LIGHTWEIGHT, is concrete containing lightweight aggregate and has an air-dry unit weight as determined by Test Method for Unit Weight of Structural Lightweight Concrete (ASTM C 567) not exceeding 1840 kg/cu.m. In this code, a lightweight concrete without natural sand is termed all-lightweight concrete and lightweight concrete in which all fine aggregate consists of normalweight sand is termed sand-lightweight concrete.

CONTRACTION JOINT is a formed, sawed, or tooled groove in a concrete structure to create a weakened plane and regulate the location of cracking resulting from the dimensional change of different parts of the structure.

CURVATURE FRICTION is friction resulting from bends or curves in the specified prestressing tendon profile.

DEFORMED REINFORCEMENT is deformed reinforcing bars, bar and rod mats, deformed wire, welded smooth wire fabric and welded deformed wire fabric.

DEVELOPEMNT LENGTH is the length of embedded reinforcement required to develop the design strength of reinforcement at a critical section.

EFFECTIVE DEPTH OF SECTION (d) is the distance measured from extreme compression fiber to centroid of tension reinforcement.

EFFECTIVE PRESTRESS is the stress remaining in prestressing tendons after all losses have occurred, excluding effects of dead load and superimposed load.

EMBEDMENT LENGTH is the length of embedded reinforcement provided beyond a critical section.

EXTREME TENSION STEEL is the reinforcement (prestressed or nonprestressed) that is the farthest from the extreme compression fiber.

ISOLATION JOINT is a separation between adjoining parts of a concrete structure, usually a vertical plane, at a designed location such as to interfere least with performance of the structure, yet such as to allow relative movement in three directions and avoid formation of cracks elsewhere in the concrete and through which all or part of the bonded reinforcement is interrupted.

JACKING FORCE is the temporary force exerted by device that introduces tension into prestressing tendons in prestressed concrete.

LOAD, DEAD, is the dead weight supported by a member.

LOAD, FACTORED, is the load, multiplied by appropriate load factors, used to proportion members by the strength design method.

LOAD, LIVE, is the live load.

LOAD, SERVICE, is the load specified (without load factors).

MODULUS OF ELASTICITY is the ratio of normal stress to corresponding strain for tensile or compressive stresses below proportional limit of material.

NET TENSILE STRAIN is the tensile strain at nominal strength exclusive of strains due to effective prestress, creep, shrinkage and temperature.

PEDESTAL is an upright compression member with a ratio of unsupported height to average least lateral dimension not exceeding of 3.

PLAIN CONCRETE is structural concrete with no reinforcement or with less reinforcement than the minimum amount specified for reinforced concrete.

PLAIN REINFORCEMENT is reinforcement that does not conform to definition of deformed reinforcement.

POST-TENSIONING is a method of prestressing in which tendons are tensioned after concrete has hardened.

PRECAST CONCRETE is a structural concrete element cast in other than its final position in the structure.

PRESTRESSED CONCRETE is structural concrete in which internal stresses have been introduced to reduce potential tensile stresses in concrete resulting fro loads.

PRETENSIONING is a method of prestressing in which tendons are tensioned before concrete is placed.

REINFORCED CONCRETE is structural concrete reinforced with no less than the minimum amounts of prestressing tendons or nonprestressed reinforcement.

REINFORCEMENT is material excluding prestressing tendons unless specifically included.

RESHORES are shores placed snugly under a concrete slab or other structural member after the original forms and shores have been removed from a larger area, thus requiring the new slab or structural member to deflect and support its own weight and existing construction loads applied prior to the installation of the reshores.

SHEATHING is a material encasing a prestressing tendon to prevent bonding the tendon with the surrounding concrete, to provide corrosion protection, and to contain the corrosion inhibiting coating.

SHORES are vertical or inclined support members designed to carry the weight of the formwork, concrete and construction loads above.

SPECIAL ANCHORAGE DEVICE is an anchorage device that satisfies the standard acceptance tests of AASHTO Standard Specifications for Highway Bridges, Division II.

SPIRAL REINFORCEMENT is continuously wound reinforcement in the form of a cylindrical helix.

SPLITTING TENSILE STRENGTH (fct) is the tensile strength of concrete determined in accordance with ASTM C 496 as described in Specifications for Lightweight Aggregate for Structural Concrete (ASTM C 330).

STIRRUP is reinforcement used to resist shear and torsion stresses in a structural member, typically bars, wires, or welded wire fabric (plain or deformed) bent into L, U or rectangular shapes and located perpendicular to or at an angle longitudinal reinforcement. (The term stirrups is usually applied to lateral reinforcement in flexural members and the term ties to those in compression members.)

STRENGTH, DESIGN, is the nominal strength multiplied by a strength-reduction factor, .

STRENGTH, NORMAL, is the strength of a member or cross section calculated in accordance with provisions and assumptions of the strength design method before application of any strength-reduction factors.

STRENGTH, REQUIRED, is the strength of a member or cross section required to resist factored loads or related internal moments and forces in such combinations.

STRESS is the intensity of force per unit area.

STRUCTURAL CONCRETE is all concrete used for structural purposes, including plain and reinforced concrete.

TENDON is a steel element such as wire, cable, bar, rod or strand, or a bundle of such elements, used to impart prestress forces to concrete.

TENSION-CONTROLLED SECTION is a cross section in which the net tensile strain in the extreme tension steel at nominal strength is greater than or equal to 0.005.

TIE is a loop of reinforcing bar or wire enclosing longitudinal reinforcement. A continuously wound bar or wire in the form of a circle, rectangle or other polygon shape without re-entrant corners is acceptable.

TRANSFER is the act of transferring stress in prestressing tendons from jacks or pretensioning bed to concrete member.

UNBONDED TENDON is a tendon that is permanently prevented from bonding to the concrete after stressing.

WALL is a member, usually vertical, used to enclose or separate spaces.

WOBBLE FRICTION in prestressed concrete, is friction caused by unintended deviation of prestressing sheath or duct from its specified profile.

YIELD STRENGTH is the specified minimum yield strength or yield point of reinforcement in megapascals (Mpa). Yield strength or yield point shall be determined in tension according to applicable ASTM standards.

VII. SEISMIC DESIGN

BASE OF STRUCTURE is a level at which earthquake motions are assumed to be imparted to a building. This level does not necessarily coincide with the ground level.

BOUNDARY ELEMENTS are portions along structural wall and structural diaphragm edges strengthened by longitudinal and transverse reinforcement.

COLLECTOR ELEMENTS are elements that serve to transmit the inertial forces within structural diaphragms to members of the lateral-force-resisting system.

CONFINED CORE is the area within the core defined by h.

CONNECTION is an element that joins two precast members or a precast member and a cast-in-place member.

COUPLING BEAM is a horizontal element in plane with the connecting two shear walls.

CROSSTIE is a continuous reinforcing bar having a seismic hook at one end and a hook not less than 90 degrees with at least six-diameter extension at the other end. The hooks shall engage peripheral longitudinal bars. The 90-degree hooks of two successive crosstie engaging the same longitudinal bars shall be alternated end for end.

DESIGN DISPLACEMENT is the total lateral displacement expected for the design-basis earthquake, as required by the governing code for earthquake-resistant design.

DEVELOPMENT LENGTH FOR A BAR WITH A STANDARD HOOK is the shortest distance between the critical section (where the strength of the bar is to be developed) and a tangent to the outer edge of the 90-degree hook.

DRY CONNECTION is a connection used between precast members, which do not qualify as a wet connection.

HOOP is a close tie or continuously wound tie. A closed tie can be made up of several reinforcing elements, each having seismic hooks at both ends. A continuously wound tie shall have a seismic hook at both ends.

JOINT is the geometric volume common to intersecting members.

LATERAL FORCE RESISTING SYSTEM is that portion of the structure composed of members proportioned to resist forces related to earthquake effects.

LIGHTWEIGHT-AGGREGATE CONCRETE is an all-lightweight or sand-lightweight aggregate concrete made with lightweight aggregates.

MOMENT FRAME is a space frame in which members and joints resist forces through flexure, shear, and axial force.

NONLINEAR ACTION LOCATION is the center of the region of yielding in flexure, shear or axial action.

NONLINEAR ACTION REGION is where the member length over which nonlinear action takes place. It shall be taken as extending a distance of no less than h/2 on either side of the nonlinear action location.

SEISMIC HOOK is a hook on a stirrup, hoop or crosstie having a bend not less than 135 degrees, except that circular hoops shall have a bend of not less than 90 degrees. Hooks shall have a six-diameter (but not less than 75mm), extension that engages the longitudinal reinforcement and projects into the interior of the stirrup or hoop.

SHELL CONCRETE is the concrete outside the transverse reinforcement confining the concrete.

SPECIFIED LATERAL FORCES are lateral forces corresponding to the appropriate distribution of the design base shear force prescribed by the governing code for earthquake-resistant design.

STRONG CONNECTION is a connection that remains elastic, while the designated nonlinear action regions undergo inelastic response under the Design Basis Ground Motion.

STRUCTURAL DIAPHRAGMS are structural members, such as floor and roof slabs, that transmit inertial forces to lateral force resisting members.

STRUCTURAL TRUSSES are assemblages of reinforced concrete members subjected primarily to axial forces.

STRUCTURAL WALLS are walls proportioned to resist combinations of shears, moment, and axial forces induced by earthquake motions.

STRUT is an element of a structural diaphragm used to provide continuity around an opening in the diaphragm.

TIE ELEMENTS are elements that serve to transmit inertia forces and prevent separation of building components such as footings and walls.

WALL PIER is a wall segment with a horizontal length-to-thickness ratio between 2.5 and 6, and whose clear height is at least two times its horizontal length.

WET CONNECTION uses any of the splicing methods to connect precast members and uses cast-inplace concrete or grout to fill the splicing closure.

VIII. GENERAL

BLOCKED DIAPHRAGM is a diaphragm in which all sheathing edges not occurring on framing members are supported on an connected to blocking.

CONVENTIONAL LIGHT-FRAME CONSTRUCTION is a type of construction whose primary structural elements are formed by a system of repetitive wood-framing members.

DIAPHRAGM is a horizontal or nearly horizontal system acting to transmit lateral forces to the vertical resisting elements. When the term diaphragm is used, it includes horizontal bracing systems.

FIBERBOARD is a fibrous-felted, homogenous panel made from lignocellulosic fibers (usually wood or crane) having a density of less than 497 kg/cu.m. but more than 160 kg/cu.m.

GLUED BUILT-UP MEMBERS are structural elements, the section of which is composed of built-up lumber, wood structural panels or wood structural panels in combination with lumber, all parts bonded together with adhesive.

GRADE (Lumber), the classification of lumber in regard to strength and utility in accordance with the grading rules of an approved lumber grading agency.

HARDBOARD is a fibrous-felted, homogenous panel made from lignocellulosic fibers consolidated under heat and pressure in a hot press to a density not less than 497 kg/cu.m.

NOMINAL SIZE (Lumber), the commercial size designation of width and depth, standard sawn lumber grades; somewhat larger than the standard net size of dressed lumber.

NORMAL LOADING is a design load that stressed a member or fastening to the full allowable stress. This loading may be applied for approximately 10 years, either continuously or cumulatively, and 90 percent of this load may be applied for the remainder of the life of the member or fastening.

PARTICLE BOARD is a manufactured panel product consisting of particles of wood or combinations of wood particles and wood fibers bonded together with synthetic resins or other suitable bonding system by a bonding process, in accordance with approved nationally recognized standard.

PLYWOOD is a panel of laminated veneers.

ROTATION is the torsional movement of a diaphragm about a vertical axis.

SUBDIAPHRAGM is a portion of a larger wood diaphragm designed to anchor and transfer local forces to primary diaphragm struts and the main diaphragm.

TREATED WOOD is wood treated with an approved preservative under treating and quality control procedures.

WOOD OR NATURAL RESISTANCE TO DECAY OR TERMITES is the heartwood of the species set forth below. Corner sapwood is permitted on 5% of the pieces provided 90% or more of the width of each side on which it occurs is heartwood. Recognized species are: Decay resistant: Narra, Kamagong, Dao, Tangile Termite resistant: Narra, Kamagong

WOOD STRUCTURAL PANEL is a structural panel product composed primarily of wood. Wood structural panels include all-veneer plywood, composite panels containing a combination of veneer and wood-based material, and mat0formed panel such as oriented stranded board and waferboard.

IX. GENERAL

AREAS:

BEDDED AREA is the area of the surface of a masonry unit, which is in contact with mortar in place of the joint.

EFFECTIVE AREA OF REINFORCEMENT is the cross-sectional area of reinforcement multiplied by the cosine of the angle between the reinforcement and the direction for which effective area is to be determined.

GROSS AREA is the total cross-sectional area of a specified section.

NET AREA is the gross cross-sectional area minus the area of ungrouted cores, notches, cells and unbedded areas. Net area is the actual surface area of a cross section of masonry.

TRANSFORMED AREA is the equivalent area of one material to a second based on the ratio of moduli of elasticity of the first material to the second.

BOND:

ADHESION BOND is the adhesion between masonry units and mortar or grout.

REINFORCING BOND is the adhesion between steel reinforcement and mortar or grout.

BOND BEAM is a horizontal grouted element within masonry in which reinforcement is embedded.

CELL is a void space having a gross cross-sectional area greater than 967 sq. mm.

CLEANOUT is an opening to the bottom of a grout space of sufficient size and spacing to allow the removal of debris.

COLLAR JOINT is the mortared or grouted space between wythes of masonry.

COLUMN, REINFORCED, is a vertical structural member in which both the reinforcement and masonry resist compression.

COLUMN, UNREINFORCED, is a vertical structural member whose horizontal dimension measured at right angles to the thickness does not exceed three times the thickness.

DIMENSIONS:

ACTUAL DIMENSIONS are the measured dimensions of s designed item. The actual dimension shall not vary from the specified dimension by more than the amount allowed in the appropriate standard of quality.

NOMINAL DIMENSIONS of masonry units are equal to its specified dimensions plus the thickness of the joint with which the unit is laid.

SPECIFIED DIMENSIONS are the dimensions specified by the manufacturer for construction of masonry, masonry units, joints or any other component of a structure.

GROUT LIFT is an increment of grout height within the total grout pour.

GROUT POUR is the total height of masonry wall to be grouted prior to the erection of additional masonry. A grout pour will consist of one or more grout lifts.

GROUTED MASONRY:

GROUTED HOLLOW-UNIT MASONRY is that form of grouted masonry construction in which certain designated cells of hollow units are continuously filled with grout.

GROUTED MULTIWYTHE MASONRY is that form of grouted masonry construction in which the space between the wythes is solidly or periodically filled with grout.

JOINTS:

BED JOINT is the mortar joint that is horizontal at the time the masonry units are placed.

HEAD JOINT is the mortar joint having a vertical transverse plane.

MASONRY JOINT is brick, tile, stone, and glass block or concrete block.

HOLLOW-MASONRY JOINT is a masonry unit whose net cross-sectional area (solid area) in any plane parallel to the surface containing cores, cells or deep frogs is less than 75% of its gross crosssectional area measured in the same plane.

SOLID-MASONRY JOINT is a masonry unit whose net cross-sectional area in any plane parallel to the surface containing the cores or cells is at least 75% of the gross cross-sectional area measured in the same plane.

PRISM is an assemblage of masonry units and mortar with or without grout used as a test specimen for determining properties of the masonry.

REINFORCED MASONRY is that form of masonry construction in which reinforcement acting in conjunction with the masonry is used to resist forces.

SHELL is the outer portion of a hollow masonry unit as placed in masonry.

WALLS:

BONDED WALL is a masonry wall in which two or more wythes are bonded to act as a structural unit.

CAVITY WALL is a wall containing continuous air space with a minimum width of 51mm and a maximum width of 114mm between wythes, which are tied with metal ties.

WALL TIE is a mechanical metal fastener, which connects wythes of masonry to each other or to other materials.

WEB is an interior solid portion of a hollow-masonry unit as placed in masonry.

WYTHE is the portion of a wall, which is one masonry unit in thickness. A collar joint is not considered a wythe. NOMINAL MAXIMUM SIZE OF COARSE AGGREGATE SHALL NOT BE LARGER THAN:

1/5 the narrowest dimension between side forms 1/3 the depth of slabs the minimum clear spacing between individual reinforcing bars or wires, bundles of bars, or prestressing tendons or ducts

CONCRETE AND STEEL TERMS

DEFORMED REINFORCEMENTS

ASTM A 184 Fabricated Deformed Steel Bar Mats ASTM A 185 Steel Welded Wire Fabric, Plain ASTM A 496 Steel Wire, Deformed ASTM A 497 Steel Welded Wire Fabric, Deformed ASTM A 615M Deformed and Plain-Billet Steel Bars ASTM A 616M Rail-Steel Deformed and Plain Bars ASTM A 617M Axle-Steel Deformed and Plain Bars

ASTM A 706M Low-Alloy Steel Deformed Bars ASTM A 767M Zinc-Coated (Galvanized) Steel Bars ASTM A 775M Epoxy-Coated Reinforcing Steel Bars ASTM A 884M Epoxy-Coated Steel Wire and Welded Wire Fabric ASTM A 934M Epoxy-Coated Prefabricated Steel Reinforcing Bars

PRESTRESSING TENDONS

ASTM A 416M Steel Strand, Uncoated Seven-Wire ASTM A 421 Uncoated Stress-Relieved Steel Wire ASTM A 722 Uncoated High-Strength Steel Bar

CURING

concrete (other than high-early strength) shall be maintained above 10C and in a moist condition for at least the first 7 days after placement high-early strength concrete shall be maintained above 10C and in a moist condition for at least the first 3 days

CONDUITS AND PIPES EMBEDDED IN CONCRETE

they (including their fittings) shall not displace more than 4% of the area of cross section when embedded within a column they shall not be larger in outside dimension than 1/3 the overall thickness of slab, wall or beam in which they are embedded they shall be spaced not closer than 3 diameters or widths on center conduits, pipes and sleeves may be considered as replacing structurally in compression the displaced concrete, provided: o they are of uncoated or galvanized iron or steel not thinner than standard Schedule 40 steel pipe o they have a nominal inside diameter not over 50mm and are spaced not less than 3 diameters on centers

concrete cover shall not be less than 40mm for concrete exposed to earth or weather, or less than 20mm for concrete not exposed to weather or in contact with ground reinforcement with an area not less than 0.002 times the area of concrete section shall be provided normal to the piping

CONSTRUCTION JOINTS

construction joints in floors shall be located within the middle third of spans of slabs, beams and girders joints in girders shall be offset a minimum distance of 2 times the width of intersecting beams

STANDARD HOOKS

180-degree bend plus 4db extension, but not less than 60mm at free end of bar 90-degree bend plus 12db extension at free end of bar

for stirrup and tie hooks: o 16mm diameter bar and smaller 90-degree bend plus 6db extension at free end of bar, or o 20 and 25mm diameter bar 90-degree bend plus 12db extension at free end of bar, or o 25mm diameter bar and smaller 135-degree bend plus 6db extension at free end of bar

MINIMUM BEND DIAMETERS

bar size of 16mm and smaller (for stirrups and ties) 4db (inside diameter) bar size of 10mm through 25mm 6db bar size of 28, 32 and 36mm 8db

SPACING LIMITS FOR REINFORCEMENT

the minimum clear spacing between parallel bars in a layer shall be db but not less than 25mm the minimum clear spacing between parallel bars in 2 or more layers shall not be less than 25mm between layers in spirally reinforced or tied reinforced compression members, clear distance between longitudinal bars shall not be less than 1.5db or less than 40mm in walls and slabs other than concrete joist construction, primary flexural reinforcement shall not be spaced farther apart than 3 times the wall or slab thickness, nor farther than 450mm

BUNDLED BARS

shall be limited to 4 bars in 1 bundle shall be enclosed within stirrups or ties bars larger than 36mm diameter shall not be bundled in beams individual bars within a bundle terminated within the span of flexural members shall terminate at different points with at least 40db stagger where spacing limitations and minimum concrete cover are based on bar diameter db, a unit of bundled bars shall be treated as a single bar of a diameter derived from the equivalent total area minimum concrete cover shall be equal to the equivalent diameter of the bundle, but need not be greater than 50mm

PRESTRESSING TENDONS AND DUCTS

center-to-center spacing of pretensioning tendons at each end of a member shall not be less than 5db for wire, nor 4db for strands

MINIMUM CONCRETE COVER FOR CAST-IN-PLACE CONCRETE (NONPRESTRESSED)

concrete cast against and permanently exposed to earth 75mm

concrete exposed to earth or weather: o 20mm through 36mm diameter bar 50mm

o 16mm diameter bar and smaller 40mm

concrete not exposed to weather or in contact with ground: o slabs, walls, joists: 45 to 60mm diameter bars 40mm 36mm diameter bar and smaller 20mm

o beams, columns: primary reinforcement, ties, stirrups, spirals 40mm

o shells, folded plate members: 20mm diameter bar and larger 20mm 16mm diameter bar and smaller 12mm

MINIMUM CONCRETE COVER FOR PRECAST CONCRETE

concrete exposed to earth or weather: o wall panels: 45mm and 60mm diameter bars 40mm 36mm diameter bar and smaller 20mm

o other members: 45mm and 60mm diameter bars 50mm 20mm through 36mm diameter bar 40mm 16mm diameter bar and smaller 30mm

concrete not exposed to earth or in contact with ground: o slabs, walls, joists: 45mm and 60mm diameter bars 30mm 36mm diameter bar and smaller 15mm

o beams, columns: primary reinforcement db but not less than 15mm and need not exceed 40mm ties, stirrups, spirals 10mm

o shells, folded plate members: 20mm diameter bar and larger 15mm 16mm diameter bar and smaller 10mm

MINIMUM CONCRETE COVER FOR PRESTRESSED CONCRETE

concrete cast against and permanently exposed to earth 75mm

concrete exposed to earth or weather: o wall panels, slabs, joists 25mm o other members 40mm

concrete not exposed to earth or in contact with ground: o slabs, walls, joists 20mm o beams, columns: primary reinforcement 40mm

ties, stirrups, spirals 25mm

o shells, folded plate members: 16mm diameter bar and smaller 10mm other reinforcement db but not less than 20mm

OFFSET BARS

slope of inclined portion of an offset bar with axis of column shall not exceed 1 in 6 portions of bar above and below an offset shall be parallel to axis of column lateral ties or spirals, if used, shall be placed not more than 150mm from points of bend offset bars shall be bent before placement in the forms where a column face is offset 75mm or greater, longitudinal bars shall not be offset bent. Separate dowels, lap sliced with the longitudinal bars adjacent to the offset column faces, shall be provided

SPIRALS

for cast-in-place construction, size of spirals shall not be less than 10mm diameter clear spacing between spirals shall not exceed 75mm or be less than 25mm anchorage of spiral reinforcement shall be provided by 1 extra turns of spiral bar or wire at each end of a spiral unit spiral reinforcement shall be lap spliced by 48db but not less than 300mm or welded in columns with capitals, spirals shall extend to a level at which the diameter or width of capital is 2 times that of the column

plain bars shall conform to one of the following specifications: o ASTM A 615M o ASTM A 616M o ASTM A 617M

plain wire shall conform to: o ASTM A 82 Steel Wire, Plain

TIES

10mm diameter lateral ties for longitudinal bars 32mm diameter or smaller 12mm diameter lateral ties for longitudinal bars 36 diameter and bundled bars vertical spacing of ties shall not exceed: o 16db of longitudinal bars o 48db of tie bars o least dimension of compression member

ties shall be arranged that no bar shall be farther than 150mm clear on each side along the tie ties shall be located vertically not more than a tie spacing above the top of footing or slab in any story where beams or brackets frame from 4 directions into a column, termination of ties not more than 75mm below reinforcement in shallowest of such beams or brackets shall be permitted

SHRINKAGE AND TEMPERATURE REINFORCEMENT

shrinkage and temperature reinforcement shall be spaced not farther apart than 5 times the slab thickness, or 450mm spacing of prestressed tendons shall not exceed 1.80m

T-BEAM CONSTRUCTION

the flange and web shall be built integrally or otherwise effectively bonded together width of slab effective as a T-beam flange on each side of the web shall not exceed: o the span length of the beam, o 8 times the slab thickness, or o the clear distance to the next web

for beams with a slab on one side only, the effective overhanging flange width shall not exceed: o 1/12 the span length of the beam, o 6 times the slab thickness, or o the clear distance to the next web

transverse reinforcement shall be spaced not farther apart than 5 times the slab thickness, nor 450mm

JOIST CONSTRUCTION

ribs shall not be less than 100mm in width and shall have a depth of not more than 3 times the minimum width of rib clear spacing between ribs shall not exceed 750mm

slab thickness over permanent fillers shall not be less than 1/12 the clear distance between ribs nor less than 40mm when removable forms or fillers are used, slab thickness shall not be les than 1/12 the clear distance between ribs, or less than 50mm where conduits or pipes are embedded within the slab, slab thickness shall be at least 25mm greater than the total overall depth of the conduits or pipes at any point

REQUIRED STRENGTH

dead load and live load o U = 1.4D + 1.7L

dead load, live load and wind load o U = 0.75 (1.4D + 1.7L + 1.7W) o U = 0.9D + 1.3W

dead load, live load and earthquake load o U = 1.3D + 1.1L + 1.1E o U = 0.99D + 1.1E

STRENGTH-REDUCTION FACTOR

flexure without axial load, 0.90 axial tension and axial tension with flexure, 0.90 axial compression and axial compression with flexure: o spiral reinforced, 0.75 o tie reinforce, 0.70

shear and torsion, 0.85 bearing on concrete, 0.70 post-tensioned anchorage zones, 0.85

MINIMUM THICKNESS OF NONPRESTRESSED BEAMS OR ONE-WAY SLABS UNLESS DEFLECTIONS ARE COMPUTED (members are not supporting or attached to partitions or other construction likely to be damaged by large deflections)

solid one-way slabs: o simply supported, L/20 o one end continuous, L/24 o both ends continuous, L/28 o cantilever, L/10

beams or ribbed one-way slabs: o simply supported, L/16 o one end continuous, L/18.5 o both ends continuous, L/21 o cantilever, L/8

for Fy other than 415Mpa, the values shall be multiplied by (0.4 + Fy/700)

DISTANCE BETWEEN LATERAL SUPPORTS OF FLEXURAL MEMBERS

spacing of lateral supports for a beam shall not exceed 50 times the least width b of compression flange or face

LIMITS FOR REINFORCEMENT OF COMPRESSION MEMBERS

minimum number of longitudinal bars in compression members shall be 3 for bars within triangular ties, 4 for bars within rectangular or circular ties, and 6 for bars enclosed by spirals

SPACING LIMITS FOR SHEAR REINFORCEMENT

shall not exceed d/2 in non-prestressed members and 3/4h in prestressed members or 600mm

SPLICES

lap splices shall not be used for bars larger than 36mm diameter lap splices of bars in a bundle shall be based on the lap splice length required for individual bars within the bundle individual bar splices within a bundle shall not overlap entire bundles shall not be lap spliced bars spliced by non-contact lap splices in flexural members shall not be spaced transversely farther apart than 1/5 the required lap splice length, or 150mm

splices shall be staggered at least 600mm

WALLS

minimum ratio of vertical reinforcement area to gross concrete area shall be: o 0.0012 deformed bars not larger than 16mm diameter with a specified yield strength not less than 420Mpa, or o 0.0015 for other deformed bars, or o 0.0012 for welded wire fabric (plain or deformed)

minimum ratio of horizontal reinforcement area to gross concrete area shall be: o 0.0020 deformed bars not larger than 16mm diameter with a specified yield strength not less than 420 Mpa, or o 0.0025 for other deformed bars, or o 0.0020 for welded wire fabric (palin or deformed)

in addition to the minimum reinforcement required, not less than 2-16mm diameter bars shall be provided around all window and door openings. Such bars shall be extended to develop the bar beyond the corners of the openings but not less than 600mm

NON-BEARING WALLS

thickness shall not be less than 100mm, or not less than 1/30 the least distance between members that provide lateral support

MINIMUM FOOTING DEPTH

depth of footing above bottom reinforcement shall not be less than 150mm for footings on soil, or not less than 300mm for footings on piles

TRANSVERSE REINFORCEMENT (HOOPS)

the first hoop shall be located not more than 50mm from the face of a supporting member maximum spacing of the hoops shall not exceed: o d/4 o 8 times the diameter of the smallest longitudinal bar o 24 times the diameter of the hoop bars o 300mm

where hoops are not required, stirrups shall be placed at no more than d/2 throughout the length of the member

STRUCTURAL STEEL

LIMITING SLENDERNESS RATIOS

for members whose design is based on compressive force, the slenderness ratio preferably should not exceed 200 for members whose designed is based on tensile force, the slenderness ratio preferably should not exceed 300

ALLOWABLE STRESSES

for tension in structural steel in terms of gross area, 0.60Fy for tension in structural steel based on effective net area, 0.50Fu for tension on pin-connected members based on net area, 0.45Fy for tension on eyebars on the body area, 0.60Fy for flexural members with compact sections, Fb = 0.66Fy for flexural members with non-compact sections, Fb = 0.60Fy

PIN-CONNECTED MEMBERS

minimum net area beyond the pinhole, parallel to the axis of the member, shall not be less than 2/3 of the net area across the pinhole width of the body of an eyebar shall not exceed 8 times its thickness pin diameter shall not be less than 7/8 times the eyebar width

pinhole diameter shall be no more than 0.8mm greater than the pin diameter

SHEAR CONNECTORS

shear connectors shall have at least 25mm of lateral concrete cover diameter of studs shall not be greater than 2 times the thickness of the flange to which they are welded minimum center-to-center spacing of stud connectors shall be 6 diameters along the longitudinal axis and 4 diameters transverse to the longitudinal axis maximum center-tocenter spacing of stud connectors shall not exceed 8 times the total slab thickness

WELDS

weld access holes shall have a length from the toe of the weld preparation not less than 1 times the thickness of the material in which the hole is made

groove welds: o effective area = effective length of the weld x effective throat thickness o effective length = width of the part joined o effective throat thickness of a complete-penetration groove weld = thickness of the thinner part joined o minimum effective throat thickness of partial-penetration groove welds = 3mm (thicker part joined to 6mm inclusive) 5mm (thicker part joined over 6 to 12mm)

6mm (thicker part joined over 12 to 20mm) 8mm (thicker part joined over 20 to 38mm) 10mm (thicker part joined over 38 to 57mm) 12mm (thicker part joined over 57 to 150mm) 16mm (thicker part joined over 150mm)

o effective throat thickness of a flare groove weld = flare bevel groove, 5/16R flare V-groove, R

fillet welds: o effective area of fillet welds = effective length x effective throat thickness o effective throat thickness of a fillet weld = shortest distance from the root of the joint to the face of the diagrammatic weld o minimum size of fillet welds = 3mm (thicker part joined to 6mm inclusive) 5mm (thicker part joined over 6 to 12mm) 6mm (thicker part joined over 12 to 20mm) 8mm (thicker part joined over 20mm)

o maximum size of fillet welds along edges = not greater than the thickness of the material (material less than 6mm thick) not greater than the thickness of the material minus 1.6mm (material 6mm or more in thickness)

o minimum effective length of a fillet weld designed on the basis of strength shall not be less than 4 times its nominal size o if greater than 4 times its nominal size, the size of the weld should not exceed its effective length

o effective length of any segment of intermittent fillet welding shall not be less than 4 times the weld size, with a minimum of 38mm o in lap joints, minimum lap shall be 5 times the thickness of the thinner part joined, but not less than 25mm o slide or end fillet welds terminating at ends or sides, respectively, of parts or members shall, wherever practicable, be returned continuously around the corners for a distance not less than 2 times the nominal size of the weld

plug and slot welds: o diameter of the hole for a plug weld shall not be less than the thickness of the part containing it plus 8mm, nor greater than the minimum diameter plus 3mm or 2 times the thickness of the weld o minimum spacing of lines of slot welds in a direction transverse to their length shall be 4 times the width of the slot o minimum center-to-center spacing in a longitudinal direction shall be 2 times the length of the slot o length of the slot shall not exceed 10 times the thickness of the weld o width of the slot shall not be less than the thickness of the part containing it plus 8mm, nor shall it be larger than 2 times the thickness of the weld o thickness of plug or slot welds in material 16mm or less thick = thickness of the material o thickness of plug or slot welds in material over 16mm thick = the thickness of the material but not less than 16mm

FASTENERS

distance between centers of standard, oversized or slotted fastener holes shall not be less than 2 2/3 times the nominal diameter of the fastener maximum distance from the center of any rivet or bolt to the nearest edge of parts in contact shall be 12 times the thickness of the connected part, but shall not exceed 150mm

CAMBER

trusses of 24.4m or greater span generally shall be cambered for approximately the dead-load deflection crane girders of 22.9m or greater span generally shall be cambered for approximately the dead-load deflection plus the live-load deflection

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- BP 344 Accessibility Law With IllustrationsDokument30 SeitenBP 344 Accessibility Law With IllustrationsEmmanuel Linguaje Managbanag II100% (1)

- Ancient GardensDokument3 SeitenAncient GardensEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Catch Basin Detail: On Vertical & Horizontal BarsDokument1 SeiteCatch Basin Detail: On Vertical & Horizontal BarsEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Isometric Layout: General SpecificationsDokument1 SeiteIsometric Layout: General SpecificationsEmmanuel Linguaje Managbanag IINoch keine Bewertungen

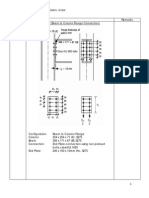

- Cantilever Beam (CB) : 4-.10M, 4-.15M REST at .20M.O.CDokument1 SeiteCantilever Beam (CB) : 4-.10M, 4-.15M REST at .20M.O.CEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Kanhuraw Site Devt - scalED-Layout1Dokument1 SeiteKanhuraw Site Devt - scalED-Layout1Emmanuel Linguaje Managbanag IINoch keine Bewertungen

- Philippine Laws On Housing and Human SettlementsDokument11 SeitenPhilippine Laws On Housing and Human SettlementsEmmanuel Linguaje Managbanag II100% (1)

- Schedule of Loads: Arch. Hervy G. Catilogo, UapDokument1 SeiteSchedule of Loads: Arch. Hervy G. Catilogo, UapEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Riser Diagram: General SpecificationsDokument1 SeiteRiser Diagram: General SpecificationsEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Construction of Perimeter FenceDokument3 SeitenConstruction of Perimeter FenceEmmanuel Linguaje Managbanag II0% (1)

- Rafter Detail: 2 X 2 X Angle Bar As Top & Bottom Chord See Detail - GDokument1 SeiteRafter Detail: 2 X 2 X Angle Bar As Top & Bottom Chord See Detail - GEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Plot Scale Drawing Units MM CM MDokument1 SeitePlot Scale Drawing Units MM CM MEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Fixing A Broken HeartDokument1 SeiteFixing A Broken HeartEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Detail of Roof Beam: SectionDokument1 SeiteDetail of Roof Beam: SectionEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Detail of C1F1: SPCD. at 0.20 M.O.C. BothwaysDokument1 SeiteDetail of C1F1: SPCD. at 0.20 M.O.C. BothwaysEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Disgrasya: By: Conrado de QuirosDokument6 SeitenDisgrasya: By: Conrado de QuirosEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Architectural Program Form: Republic of The Philippines Tacloban CityDokument7 SeitenArchitectural Program Form: Republic of The Philippines Tacloban CityEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Lot DescriptionDokument1 SeiteLot DescriptionEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Types of RoofsDokument4 SeitenTypes of RoofsEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Greek ArtsDokument7 SeitenGreek ArtsEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Types of RoofsDokument4 SeitenTypes of RoofsEmmanuel Linguaje Managbanag IINoch keine Bewertungen

- Swatches 2Dokument2 SeitenSwatches 2Emmanuel Linguaje Managbanag IINoch keine Bewertungen

- 7721 CarpentryDokument2 Seiten7721 CarpentrywarrencareertechNoch keine Bewertungen

- Tos 3: Unit 1: Fixed & Continuous Beams and Effects of TorsionDokument19 SeitenTos 3: Unit 1: Fixed & Continuous Beams and Effects of TorsionAftab HawaldarNoch keine Bewertungen

- Period 17 Flexure With Composite BeamsDokument9 SeitenPeriod 17 Flexure With Composite BeamsVinod KumarNoch keine Bewertungen

- WTanksDokument26 SeitenWTanksestebanosorionovaNoch keine Bewertungen

- Equipment Schedule HVACDokument7 SeitenEquipment Schedule HVACHussainShabbirNoch keine Bewertungen

- Siwestechnicalreport PDFDokument68 SeitenSiwestechnicalreport PDFishaq kazeem100% (1)

- E-Tabs GuideDokument9 SeitenE-Tabs GuideabdizamadNoch keine Bewertungen

- Template - Project Percentage Completion ReportDokument67 SeitenTemplate - Project Percentage Completion ReportMark Angelo De GuzmanNoch keine Bewertungen

- Equipment and Apparatus For Testing: Cement 1. Blaine Air ApparatusDokument11 SeitenEquipment and Apparatus For Testing: Cement 1. Blaine Air ApparatusGabriel VergaraNoch keine Bewertungen

- Kelas B1 PMMEDokument1 SeiteKelas B1 PMMESaya NamaNoch keine Bewertungen

- Id Sample Submission LogDokument32 SeitenId Sample Submission Logfuadlutfi91Noch keine Bewertungen

- Design of MonorailDokument9 SeitenDesign of MonorailAnonymous Q8XIGqHyCNoch keine Bewertungen

- RCC - SDS Sir Format - 06-Aug-21 (SEP-21)Dokument15 SeitenRCC - SDS Sir Format - 06-Aug-21 (SEP-21)Baladaru Krishna PrasadNoch keine Bewertungen

- CHAPTER 5 Structural AnalysisDokument76 SeitenCHAPTER 5 Structural AnalysisDavid MurphyNoch keine Bewertungen

- WH# 06 - Petrokemya NorthDokument4 SeitenWH# 06 - Petrokemya NorthEAC Alim KhanNoch keine Bewertungen

- Vadodra Airport, Vadodra: "Galloping Into The Future"Dokument2 SeitenVadodra Airport, Vadodra: "Galloping Into The Future"apurvaNoch keine Bewertungen

- Construction MethodologyDokument44 SeitenConstruction MethodologyAmar WadoodNoch keine Bewertungen

- Module 3 - Flexural Strength in Beams (WSD & Cracked Sections - Tansformed Section Method)Dokument5 SeitenModule 3 - Flexural Strength in Beams (WSD & Cracked Sections - Tansformed Section Method)Mika Vernadeth SingNoch keine Bewertungen

- SDCS 02 14Dokument11 SeitenSDCS 02 14Mahmoud AbdulmonemNoch keine Bewertungen

- Qatar Piling ContractorsDokument1 SeiteQatar Piling Contractorssilvereyes18100% (1)

- Steel Joint Design (Flexible End Plate)Dokument6 SeitenSteel Joint Design (Flexible End Plate)Wazini D. IzaniNoch keine Bewertungen

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDokument21 SeitenWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For Scientistsnonzero15Noch keine Bewertungen

- Saes Q 005Dokument10 SeitenSaes Q 005malika_00100% (1)

- MCE487 Steel Cage LiftingDokument5 SeitenMCE487 Steel Cage LiftingAnonymous S7Cq7ZDgPNoch keine Bewertungen

- Design of Stringer (Road Way Bridges)Dokument10 SeitenDesign of Stringer (Road Way Bridges)Karim NasserNoch keine Bewertungen

- SC+ Design Guidelines EnglishDokument27 SeitenSC+ Design Guidelines EnglishMyron OikonomakisNoch keine Bewertungen

- Design of Retaining Structures Notes-5Dokument3 SeitenDesign of Retaining Structures Notes-5Mark RamnarineNoch keine Bewertungen

- Fatigue Behavior of Ring Stiffened Tubular JointDokument8 SeitenFatigue Behavior of Ring Stiffened Tubular JointManishNoch keine Bewertungen

- Volume 2Dokument649 SeitenVolume 2Denny Azumi ZurinairaNoch keine Bewertungen

- P Delta AnalysisDokument4 SeitenP Delta AnalysisAnonymous dxsNnL6S8hNoch keine Bewertungen